A road bridge concrete detection device

A detection device and concrete technology, which is applied to measurement devices, testing material hardness, optical testing flaws/defects, etc., can solve problems such as time-consuming, reducing the efficiency of concrete quality detection, unevenness, etc., and achieve the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

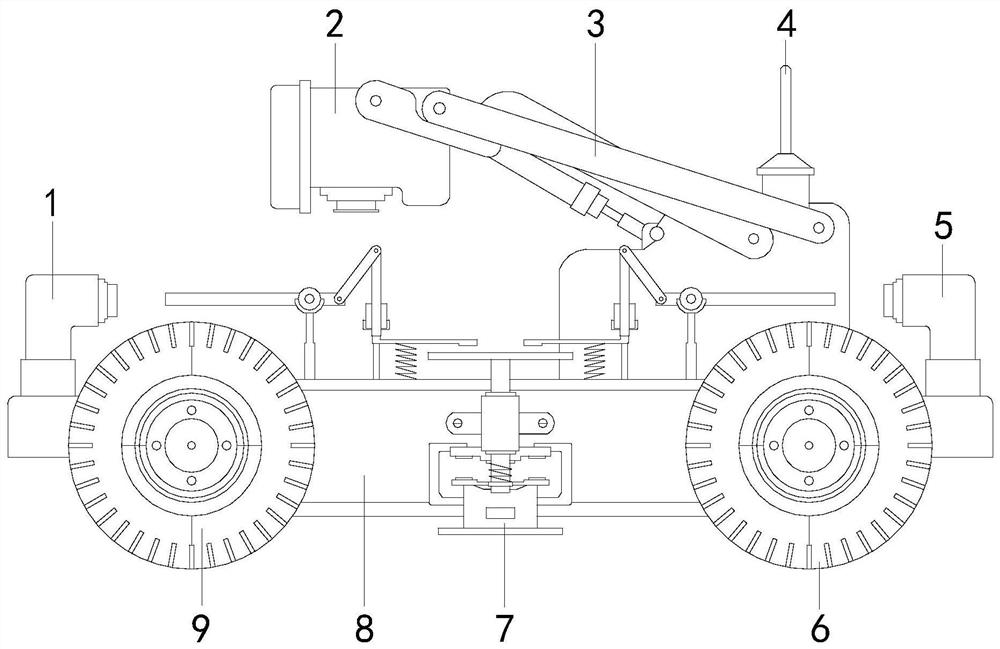

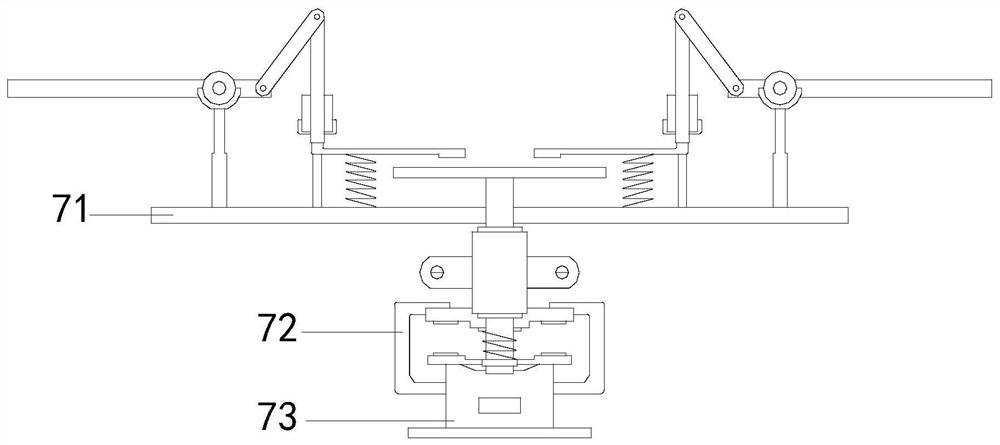

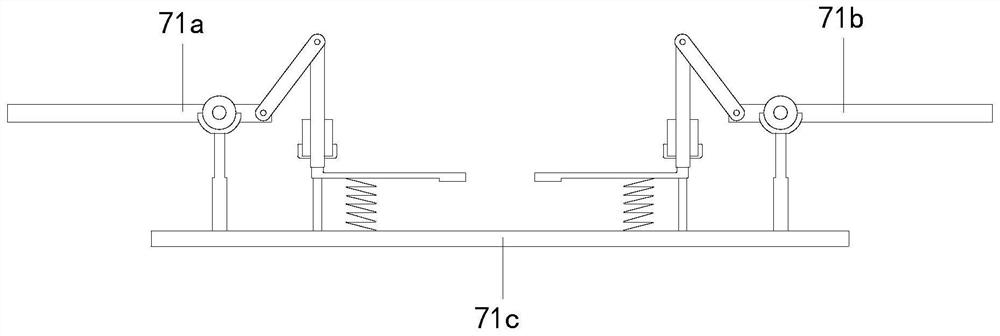

[0025] see figure 1 , a road and bridge concrete detection device, its structure includes a front continuous camera 1, a road detection camera 2, a telescopic arm 3, a wireless receiver 4, a rear continuous camera 5, a rear driving wheel 6, a road condition feedback detection device 7, and a main control chassis 8. Front drive wheels 9, front drive wheels 9 are provided on both sides of the front end of the main control chassis 8, rear drive wheels 6 are provided on both sides of the rear end of the main control chassis 8, the front drive wheels 9 and Shock absorbers are installed on the rear drive wheels 6, and the main control chassis 8 can maintain relative balance under the bumpy situation of the road surface or the bridge surface. The central position of the rear end of the main control chassis 8 is provided with a rear continuous camera 5, the two sides of the main control chassis 8 are provided with road condition feedback detection devices 7, and the front continuous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com