A High Concentricity Composite Insulator Injection Mold

A technology of composite insulators and injection molds, applied in the direction of coating, etc., can solve problems such as self-weight deformation, and achieve the effects of enhanced high coaxiality, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

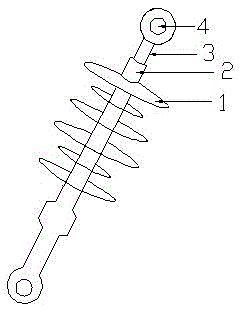

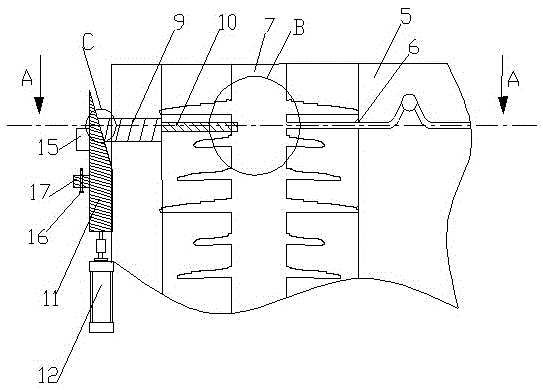

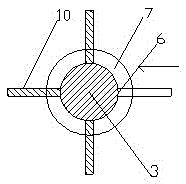

[0019] Such as figure 1 ,Such as figure 2 and Figure 4 As shown, a high-coaxiality composite insulator injection mold includes an upper mold and a lower mold 5, and a gate 6 and a runner are arranged inside, and the two molds cooperate to form an injection mold cavity, and the top of the upper mold is provided with a material injection hole; the injection The center of the mold cavity has a mandrel accommodating cavity 7, the mandrel accommodating cavity 7 is cylindrical, and a number of thimbles are arranged outside the circumference of the mandrel accommodating cavity 7 at the position of the gate 6, and each thimble points to The axis of the mandrel accommodation chamber 7, and the thimbles are evenly distributed around the mandrel accommodation chamber 7 in a circular shape with the axis center of the mandrel accommodation chamber 7 as a circle, and are staggered from the gate 6;

[0020] Described thimble is made up of slide block 9, push rod 10 and guide seat 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com