Construction method of municipal rain and sewage diversion pipeline

A technology of rain and sewage diversion and construction methods, which is applied in sewer systems, waterway systems, buildings, etc., can solve the problems of difficult jacking operation of rain and sewage diversion pipes, poor wear resistance of lubricating coatings, and wear of lubricating coatings, etc., to achieve The jacking operation is not easy, the effect of improving the wear resistance and reducing the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

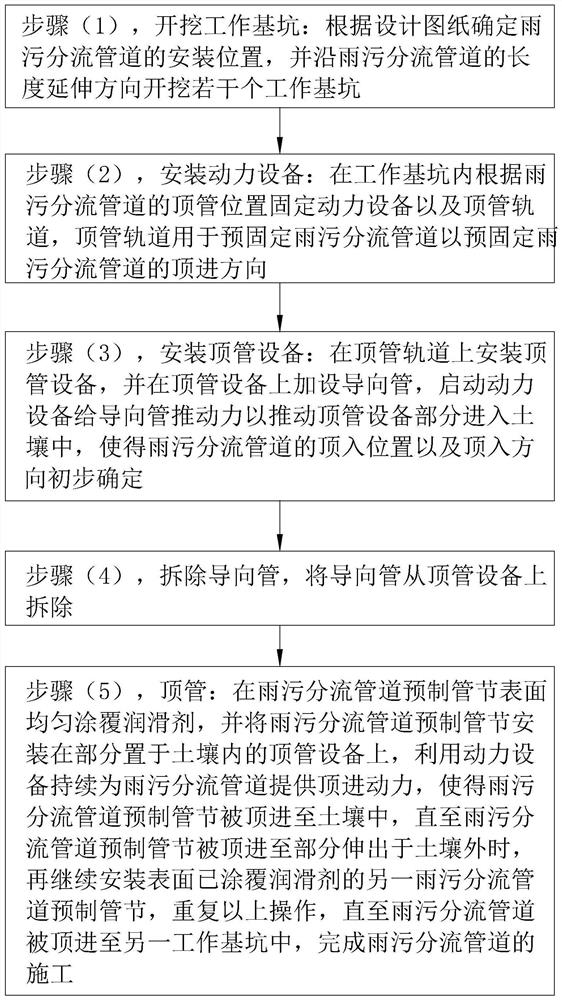

[0071] Refer figure 1 The construction method of a municipal rain split pipeline is disclosed in the present invention, including the following steps:

[0072] Step (1), excavation of the working foundation pit, specifically as follows:

[0073] According to the design drawings, the mounting position of the rain is determined, and several working foundation pits are excavated in the extended direction of the length of the rain sprout pipe.

[0074] Step (2), install the power equipment, specifically as follows:

[0075] In the working foundation pit, according to the top pipe position of the rain splitting pipe and the top pipe track, the top pipe track is fixed to the bottom wall of the working foundation pit, the top pipe is used to pre-solid the rain and sprout pipe to fix the rain-saving shunt pipeline. In the top direction, when the rain-saving diversion pipe prefabricated tube is placed on the top pipe track, the topping position of the rain-saving shunt pipeline and the ra...

Embodiment 2

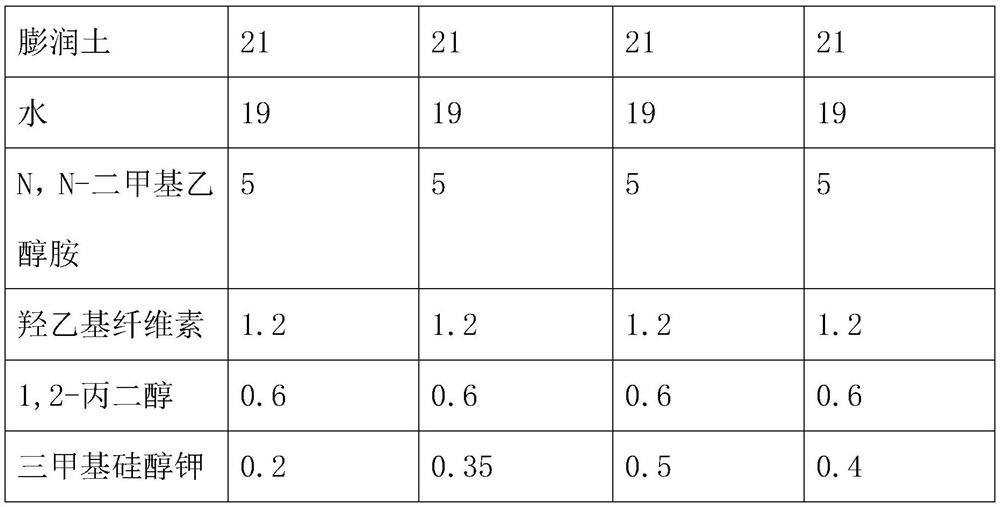

[0086] The difference from Example 1 is that the raw material components and content of the lubricant are as shown in Table 1.

Embodiment 3

[0088] The difference from Example 1 is that the raw material components and content of the lubricant are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com