Automatic gauze element mounting equipment

An automatic installation and gauze technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of difficulty in further improving the production efficiency and product quality of forming screen windows, affecting the overall appearance of screen windows, and low installation quality. Achieve the effect of not easy to break, high degree of automation, smooth and stable conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

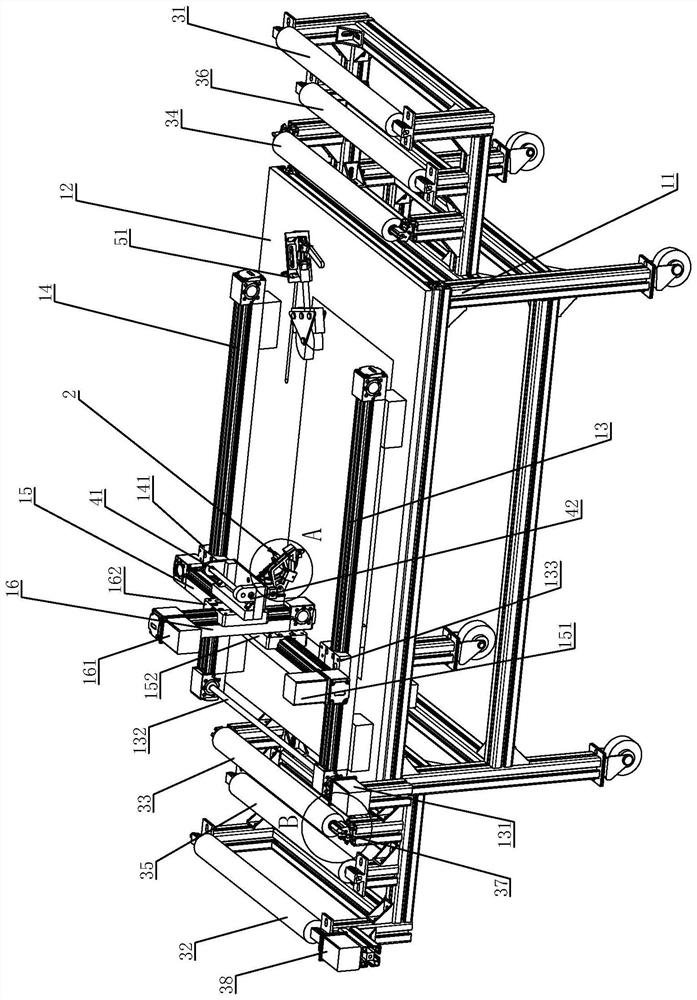

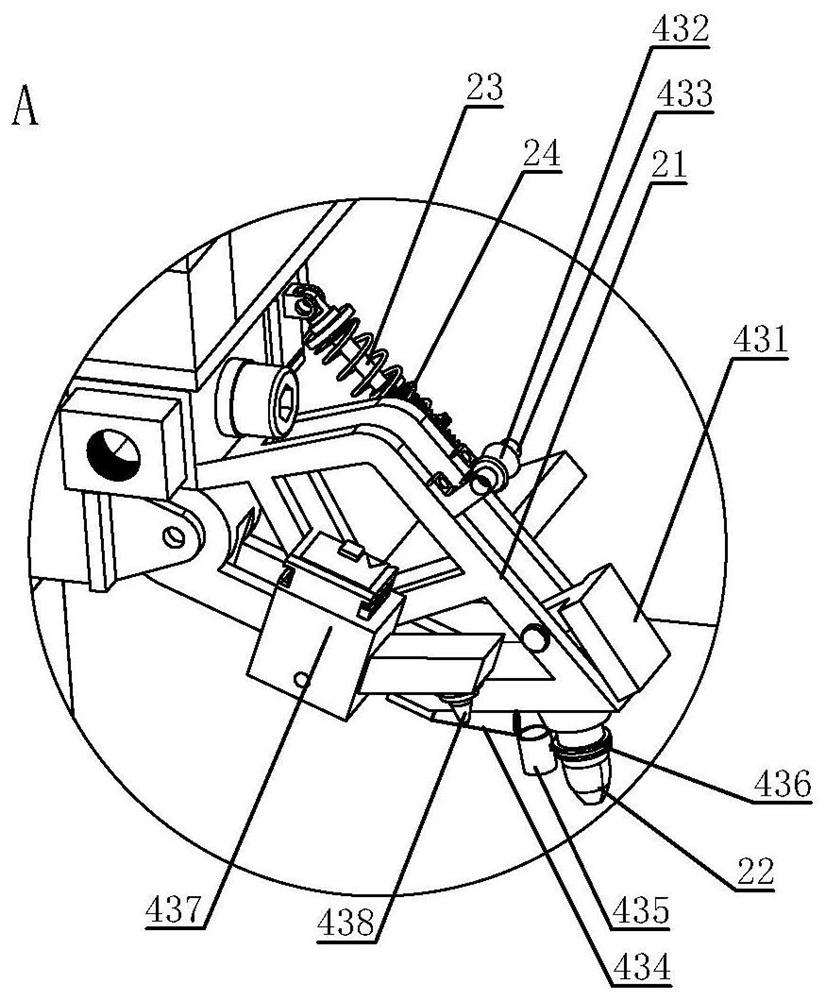

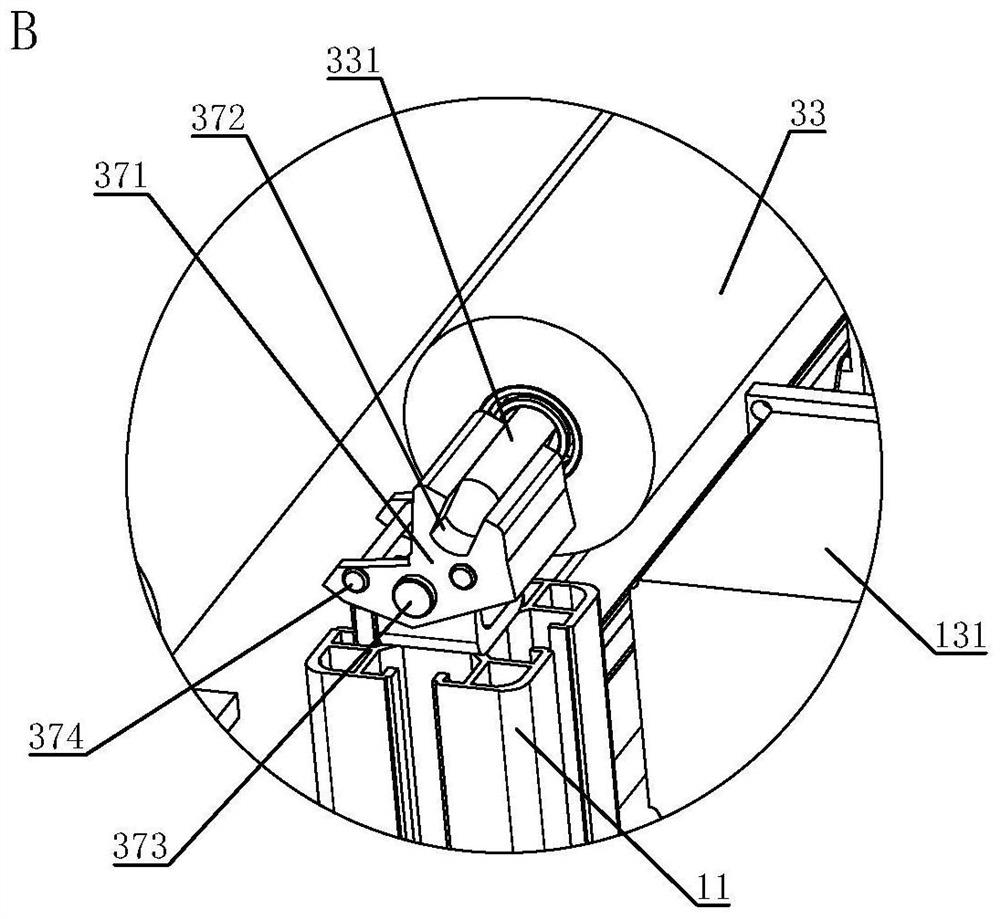

[0041] In order to clearly illustrate the technical characteristics of this program, the following specific implementation methods, combined with its attached Figures 1 to 8 , the present invention is described in detail.

[0042] In view of the large demand for formed screen windows at present, and the manual operation mode of transmission, the production efficiency and quality of products need to be improved. , Complete gauze installation reliably.

[0043] like figure 1 As shown, the equipment in this implementation includes a gantry-type three-axis operation platform, which includes a bracket 11, a workbench 12 and a three-axis gantry-type combined module, and is provided with an absolute coordinate system o-xyz; the three-axis The gantry-type combined module includes an x-axis module, a y-axis module 15, and a z-axis module 16. The x-axis module includes an x-axis module 13 and an auxiliary linear module 14; the workbench 12 is fixed on the bracket 11, and the x-axis m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com