Pole group inserting machine and use method thereof

A plug-in machine and extreme group technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve problems such as low work efficiency, battery box deformation, heavy weight, etc., to save labor costs and improve The effect of production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

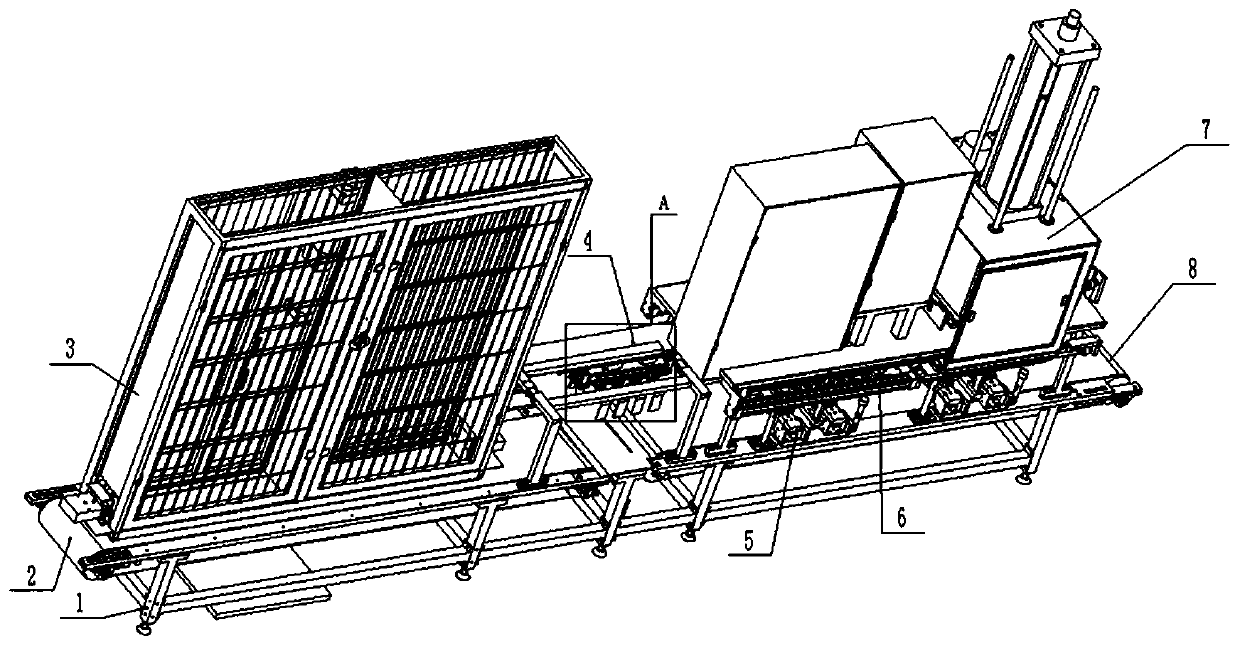

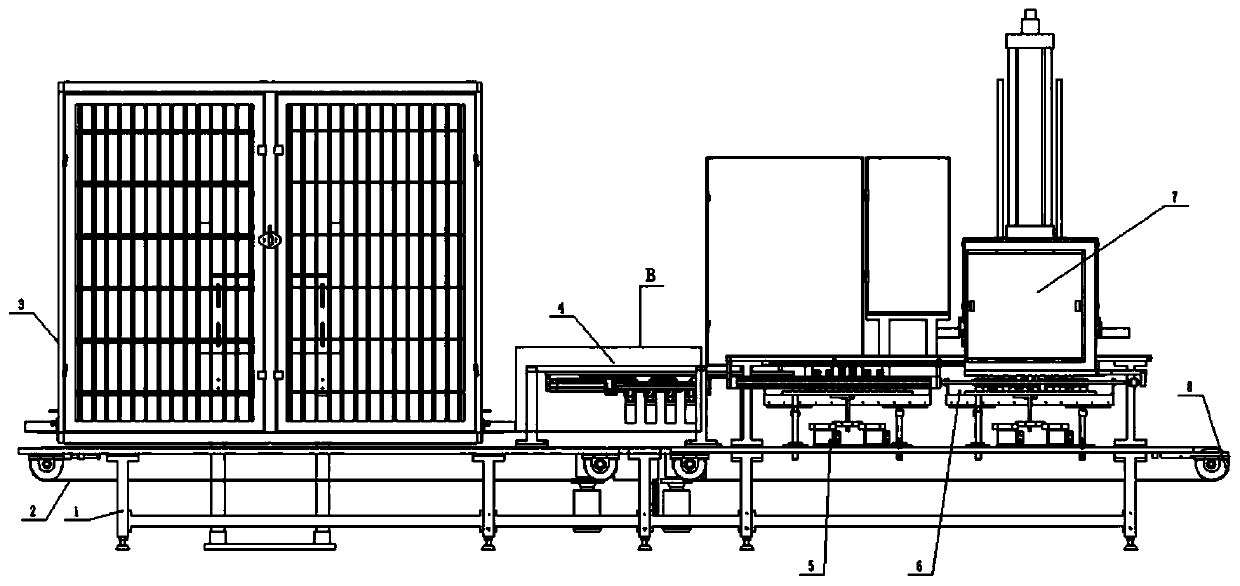

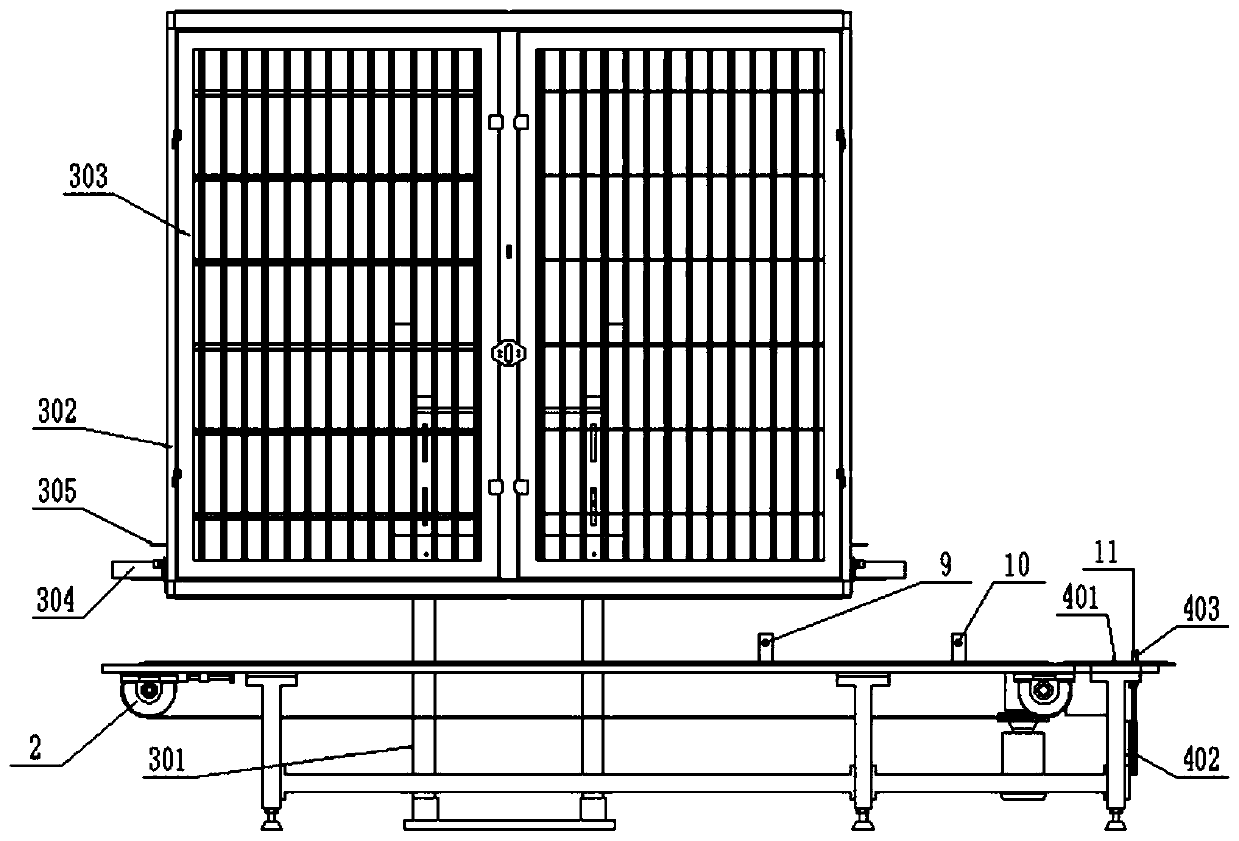

[0035] Such as Figure 1-2 As shown, a pole group inserting machine includes a frame 1, a first conveyor belt 2 and a second conveyor belt 8 are arranged on the frame 1, and a battery for supplying the first conveyor belt 2 is arranged on the frame 1 above the first conveyor belt 2 Shell feeding mechanism 1, the frame 1 between the first conveyor belt 2 and the second conveyor belt 8 is provided with a transfer mechanism 4 that transfers the battery case on the first conveyor belt 2 to the second conveyor belt 8, the second conveyor belt 8 The frame 1 above is provided with a plurality of stabilizing mechanisms 5 for stabilizing the battery case on the second conveyor belt 8, the frame 1 above the stabilizing mechanism 5 is provided with a movable plate 612, and a plurality of vertical plates 612 are fixed on the movable plate 612. The sixth cylinder 613 of the sixth cylinder, the telescopic rod of the sixth cylinder 613 is fixedly connected with the frame 1 below, the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com