Grate etching method

An over-etching and gas technology, applied in the field of gate etching, can solve the problems of difficulty in forming a uniform gas flow distribution, large gas flow rate, and poor gas fluidity, so as to reduce consumption costs, improve gas flow uniformity, and avoid variables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

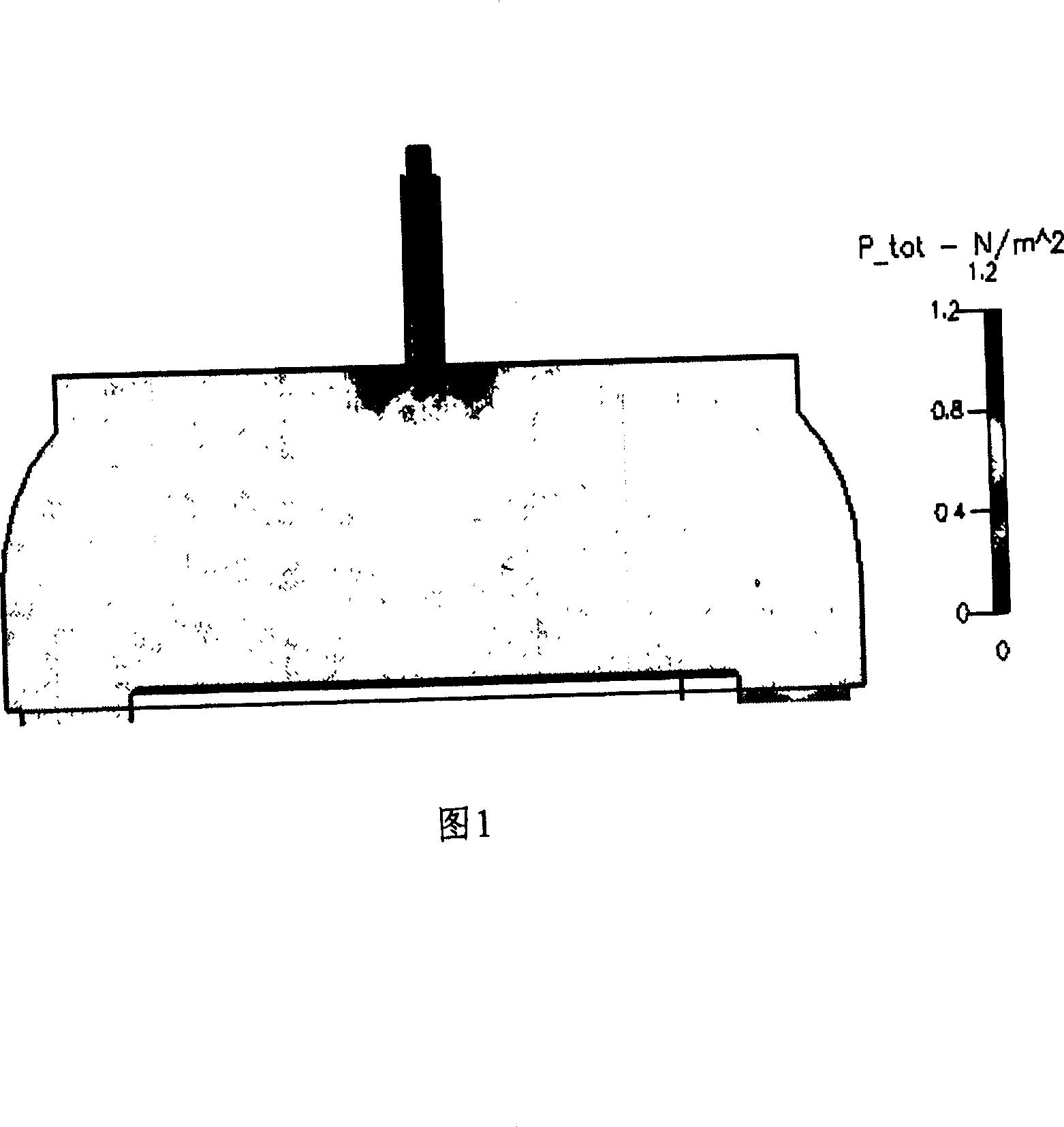

[0026] In the 300mm etching chamber, 20sccm Cl is injected in the main etching step 2 , 250sccmHBr, 10sccmO 2 , 80sccm He, 100sccm N 2 The composition of the mixed gas a and the gas simulation distribution state are shown in Figure 1.

[0027] The silicon etching equipment used is the North Microelectronics 300mm principle machine, which adopts a single-zone nozzle design, and the nozzle angle is 100-150 degrees.

[0028] The structure of the silicon wafer used is: silicon wafer = "silicon dioxide (10-100 angstroms) = "polysilicon (1700-2500 angstroms) =) "silicon dioxide (100-150 angstroms) = "silicon oxynitride (200-200 angstroms) 300A). (The etching pattern has been transferred from the photoresist to the hard mask, that is, the silicon dioxide / silicon oxynitride double layer structure)

[0029] In the etching process, the silicon wafer is first introduced into the etching reaction chamber, and is fixed by the electrostatic chuck. The temperature of the chamber is contr...

Embodiment 2

[0035] According to the method described in Example 1, the difference is that, in the main step, pass through 50sccm Cl 2 , 230sccm HBr, 15sccm O 2 , and 150sccm He on the mixed gas, the power of the RF power supply is 400-500W, and the process time is 80-105s.

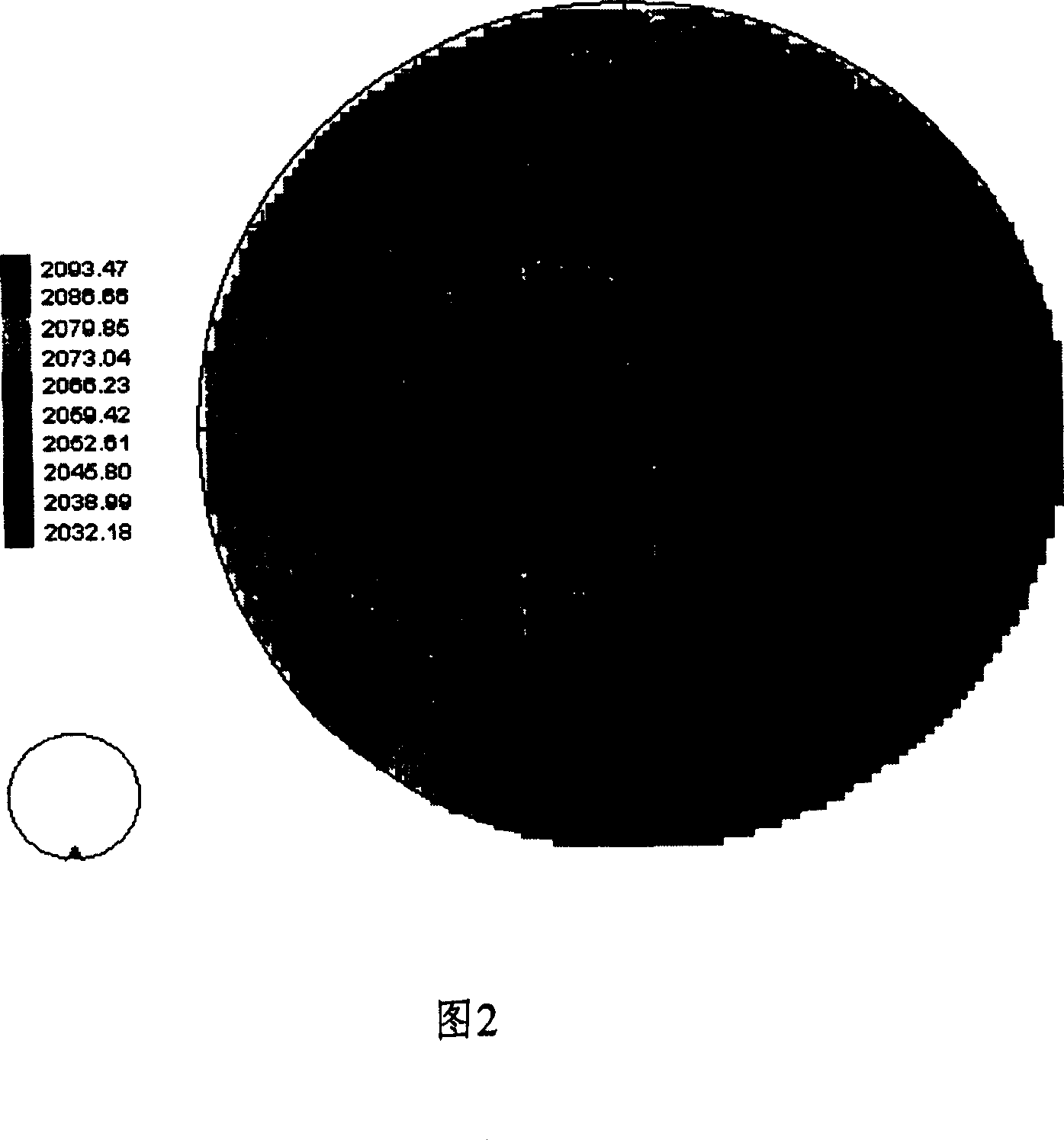

[0036] In the main step gas simulation, the gas flow uniformity on the surface of the silicon wafer is very high, which is 0.5-0.6 Pa. However, because the He gas plasma ignition ability is relatively weak and the plasma concentration is medium, in the actual process, the power of the upper RF power supply is 400 ~500W, the process time is longer, 80~105s. In the final etching result, the etching uniformity of the silicon wafer is as high as 1.80-2.10 (3 Sigma), which can fully meet the needs of the 300mm advanced etching process even without the use of hardware configurations such as dual-zone nozzles to improve the uniformity of the gas flow.

Embodiment 3

[0038] According to the method described in Example 1, the difference is that, in the main step, pass through 50sccm Cl 2 , 230sccm HBr, 15sccm O 2 、150sccmN 2 Composed of gas mixtures. The power of the upper RF power supply is 300-350W, and the process time is 45-65s.

[0039] The gas simulation of the main step, the uniformity of the gas flow on the surface of the silicon wafer is 0.6-0.8Pa, which is better. N2 gas plasma has strong ignition ability and high plasma concentration. Therefore, in the actual process, the power of the upper RF power supply is only 300-350W to maintain the normal etching process, and the process time is very short, 50-65s. The final etching result shows that the etching uniformity of silicon wafers is 2.65-2.90 (3 Sigma), which can basically meet the needs of 300mm advanced etching process when hardware configurations such as dual-zone nozzles are not used to improve airflow uniformity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com