Metal filler for controlling brittle phases in titanium-aluminum dissimilar metal welded joints and application of metal filler

A technology of metal filling and dissimilar metals, applied in the field of welding fillers, can solve the problems of high cost, lack of brittle phases, and high requirements for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

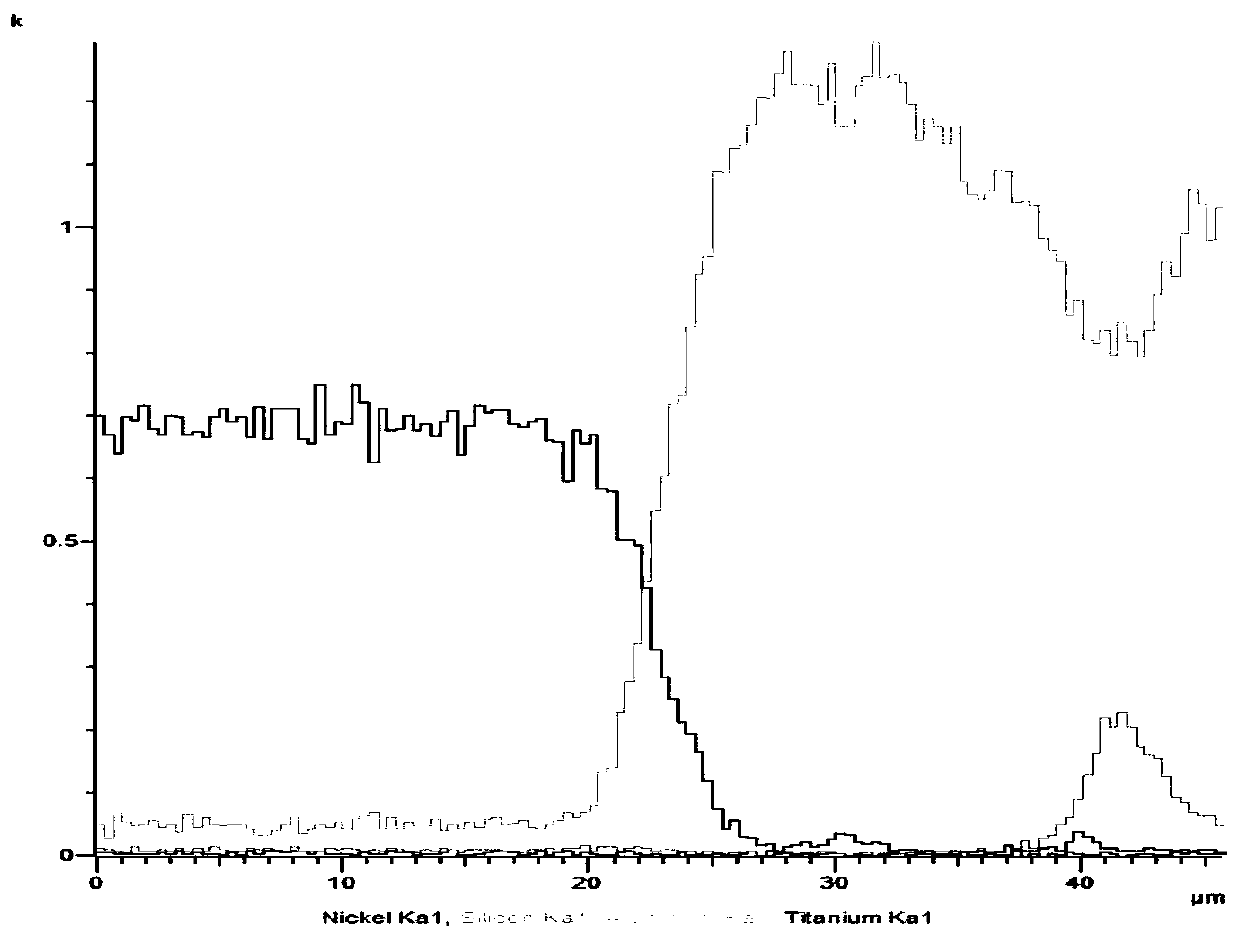

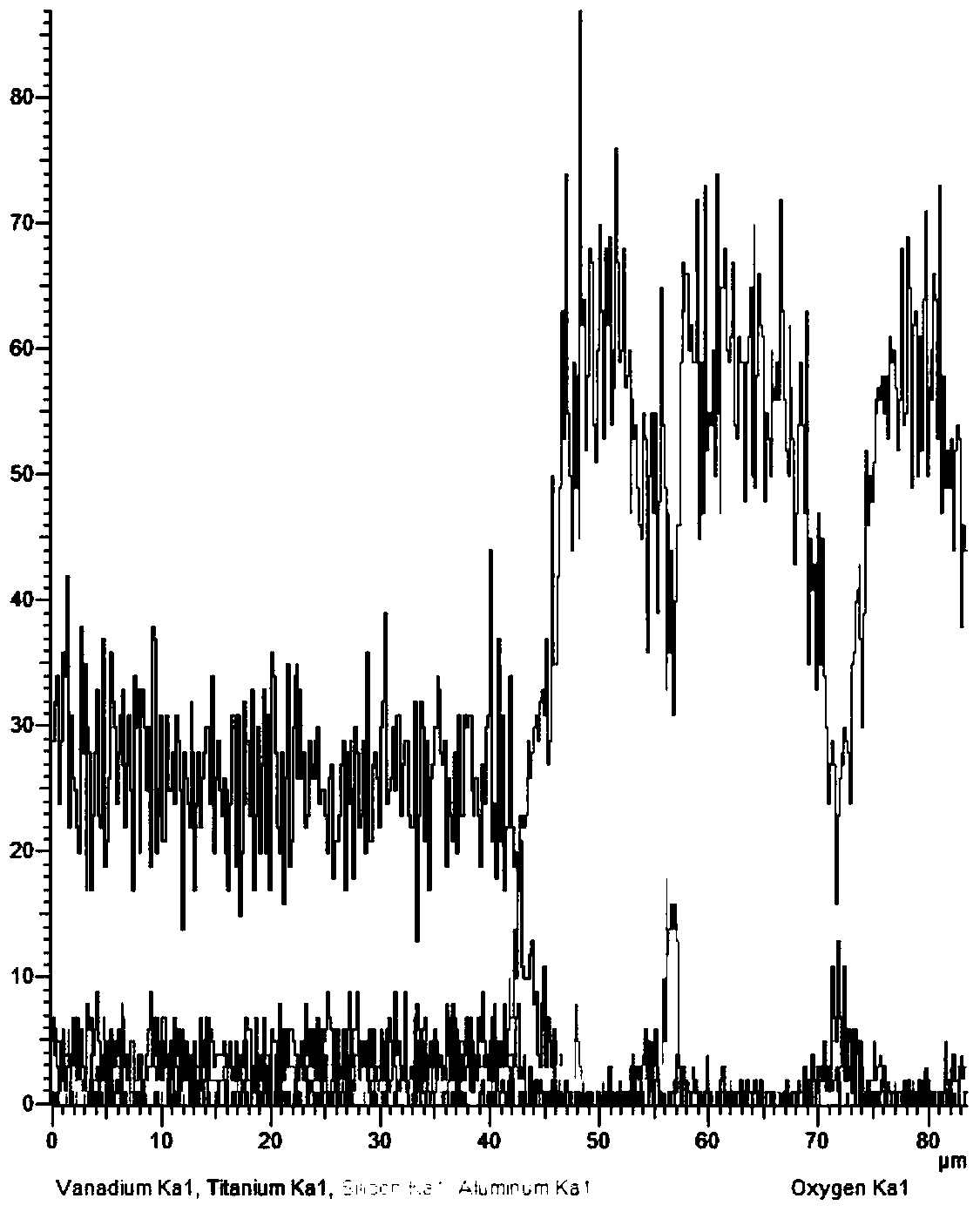

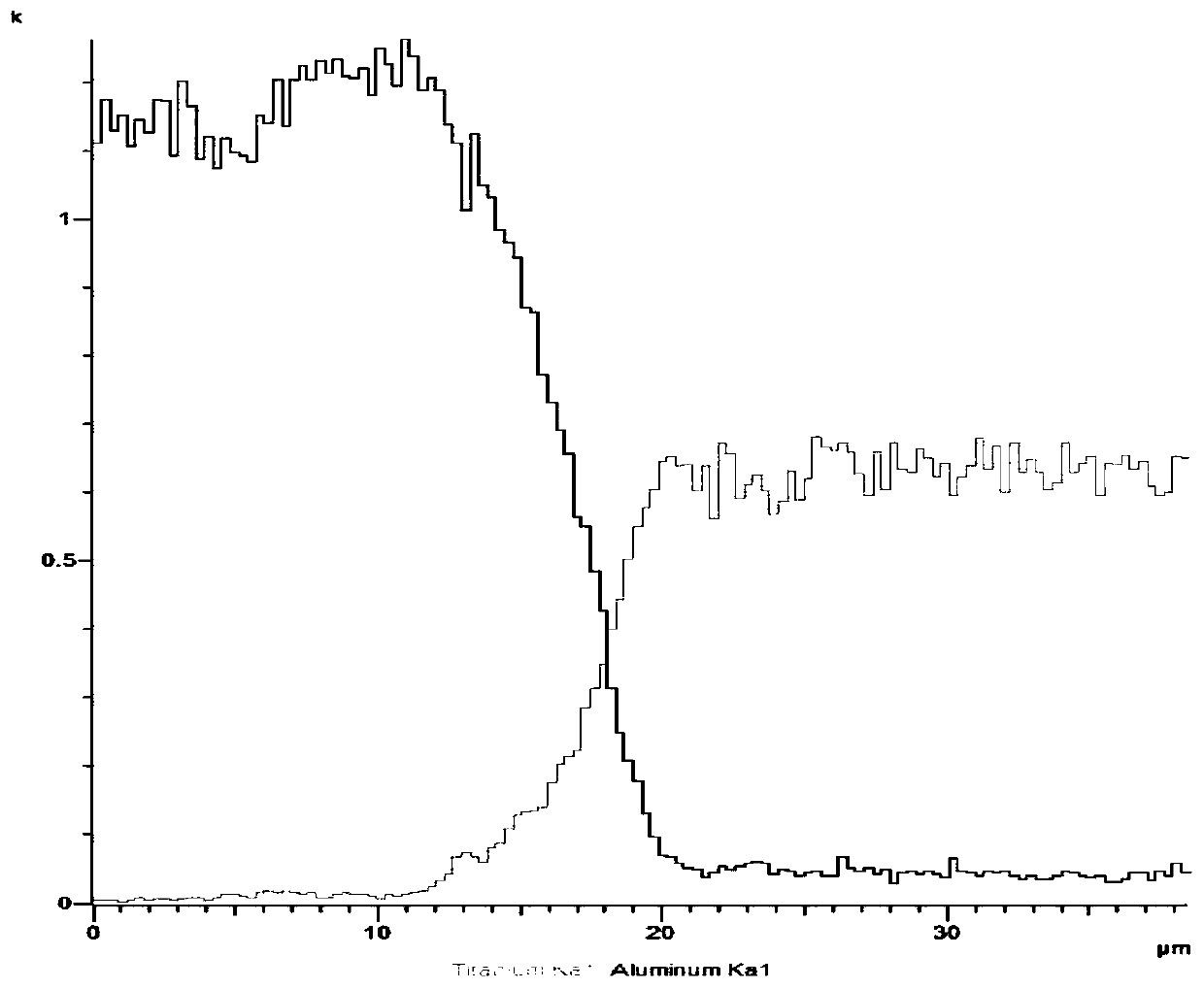

Image

Examples

Embodiment 1

[0048] A metal filling material for controlling the brittle phase in the welded joint of titanium-aluminum dissimilar metals in powder form, comprising the following components in mass percentage: 73% of 400-mesh aluminum powder, 10% of 400-mesh silicon powder, 9% of 325-mesh nickel powder, 300 mesh silver powder 8%.

[0049] The application method of the above-mentioned metal filling material comprises the following steps:

[0050] (1) Clean the butt surface of TC4 titanium alloy and 2A14 aluminum alloy plate within 20mm with a wire brush to reveal the metallic luster, and obtain the pretreated titanium alloy plate and aluminum alloy plate; then use an angle grinder to grind the pretreated aluminum alloy plate After forming a groove angle of 45°, use a wire brush and acetone to clean the 20mm range of the weld, and then fix it in the fixture; evenly fill the powdered metal filling material in the pretreated titanium alloy plate and pretreated aluminum alloy plate. In the sin...

Embodiment 2

[0053] A powdery metal filling material for controlling the brittle phase in welded joints of titanium-aluminum dissimilar metals, comprising the following components in mass percentage: 68% of 400-mesh aluminum powder, 12% of 400-mesh silicon powder, 10% of 325-mesh nickel powder, 300 mesh silver powder 10%.

[0054] The application method of the above-mentioned metal filling material is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com