Intelligent detection method and system of crankshaft thrust pieces

A technology of intelligent detection and thrust piece, which is used in measuring devices, optical testing of flaws/defects, and material analysis by optical means, etc. Production needs, reduce manual feature extraction process, and meet the effect of online product detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

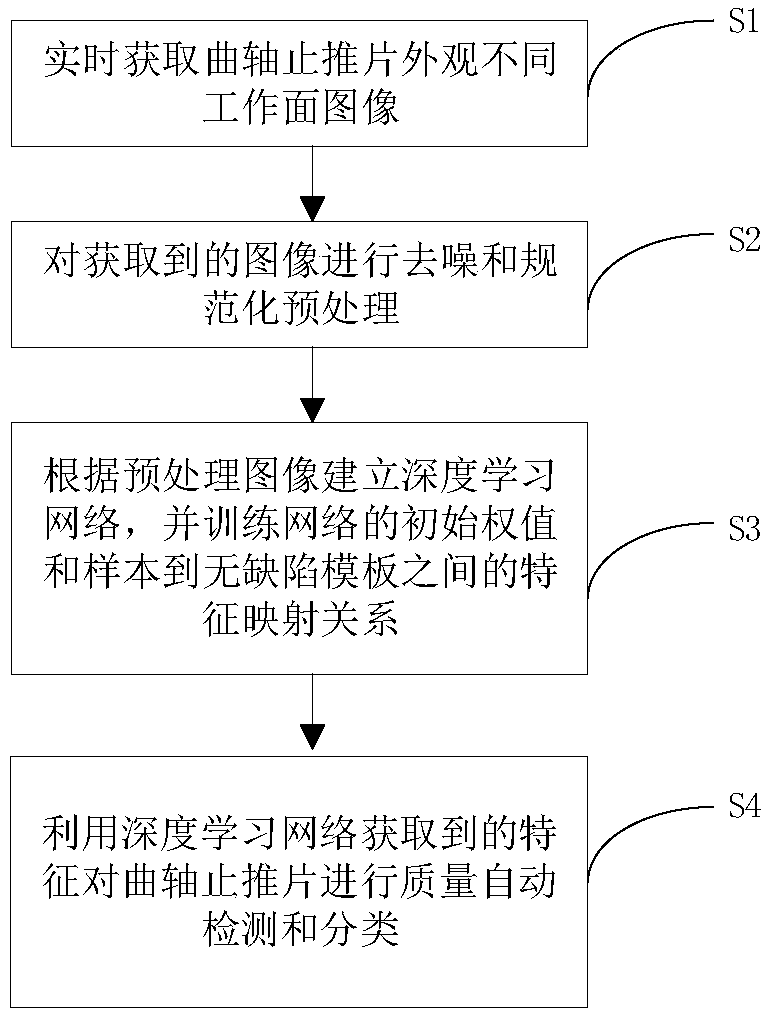

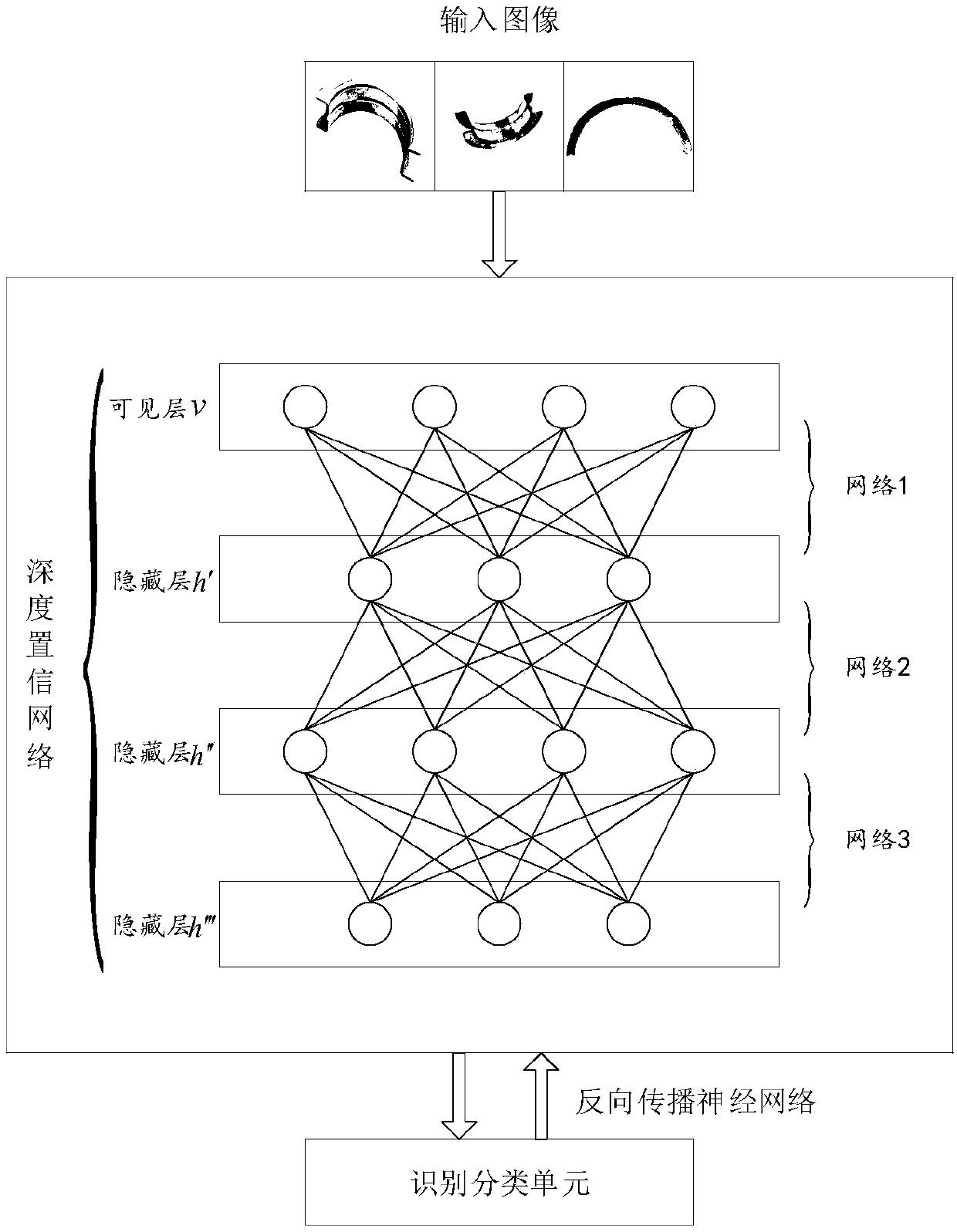

[0022] Such as figure 1 As shown, an intelligent detection method for the crankshaft thrust piece includes the following steps: S1 acquires images of different working surfaces of the crankshaft thrust piece, S2 performs denoising and normalized preprocessing on the obtained images, and S3 establishes deep learning based on the preprocessed images Network, and train the initial weight of the network and the feature mapping relationship between the sample and the non-defective template. S4 uses the features obtained by the deep learning network to detect and classify the crankshaft thrust plate to be tested.

[0023] For step S1, obtain images of different working surfaces of the crankshaft thrust plate:

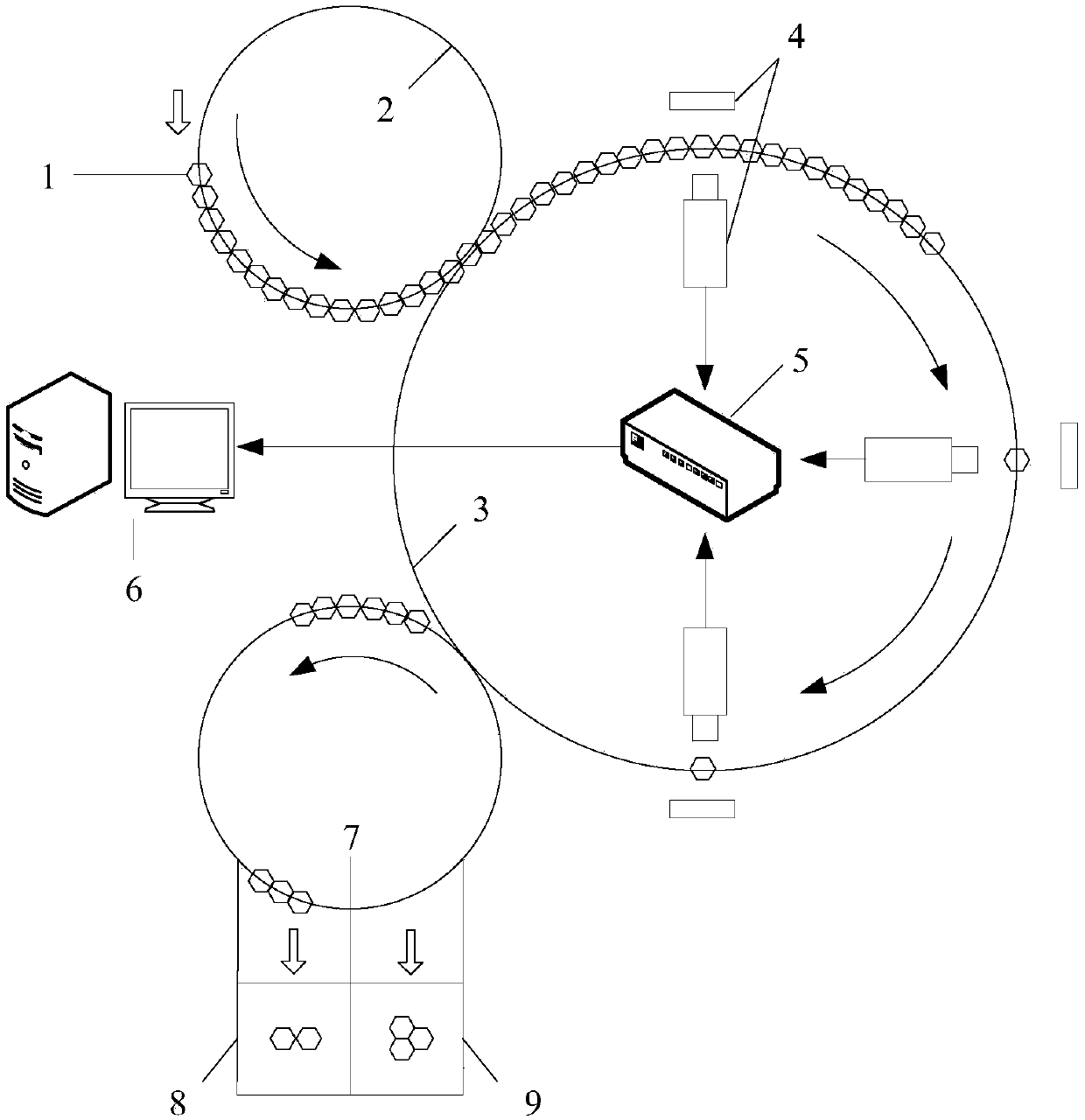

[0024] The images of different working surfaces of the crankshaft thrust plate are acquired by the image acquisition device, and multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com