Composite protection film of wind power blade and detachable wind power blade protection device

A technology for wind power blades and protection devices, applied in the field of wind power devices, can solve the problems of blade aerodynamic performance decline, damage, low overall strength, etc., and achieve the effects of saving maintenance costs, prolonging service life, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

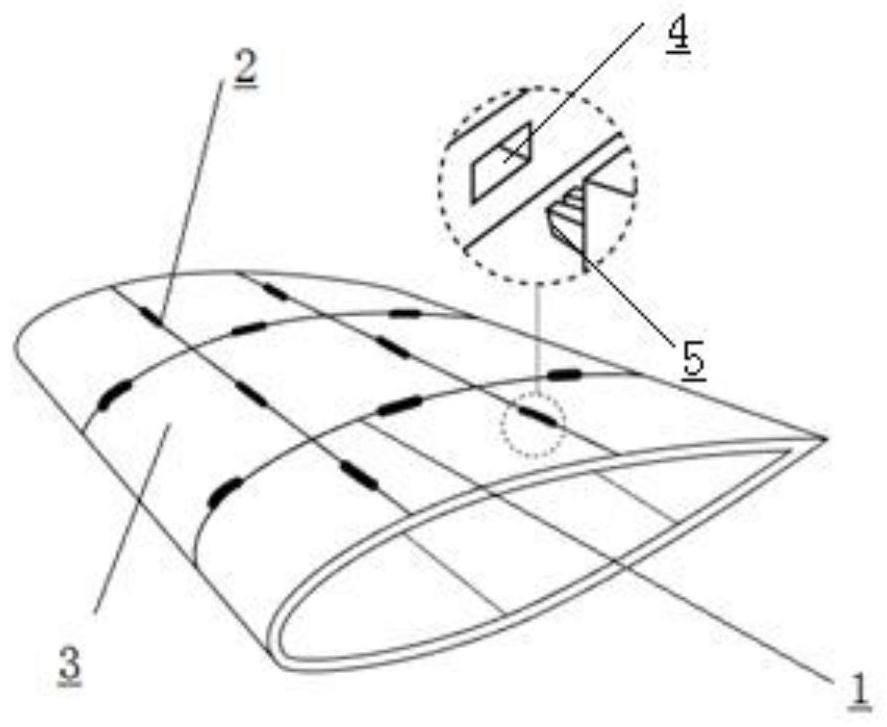

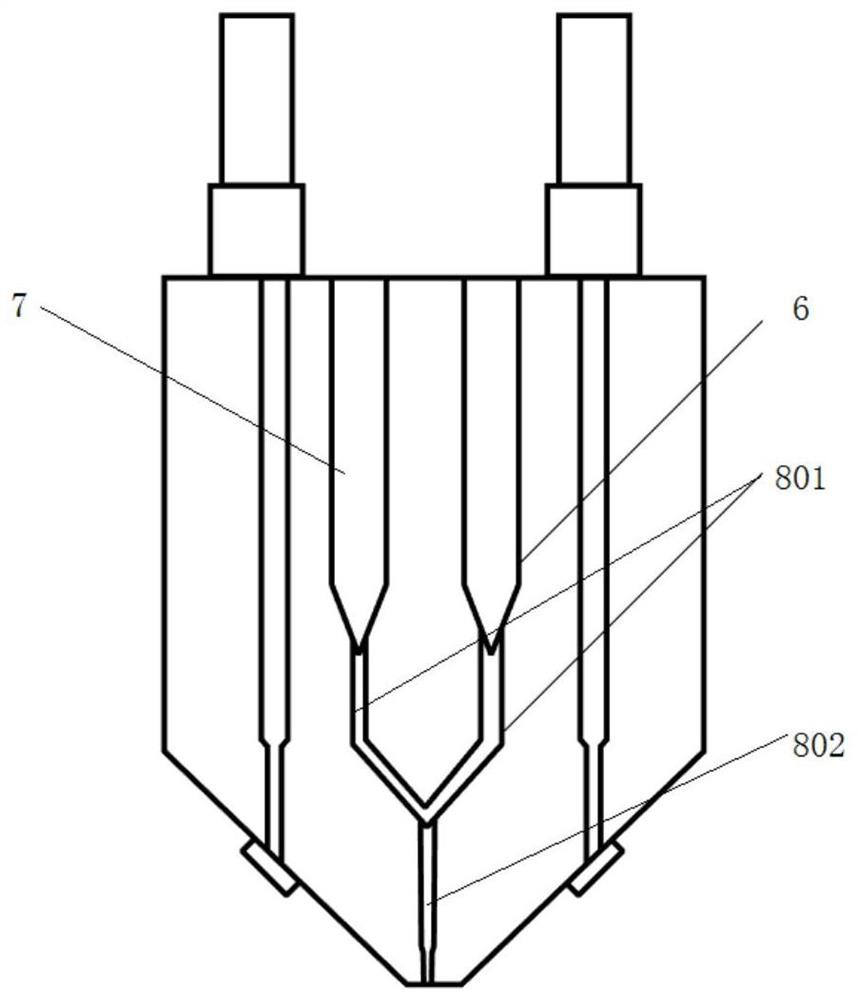

[0028] like figure 1 As shown, a grid-shaped detachable wind turbine blade protection device related to this embodiment includes a first fixing rib 1, a second fixing rib 2, a grid plate 3 and a skin, and several A first fixed rib 1, a number of second fixed ribs 2 are fixed along the direction parallel to the length of the blade, the first fixed rib and the second fixed rib are handed over to form a mesh protection bracket containing several grids that adapt to the shape of the blade , the grid plate 3 is fixed in the grid, and is detachably connected with the first fixed rib 1 and the second fixed rib 2 around the grid, and the skin is fixedly attached to the grid plate 3 to protect the entire wind turbine blade Device wrapping.

[0029] Further, at the intersection of the first fixed rib 1 and the second fixed rib 2, strong connection methods such as welding and screw connection are used, and the connecting angle material is fixedly arranged at the joint between the first ...

Embodiment 2

[0032] The protection device for wind power blades described in Embodiment 1 further includes a composite protective film, and the composite protection film is bonded to the protection device for wind power blades. The bonding process is divided into two situations. One is to bond the composite protective film to the wind power blade before the blade leaves the factory; the other is to use vacuum infusion to allow the adhesive to flow evenly between the blade and the protective film. This method can be used not only before the blade leaves the factory, but also during outdoor maintenance.

Embodiment 3

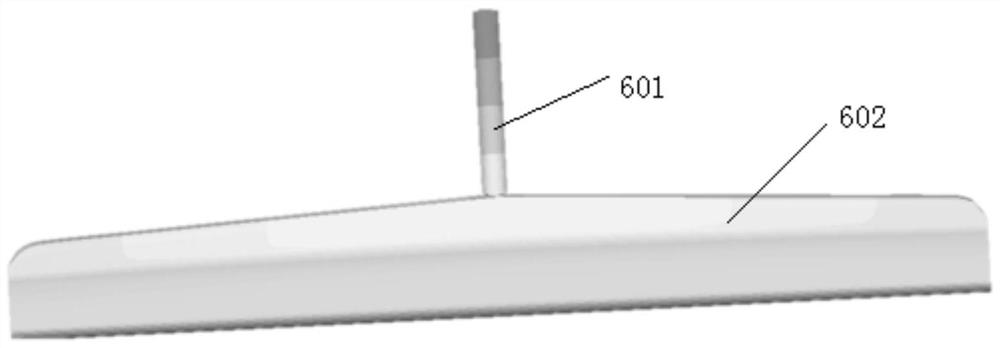

[0035] The protective film for wind turbine blades in this embodiment includes a support layer and an elastic layer. The support layer is made of a material with a certain strength. The elastic layer includes but is not limited to one of a thermoplastic elastic layer, a rubber layer, and a foam layer.

[0036]Further, the above-mentioned wind power blade protective film is directly prepared by a one-step method, specifically: a preparation method of a wind power blade protective film, which specifically includes the following steps:

[0037] (1) Mix 80-100 parts of the main material of the support layer, 0.5-10 parts of antioxidant, 1-8 parts of disentangling agent, 0.5-5 parts of coloring agent, 2-15 parts of lubricant and 0-5 parts of anti-aging agent Pour it into the mixer and stir for 5-60 minutes, then transport it to the silo through the feeder, transport it to the die head for extrusion through the twin-screw extruder, cut it into pellets with a water ring cutter, and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com