Banner rolling-up machine and working method

A banner and banner machine technology, which is applied in the field of rolling banner machines and working methods, can solve the problems of limited work efficiency, unsolved post-processing, post-processing and collection and stay, etc., to achieve lateral movement, simple long-distance control, and realization of position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

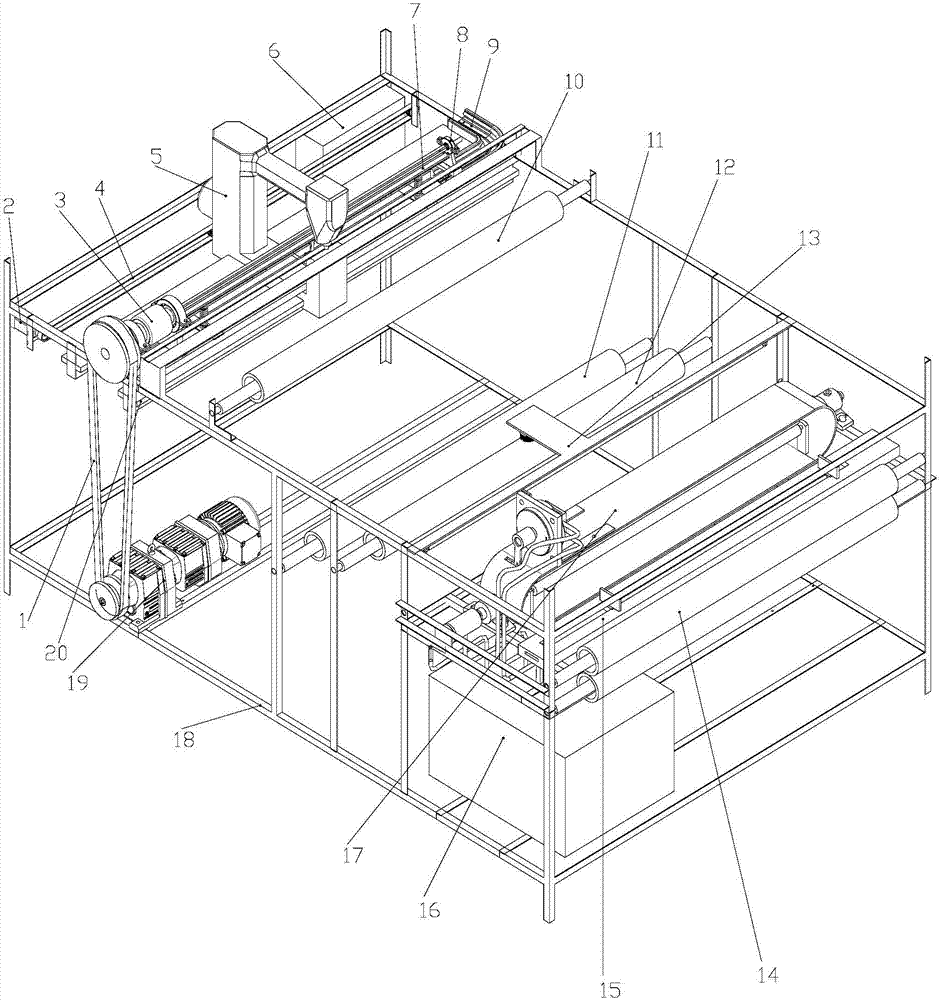

[0074] A banner rolling machine, comprising a support frame 18, one end of the support frame 18 is provided with a front double idler roller 14, and the front double idler roller 14 includes two vertically arranged rotating rollers, and the banner enters between the two rotating rollers; The other end of the support frame 18 is provided with a variable cross-section rolling banner device 3 and a hemming device 5;

[0075] The variable cross-section rolling banner device 3 includes a large pulley 301, a mandrel 304 and a section adjustment device, the large pulley 301 is arranged on the support frame 18, one side of the large pulley 301 is connected with one end of the mandrel 304, and the mandrel 304 passes through the bearing It is connected with the bearing seat, and the bearing seat is connected with the support frame 18; the section adjustment device includes a rotating shell 307, a vertebral thread 306 and a thread claw 311, and the vertebral thread 306 includes two semi-c...

Embodiment 2

[0082] A banner rolling machine, the structure of which is as described in Embodiment 1, the difference is that the radial side of the thread of the vertebral body is provided with a groove 314, and the surface of the inner cavity of the rotating shell 307 is provided with a boss, and the radial side of the boss is A bump 315 is provided, and the bump is mated with the groove of the vertebral thread, such as Figure 7a and Figure 7b . Through the concavo-convex connection between the vertebral body thread 306 and the radial side of the rotating shell 307, the two can rotate simultaneously. When the rotating shell rotates, the vertebral body thread is also driven to rotate.

Embodiment 3

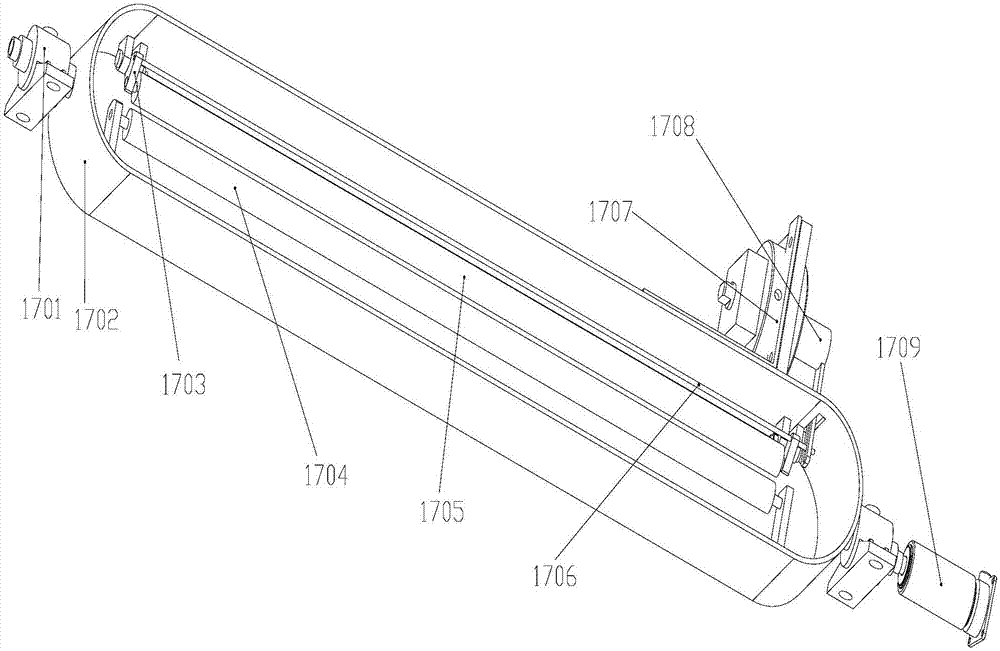

[0084] A banner rolling machine, the structure of which is as described in Embodiment 1. The difference is that two bearings are provided on the mandrel 304, which are respectively bearing C312 and bearing B310. Both bearings are connected to the support frame through the bearing seat. A shaft stop washer A305 is provided between the bearing C312 and the mandrel, such as Figure 6 , The two sides of the bearing C are the radial table of the mandrel and the shaft stop washer A for the shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com