Suspension bridge steel wire rope damage patrolling robot

A technology for inspection robots and steel wire ropes, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high manual inspection costs, reduced steel wire rope carrying capacity, and high inspection costs, and facilitates daily maintenance, replacement, and inspection processes Safe and convenient, high operational reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

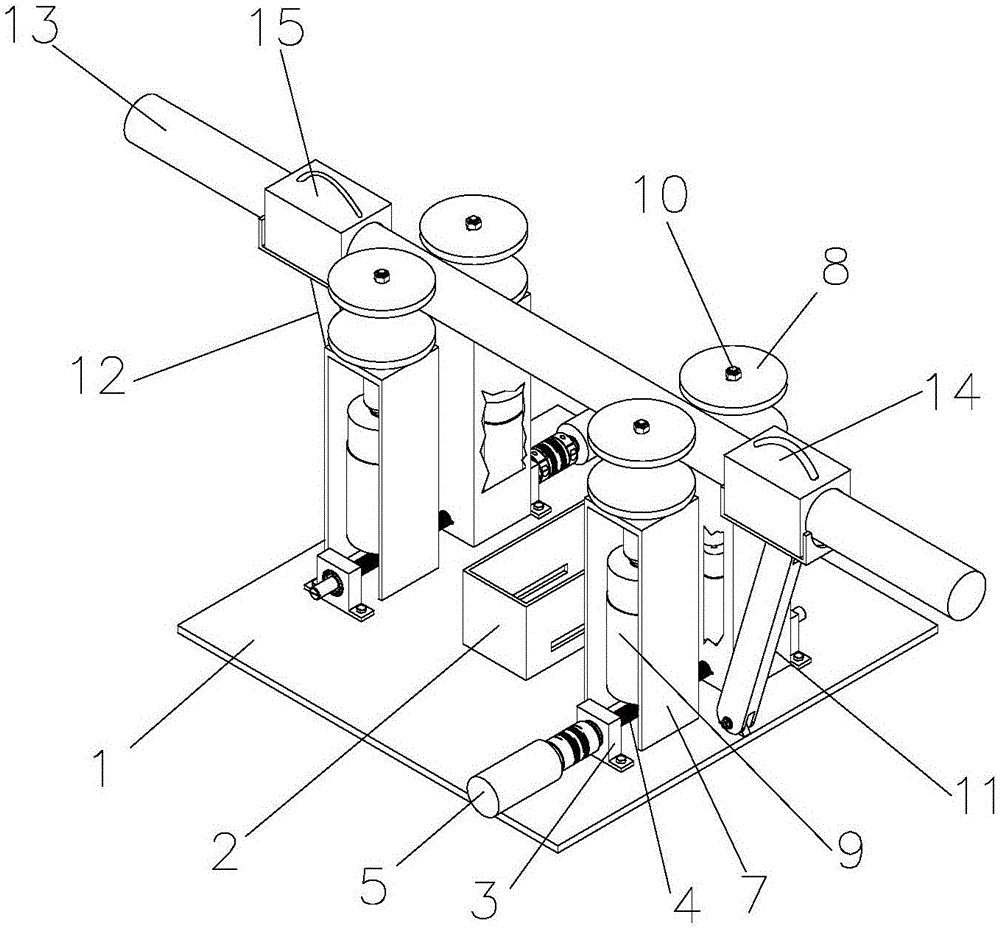

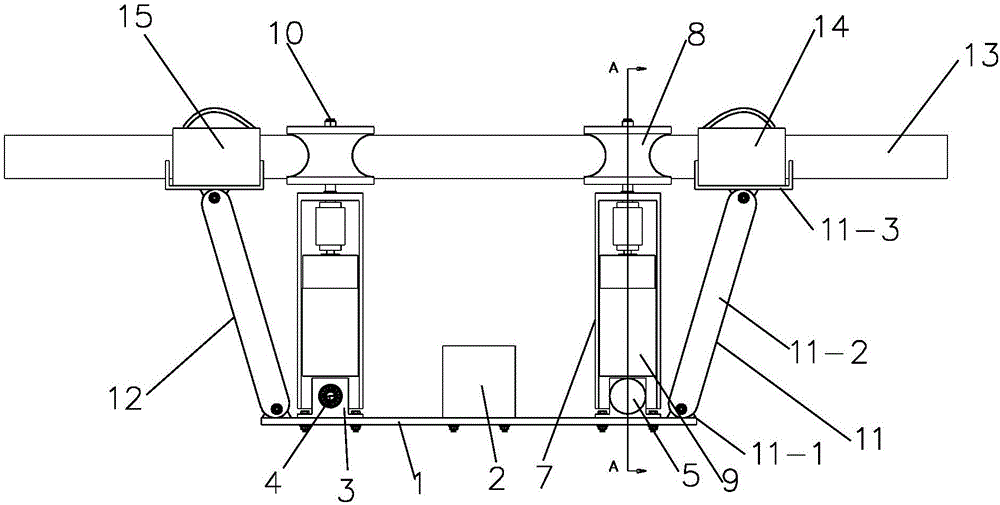

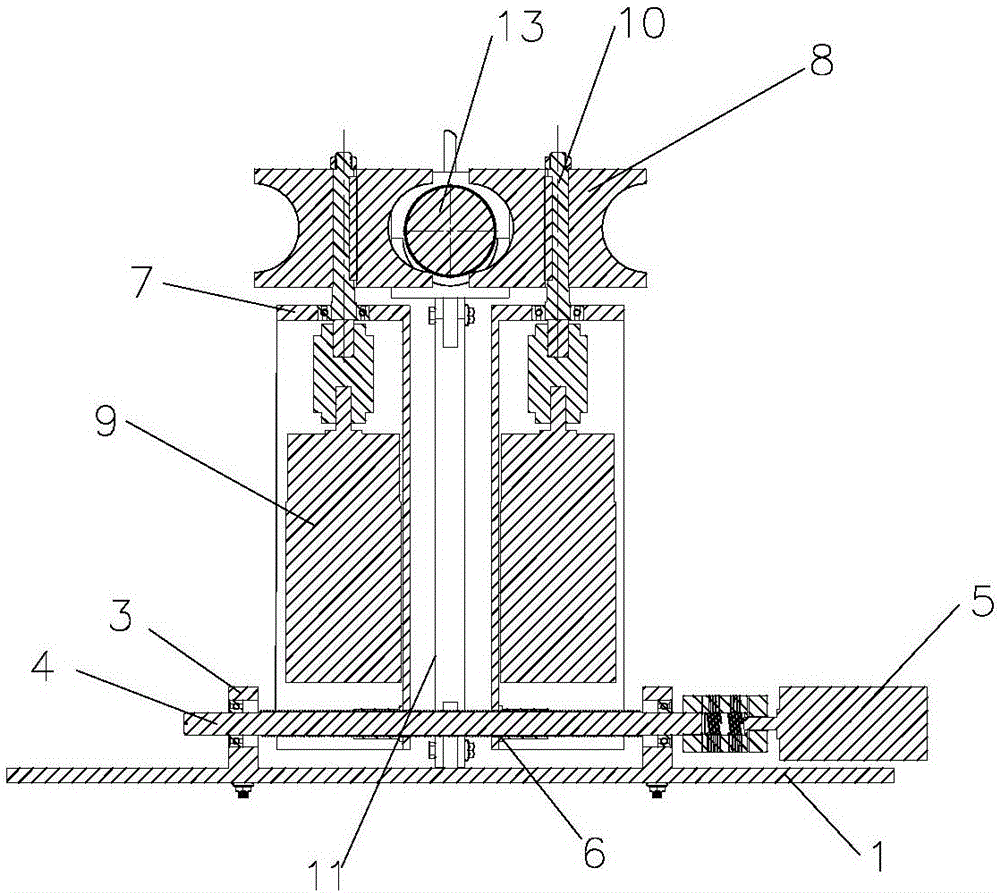

[0047] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a base 1, an inspection device installed on the base 1 and inspecting the damage of the steel wire rope 13 of the suspension bridge, and a control device for controlling the inspection device. A wire rope damage detection mechanism for detecting damage to the wire rope 13 and a mobile robot mechanism that can move along the suspension bridge wire rope 13, the number of the mobile robot mechanisms is two, and the two mobile robot mechanisms are located at both ends of the base 1. Two described mobile robot mechanisms all comprise the clamping traveling mechanism that is installed on the suspension bridge steel wire rope 13, drive described clamping traveling mechanism to move along the walking driving mechanism of suspension bridge steel rope 13 and drive described clamping traveling mechanism to suspension bridge steel rope 13 A clamping drive mechanism for cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com