Surface treatment method for resisting frosting

A surface treatment and anti-frosting technology, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of poor frost resistance and inability to effectively solve the problem of frost formation, and achieve improved durability and excellent anti-frosting. Cream effect, simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

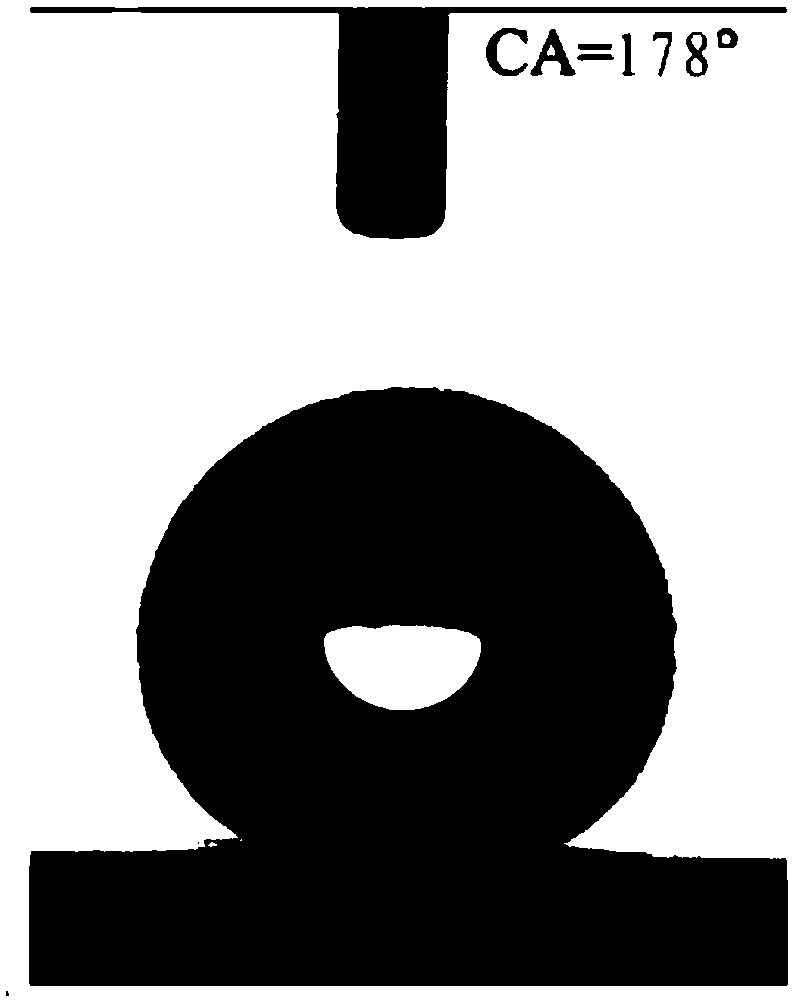

[0034] The preparation method provided by the present invention firstly performs anodic oxidation treatment on the workpiece to form a special micro-nano structure on the surface of the workpiece, and then performs surface modification on the workpiece to further modify the micro-nano structure, adjust the free energy of the workpiece surface, and form a special surface on the workpiece surface On the one hand, the surface of the workpiece has a high contact angle and extremely low adhesion, so that the solution is easy to fall off from the hydrophobic surface; The workpiece has excellent anti-frost effect, and the anti-frost performance is durable and effective.

[0035] In the present invention, before performing the above step a), it is preferable to perform surface cleaning and electrochemical polishing in sequence on the workpiece to be treated.

[0036] In the present invention, the surface cleaning preferably includes detergent cleaning and corrosive solution corrosion....

Embodiment 1

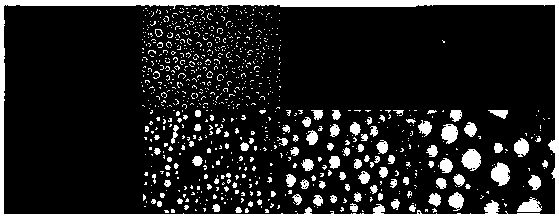

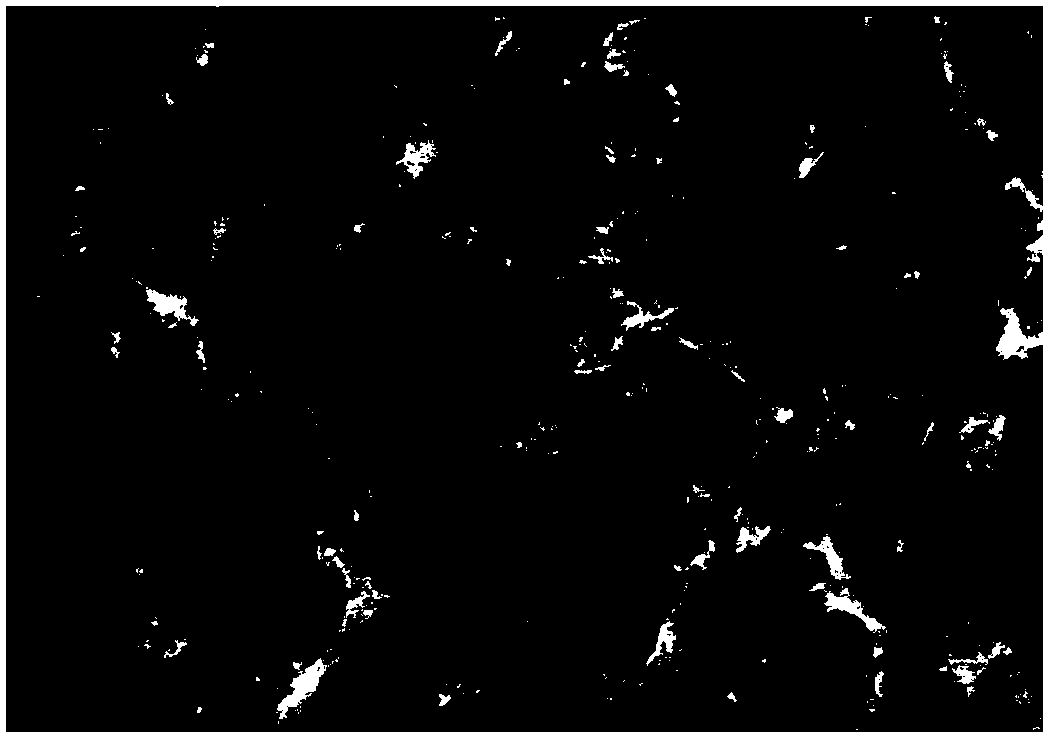

[0056] 1.1 Sample processing

[0057] After ultrasonically cleaning the grease stains on the surface of aluminum fins with acetone, corrode them with 1mol / L NaOH solution for 5 minutes to remove the natural oxide film; put the cleaned aluminum fins into anhydrous ethanol and perchloric acid with a volume ratio of 9:1 In the composed polishing solution, at a voltage of 20V, a current of 0.3A / cm 2 , electrochemical polishing at room temperature for 1 to 2 minutes; put the polished aluminum fins into 0.3mol / L oxalic acid solution for anodic oxidation, the treatment temperature is 0°C, and the current density is 0.10A / cm 2 , the treatment time is 15 minutes; the treated aluminum fins are immersed in 1% lauric acid absolute ethanol solution, taken out after 30 minutes, and dried in a dryer at 120°C for 30 minutes to obtain anti-frosting Aluminum fins.

[0058] 1.2 Characterization and testing

[0059] The surface structure of the obtained aluminum fins was observed by scanning e...

Embodiment 2

[0063] 1.1 Sample processing

[0064] After ultrasonically cleaning the grease stains on the surface of aluminum fins with acetone, corrode them with 1mol / L NaOH solution for 5 minutes to remove the natural oxide film; put the cleaned aluminum fins into anhydrous ethanol and perchloric acid with a volume ratio of 9:1 In the composed polishing solution, at a voltage of 15V, a current of 0.1A / cm 2 , electrochemical polishing at room temperature for 1 to 2 minutes; put the polished aluminum fins into 0.5mol / L oxalic acid solution for anodic oxidation, the treatment temperature is 5°C, and the current density is 0.20A / cm 2 , the treatment time is 10 minutes; the treated aluminum fins are immersed in lauric acid absolute ethanol solution with a mass fraction of 1%, taken out after 30 minutes, and dried in a dryer at a temperature of 120°C for 30 minutes to obtain anti-frosting Aluminum fins.

[0065] 1.2 Characterization and testing

[0066] Observing the surface structure of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com