A kind of preparation method of high plasticity tini51 alloy wire

A technology of alloy wire and high plasticity, which is applied in the field of preparation of high-plasticity titanium-nickel shape memory alloy Ti-Ni51at% wire, which can solve the problems of poor alloy fluidity, reduced material processing performance, and not being widely used, so as to improve plastic processing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The processing method of TiNi51 (Ti-Ni51at%) alloy Φ6.5mm wire material: firstly, the raw material 0-grade sponge titanium and Ni9999 electrolytic nickel are melted in 25Kg medium frequency vacuum induction according to the ratio of Ti-Ni51at% (Ti-Ni56.06wt%) Φ100-15Kg primary titanium-nickel alloy ingot. Cut off the riser of the primary ingot, peel off the skin, select 4 for assembly and welding as consumable electrodes, weighing 45Kg. A Φ160mm copper crucible is used for smelting in a vacuum consumable furnace to obtain a Φ160-45Kg ingot. Then homogenize the ingot at high temperature, the temperature is 950-1150°C, and the holding time is 4-6 hours. After forging and rolling, it is processed into a wire billet; finally, it is drawn and straightened to produce a finished wire.

Embodiment 2

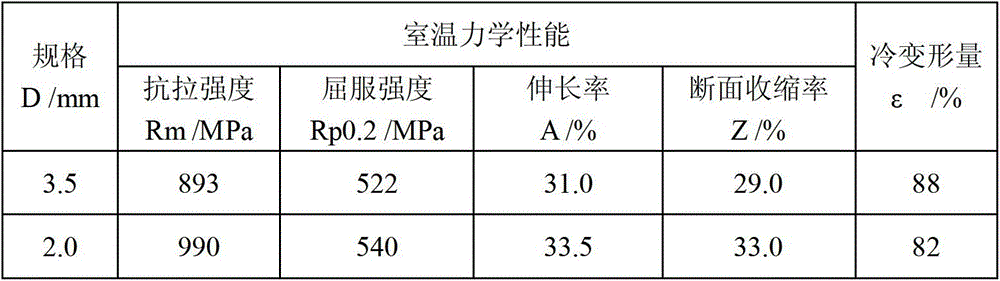

[0032] The processing method of TiNi51 (Ti-Ni51at%) alloy Φ3.5mm wire material: firstly, the raw material 0-grade sponge titanium and Ni9999 electrolytic nickel are melted in 25Kg medium frequency vacuum induction according to the ratio of Ti-Ni51at% (Ti-Ni56.06wt%) Φ100-15Kg primary titanium-nickel alloy ingot. Cut off the riser of the primary ingot, peel off the skin, and select 10 ingots for assembly and welding as consumable electrodes with a weight of 110Kg. A Φ160mm copper crucible is used for smelting in a vacuum consumable furnace to obtain a Φ160-110Kg ingot. Then homogenize the ingot at high temperature, the temperature is 950-1150°C, and the holding time is 6-8 hours. After forging and rolling, it is processed into a wire billet; finally, it is drawn and straightened to produce a finished wire. The straightening process is at a temperature of 800-950°C, a speed of 5-14mm / s, and water cooling. The wire can be automatically threaded to Φ1.1mm at one time, and the c...

Embodiment 3

[0034] The processing method of TiNi51 (Ti-Ni51at%) alloy Φ1mm wire material: first, the raw material 0-grade sponge titanium and Ni9999 electrolytic nickel are smelted in 25Kg medium frequency vacuum induction melting Φ100- 15Kg primary titanium-nickel alloy ingot. Cut off the riser of the primary ingot, peel off the skin, and select 14 for assembly welding as consumable electrodes with a weight of 150Kg. A Φ160mm copper crucible is used for smelting in a vacuum consumable furnace to obtain a Φ160-150Kg ingot. Then homogenize the ingot at high temperature, the temperature is 950-1150°C, and the holding time is 6-8 hours. After forging and rolling, it is processed into a wire billet; finally, it is drawn and straightened to produce a finished wire. Temperature 800~860℃, speed 10~20mm / s, water cooling.

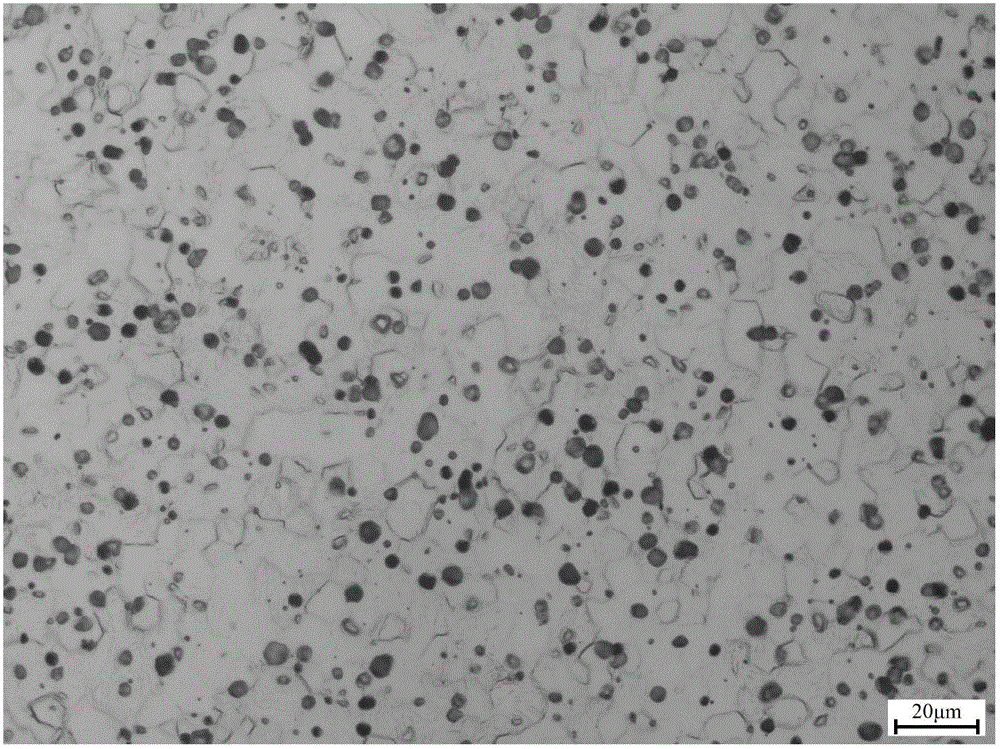

[0035] Metallographic appearance of TiNi51at%-Φ2.0mm alloy wire prepared by the present invention figure 1 , belonging to equiaxed organization, distribution of fine two-ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com