Anchor rod structure and construction method thereof

A construction method and bolt technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems that the preset anchor cable position deviates from the design position, is prone to settlement, affects the support effect, etc., and achieves support Good effect, increased rigidity and anti-deformation ability, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

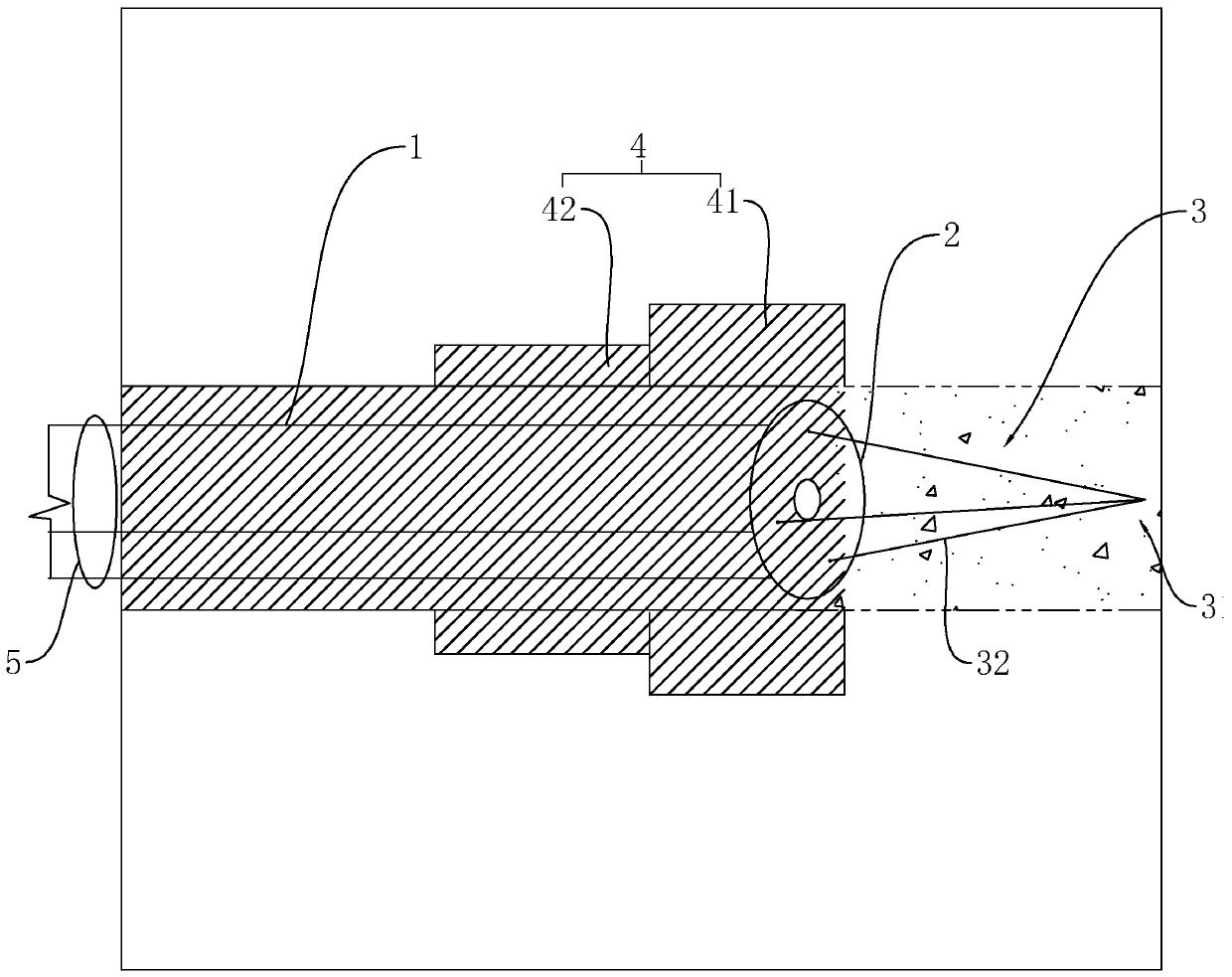

[0046] refer to figure 1 , is a kind of anchor rod structure disclosed in the present invention, comprises anchor cable 1, and anchor cable 1 is made of steel strand, is provided with anchor plate 2 at the end of anchor cable 1 inserted in the anchor hole, and anchor plate 2 is made of steel In order to increase the anchoring capacity with the slope, at least three anchor cables 1 are pierced on one anchor disk 2. In this embodiment, three anchor cables 1 are selected, and the anchor cables 1 pass through the anchor disk 2 and are fixed by extrusion anchors. On anchor plate 2. An anti-sinking part 3 for preventing the anchor cable 1 from sinking is arranged on the side of the anchor plate 2 away from the anchor cable 1 . One end of the anti-sinking component 3 is connected to the anchor plate 2 , and the other end is provided with a pointed cone portion 31 . By setting the anti-sinking part 3 at the front end of the anchor cable 1, setting an ultra-deep section for placing t...

Embodiment 2

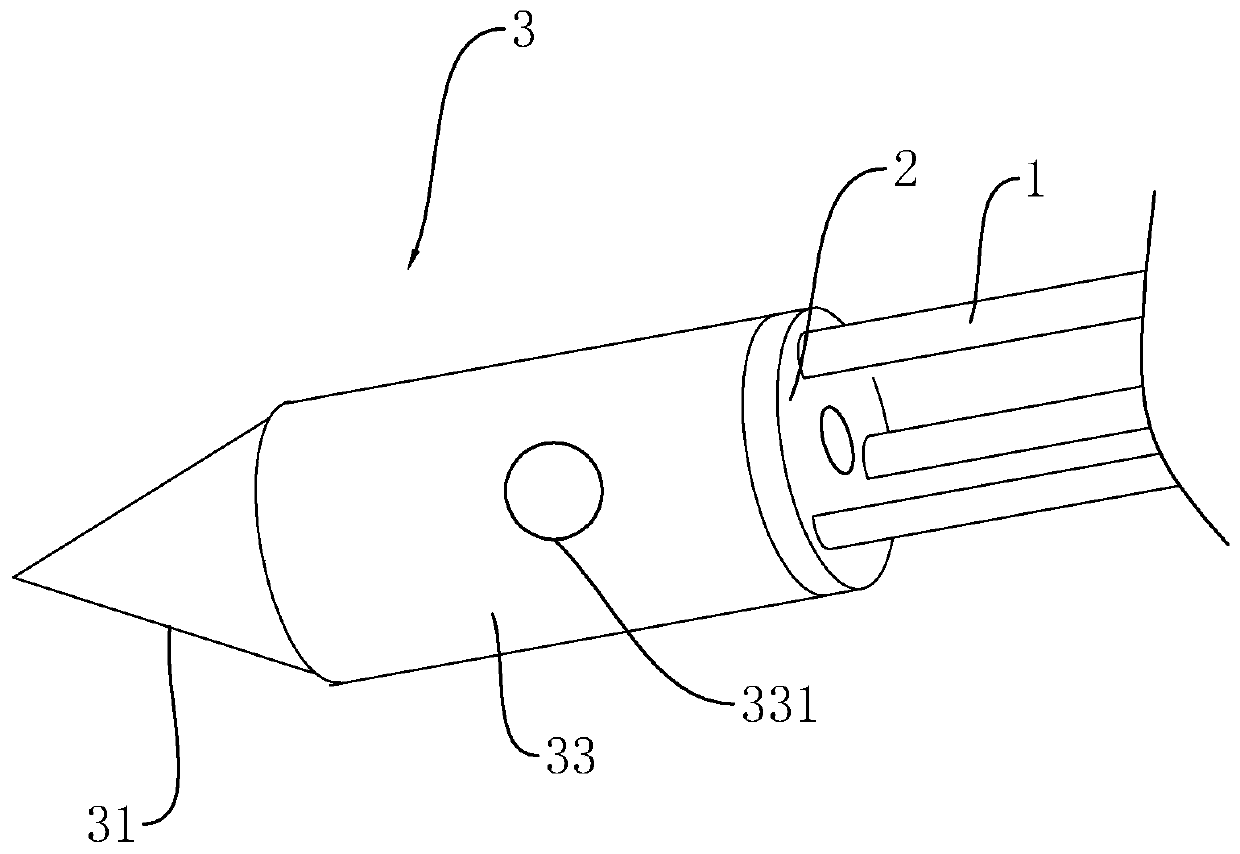

[0052] refer to figure 2 , the difference from Embodiment 1 is that the anti-sinking part 3 includes a cylinder 33 with the same diameter as the anchor plate 2 and a tapered portion 31 fixed at one end of the cylinder 33, and the cylinder 33 is far away from the tapered portion 31. One end is welded on the anchor plate 2 after the anchor cable 1 and the anchor plate 2 are fixed, and the tapered portion 31 is conical and fixed on the cylinder 33 by welding. A slurry outlet 331 is opened on the side wall of the cylinder 33 . By arranging the cylinder 33 and the conical pointed cone portion 31, the rigidity and deformation resistance of the anti-sinking part 3 are increased to prevent the anti-sinking part 3 from being damaged due to the deep anchor hole when the anchor cable 1 is pushed into the anchor hole. The resistance is large, and the problem of deformation occurs. At the same time, through the grout hole 331, the rotary sprayed cement slurry can completely fill the ult...

Embodiment 3

[0054] A kind of bolt structure construction method, comprises the following steps:

[0055] S1. Anchor hole positioning: After excavation, the wall of the foundation pit has been corrected and sprayed with anchors. According to the elevation and horizontal spacing required by the design, use the total station to set out the position of the anchor hole on the wall of the foundation pit, and mark the anchor hole .

[0056] S2. Drilling: Use a special anchor drill to align the placed holes, adjust the angle according to the designed angle of the anchor hole, select a hard alloy high-pressure rotary drill bit, and set multiple nozzles on the side of the drill bit for high-pressure rotary rotary drilling process , start drilling, and the depth of the hole is drilled until it is 30-100 cm deeper than the design hole depth. In the present embodiment, the ultra-deep section is selected as 50 cm, and the ultra-deep section of the anchor hole is used to place the anti-sinking part 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com