Method and system for jacking open-cut box culverts across operating subway interval

A box culvert and jacking technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as increasing the cost of excavation of foundation pits, cross-section convergence deformation, tunnel safety effects, etc., to avoid long-term exposure. In the air, reducing the demand for jacking force, and the effect of convenient jacking of box culverts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the technical solution of the present invention will be described in detail through specific examples.

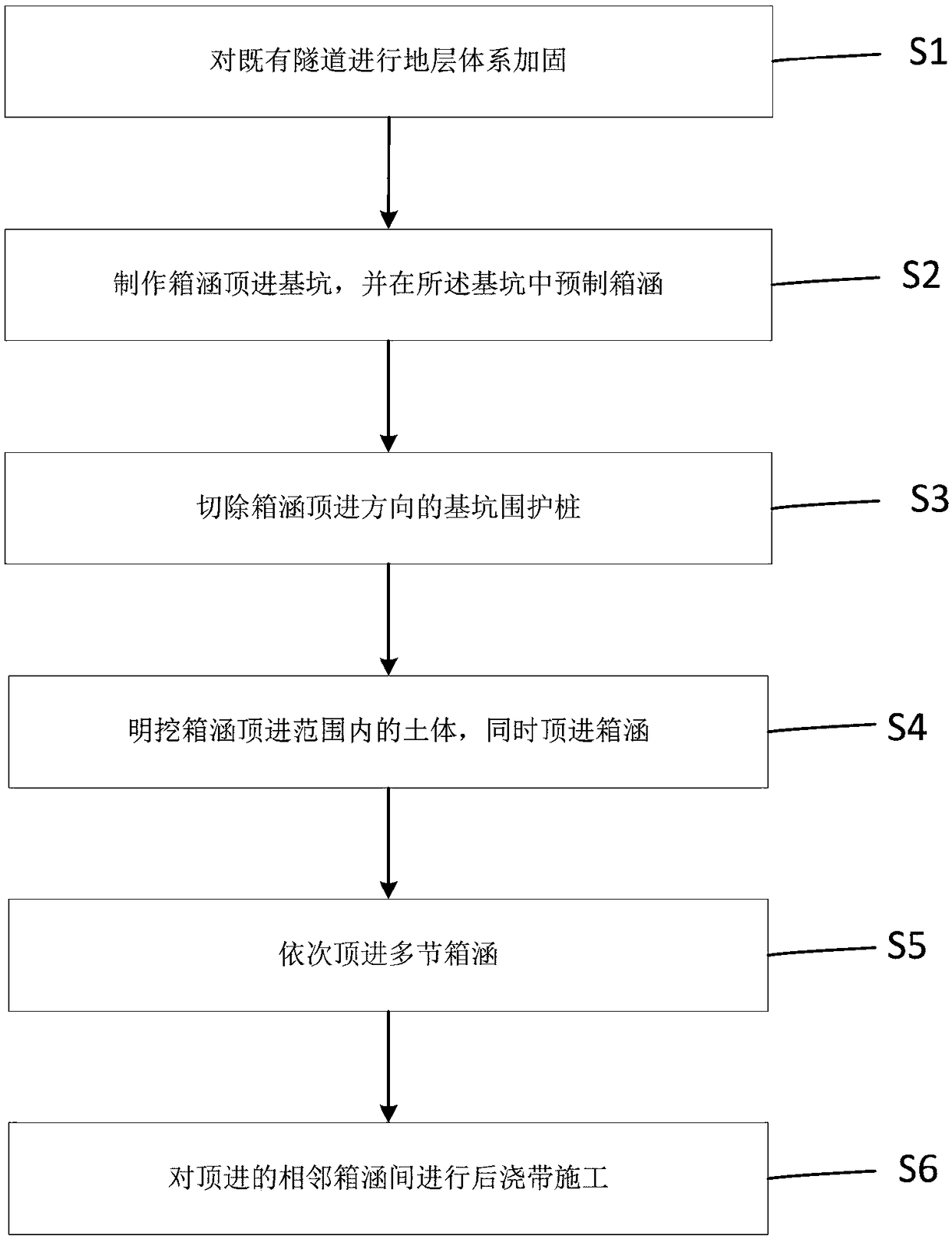

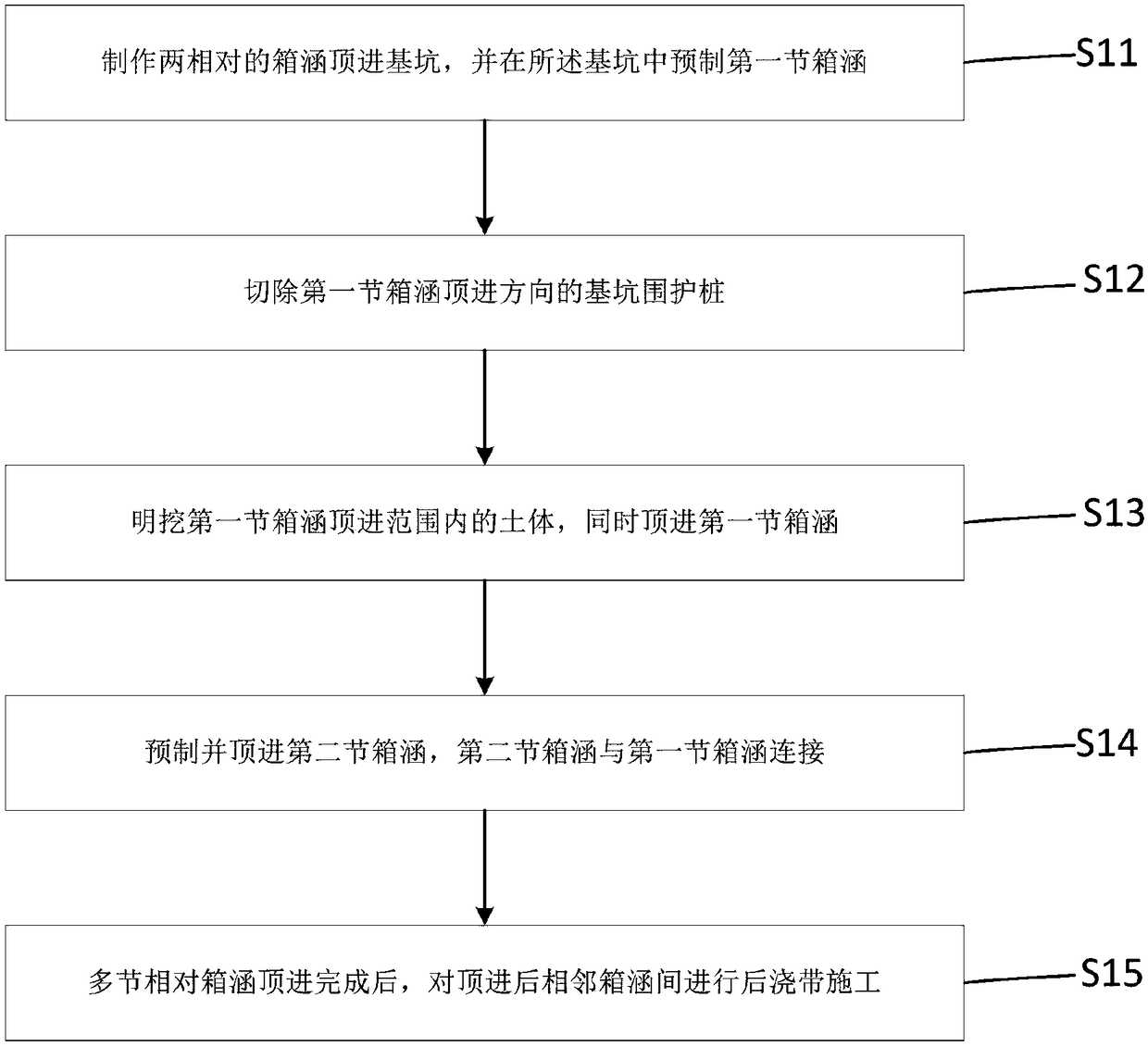

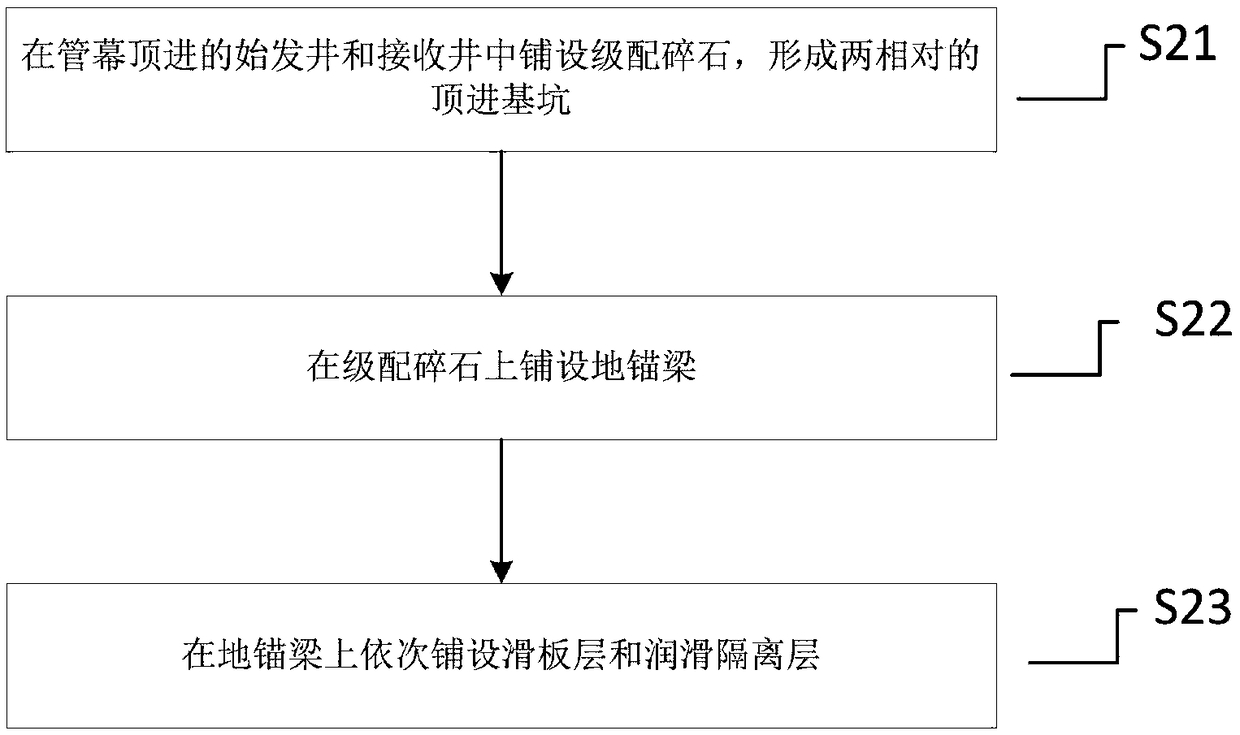

[0040] refer to figure 1 , 4 , 7, a kind of open-cut box culvert jacking method that the present invention proposes across the operation subway interval, comprises the following steps:

[0041] S1: Strengthen the stratum system of the existing tunnel 1;

[0042] The stratum system of the existing tunnel 1 is reinforced through the pipe curtain 4 and the uplift pile 3, and the existing tunnel 1 is reinforced through the pipe curtain 4 and the uplift pile 3. The uplift pile 3 and the pipe curtain 4 are rigidly connected to form a The integrated structure increases the connection strength between the uplift pile 3 and the pipe curtain 4, thereby improving the reinforcement strength of the existing tunnel 1.

[0043] like Figure 5 As shown, the adjacent pipe curtains 4 are locked and connected by the channel steel 6 and the I-beam 5; avoiding the deviation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com