Subway train pantograph control method based on train network system

The technology of a train network system and control method, which is applied in the field of pantograph control of subway trains, can solve the problems of increasing train weight, increasing train manufacturing cost, wiring troubles, etc., and achieves reduction of train manufacturing cost, low equipment cost, and realization of simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

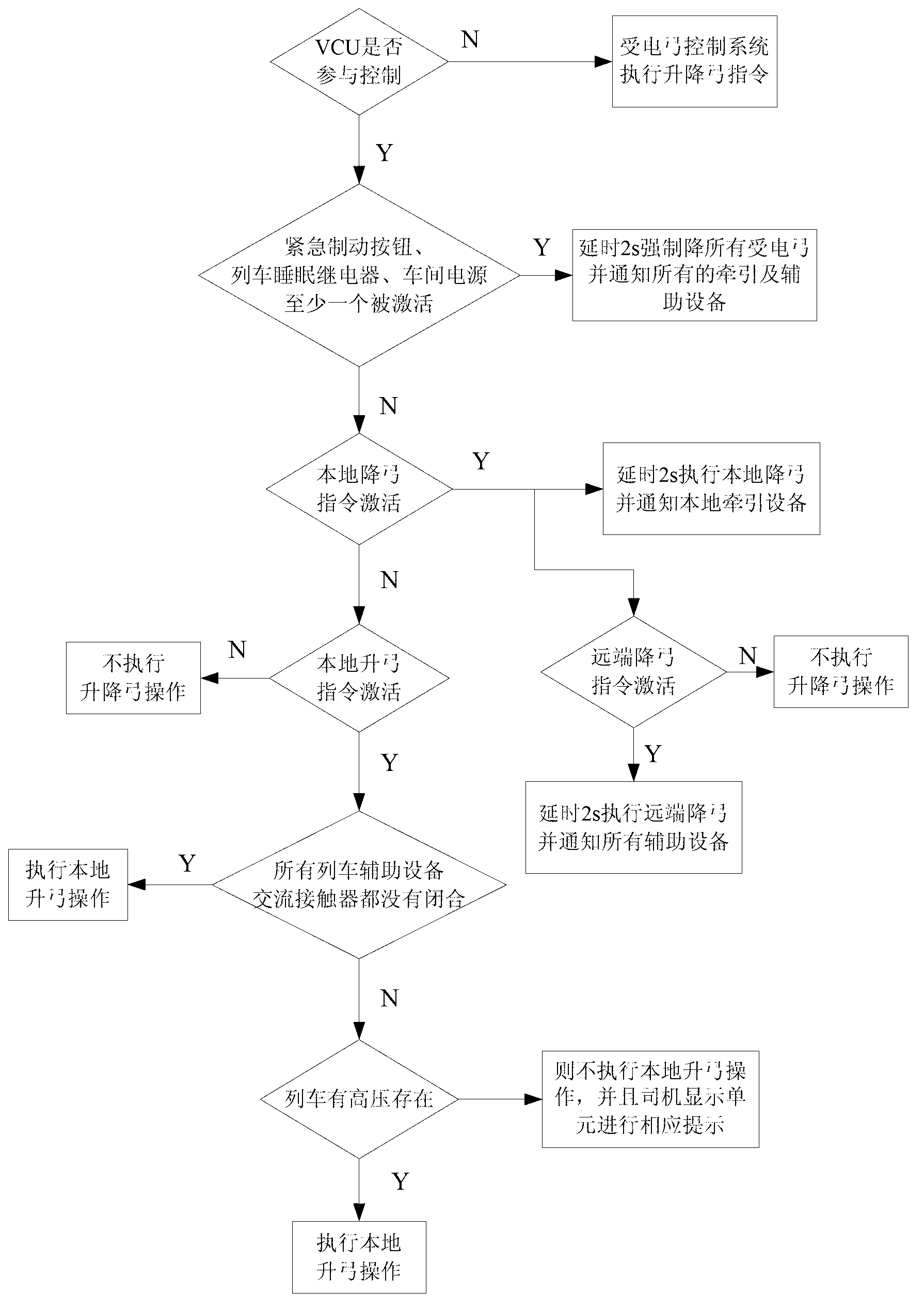

[0018] Such as figure 1 Shown is the flow chart of the method of the present invention. The embodiment of the present invention is based on the subway train pantograph control method of the train network system. In terms of hardware, the remote input and output module of the train network system is connected to the pantograph control system. The pantograph control method is as follows:

[0019] The first step, when the central control unit (VCU) of the train network system receives the operation command of the pantograph lifting (the operation command of the pantograph lifting is sent to the train network system by the driver operating the driver's console or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com