Sectional type advection smoke discharging drying device and drying method

A drying device and segmented technology, which is used in drying gas arrangement, drying solid materials, drying goods handling, etc., can solve the problems of low production efficiency and insignificant drying effect, and achieve short drying time and increased production output. , the effect of improving product quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

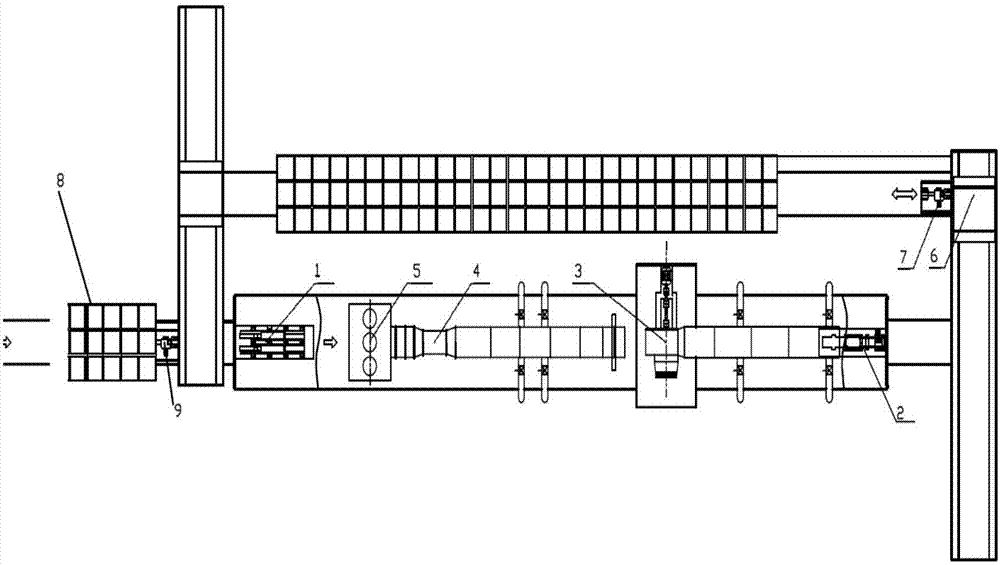

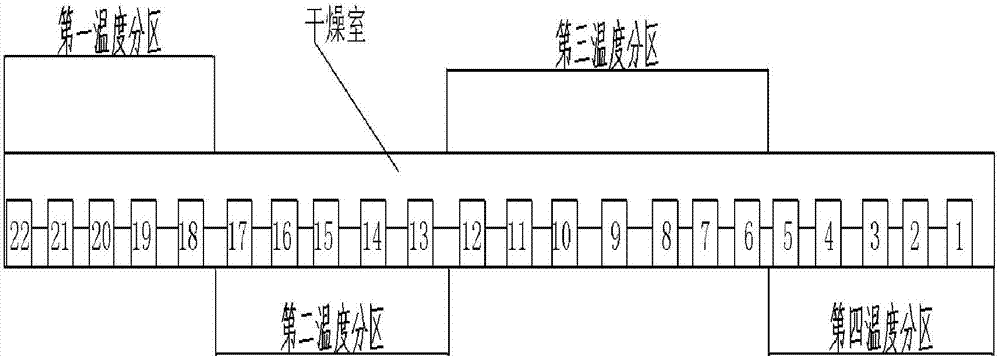

[0028] Such as Figure 1~2 As shown, a segmented advective smoke exhaust drying device includes a hydraulic jacking machine 1, a kiln discharge tractor 2, a drying kiln heating fan 3, a drying chamber exhaust fan 4, a drying chamber main exhaust fan 5, and a ferry Car 6, two-way car return tractor 7, kiln car 8, car return tractor 9 and drying room 10; the drying room has a total of 22 parking spaces, and the drying room is divided into four sections; the drying room blower 3 is installed in On the side of the drying chamber 10, the hot air duct of the drying chamber hot air blower 3 leads to the drying chamber from the top of the drying chamber; The exhaust pipe of the drying chamber leads from the top of the drying chamber to the inside of the kiln head of the tunnel drying chamber; the main exhaust fan 5 of the drying chamber is installed on the top of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com