A preparation method of functionally graded aluminum matrix composite brake disc

An aluminum-based composite material and functional gradient technology, applied in the direction of brake discs, mechanical equipment, brake types, etc., can solve problems such as high thermal stress, reduced friction, and fracture, and achieve the goal of enhancing toughness, reducing fracture, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: the brake disk of common truck.

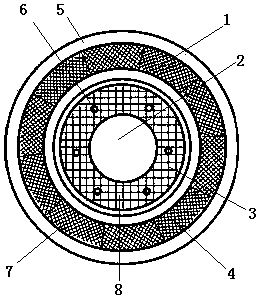

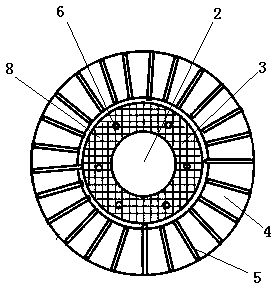

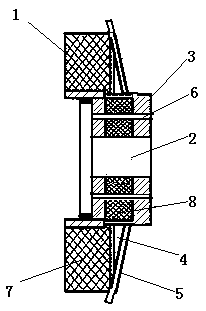

[0031] exist figure 1 , figure 2 with image 3 Among them, this functionally graded aluminum-based composite brake disc is characterized in that the material is an aluminum alloy with a gradient reinforcement skeleton, the disc edge 1 is a friction layer containing high-density reinforcing material 7, and the center of the disc is a shaft hole 2. The shaft hole 2 is surrounded by connecting discs 3, which contain medium and bottom density reinforcing materials 8. Connecting discs 3 are evenly distributed with connecting screw holes 6, and the periphery of connecting discs 3 is aluminum alloy cooling ring 4, which can dissipate heat from aluminum alloys. The back side of the ring 4 has radial aluminum alloy cooling ribs 5 evenly distributed thereon.

[0032] exist Figure 5 Among them, a large number of particles 9 and fibers 10 are wrapped by the aluminum alloy matrix 11, forming a very wear-resistant structure.

...

Embodiment 2

[0048] Embodiment 2: heavy-duty vehicle brake disc.

[0049] The structure of this functionally graded aluminum matrix composite brake disc is similar to that of the first embodiment.

[0050] The manufacturing method of the functionally graded aluminum-based composite brake disc is prepared by high-temperature extrusion molding of the cast aluminum alloy and the reinforcing body skeleton, followed by mechanical processing and heat treatment; it is characterized in that it includes the following preparation steps:

[0051] (1) Preparation of reinforced skeleton slurry: Add reinforced fibers, granules, and water-soluble binders to water in sequence according to a certain proportion, mix to form an aqueous solution, stir evenly and settle at the bottom of the aqueous solution to obtain thick slurry, thick slurry The solid content is 70%;

[0052] (2) Place a permeable membrane inside the disc-shaped mold to facilitate water penetration. Pour the thick slurry into the disc-shape...

Embodiment 3

[0066] Embodiment three: rail train brake disc.

[0067] The structure of this functionally graded aluminum matrix composite brake disc is similar to that of the first embodiment.

[0068] The manufacturing method of the functionally graded aluminum-based composite brake disc is prepared by high-temperature extrusion molding of the cast aluminum alloy and the reinforcing body skeleton, followed by mechanical processing and heat treatment; it is characterized in that it includes the following preparation steps:

[0069] (1) Preparation of reinforced skeleton slurry: Add reinforced fibers, granules, and water-soluble binders to water in sequence according to a certain proportion, mix to form an aqueous solution, stir evenly and settle at the bottom of the aqueous solution to obtain thick slurry, thick slurry The solid content is 80%;

[0070] (2) Place a permeable membrane inside the disc-shaped mold to facilitate water penetration. Pour the thick slurry into the disc-shaped mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com