Temperature shrinkage active-control type cement stabilized macadam and preparation method thereof

A cement-stabilized gravel and active control technology, which is applied in the field of road construction materials, achieves the effects of simple preparation process, delaying the formation and development of temperature shrinkage cracks, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

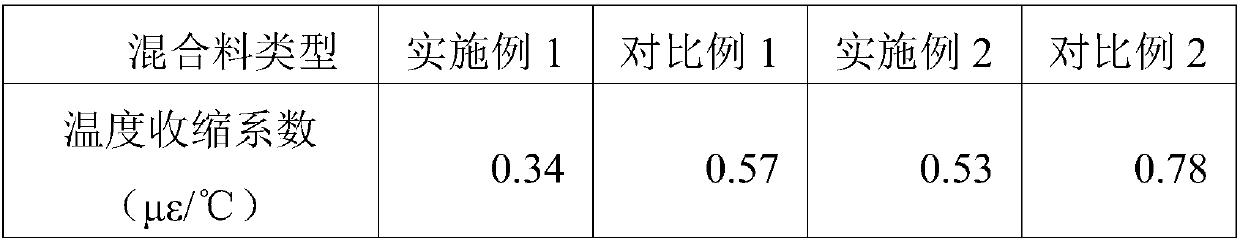

Examples

Embodiment 1

[0033] The raw materials used in this example are by weight: P.O.4 2.5 ordinary portland cement 4.0, SBR latex 0.5, phase change crushed stone 55, ordinary crushed stone 45, water 4.7.

[0034] The invention provides a method for preparing cement-stabilized gravel with active temperature shrinkage control, comprising the following steps:

[0035] (1) Heat n-tetradecane to 100°C to make it fully melt into a liquid state, heat diatomaceous earth to 200°C, then add diatomaceous earth to the liquid n-tetradecane, control diatomite and n-tetradecane The mass percentage of tetradecane is 65%: 35%, fully stirred, dried, crushed and ground, and passed through a 0.075mm square hole sieve to obtain a composite phase change material with a phase change temperature of 5.8°C;

[0036] (2) Mix the composite phase change material, P.O.42.5 ordinary Portland cement and water, control the water-cement ratio to 0.3, the mass percentage of the composite phase change material and cement is 4%: 96...

Embodiment 2

[0044] The raw materials used in this embodiment are by weight: P.O.4 2.5 ordinary Portland cement 5.0, SBR latex 0.7, phase change crushed stone 60, ordinary crushed stone 40, water 5.5.

[0045] The invention provides a method for preparing cement-stabilized gravel with active temperature shrinkage control, comprising the following steps:

[0046](1) Heat n-heptadecane to 100°C to make it fully melt into a liquid state, heat diatomaceous earth to 200°C, then add diatomaceous earth to liquid n-heptadecane, control diatomite and n-heptadecane The mass percentage of heptane is 73%: 27%, fully stirred, dried, crushed and ground, and passed through a 0.075mm square hole sieve to obtain a composite phase change material with a phase change temperature of 21.6°C;

[0047] (2) Mix the composite phase change material, P.O.42.5 ordinary Portland cement and water, control the water-cement ratio to 0.5, the mass percentage of the composite phase change material and cement is 7%:93%, mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com