Direct-current motor forward and reverse rotation control system

A DC motor and control system technology, applied in the direction of DC motor rotation control, etc., can solve the problems of low work efficiency and labor consumption, and achieve the effect of improving work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

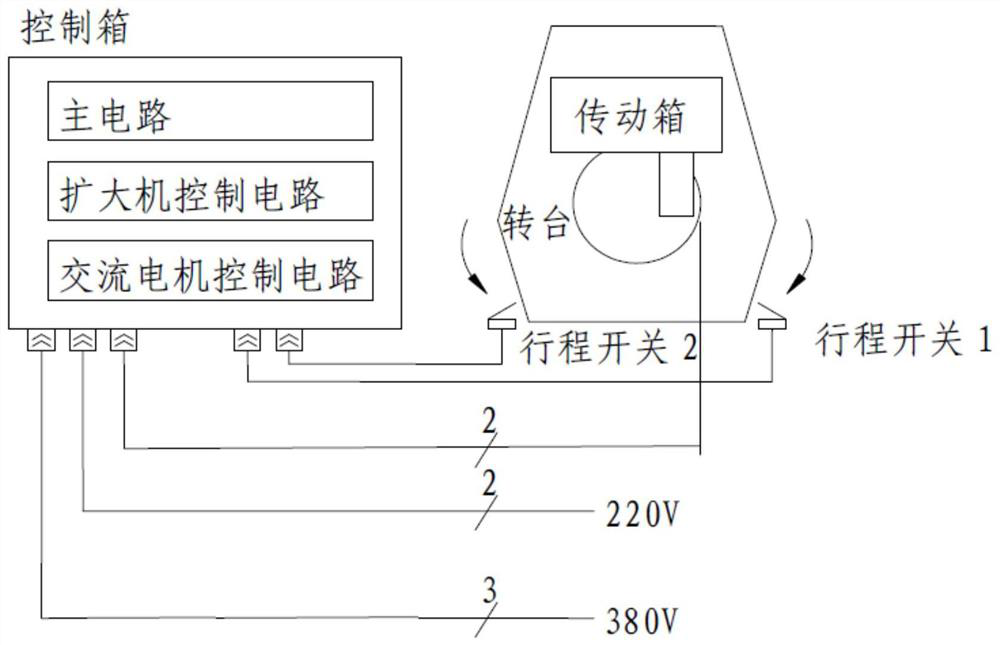

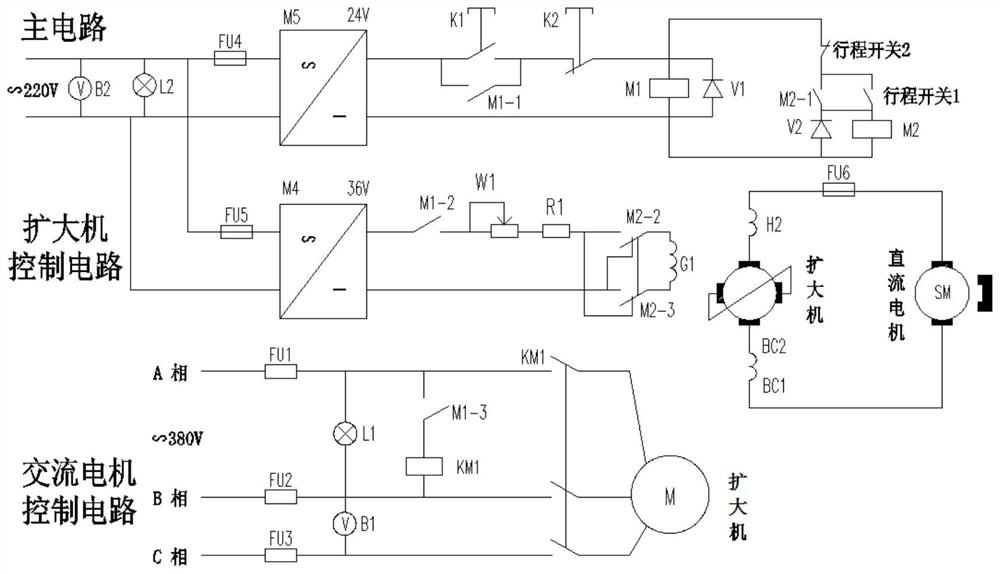

[0027] Such as figure 1 , figure 2 As shown, before the DC motor control system works, two inputs should be connected, namely AC 220V and AC 380V, among which the AC 220V is converted to DC 24V by the 24V conversion power module power module M5, and converted to DC by the 36V conversion power module M4 36V; AC 380V provides working voltage for the amplifier through the AC motor control circuit. The output end of the external control box is connected with the input port of the amplifier, and finally the first travel switch 1 and the second travel switch 2 are connected to the system through a cable and installed on the limit position of the turntable.

[0028] Press the first button switch K1, the wire pack of the first relay M1 is powered on, and the normally open contacts M11, M12, M13 provided by the first relay M1 are closed accordingly. In the main circuit unit, the contact M11 and its wire package form a power-on self-locking, release the start button, M11 is still clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com