Floor type chain link disassembling and assembling machine

A dismounting machine, floor-standing technology, applied in the direction of metal chains, etc., can solve the problems of difficult fixing of adjacent two chain links, long working time, inaccurate pin hole alignment, etc., to meet the needs of field operations, installation and Easy operation, simple structure and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

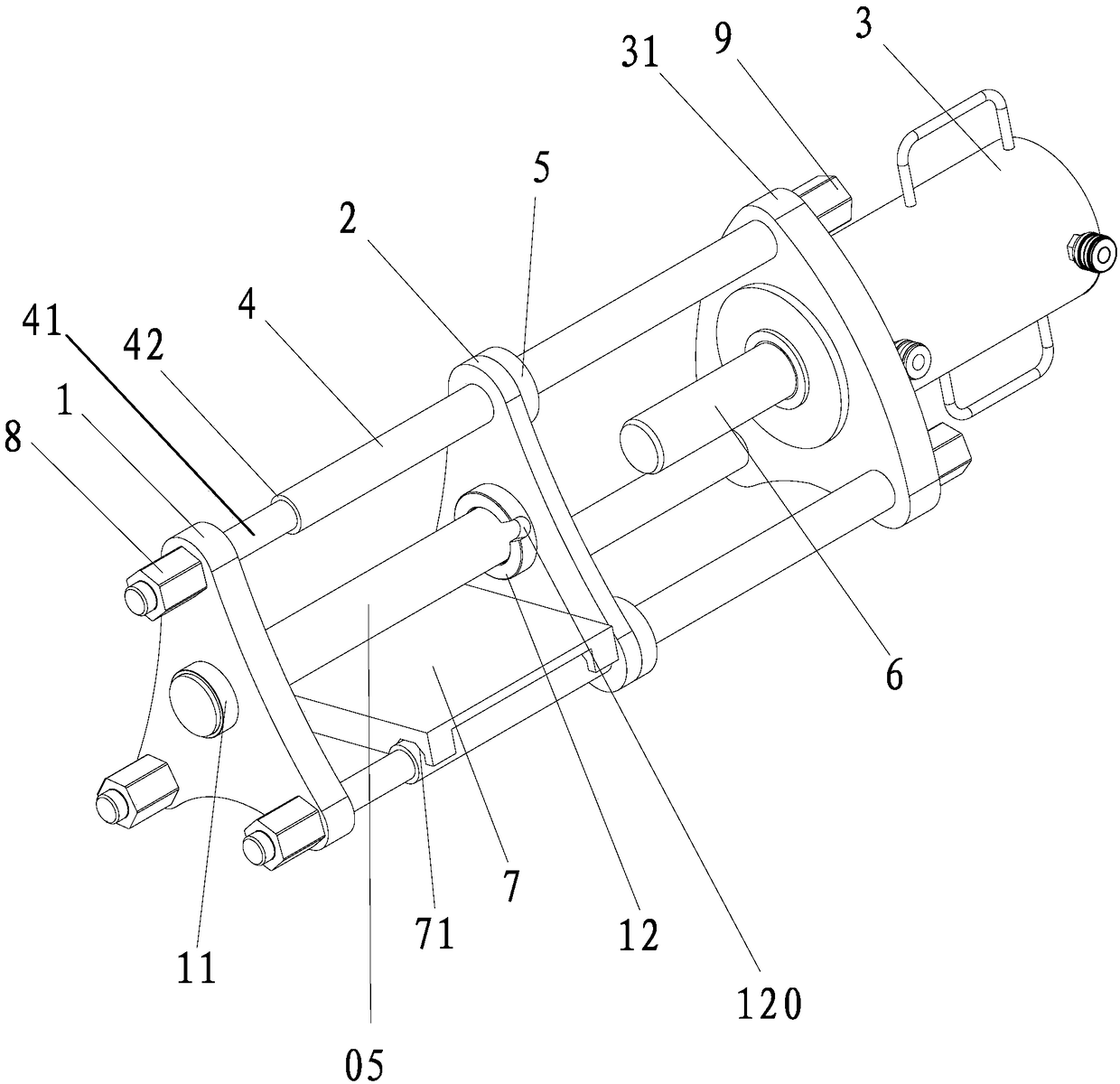

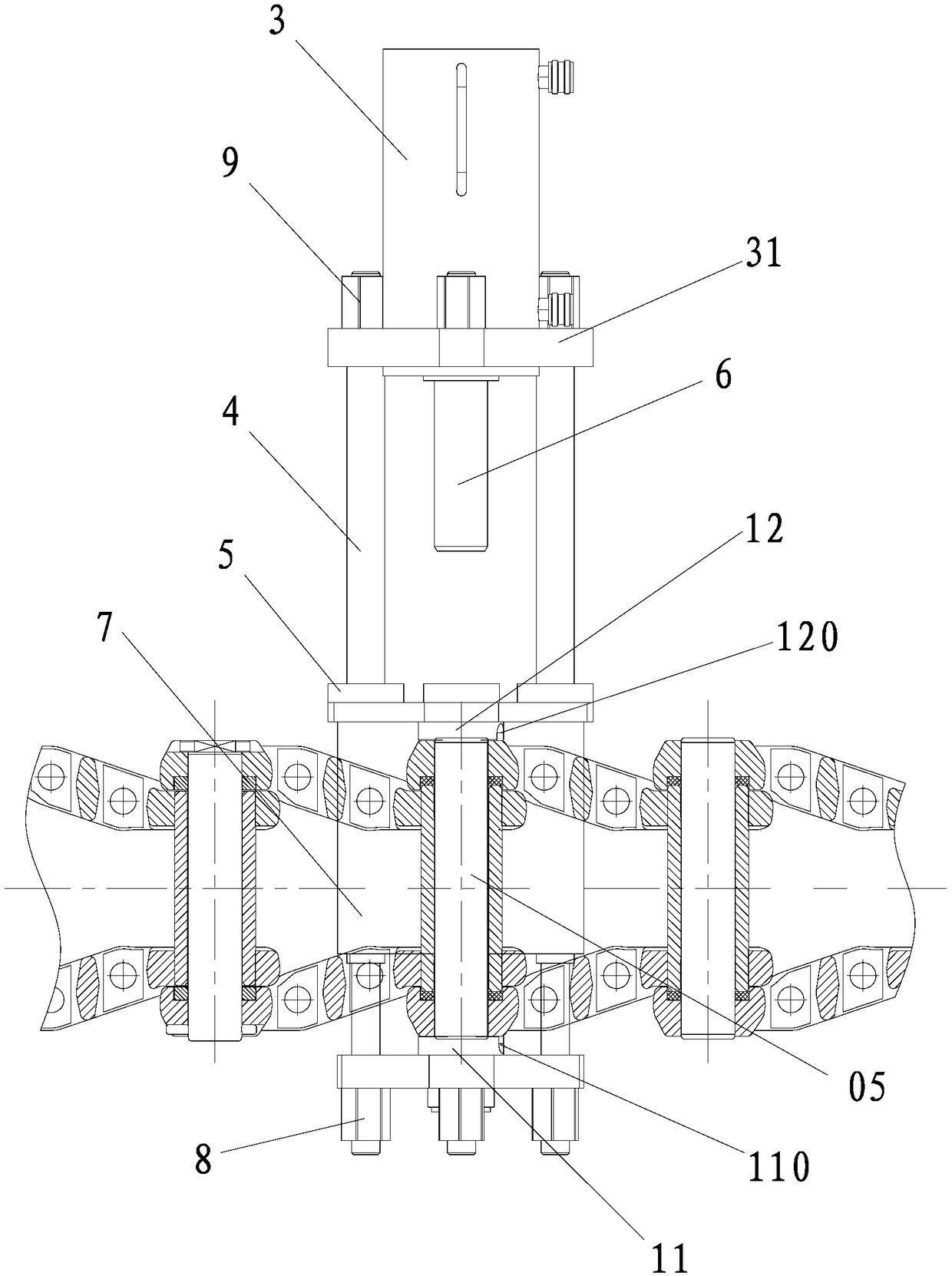

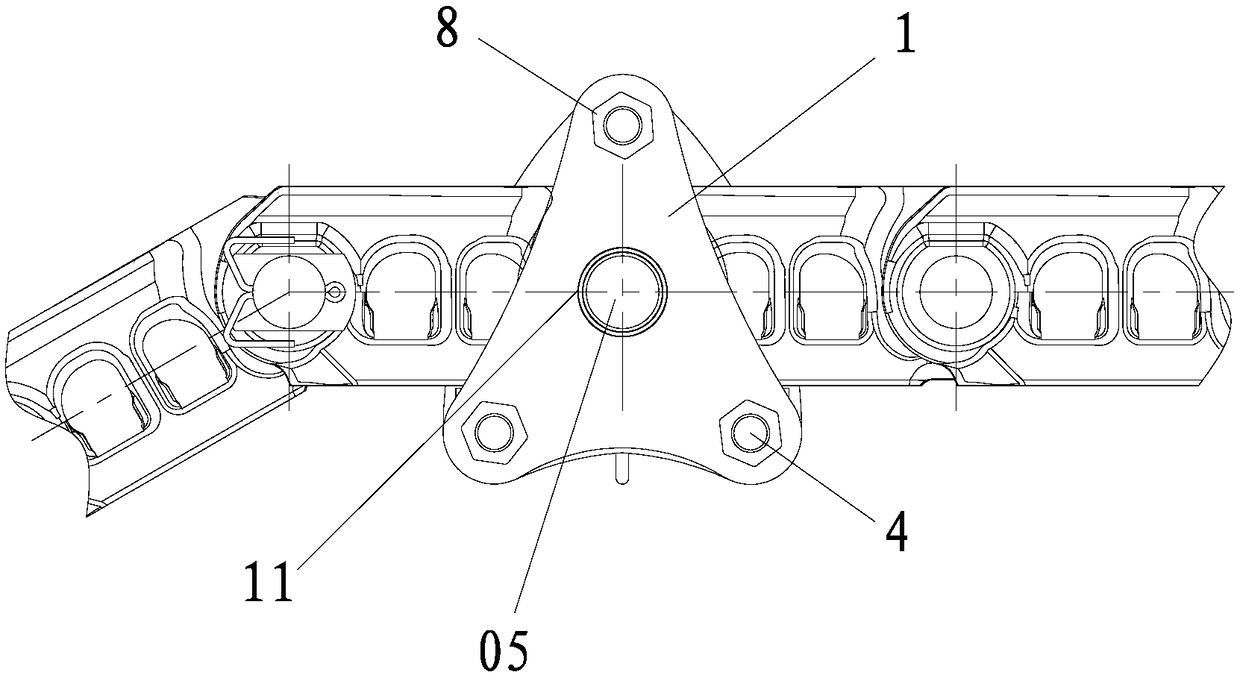

[0025] Such as Figure 1-3 As shown, the floor type chain link dismounting machine of the present invention includes an adjusting plate 1, a supporting plate 2 and an oil jack 3 with a bottom plate 31, and the supporting plate 2 is located between the adjusting plate 1 and the oil jack 3 In between, the adjusting plate 1 is connected to the bottom plate 31 of the hydraulic jack 3 through at least three parallel connecting rods 4, the adjusting plate 1 is detachably connected to the connecting rods 4, the hydraulic jack The bottom plate 31 of the jack is connected to the connecting rod 4 in a detachable manner; The fixed ring 5 for limiting the sliding stroke (specifically: the fixed ring 5 and the connecting rod 4 are integrally formed), the plunger of the hydraulic jack faces the support plate 2, and the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com