Conversion valve

A switching valve and rotary cap technology, applied in the field of switching valves, can solve problems such as high cost, hidden dangers of oil circuit sealing, complex structure of oil circuit switching valves, etc., and achieve the effect of reducing costs and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

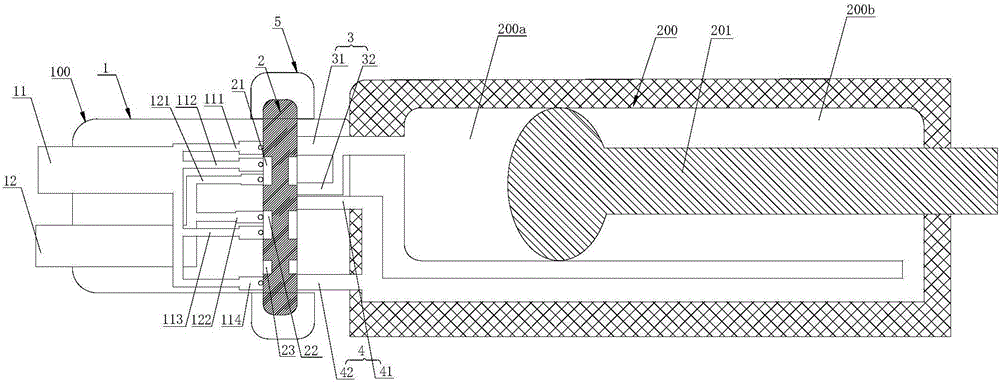

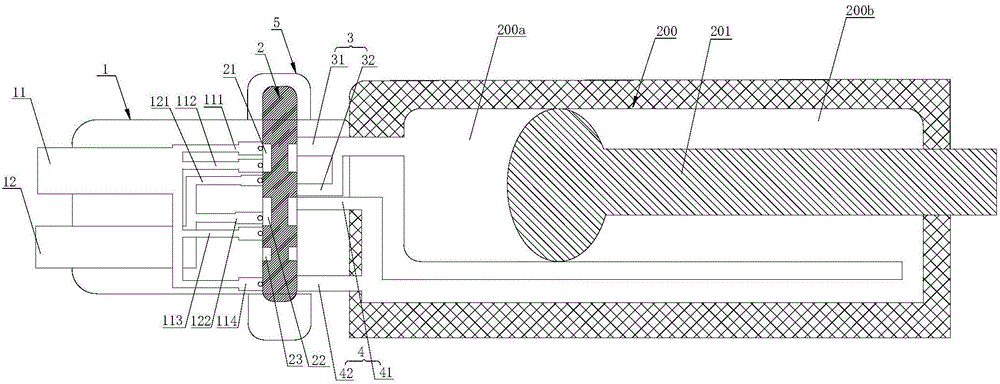

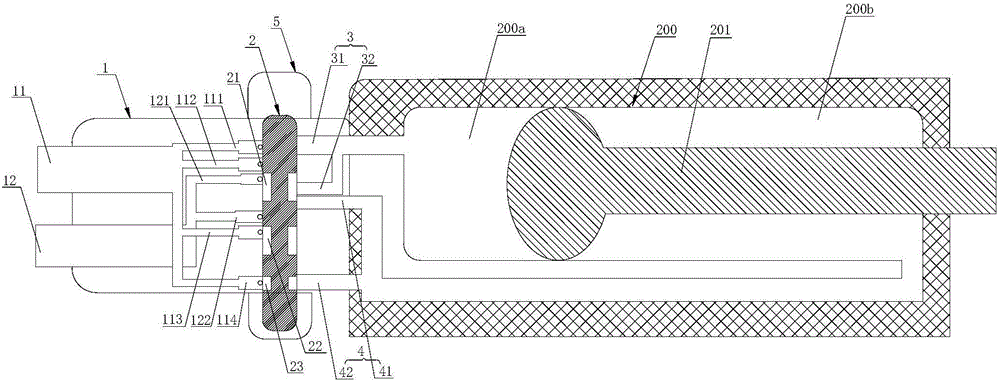

[0028] The switching valve provided in this embodiment includes a housing 1 , a switching control 2 , a first connecting pipe 3 and a second connecting pipe 4 . The housing 1 has a fluid inlet 11 and a fluid outlet 12 inside. The conversion control 2 is arranged in the housing 1 along the axial direction perpendicular to the housing 1. The conversion control 2 has a plurality of through holes whose axes are parallel to the direction of the fluid inlet 11. When the flow direction is converted, the conversion control 2 is vertical to the housing 1. axial movement. The first connecting pipe 3 and the second connecting pipe 4 are respectively connected to the conversion control 2 and the external sealing device to form a fluid circulation.

[0029] Specifically, the conversion control 2 is provided with three through holes at equal intervals, the fluid inlet 11 includes four inflow branch pipes with equal diameters, the fluid outlet 12 includes three outflow branch pipes with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com