Laser cutting positioner of drawn component

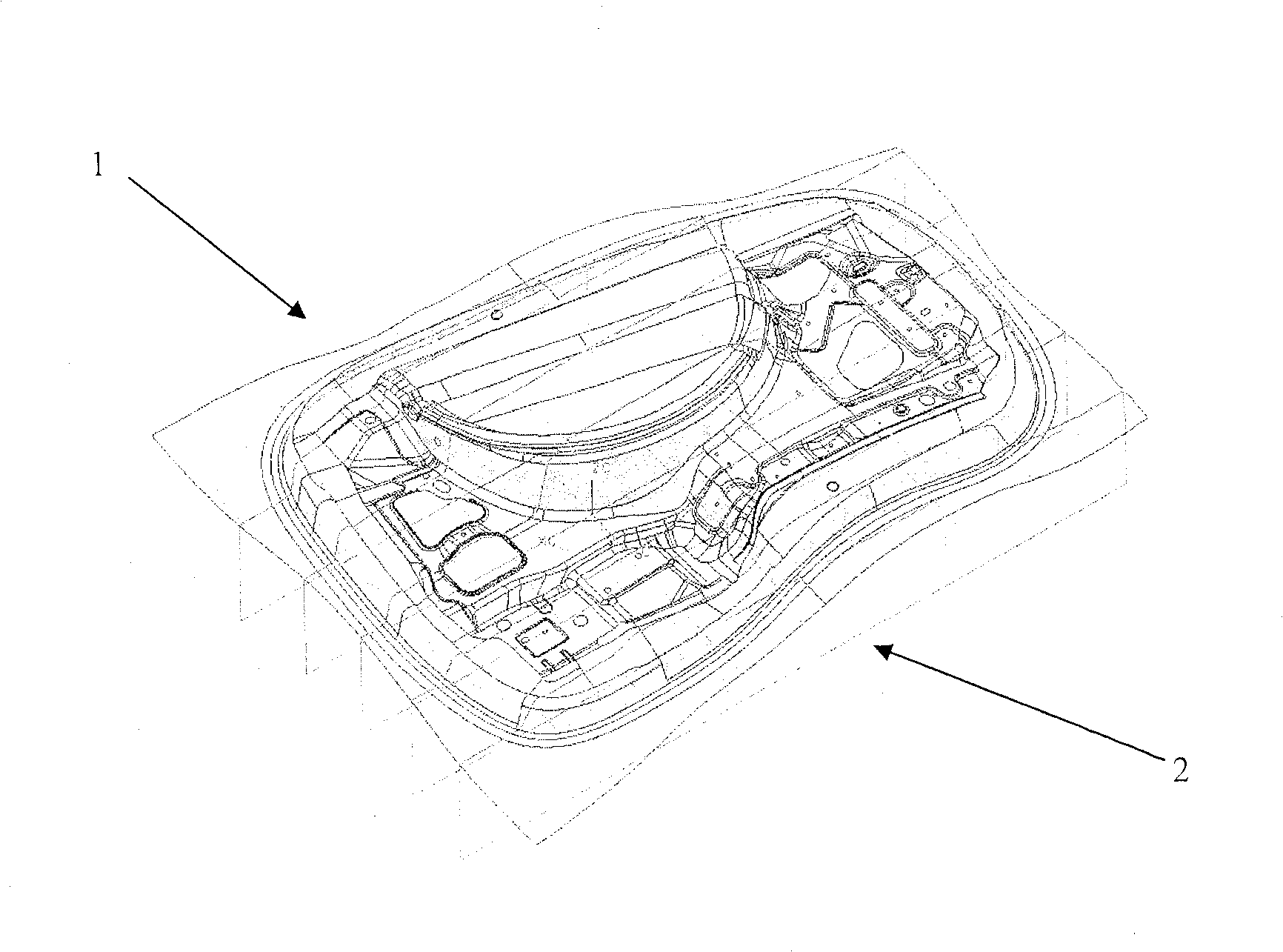

A positioning device, laser cutting technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable structure, increased production cost, inaccurate positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and principle of the present invention will be described in detail below with reference to the accompanying drawings.

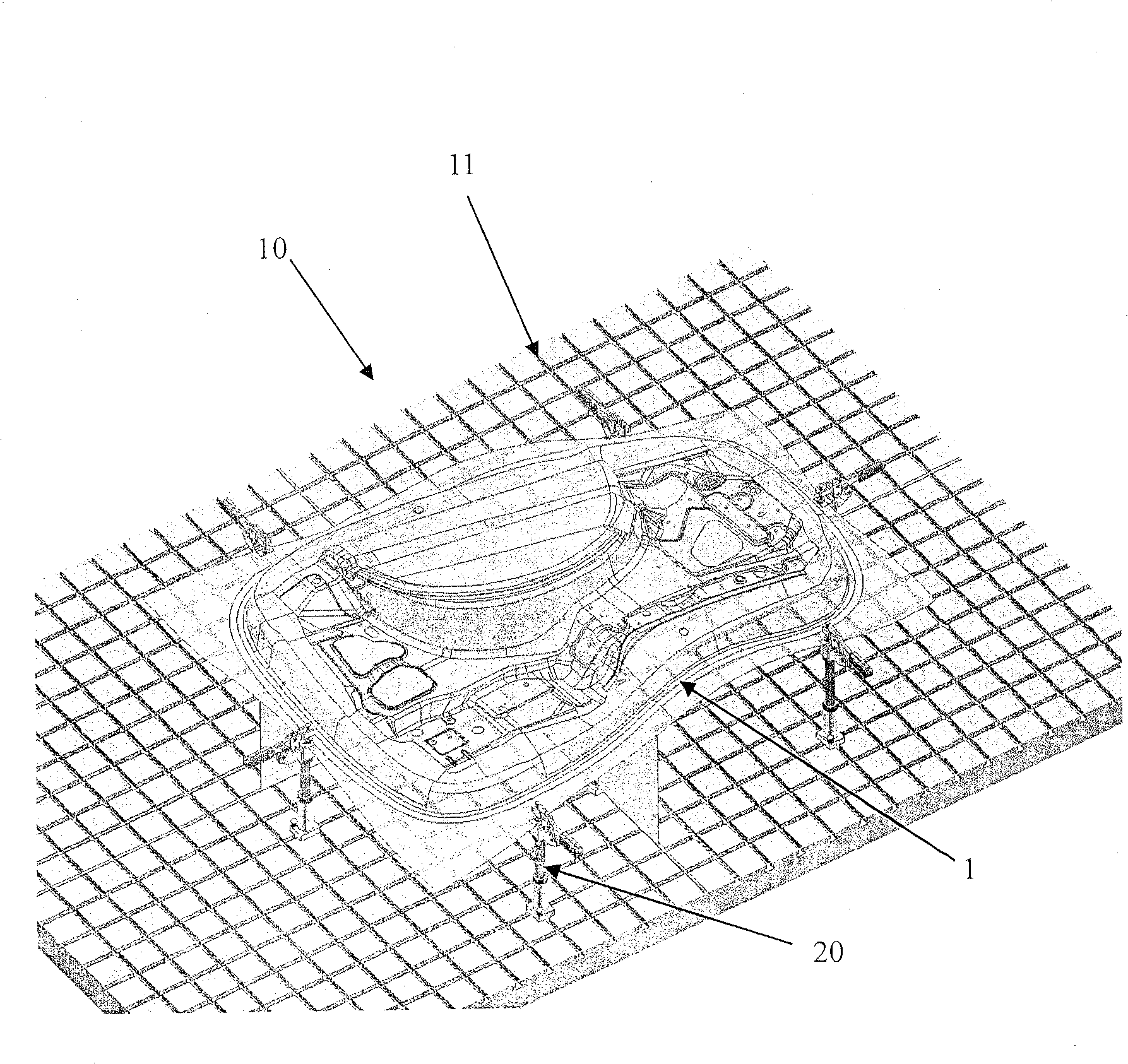

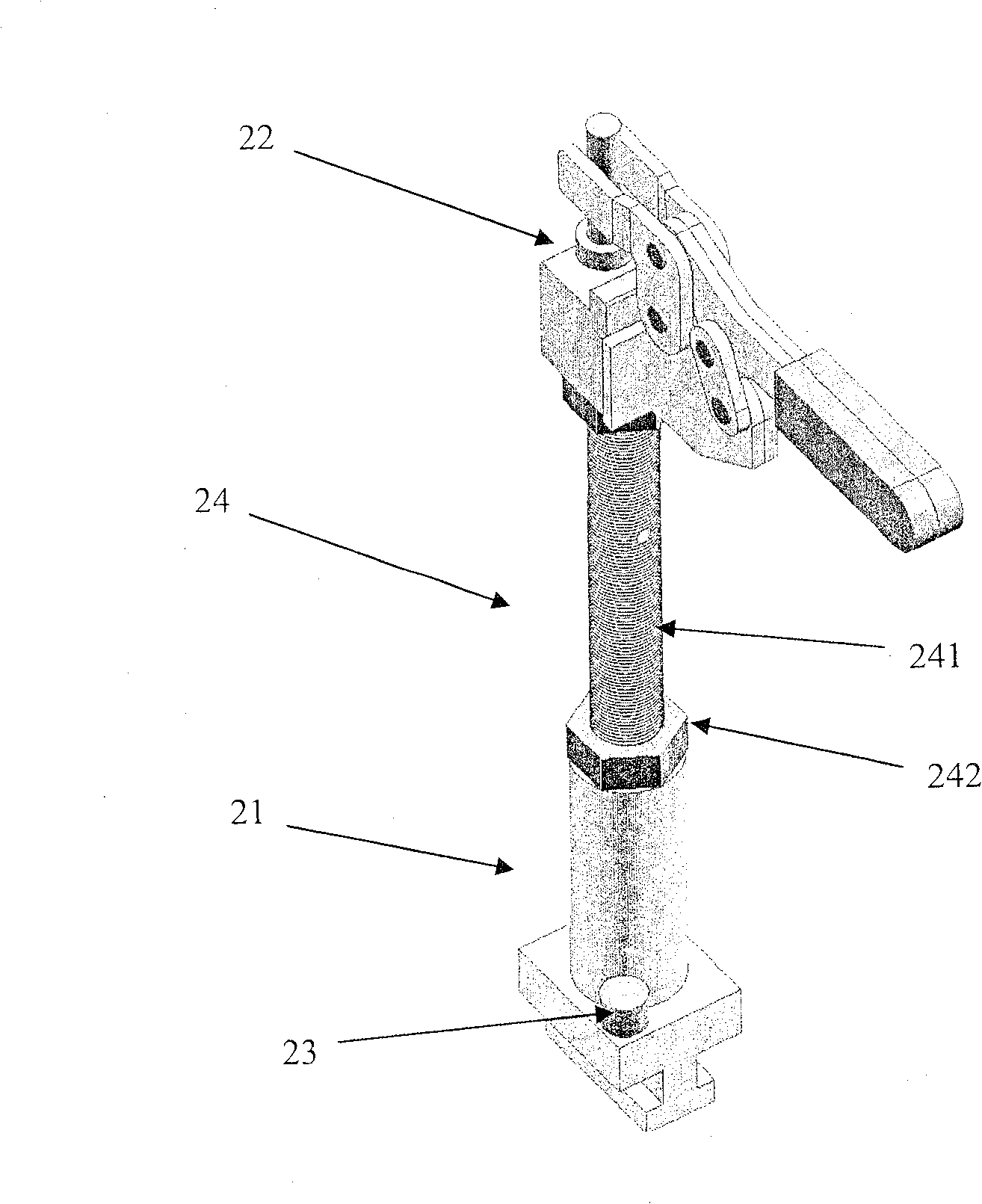

[0015] Such as figure 2 As shown, the laser cutting and positioning device for drawn parts according to the present invention includes a base plate 10 and a plurality of clamping mechanisms 20, wherein there are a plurality of criss-cross guide positioning grooves 11 on the base plate, and each clamping mechanism The lower part has a clamping mechanism slider 21 , and the upper part has a clip 22 , and the clamping mechanism slider can slide or lock in the guide positioning groove 11 .

[0016] The guiding and positioning grooves 11 on the base plate 10 are criss-crossed, just like a Go board. The distance between the guiding and positioning grooves 11 can be determined according to the actual situation, for example, it is 100 mm. The sliding block 21 of the clamping mechanism can move arbitrarily in these guiding and positioning groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com