Ice coverage preventing electricity transmission cable and production method therefor

A technology for power transmission cables and production methods, applied in the direction of insulating cables, insulating conductors/cables, cables, etc., can solve problems such as aggravation, large manpower, material resources and time consumption, and increased infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with embodiment:

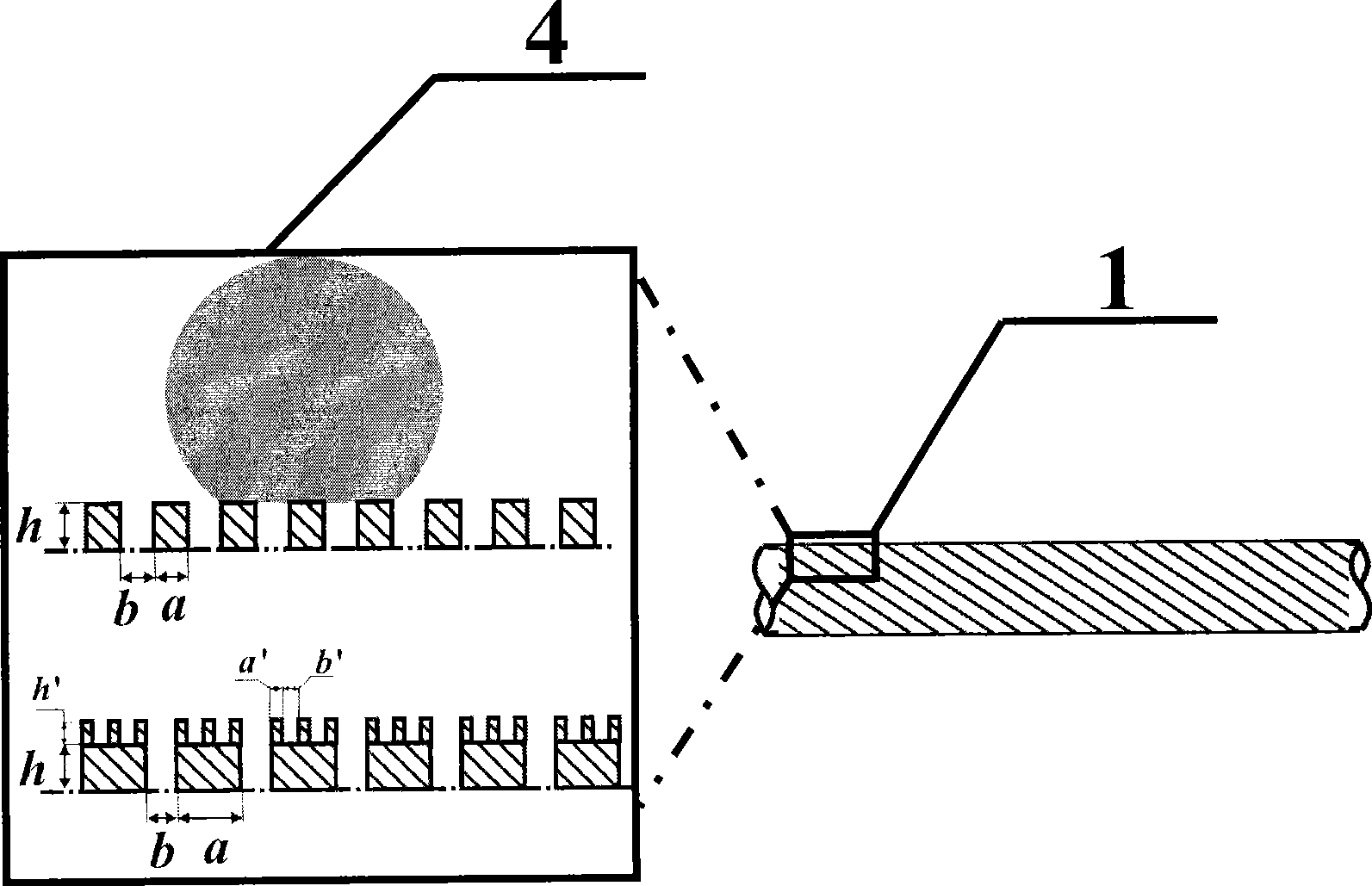

[0011] Such as figure 1 As shown, a kind of anti-icing power transmission cable 1 is coated with n-hexadecane hydrophobic layer 2 on the surface of power transmission cable 1. Surface microstructure width a=2~4μm, microstructure spacing b=4~6μm, microstructure height h=4~6μm, fractal nanostructure width a’=100~150nm, nanostructure spacing b’=200~300nm , the nanostructure height h'=150-250nm.

[0012] A kind of production method of anti-icing power transmission cable, utilizes the evaporation coating technology in the physical vapor deposition method (PVD) to coat the surface of the power transmission cable, put the cable bare wire (aluminum-clad steel strand, copper-clad steel wire, etc.) into a vacuum Room (-5 ), put the evaporation source material n-hexacane into the heater, slowly increase the temperature of the heater until the evaporation source material is completely liquefie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com