Stainless steel plate pressure finishing device capable of detecting finishing defects

A kind of technology of stainless steel plate and pressure device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

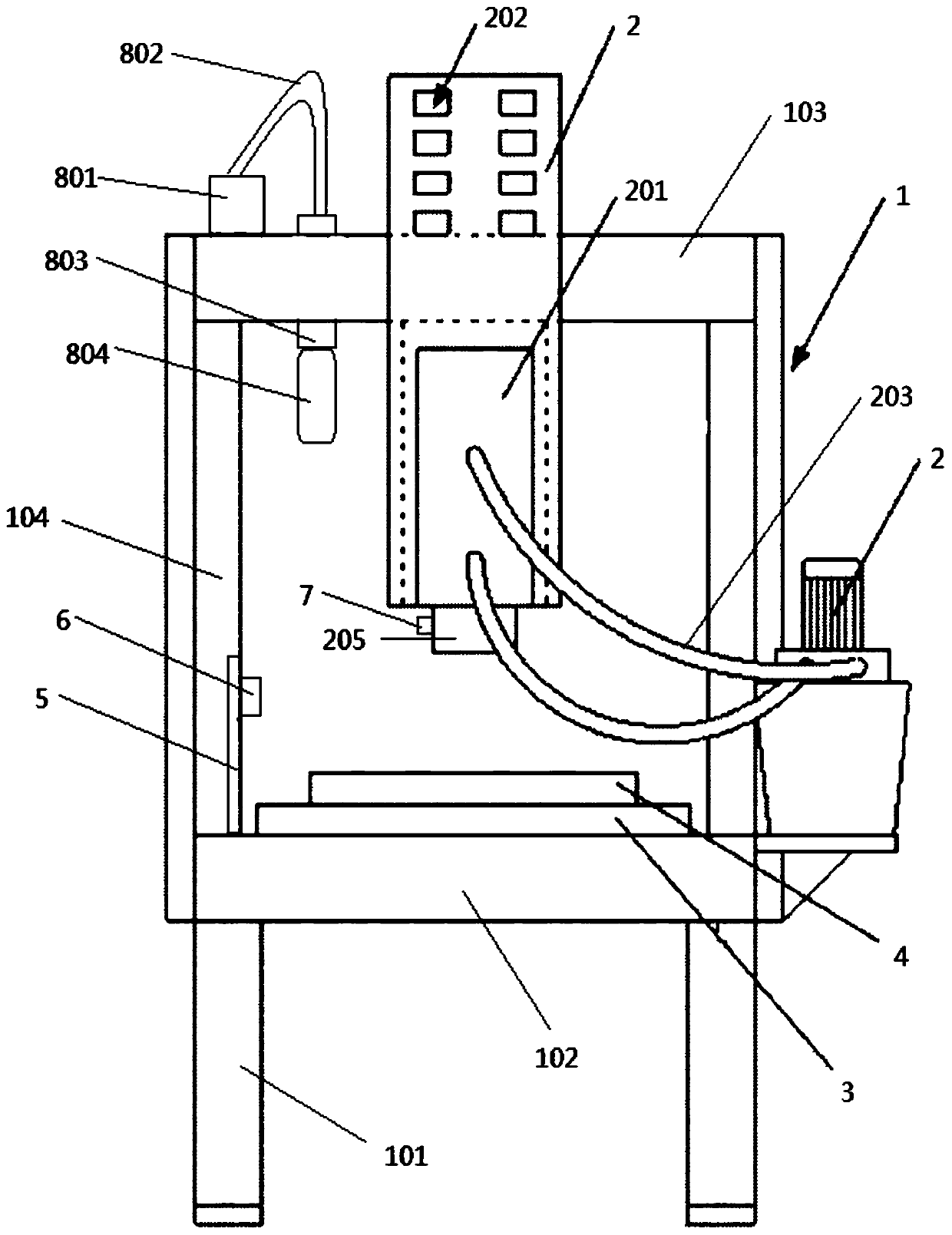

[0054] like figure 1 As shown, a stainless steel plate pressure finishing device that can detect finishing defects includes a frame 1, the bottom of the frame 1 is a support column 101, and the upper end of the support column 101 is fixedly connected to an operation platform 102, and the operation platform The edge of the upper end surface of 102 is fixedly provided with a support frame 104, and the upper end of the support frame 104 is fixedly connected with a support beam 103;

[0055] The operation platform 102 is provided with pads 3 movably, and stainless steel plates 4 are placed on the pads 3; the size and thickness of the pads correspond to the size and thickness of the stainless steel plates one by one. When the thickness changes, the spacer can be removed and replaced with a spacer suitable for the stainless steel plate that needs to be finished;

[0056] The middle part of the support beam 103 is fixed with a finishing pressure device 2, and the finishing pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com