Annular conveyor and mobile vehicle associated with same

A circular conveying and mobile vehicle technology, applied in the field of mobile vehicles, can solve the problems of increasing operating costs, occupying manpower and material resources, etc., and achieve the effect of saving operating costs and improving discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

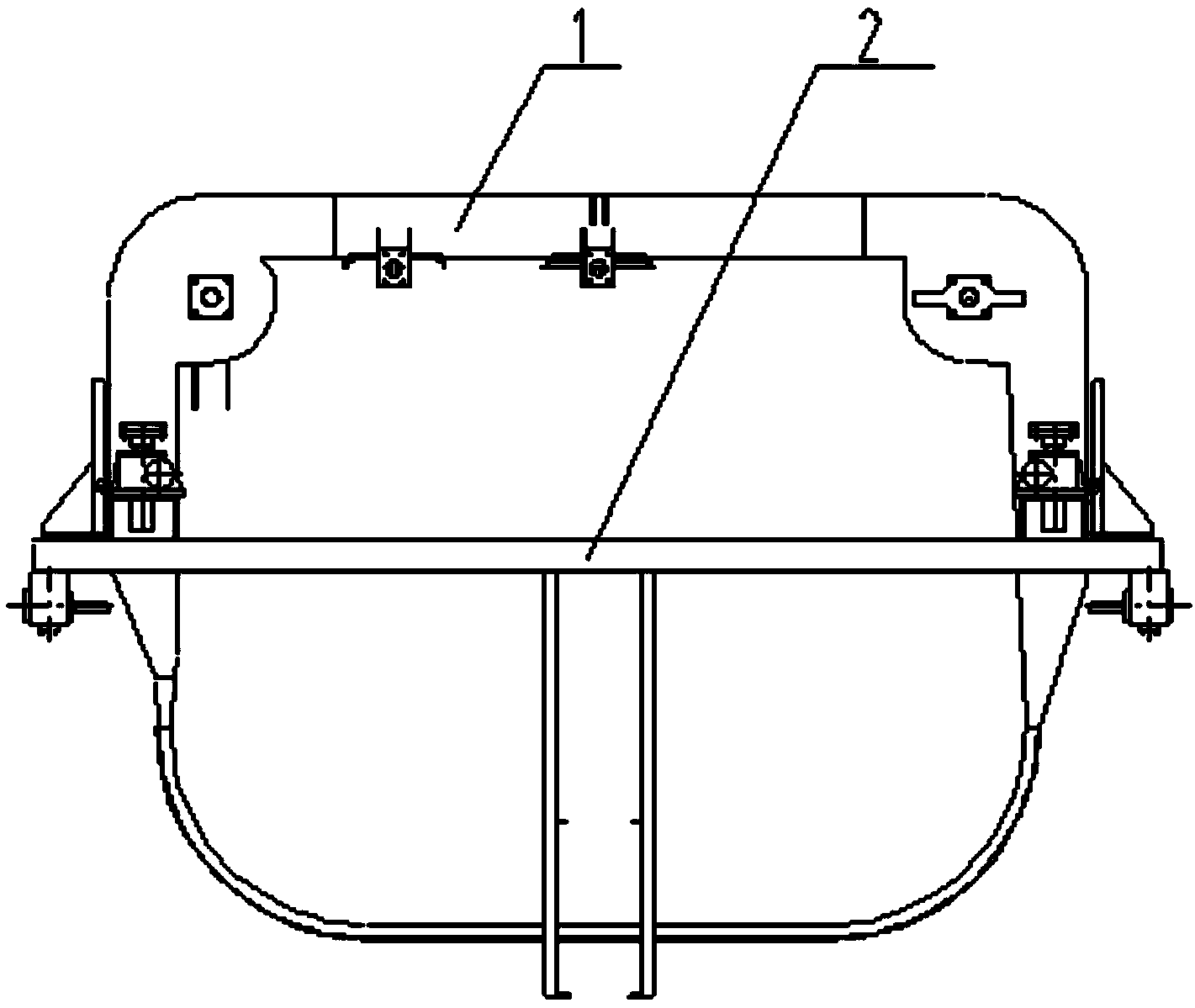

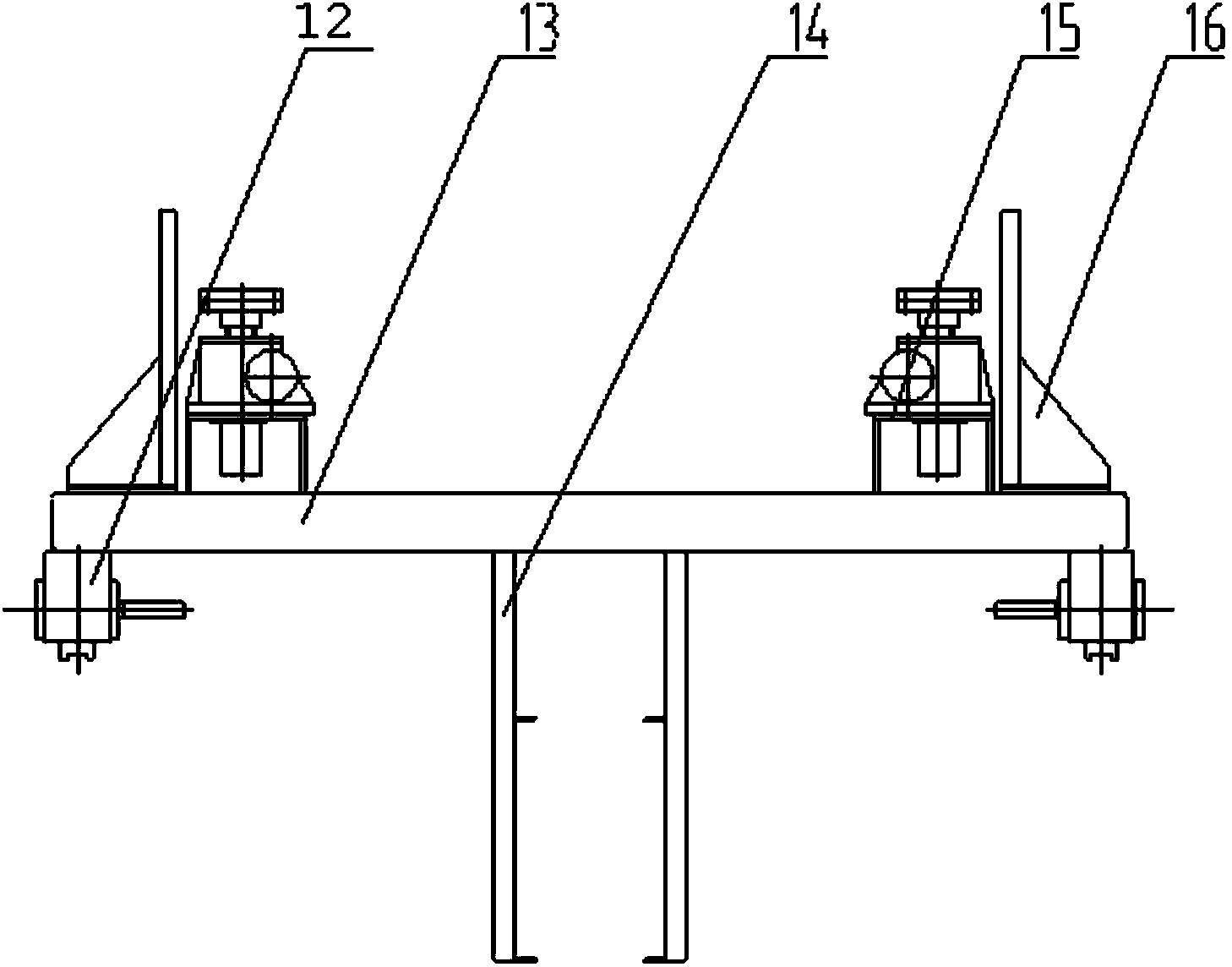

[0015] figure 1 An embodiment of an endless conveyor and its associated moving vehicle according to the present invention is shown, which is composed of an endless conveyor 1 and a moving vehicle 2 .

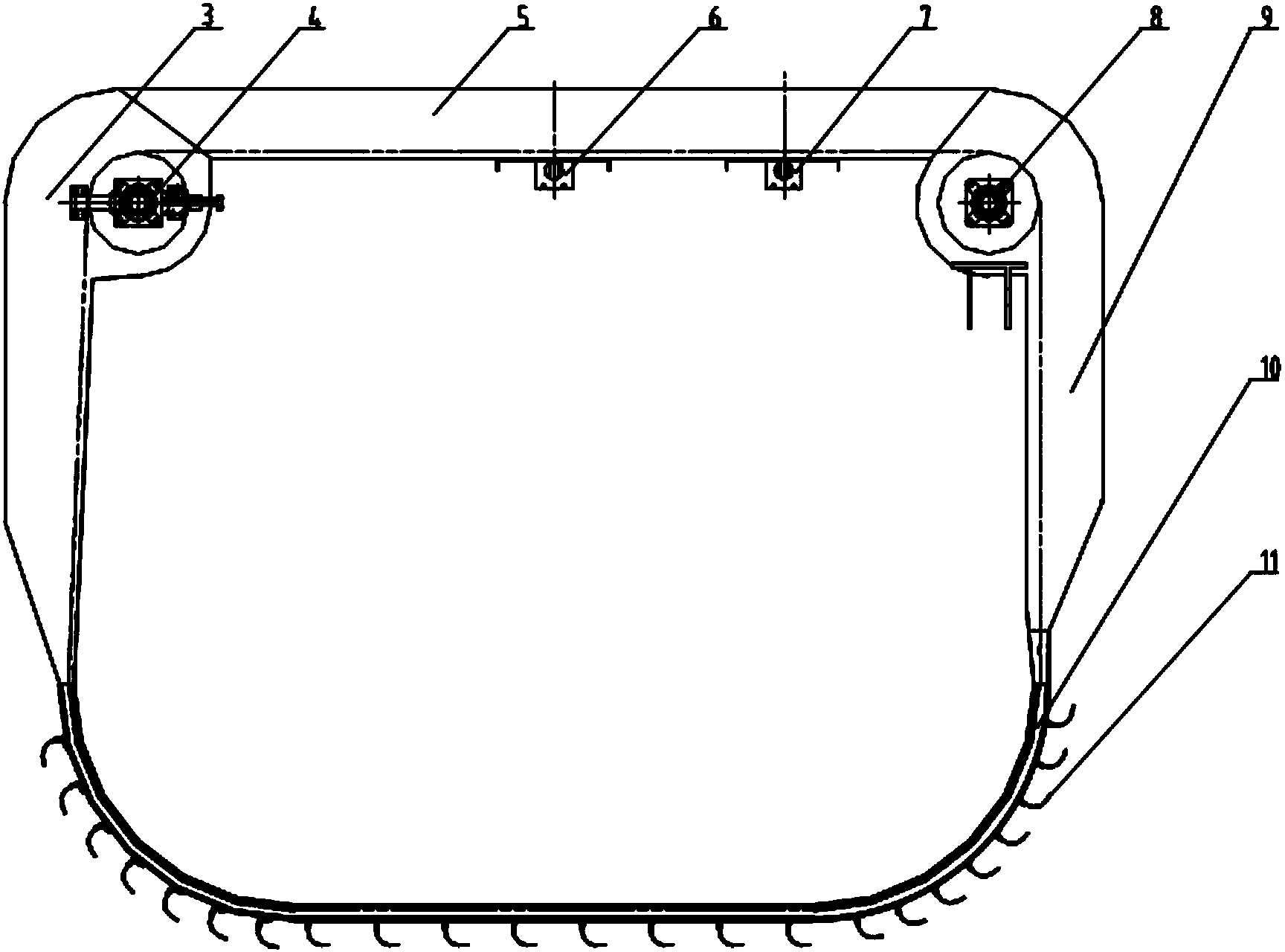

[0016] The endless conveyor includes an annular outer casing, a scraper 11 with opposite sex, a driving device 8 and a driven device 4 . The annular outer shell includes an upper shell 5, left and right vertical section shells 3 and 9, and an open arc section 10. The upper shell 5 is a U-shaped tank, and the bottom of the U-shaped tank is provided with discharge ports 6 and 7; The vertical segment housings 3, 9 and the bottom open arc segment 10 are connected in a tapered transition, with the upper part being larger and the lower part being smaller. The special-shaped scraper 11 is an arc-shaped scraper; the driving device 8 drives the arc-shaped scraper to scrape the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com