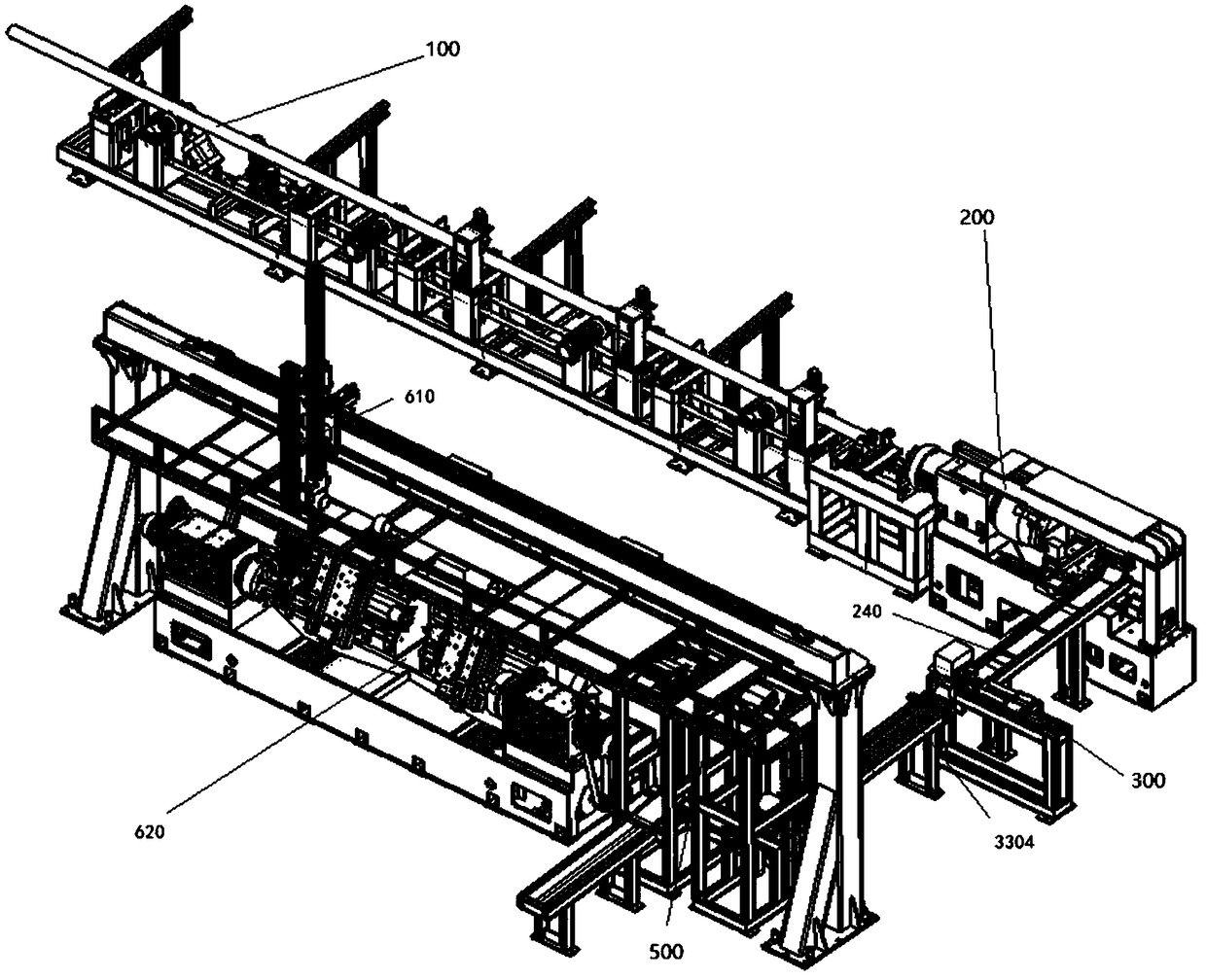

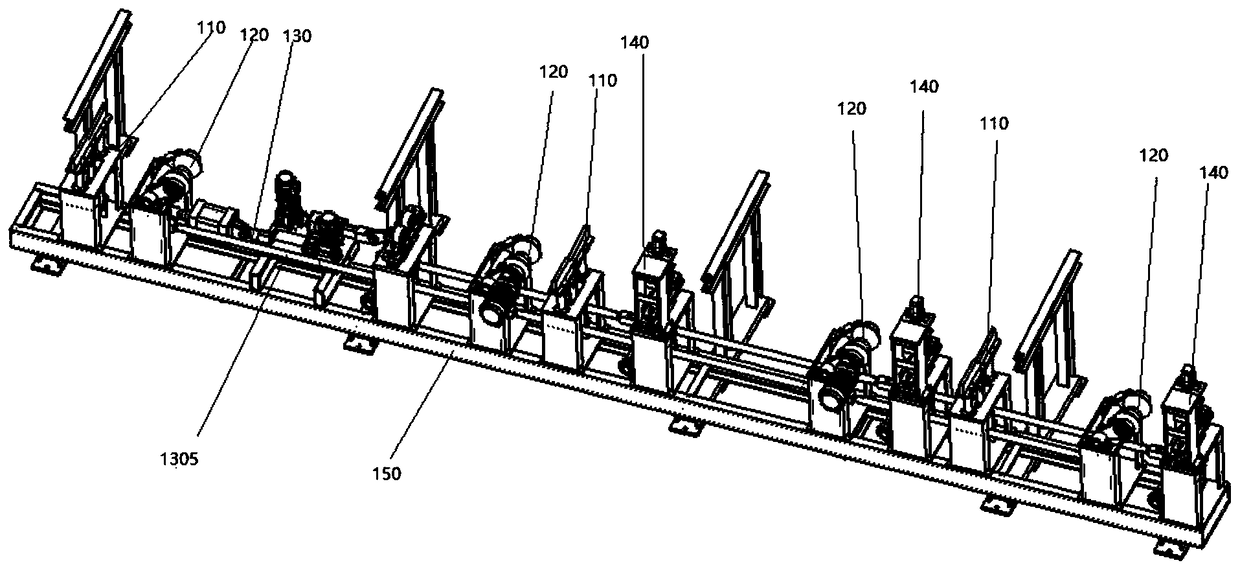

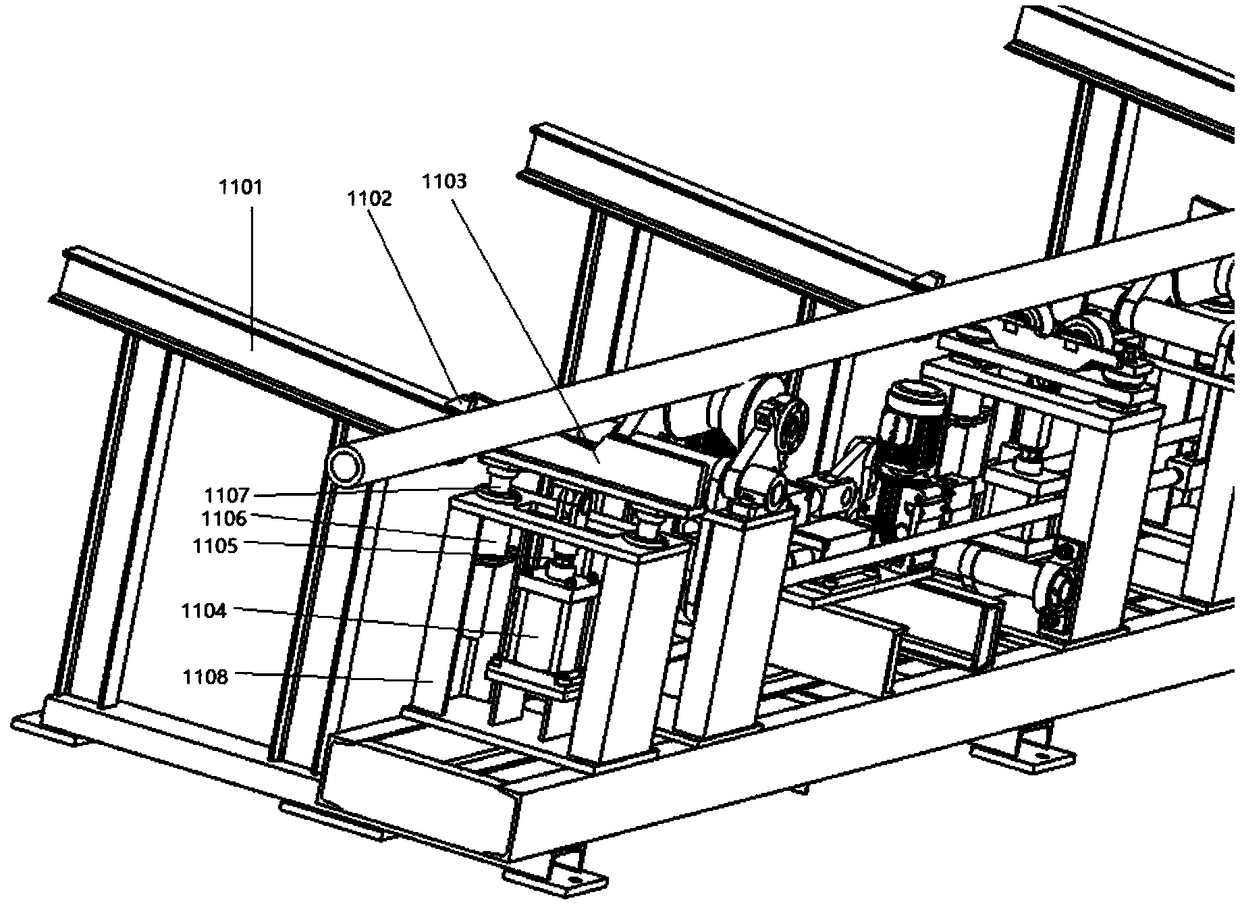

Petroleum casing collar automatic production line

An automated production line, oil casing technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems affecting normal work, labor-intensive, high equipment costs, etc., to achieve the effects of ensuring stability, saving manpower, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0130] The specific working mode of the coupling blank conveying device 400 in the petroleum oil casing coupling automatic production line of the present invention is as follows:

[0131] Figure 25 It is a schematic diagram of a plurality of coupling blanks in the coupling blank conveying device in the automatic production line of petroleum oil casing casings of the present invention being queued and waiting to be moved. Figure 26 It is a partial enlarged view of a plurality of coupling blanks in the automatic production line of petroleum oil casing couplings of the present invention, where multiple coupling blanks are lined up in a limited position and waiting to be moved. Figure 27 It is a schematic diagram of a coupling blank being pushed over the limit protrusion in the coupling blank conveying device in the petroleum oil casing coupling automatic production line of the present invention.

[0132] Such as Figure 25 and Figure 26 shown. A plurality of coupling blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com