Cyclonic separator for vacuum cleaner

A technology of cyclone separation device and cyclone separator, which is applied in the direction of suction filter, etc., can solve the problems of limited cyclone space, reduced dust separation efficiency, and high noise, and achieve the effects of reducing flow speed, increasing air capacity, and improving proportional size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

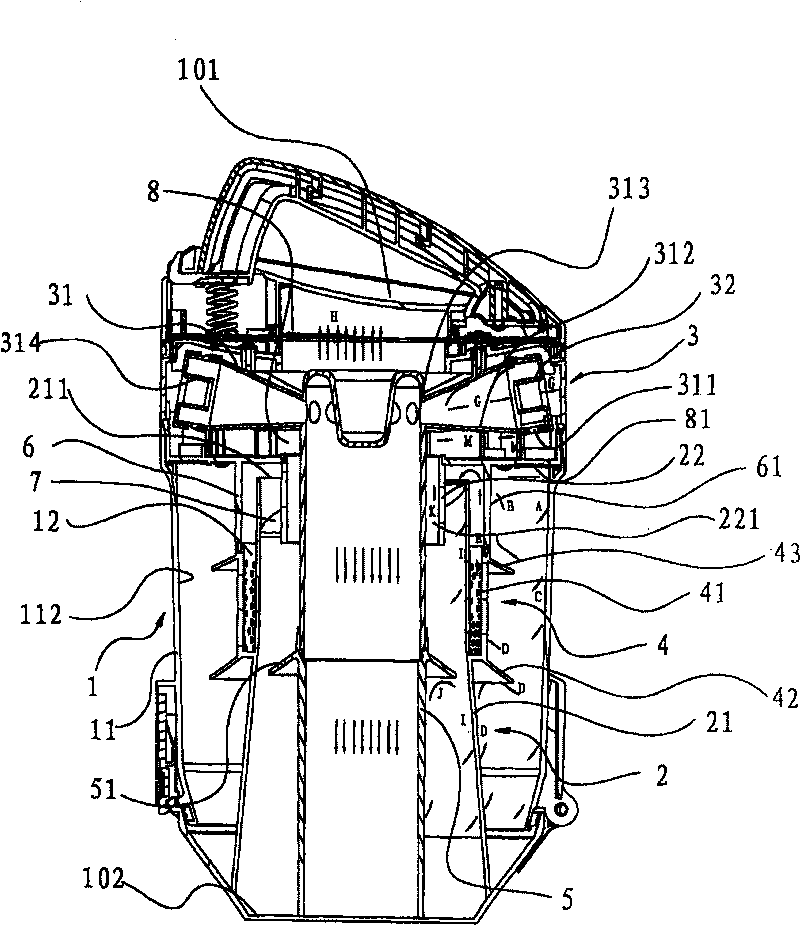

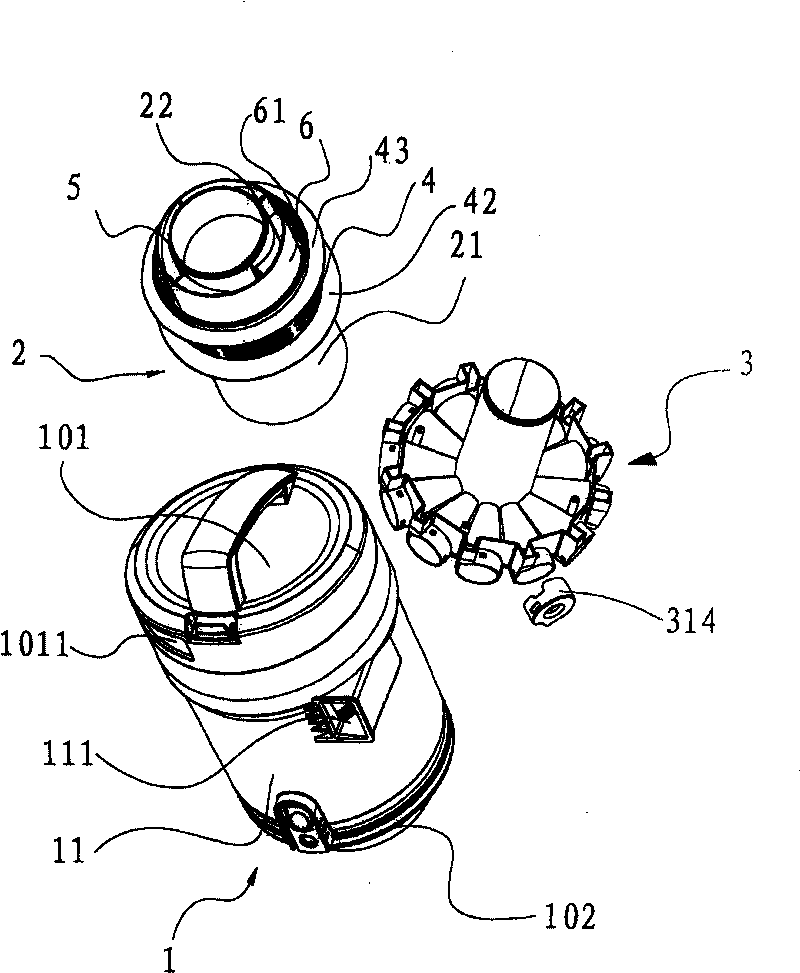

[0028] Such as figure 1 and figure 2 The shown cyclone separation device of a vacuum cleaner has a primary cyclone separator 1 located upstream, a secondary cyclone separator 2 located downstream of the primary cyclone separator 1, and a tertiary cyclone separator located at the secondary cyclone separator 2 3.

[0029] The first-stage cyclone separator 1 has a first-stage cyclone barrel 11, and the side wall of the first-stage cyclone barrel 11 is provided with a first-stage air inlet 111, and the air flow with dust enters the first-stage cyclone barrel 11 from here, and the first-stage air inlet 111 is opposite The inner wall of the primary cyclone barrel 11 is arranged tangentially, so that the air entering from the primary air inlet 111 enters the primary cyclone barrel 11 in a direction tangential to the side wall, so that the air inside the primary cyclone separator 1 Create a vortex.

[0030] The secondary cyclone separator 2 has a secondary cyclone barrel 21, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com