Reservoir for a liquid medium having a suction device and a filter unit

A technology of suction device and liquid medium, which is applied to power devices, mufflers, exhaust devices, etc., can solve problems such as failure, SCR system failure, blockage, etc., and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

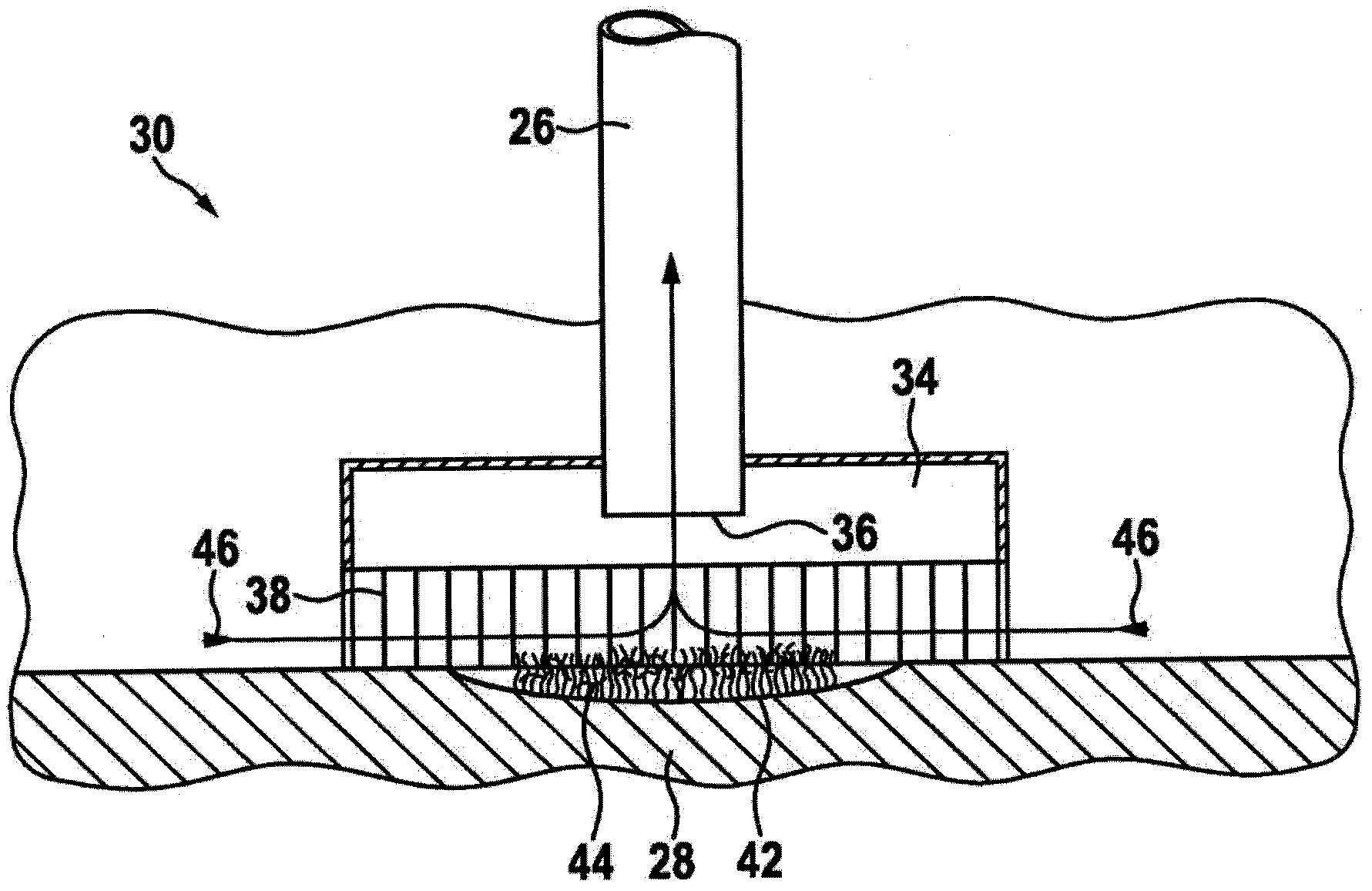

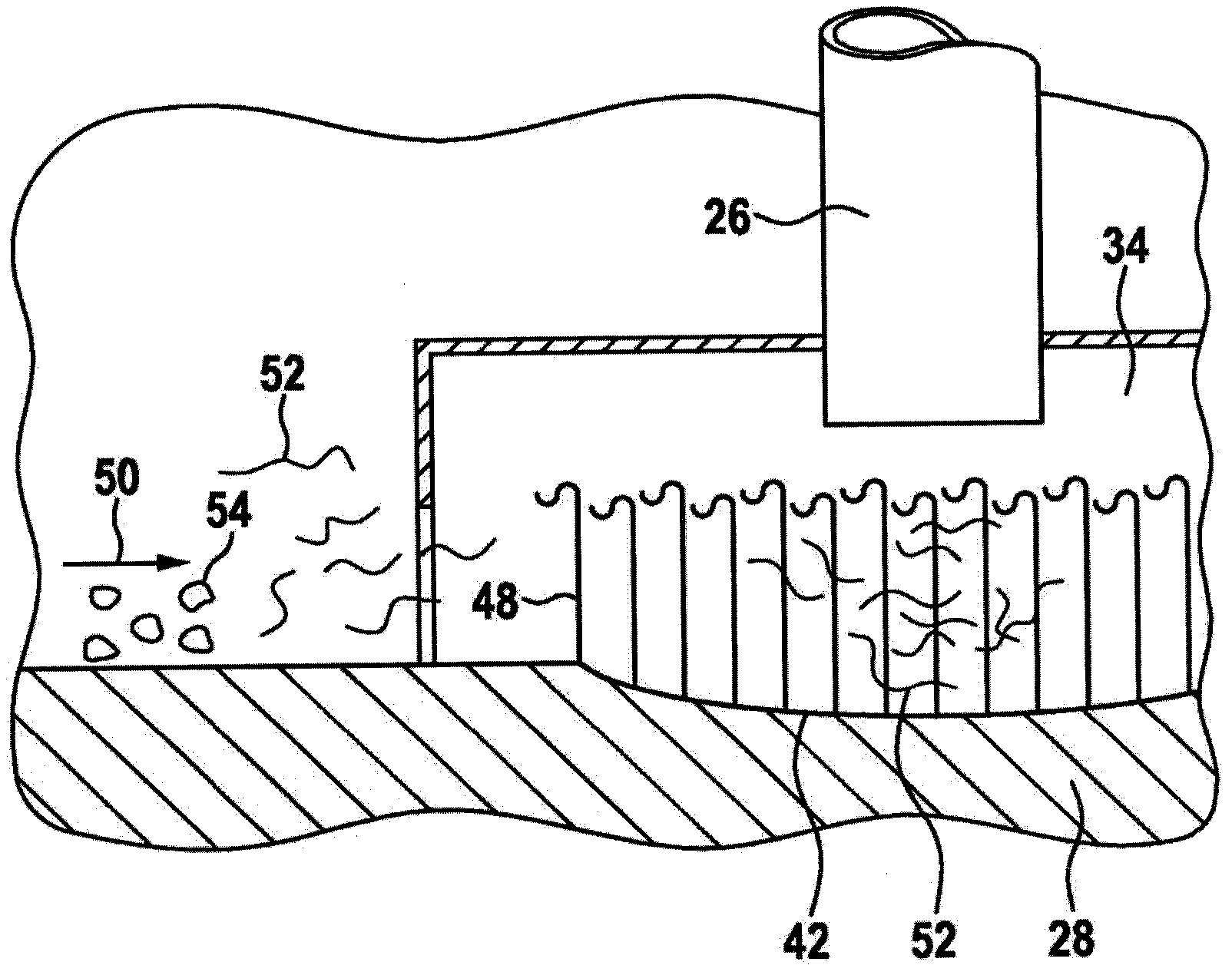

Embodiment Construction

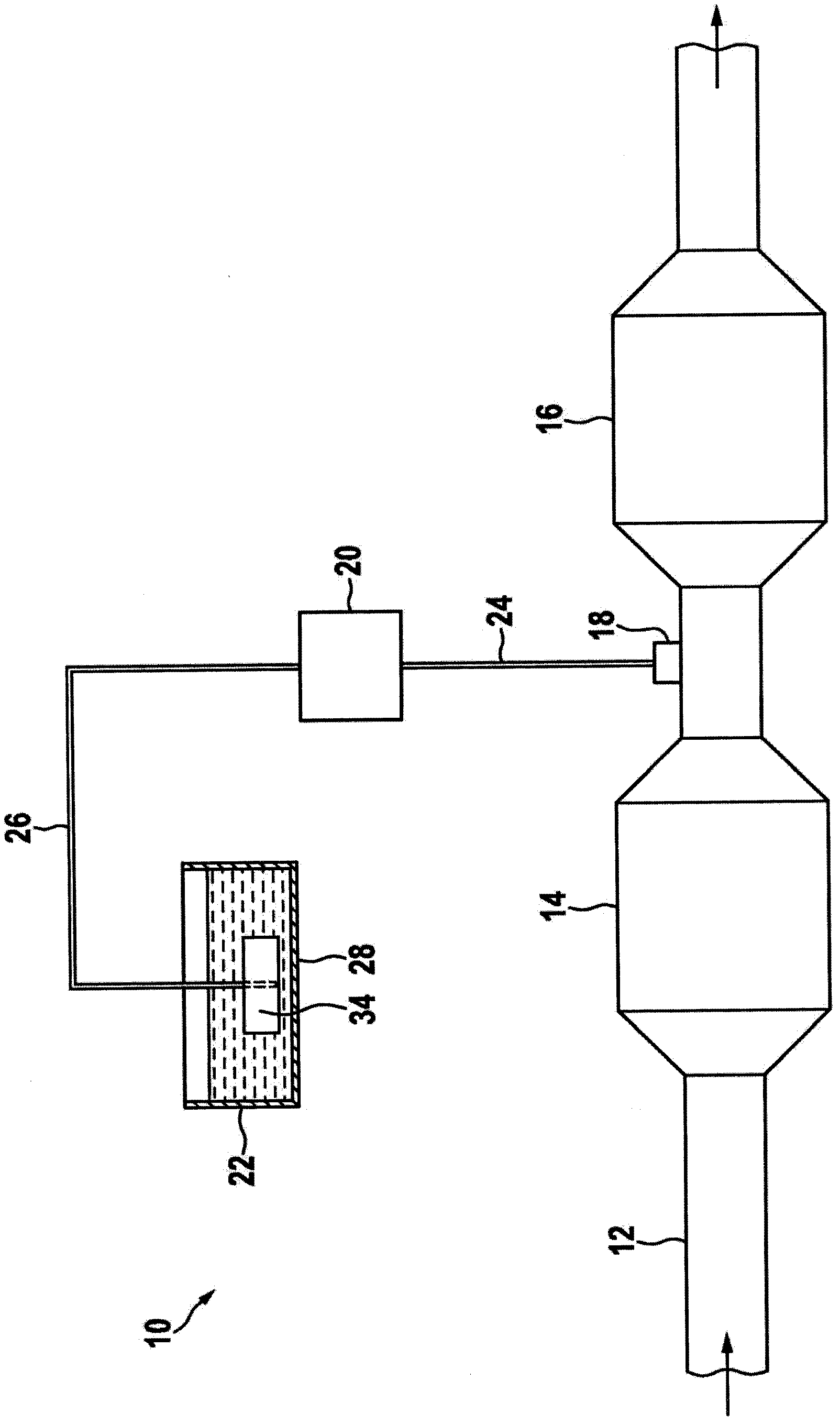

[0015] figure 1 An exhaust gas aftertreatment device 10 of an internal combustion engine is shown in a simplified and schematic manner as well as the environment in which the invention is represented. Exhaust gas aftertreatment device 10 includes an exhaust pipe 12 , an oxidation catalytic converter 14 and an SCR catalytic converter 16 . A particulate filter is not shown, which is usually arranged downstream of the oxidation catalyst 14 . The flow direction of the exhaust gas through the exhaust pipe 12 is marked by arrows (no reference numerals).

[0016] In order to supply the SCR catalyst 16 with a liquid reducing agent, for example an aqueous urea solution (so-called AdBlue) or another liquid reducing agent, a metering device 18 for the aqueous urea solution is arranged on the exhaust line 12 upstream of the SCR catalyst 16 . The metering device 18 injects an aqueous urea solution into the exhaust pipe 12 upstream of the SCR catalytic converter 16 as required.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com