A kind of niti shape memory alloy and stainless steel electron beam welding method

A technology of electron beam welding and memory alloy, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as weld cracking, achieve fast heating and cooling speed, improve mechanical properties, and form good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

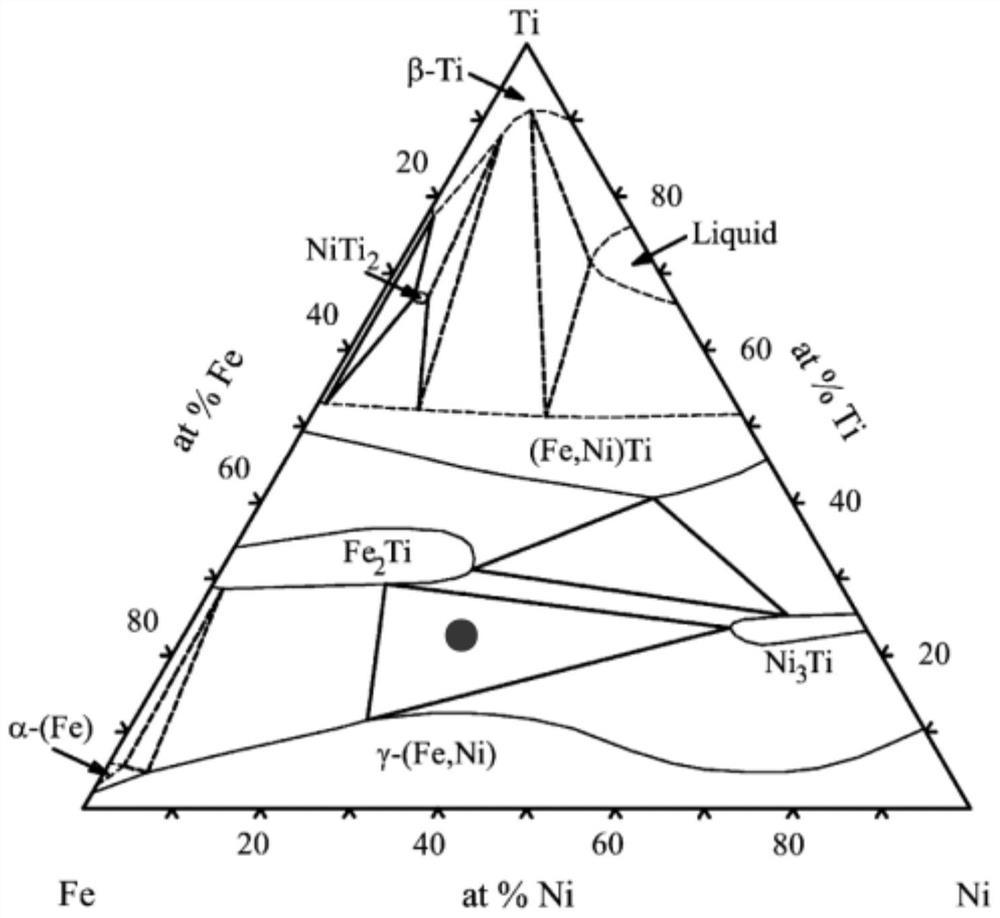

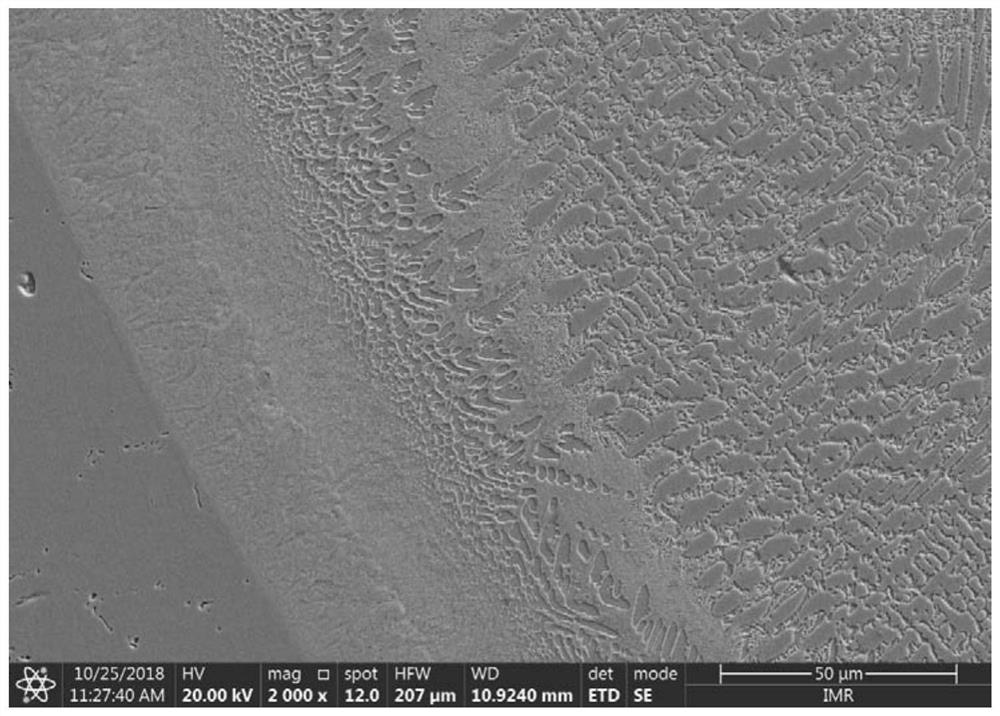

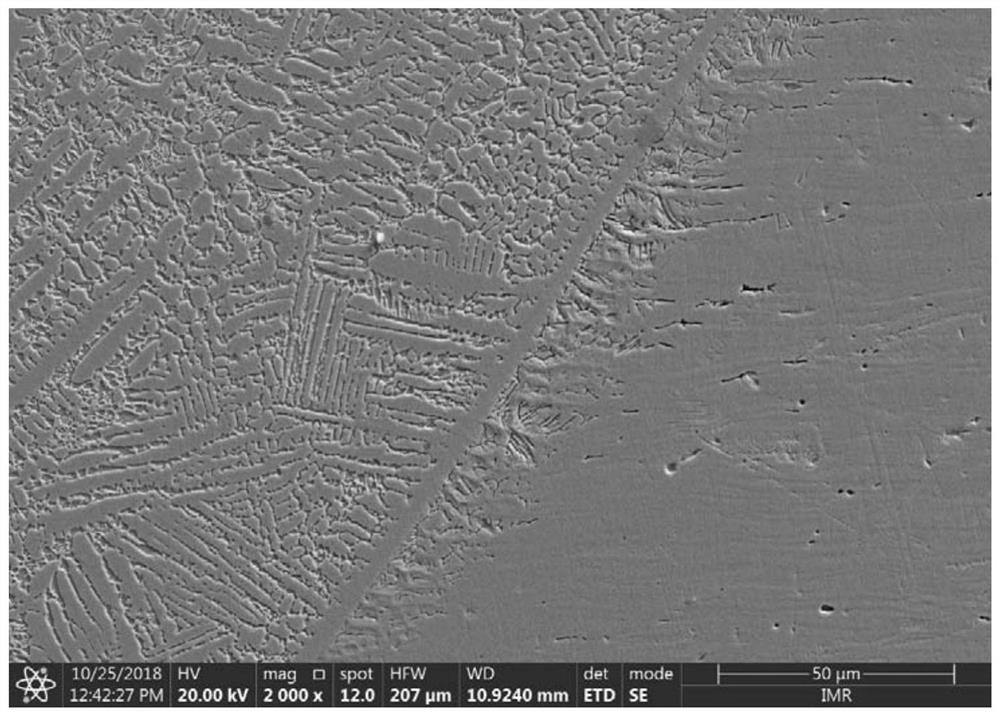

[0046] In this embodiment, the surfaces of the NiTi plate and the stainless steel plate with a thickness of 1.6 mm were firstly polished, and then ultrasonic cleaning was performed with acetone and alcohol solvents to remove oil stains, and then dried for later use. The thickness is 0.3mm, the FeNi alloy foil of equiatomic ratio is cut into 1.6mm wide, after pickling (by weight percentage, with the proportioning preparation pickling of 20% nitric acid+5% hydrofluoric acid+75% water solution), ultrasonically cleaned with acetone and alcohol for 20 minutes, and then dried for use. The treated FeNi alloy is placed between the NiTi plate and the stainless steel plate to be welded as an intermediate transition layer to form the welded piece and fixed to the fixture. A compressive stress of 0.2MPa is applied at both ends of the fixture to prevent the intermediate transition layer from falling off during welding. Put the parts to be welded together with the fixture into the vacuum c...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] 1) The compressive stress applied at both ends of the fixture is 0.1MPa.

[0051] 2) The composition of the selected FeNi alloy intermediate transition layer is Fe: 45 at.% Ni: 55 at. %.

[0052] 3) Focus the electron beam on the side of the FeNi intermediate transition layer that is 0.2mm away from the stainless steel side (this is to make up for the difference caused by the difference in thermal physical properties when the two base materials are directly welded), and perform vacuum electron beam welding. The welding parameters are as follows: the welding speed is 800mm / min, the accelerating voltage is 40KV, the focusing current is 2325mA, the electron beam current is 15mA, and the working distance is 150mm. After the program is completed, cool in vacuum for 10 minutes, then remove the vacuum and take out the workpiece to complete the welding of NiTi shape memory alloy and stainless steel.

[0053] In this embodiment, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com