Method for assessing safety of pressure bearing apparatus after fire hazard

A technology for pressure equipment and safety assessment, applied in the investigation phase/state change, material defect testing, etc. Effective in evaluating and evaluating high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

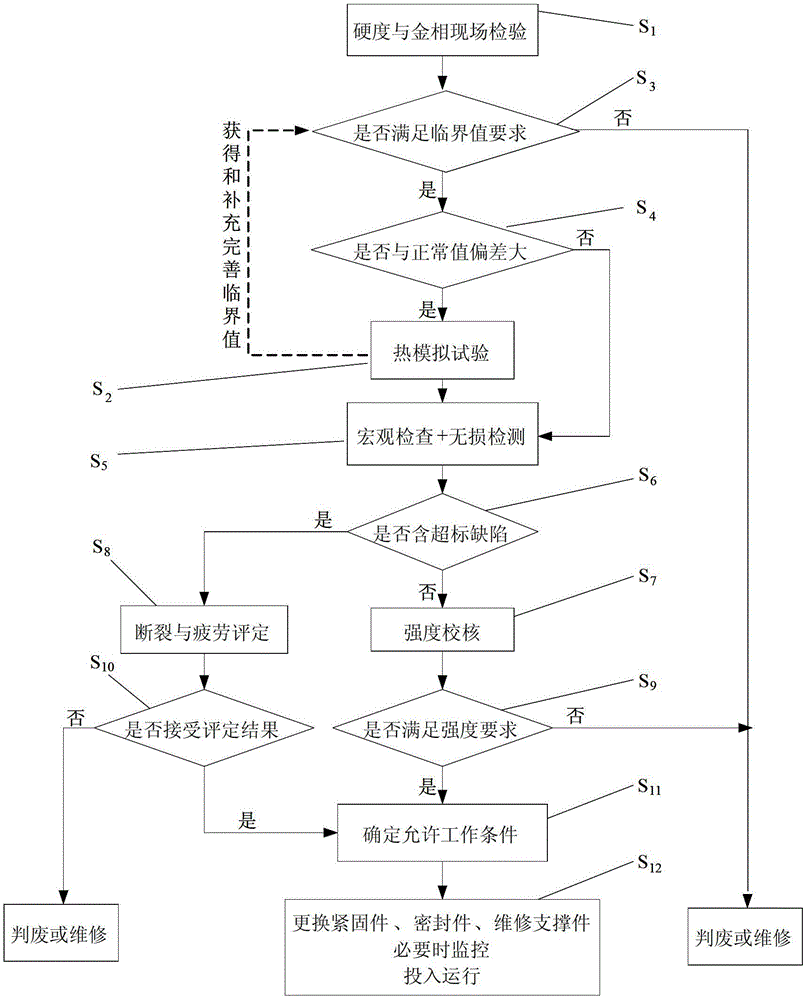

[0041] After a certain vertical pressure vessel made of Q345R has been fired, it is necessary to carry out post-fire safety assessment operations to determine whether they are suitable for continued service or downgraded use. Use at this time figure 1 The flow chart of the safety assessment method for fire-exposed pressure equipment is shown. First, the hardness and metallographic structure of the material used in the fire-fired pressure vessel are inspected on-site and the thermal simulation test is carried out with the same material to obtain the critical value of the hardness and metallographic structure of the Q345R material. Then carry out numerical comparison with the on-site inspection; then conduct macro inspection and non-destructive testing on the burnt pressure vessel, and then judge and calculate the safety assessment of the burnt pressure vessel to obtain the final result. The specific evaluation steps are as follows:

[0042] 1) On-site inspection of hardness an...

Embodiment 2

[0054] After a certain horizontal pressure vessel made of Q245R has been fired, it is necessary to carry out post-fire safety assessment operations to determine whether they are suitable for continued service or to be scrapped. Use at this time figure 1 The flow chart of the safety assessment method for fire-exposed pressure equipment is shown. First, the hardness and metallographic structure of the fire-fired pressure vessel made of Q245R are inspected on-site and the thermal simulation test is carried out with the same material to obtain the critical hardness and metallographic structure of the Q245R material. After the value is compared with the numerical value of the field inspection. The specific evaluation steps are as follows:

[0055] 1) On-site inspection of hardness and metallographic structure of pressure vessels that have been fired. Use the Leeb portable hardness tester to measure the hardness of different parts of the overfired pressure vessel, and at the same ...

Embodiment 3

[0059] After a certain vertical pressure vessel made of Q245R has been fired, it is necessary to carry out post-fire safety assessment operations to determine whether they are suitable for continued service or downgraded use. Use at this time figure 1 The flow chart of the safety assessment method for fire-exposed pressure-bearing equipment is shown. Firstly, the hardness and metallographic structure of the Q245R material are inspected on site and the thermal simulation test is carried out with the same material, and the hardness and metallographic structure of the Q245R material are obtained. Numerical comparison of on-site data; after that, the final result is obtained by macroscopic inspection and non-destructive testing of the burned pressure vessel, and then judgment and calculation of the safety assessment of the burned pressure vessel. The specific evaluation steps are as follows:

[0060] 1) On-site inspection of hardness and metallographic structure of pressure vesse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com