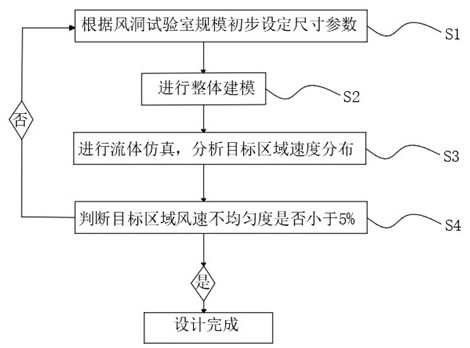

Device for Improving Airflow Uniformity in Aircraft Experimental Wind Tunnel and Its Parameter Optimization Method

A uniformity and wind tunnel technology, which is applied in the field of devices for improving the airflow uniformity of aircraft experimental wind tunnels, can solve the problems of large wind speed unevenness, low airflow uniformity, and unfavorable aircraft blowing, and achieves increased airflow uniformity and interference. The effect of reducing the degree of turbulence and reducing the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

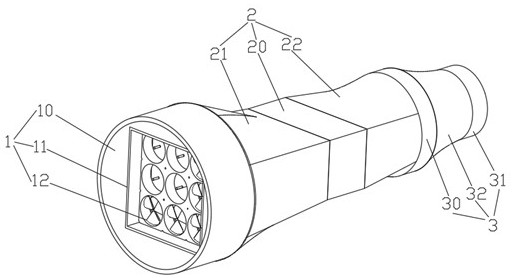

[0051] Such as figure 2A device for improving airflow uniformity in an aircraft experimental wind tunnel is shown, including a power section 1, a steady flow adjustment section 2, and a contraction section 3;

[0052] The power section 1 includes a tubular power body section 10, a fan installation structure 11 arranged in the power body section 10, and 3 rows of fans 12 arranged in a matrix on the fan installation structure 11;

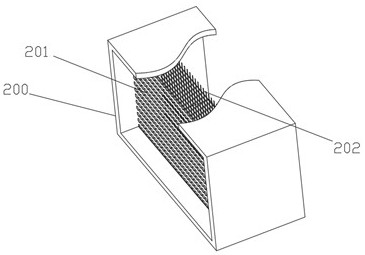

[0053] The steady flow adjustment section 2 includes a turbulent flow adjustment section 20 communicated with the power body section 10, a first variable-section connection section 21 that communicates with the power main body section 10 and the other end communicates with the turbulence adjustment section 20, and communicates with the turbulence section 20. The flow adjustment section 20, the second variable section connection section 22 of the constriction section 3;

[0054] The central axes of the power body section 10, the first variable-sectio...

Embodiment 2

[0075] Different from Embodiment 1, the ratio of the diagonal length A of the rectangular section of the rectangular duct 200 to the diameter D of the main power section 10 is 4.2:5;

[0076] The ratio of the diameter d of the large diameter connecting pipe 30 to the diameter D of the main power section 10 is 3.9:5;

[0077] The height of the windward end of the rectifying vane 310 is 18.5 cm; the length of the rectifying vane 310 is 120 cm.

Embodiment 3

[0079] A device for improving airflow uniformity in an aircraft experimental wind tunnel, comprising a power section 1, a steady flow adjustment section 2, and a contraction section 3;

[0080] The power section 1 includes a tubular power body section 10, a fan installation structure 11 arranged in the power body section 10, and four rows of fans 12 arranged in a matrix on the fan installation structure 11;

[0081] The steady flow adjustment section 2 includes a turbulent flow adjustment section 20 communicated with the power body section 10, a first variable-section connection section 21 that communicates with the power main body section 10 and the other end communicates with the turbulence adjustment section 20, and communicates with the turbulence section 20. The flow adjustment section 20, the second variable section connection section 22 of the constriction section 3;

[0082] The central axes of the power body section 10, the first variable-section connecting section 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com