Pipe jacking construction method of municipal gas pipelines

A technology for gas pipelines and construction methods, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of many leakage points, damage, poor corrosion resistance of pipelines, etc., to prevent ground subsidence, The effect of improving work efficiency and increasing the strength of the carbon layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

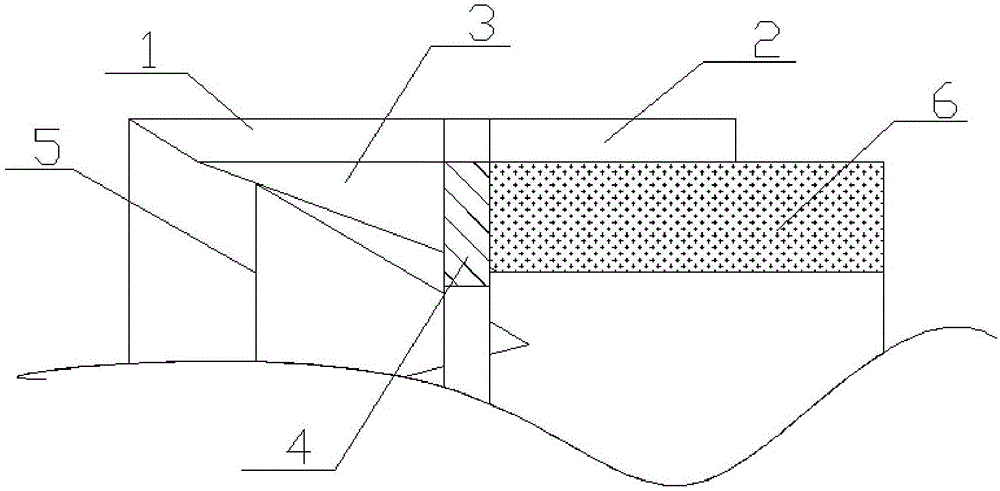

[0028] A pipe jacking construction method of a municipal gas pipeline in this embodiment comprises the following steps:

[0029] (1) According to the given control pile position in the design, use theodolite to release the crossing axis, and determine the crossing center pile and construction belt sideline pile, and sprinkle gray lines, and release the position and size of the originating well at the same time when setting out the lines.

[0030] (2) Level the position of the caisson given in the design, and then prefabricate the caisson as a whole on the ground according to the requirements of the design drawings, and construct the sending well and the receiving well at the same time.

[0031] (3) When the strength of the reinforced concrete caisson poured on site reaches the design requirements after maintenance, the caisson is sunk evenly, and the caisson operation is stopped after reaching the design elevation; A dewatering well is evenly spaced at 3m, so that the water le...

Embodiment 2

[0041]The method of this embodiment is the same as that of Embodiment 1, the difference is that: the polypropylene foam material and the outer surface of the outer tube are coated with an anti-icing adhesion emulsion, and the components by weight of the polypropylene foam material of this embodiment are composed of: Acrylic resin: 106 parts, nucleating agent: 7 parts, antioxidant: 2 parts, lubricant: 1.6 parts, filler: 18 parts, nano silica: 14 parts, methyl hydrogen silicone oil: 66 parts, hydroxyl poly Dimethicone: 12 parts, Vinyltrimethoxysilane: 12 parts, Ammonium Polyphosphate: 6 parts, Alkyl Dimethicone: 13 parts, Polyisobutylene: 12 parts, Alkylphenol poly Oxyethylene ether: 8 parts, reactive diluent: 5.6 parts, coupling agent: 1.6 parts, leveling agent: 3.4 parts; the particle diameter of the nano silicon dioxide is 25nm. The nucleating agent is one or more mixtures of silicon dioxide, calcium carbonate, carbon black, graphite, talcum powder, and inorganic oxides; the ...

Embodiment 3

[0044] The method of this embodiment is the same as that of Embodiment 1, the difference is that: the polypropylene foam material and the outer surface of the outer tube are coated with an anti-icing adhesion emulsion, and the components by weight of the polypropylene foam material of this embodiment are composed of: Acrylic resin: 107 parts, nucleating agent: 8 parts, antioxidant: 3 parts, lubricant: 1.7 parts, filler: 19 parts, nano silica: 15 parts, methyl hydrogen silicone oil: 67 parts, hydroxyl poly Dimethicone: 13 parts, Vinyltrimethoxysilane: 13 parts, Ammonium Polyphosphate: 7 parts, Alkyl Dimethicone: 15 parts, Polyisobutylene: 13 parts, Alkylphenol poly Oxyethylene ether: 9 parts, reactive diluent: 5.7 parts, coupling agent: 1.7 parts, leveling agent: 3.5 parts; the particle diameter of the nano silicon dioxide is 30nm. The nucleating agent is one or more mixtures of silicon dioxide, calcium carbonate, carbon black, graphite, talcum powder, and inorganic oxides; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com