Wet-type hydraulic blank taking system capable of achieving protective demolding

A wet and hydraulic technology, applied in ceramic extrusion dies, auxiliary molding equipment, unloading devices, etc., to achieve simple working mechanism, reduce operating procedures, and save human capital

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

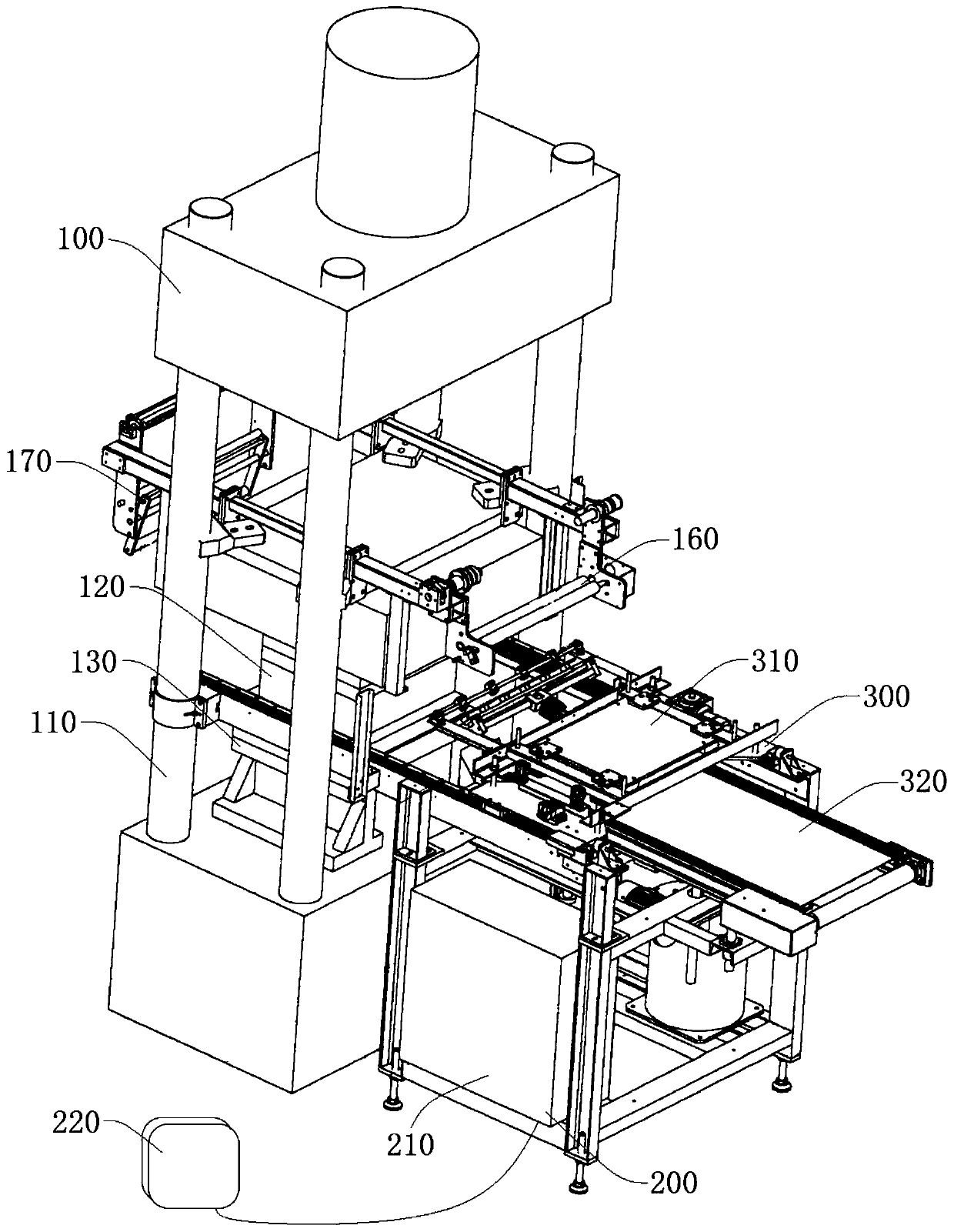

[0042] like figure 1 , figure 2 , image 3 As shown, a wet hydraulic preform removal system of the present invention that realizes protective demoulding includes a pressing module 100, a control module 200, and a preform removal module 300. and the preform removal module 300 are respectively electrically connected to control the operation of the two modules. The pressing module 100 is used for pressing the magnetic material, and the control module 200 is used for controlling the pressing process of the pressing module 100, and demoulding the magnetic material after the pressing is completed. By using the mode of protective demoulding, the magnetic material is improved The pass rate of press molding. After the demoulding of the magnetic material forming is completed, the formed magnetic material needs to be taken out for the next pressing of the magnetic material. During the pressing process of the machine, there are potential safety hazards in manual billet removal, and t...

Embodiment 2

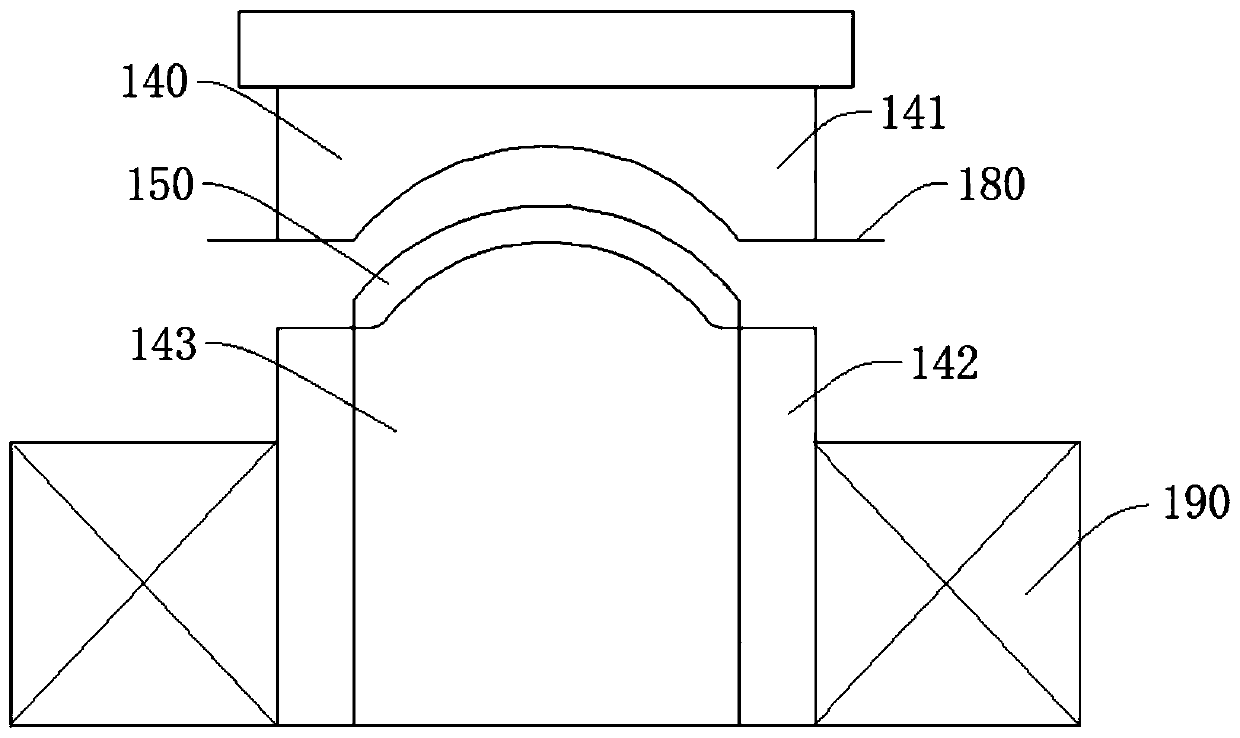

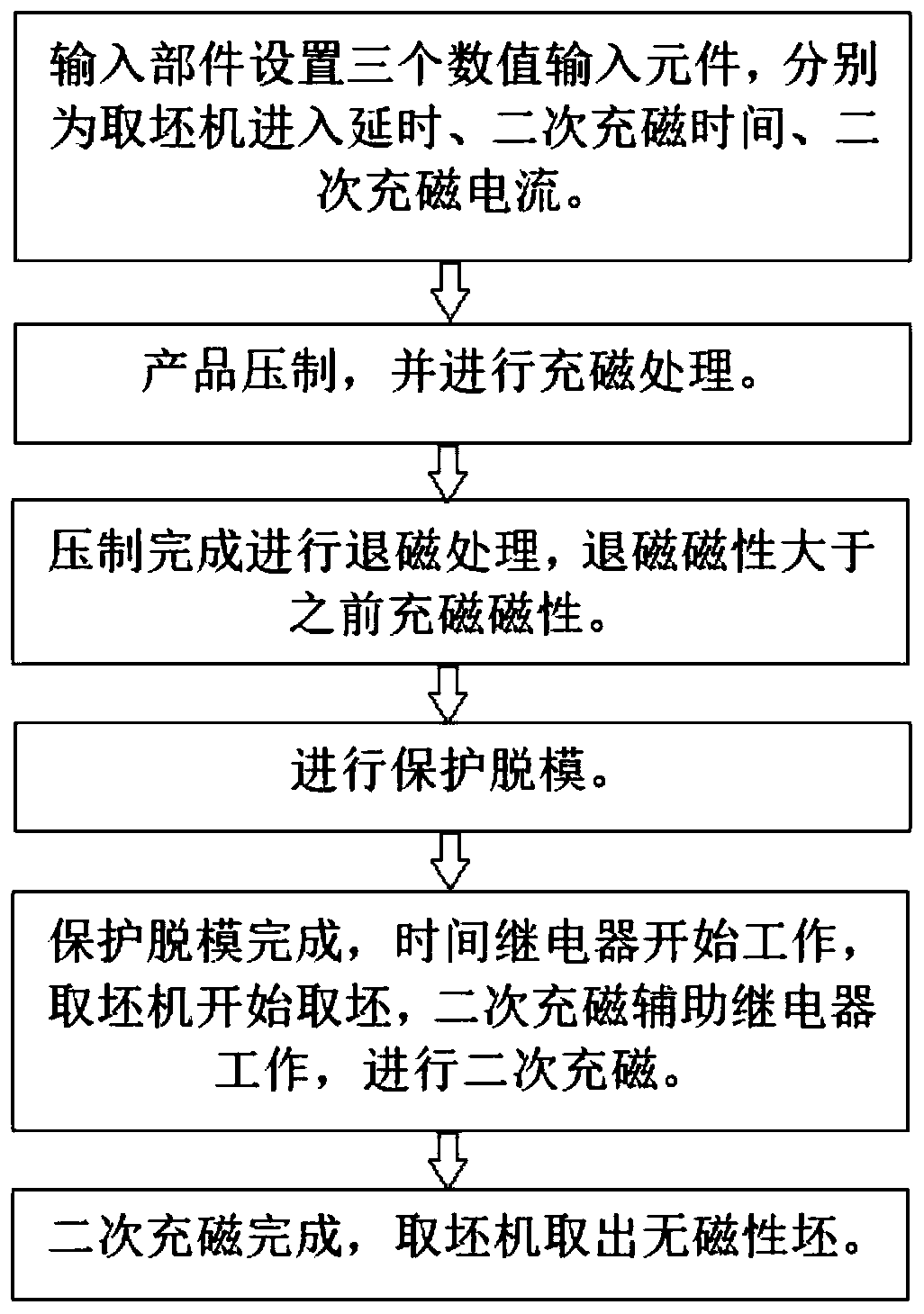

[0048] A wet hydraulic preform removal system of the present invention that realizes protective demoulding has the same structure as that of Embodiment 1, except that the working process is further described. Set three numerical input elements on the touch screen, which are respectively the entry delay of the billet taking machine, the second magnetization time, and the second magnetization current. When debugging the product, properly increase the demagnetization current and lengthen the demagnetization time, so that the demagnetization magnetism is greater than that of the previous magnetization, so that after the product has demagnetization magnetism, use the protection to remove the mold. Cylinder returns, upper cylinder returns, the product will be tightly sucked on the mold punch 143 due to its magnetism, so that the product will not be carried upward by the filter paper 180, for the convenience of stacking and subsequent sintering, the product cannot be magnetic, so it n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com