Stove combustor with temperature sensor

A technology of temperature sensor and burner, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of affecting the output of the temperature measured by the temperature sensor, unreliable positioning, easy deformation, etc., and achieve better air mixing effect. Excellent, reasonable installation structure, good airflow uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

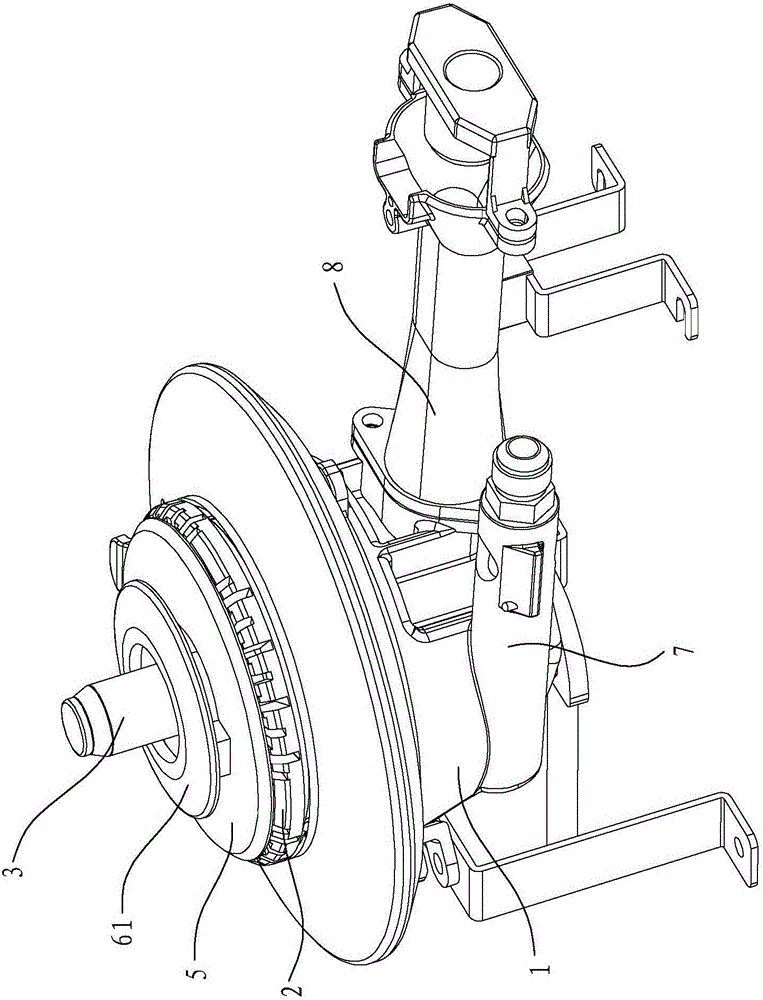

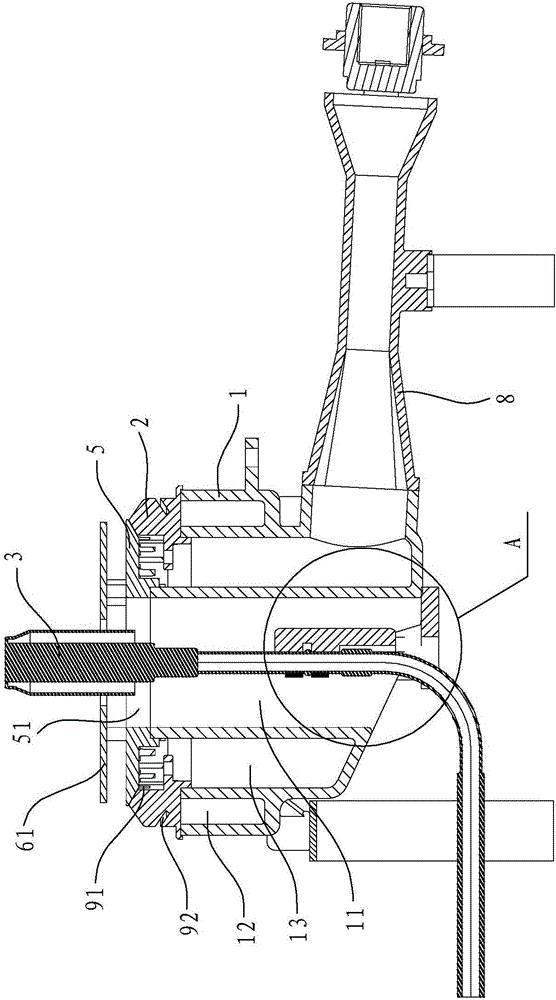

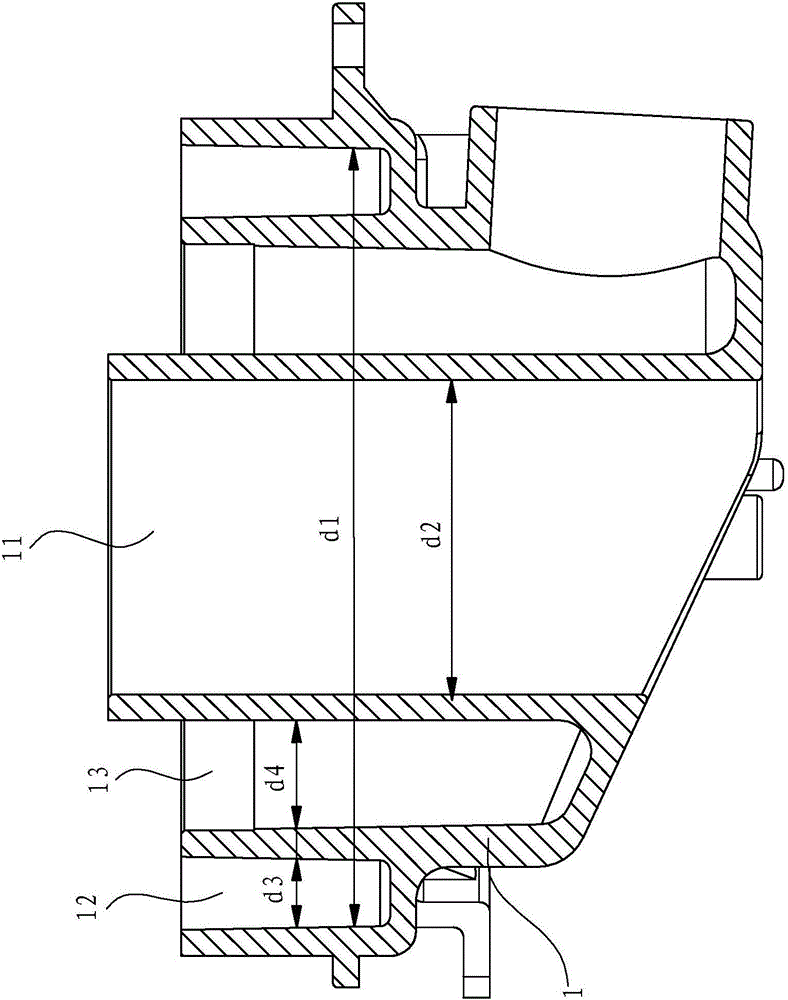

[0033] Such as Figure 1 to Figure 3 As shown, the cooker burner in this embodiment includes a base 1, a fire cover 2, a temperature sensor 3, a sensor bracket 4, a cover plate 5, a first heat shield 61, an outer ring gas injection pipe 7 and an inner ring gas injection pipe. Injection pipe 8 and other components, wherein the base 1 includes an outer ring cavity 12 and an inner ring cavity 13, the outer ring cavity 12 communicates with the outer ring gas injection tube 7, and the inner ring cavity 13 communicates with the inner ring cavity The gas injection pipes 8 are connected. The fire cover 2 is an annular fire cover, an upper ring fire channel 91 communicating with the inner ring cavity 13 is formed between the cover plate 5 and the fire cover 2, and the upper ring fire channel forms a large fire ring, and the inside of the fire cover 2 is formed to connect with the outer ring cavity. Body 12 communicates with the lower ring fire channel 92, and the lower ring fire chann...

Embodiment 2

[0047] Such as Figure 7 As shown, the cooker burner in this embodiment is equipped with an annular second heat-proof plate 62 on the upper end of the temperature sensor 3, the second heat-proof plate 62 can move synchronously with the temperature sensor 3, and the second heat-proof plate 62 is located above the cover plate 5 . The rest of the structure of the cooktop burner in this embodiment is the same as that in Embodiment 1, and will not be further described here.

Embodiment 3

[0049] Such as Figure 8 As shown, the cooker burner in this embodiment is not provided with a heat-resistant plate, and the rest of the structure is the same as that in Embodiment 1, and will not be described here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com