Feedstock tensioning mechanism for garment tailoring equipment

A tensioning mechanism and equipment technology, applied in the field of garment machinery, can solve the problems of reduced production efficiency, non-conforming fabrics, inaccurate blanking of fabrics, etc., to achieve the effects of reduced production efficiency, avoidance of cutting errors, and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

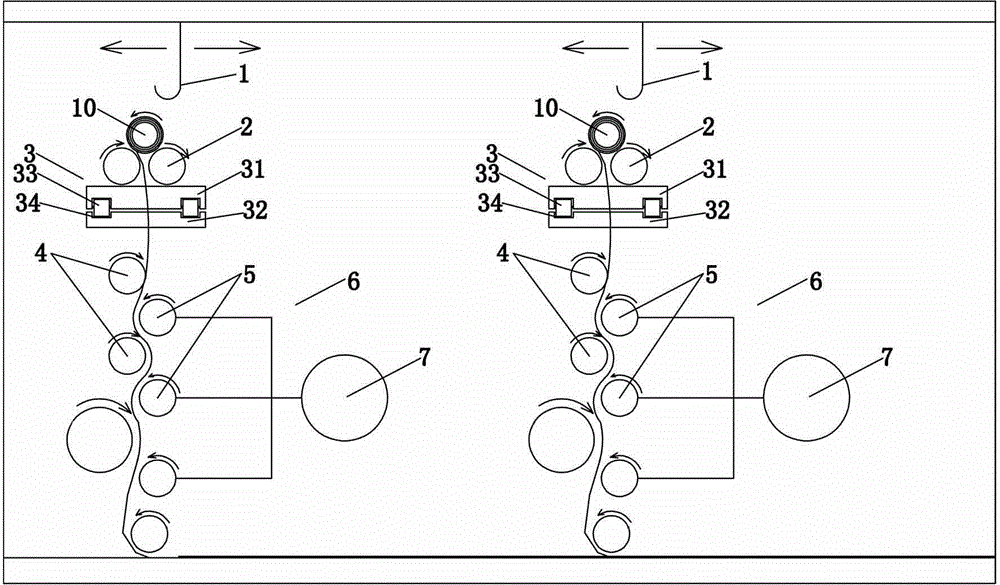

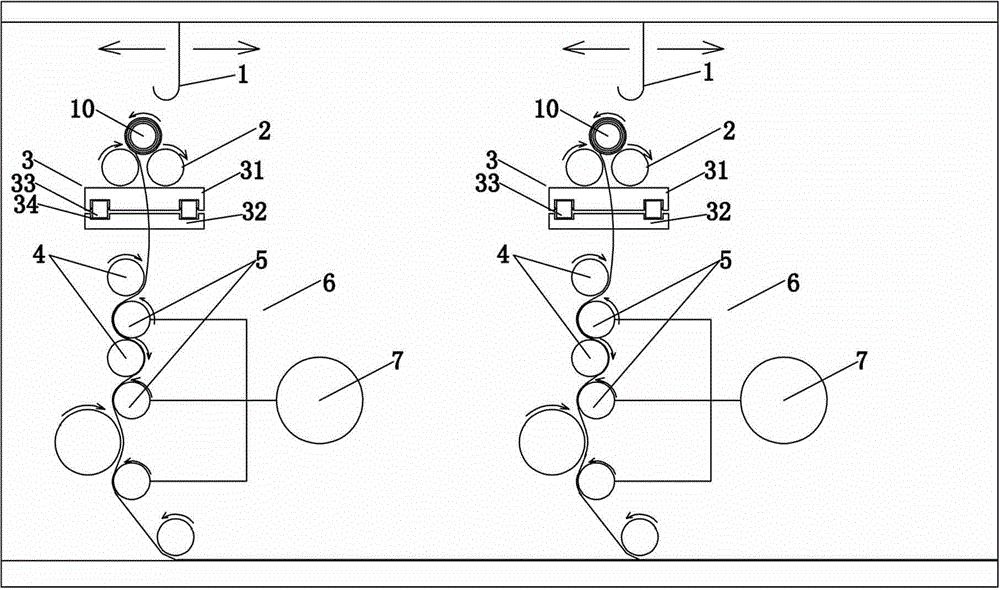

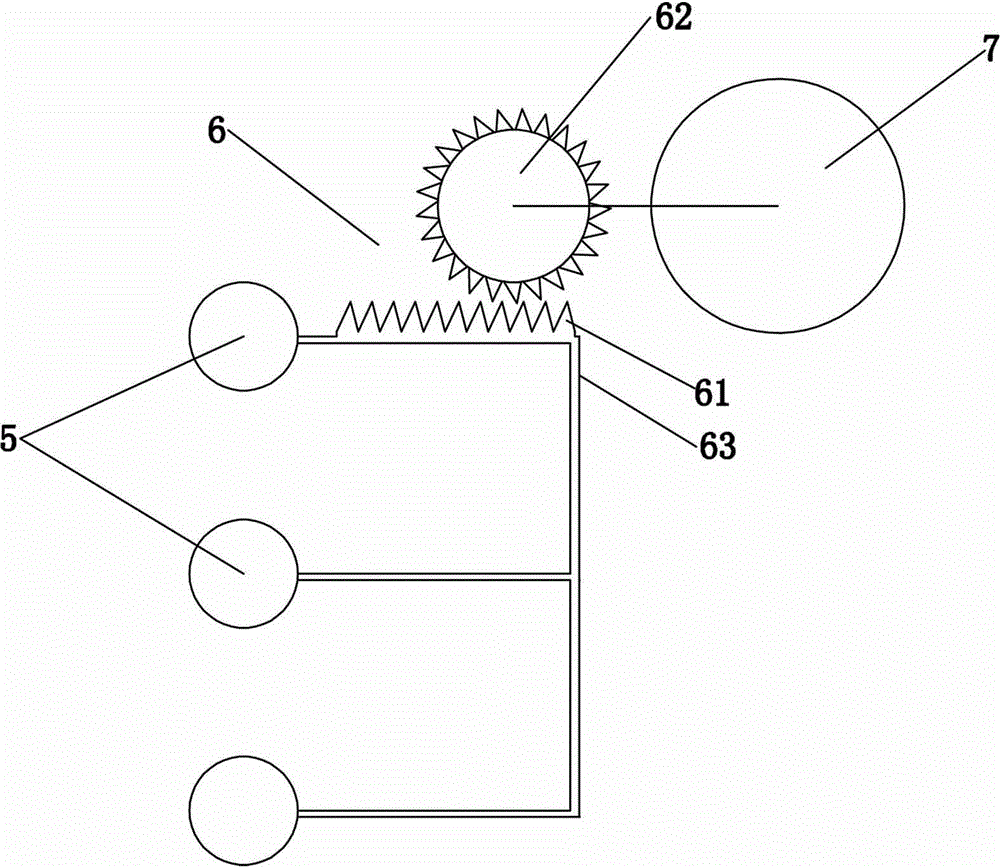

[0019] Example 1, such as Figure 1 to Figure 4 As shown, a garment cutting device includes a feeding tension mechanism, and the feeding tension mechanism includes a mounting base 3, two feed rollers 2 arranged side by side on the mounting base, and three parallel and horizontal tensioning rollers. The tension roller 5, two feed rollers 4 that are parallel to each other and arranged horizontally, and the driving assembly 6 that drives the tension roller 5 to move laterally so that the tension roller 5 and the feed roller 4 are vertically staggered. The two feeding rollers 2 rotate in the same direction and are separated from each other. The feeding roller 4 is arranged below the mounting seat, and the tension roller 5 is arranged on one side of the feeding roller 4. The tension roller 5 and the feeding roller 4 are adjacent in pairs, parallel to each other, and rotate in opposite directions. Of course, in order to increase or decrease the tension of the cloth so that the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com