High-temperature nitridation airflow field control device and method

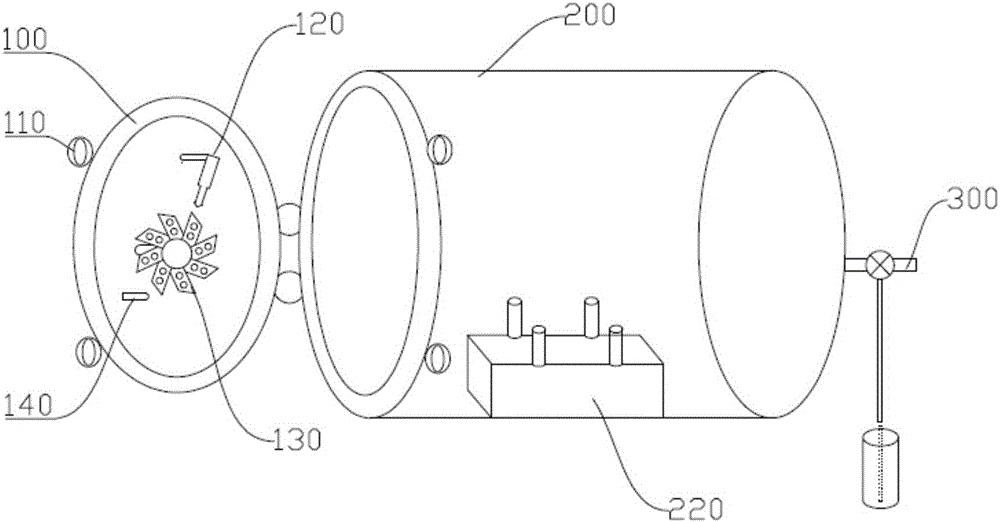

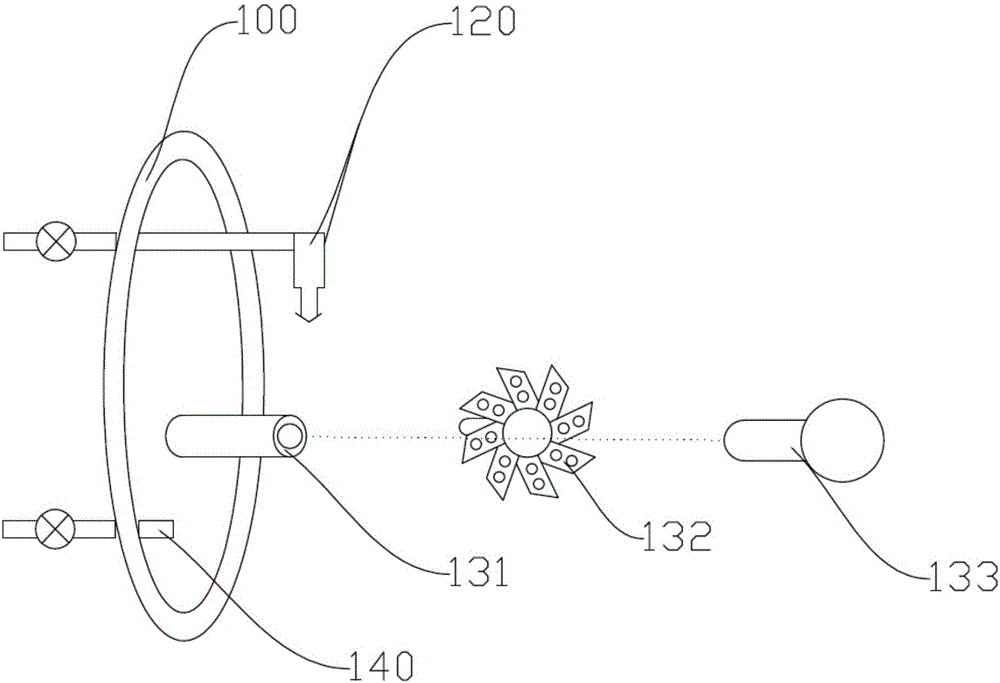

The technology of a control device and a control method, which is applied in the field of airflow control, can solve the problem of uneven distribution of nitrogen gas flow field and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

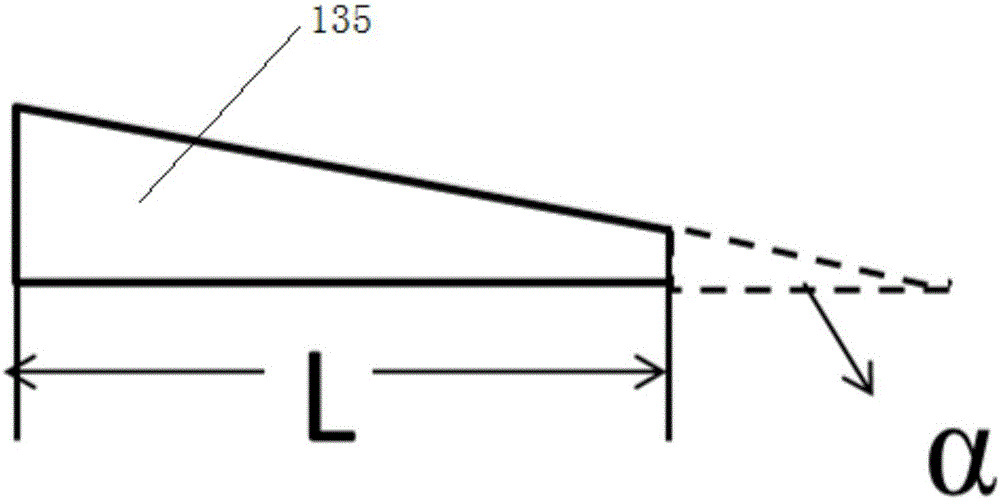

Method used

Image

Examples

Embodiment 1

[0048] (1) 100g of non-melting PCS fiber samples, fiber monofilament diameter 14 microns, placed in the constant temperature zone of high-temperature furnace, replaced with high-purity argon three times to remove the air in the furnace; (2) heating up to 3°C / min speed 300°C; (3) Introduce high-purity ammonia gas at a flow rate of 5L / min, and high-purity argon gas flow rate at 5L / min; (4) Raise the temperature to 1200°C at a rate of 3°C / min, keep it warm for 1h, and cool naturally to At room temperature, high temperature nitriding is completed. The average nitrogen content of the obtained nitrided fiber is 38.5wt%, the oxygen content is 0.76wt%, and the difference between the fiber nitrogen content at the near end and the far end of the air inlet is less than 0.5wt%. The test results of the nitrogen content of each part of the product obtained in this example are listed in Table 1.

[0049] The nitrogen content of each part of the product obtained in table 1 embodiment 1

[0...

Embodiment 2

[0054] (1) Press 100g of N-methylpolyborazane sample into a disc with a diameter of 100mm, place it in the constant temperature zone of the high-temperature furnace, and replace it with high-purity argon three times to remove the air in the furnace; (2) at 1°C Raise the temperature to 400°C at a speed of 5°C / min; (3) feed high-purity ammonia gas with a flow rate of 1L / min, and a flow rate of high-purity argon gas of 4L / min; (4) heat up to 1500°C at a speed of 5°C / min, Keep it warm for 1 hour, then cool it down to room temperature naturally, and complete the high temperature nitriding. The obtained boron nitride sample has an average nitrogen content of 56.2wt%, an oxygen content of 0.88wt%, and the difference in nitrogen content between the near end and the far end of the gas inlet is less than 0.5wt%.

Embodiment 3

[0056] (1) Press 100g of polyborosilazane into a square sheet of 50mm×500mm, place it in the constant temperature zone of the high-temperature furnace, and replace it with high-purity argon three times to remove the air in the furnace; (2) at a speed of 2°C / min Raise the temperature to 500°C; (3) feed high-purity ammonia gas at a flow rate of 2L / min, and high-purity argon gas flow rate of 4L / min; (4) raise the temperature to 1350°C at a rate of 4°C / min, keep it warm for 1h, and naturally Cooling to room temperature completes high temperature nitriding. The average nitrogen content of the obtained silicon boron nitrogen thin film sample is 45.6wt%, the oxygen content is 1.02wt%, and the difference between the sample nitrogen content at the near end and the far end of the gas inlet is less than 0.5wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com