Method for indirect extrusion casting by utilizing filling of electromagnetic force and device thereof

A squeeze casting, electromagnetic force technology, applied in the field of squeeze casting, can solve the problems of increasing the friction and wear of the pressure chamber and the extrusion punch, difficult to accurately control the pouring amount of the liquid metal, and the temperature of the liquid metal dropping rapidly. Reduce oxidation and gettering, avoid artificial pouring, and facilitate the effect of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The aluminum alloy support is produced by the invention.

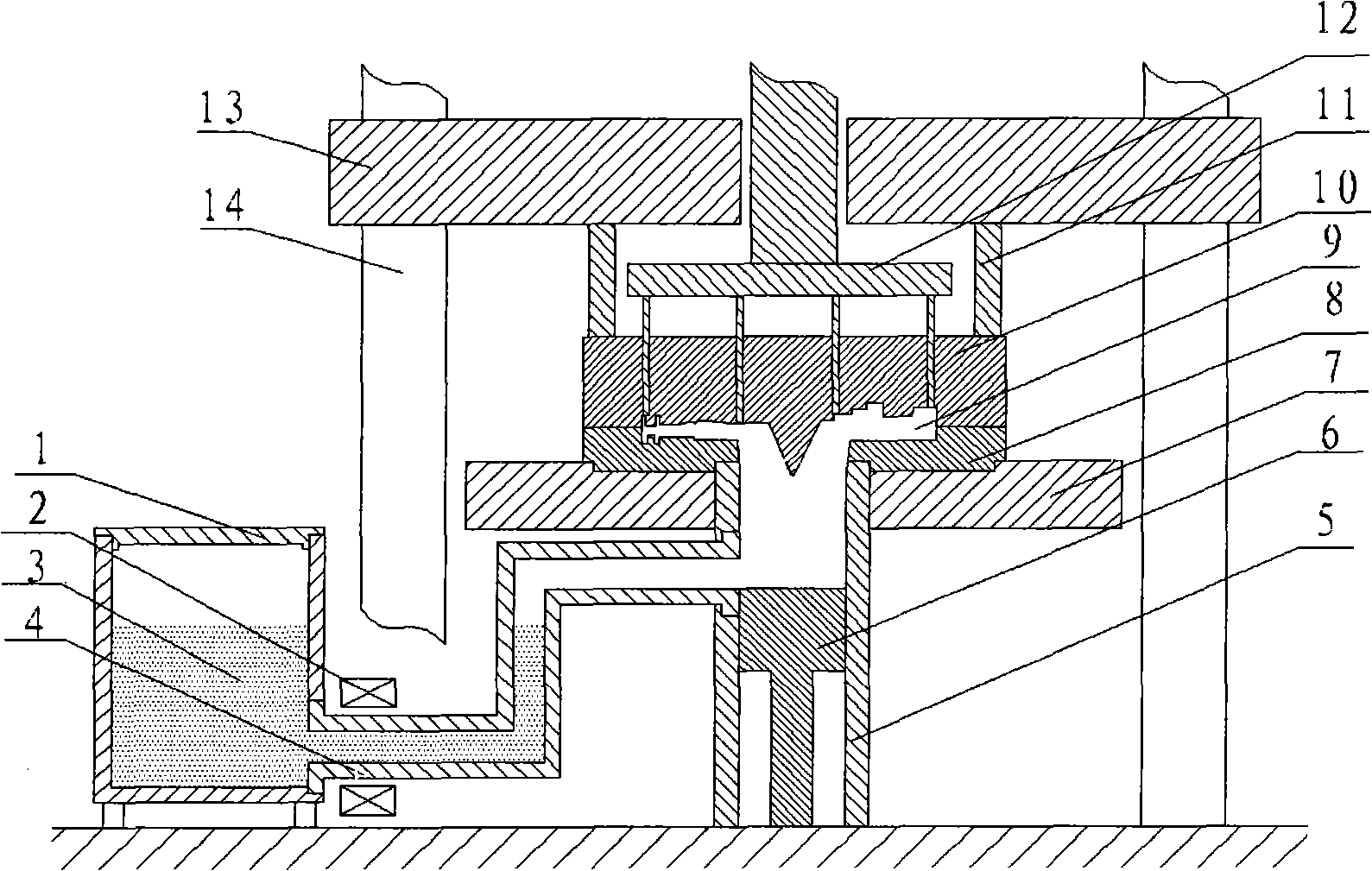

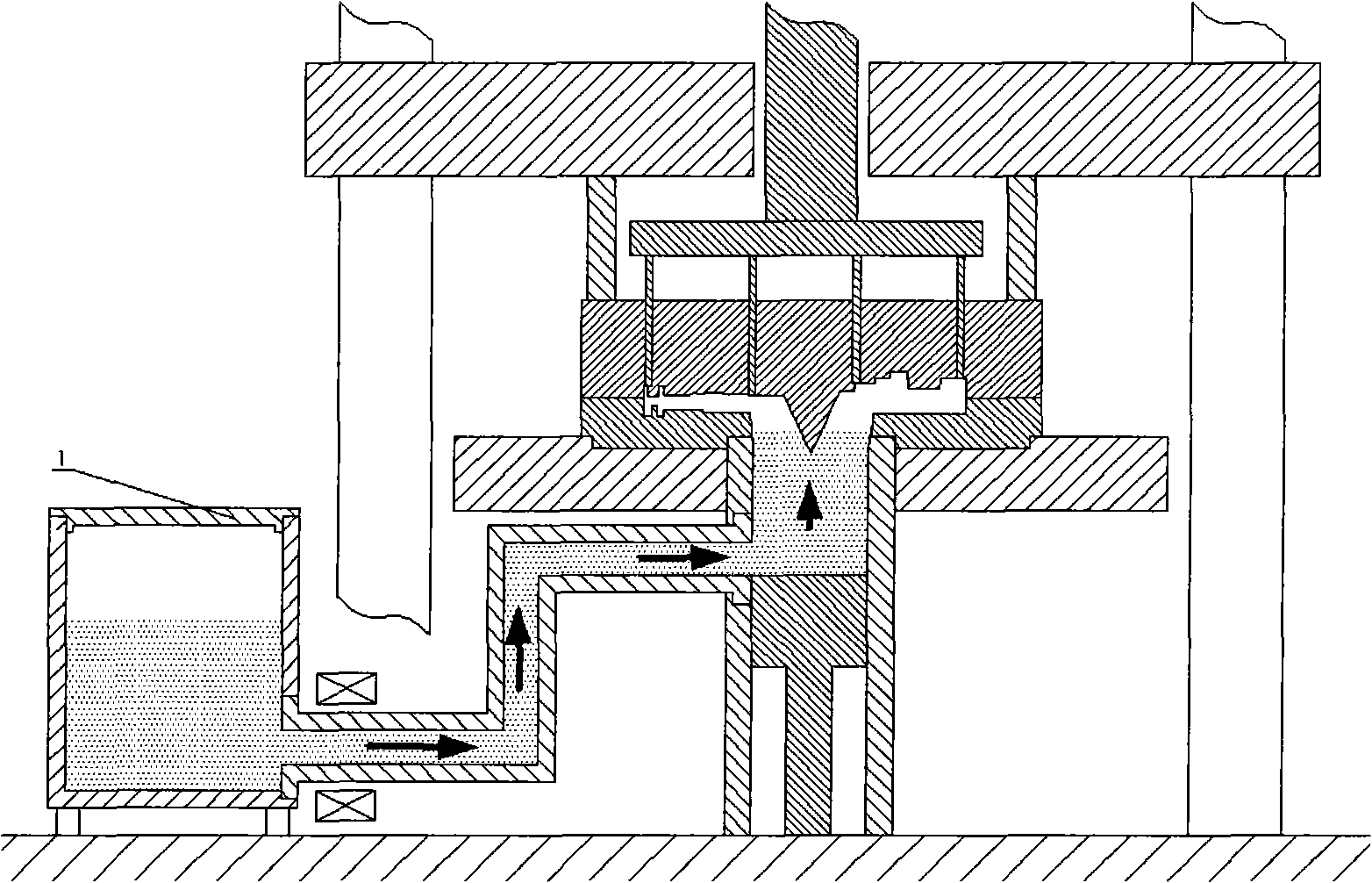

[0033] The casting machine of the present embodiment is a vertical casting machine (model LY-1600) of 16000KN, and the electromagnetic pump system is EMPS-LC. The specific structure of the vertical indirect squeeze casting device for realizing the electromagnetic force filling of the inventive method is as follows figure 1 shown. The device is composed of a holding furnace 1, an electromagnetic pump 2, a transmission pipeline 4, a pressure chamber 5, an extrusion punch 6, a fixed die plate 7, a fixed die 8, a movable die 10, a movable die pad 11, an ejection system 12 and The movable mold plate 13 is composed of; the connection relationship between them and the casting machine is as follows: the holding furnace 1, the transmission pipeline 4, the pressure chamber 5 and the mold cavity 9 are sequentially connected and communicated; the electromagnetic pump 2 is installed in the holding furnace 1 The connection b...

Embodiment 2

[0048] The invention is adopted to produce aluminum alloy wheel hubs.

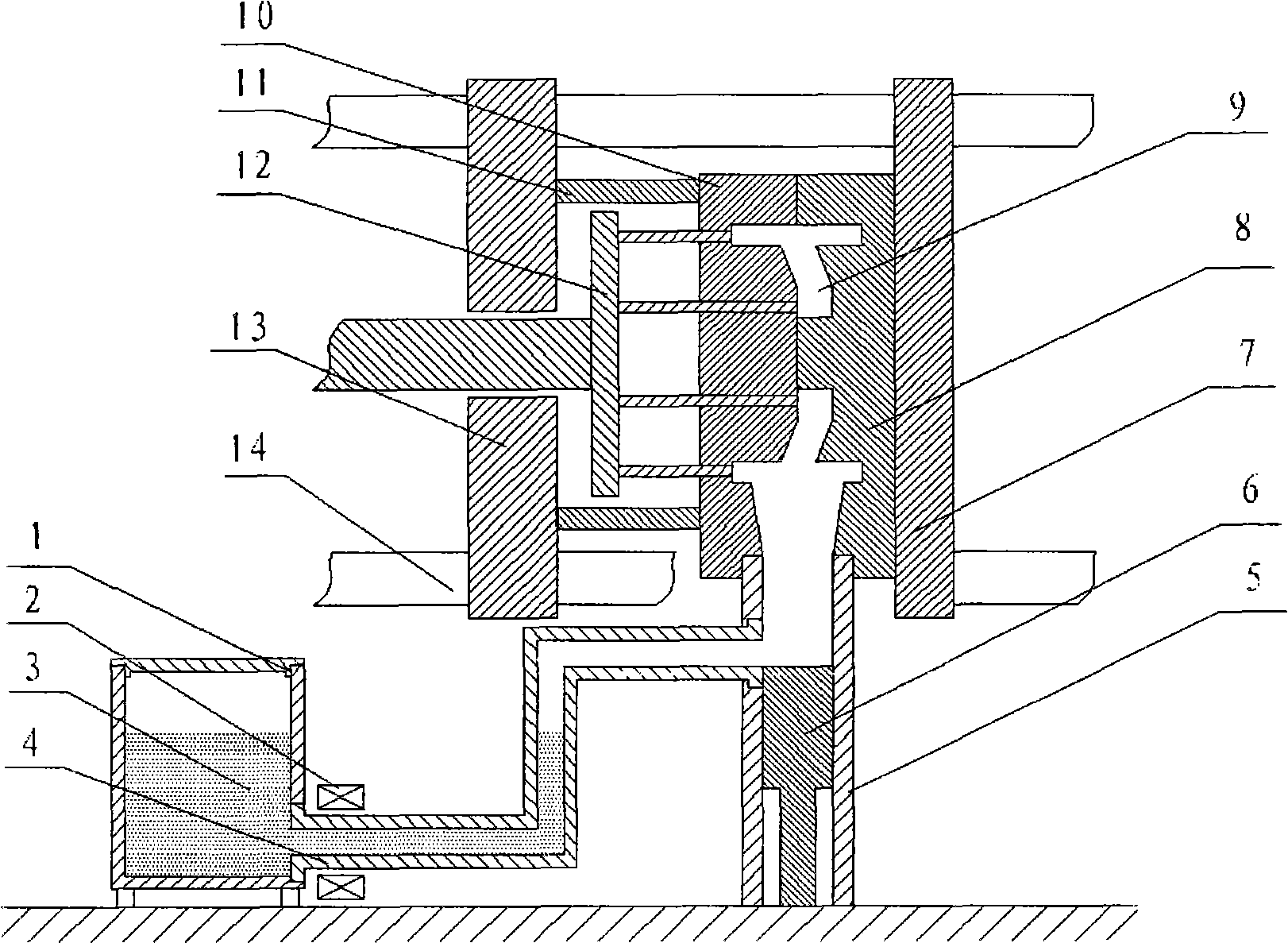

[0049] The casting machine of this embodiment is a 20000KN horizontal casting machine, the electromagnetic pump system is EMPS-LC, and the specific structure of the device for realizing the horizontal indirect squeeze casting method of electromagnetic force filling is as follows figure 2 shown. The device is composed of a holding furnace 1, an electromagnetic pump 2, a transmission pipeline 4, a pressure chamber 5, an extrusion punch 6, a fixed die plate 7, a fixed die 8, a movable die 10, a movable die pad 11, an ejection system 12 and The movable mold plate 13 is composed of; the connection relationship between them and the casting machine is as follows: the holding furnace 1, the transmission pipeline 4, the pressure chamber 5 and the mold cavity 9 are sequentially connected and communicated; the electromagnetic pump 2 is installed in the holding furnace 1 The connection between the outlet and the ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com