Ventilation module and clothes processing device

A clothing processing device and channel technology, which is applied to washing devices, other washing machines, household dryers, etc., can solve problems such as retained dirt, and achieve the effect of improving the uniformity of airflow, the effect is remarkable, and it is suitable for popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

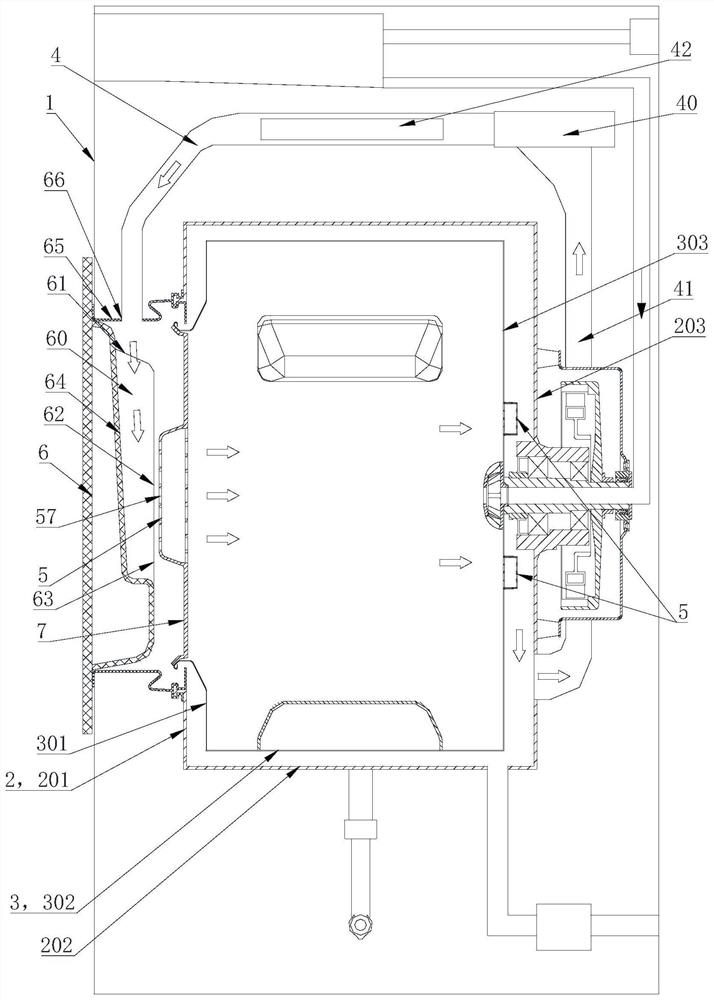

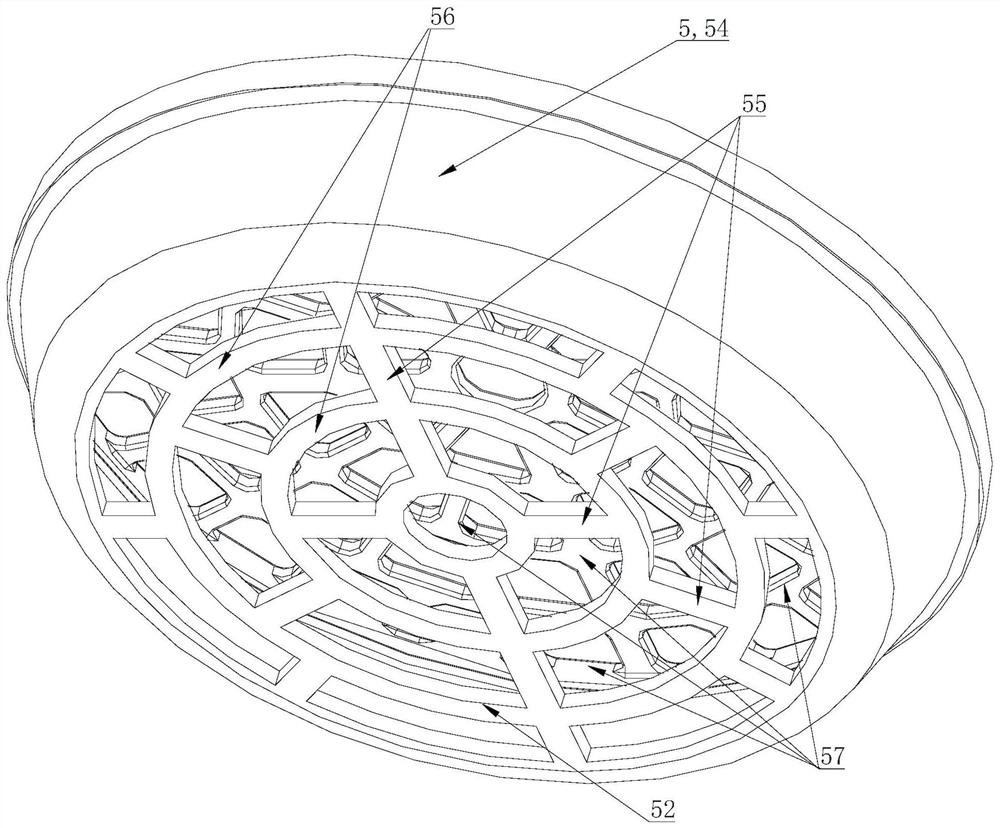

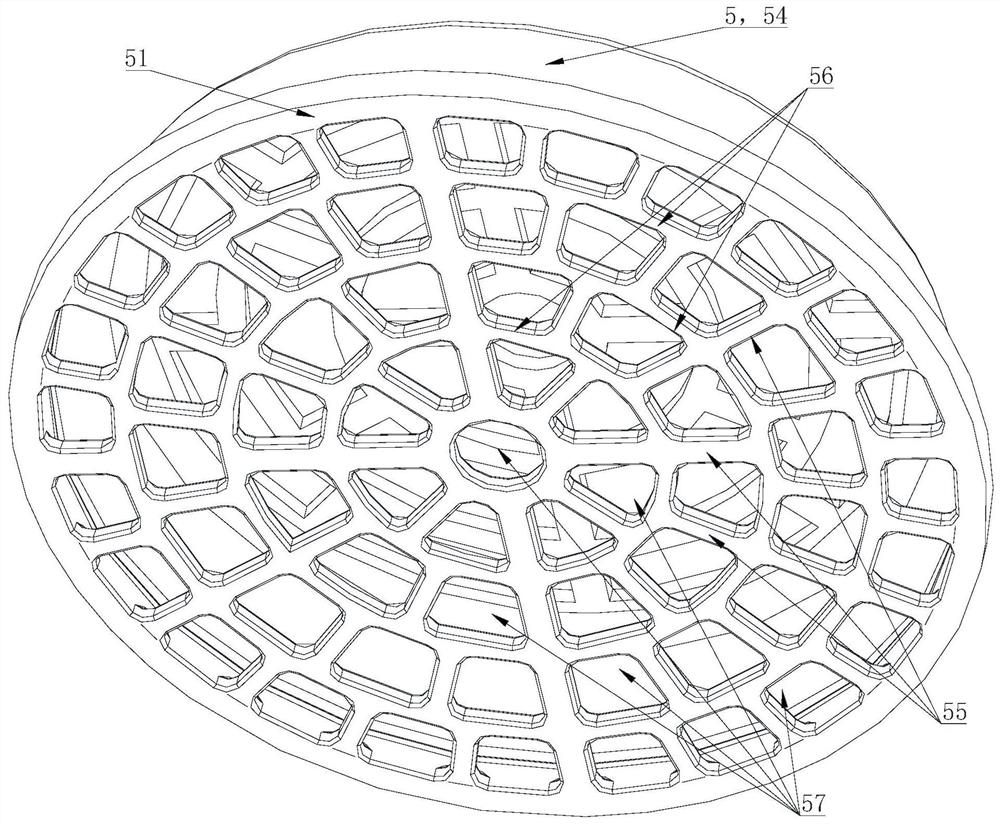

[0054] like Figure 1 to Figure 4 As shown in the figure, a ventilation module 5 is introduced in this embodiment, which includes a casing 54, the casing 54 encloses a hollow channel 53, the two ends of the channel 53 are respectively arranged with retaining ribs, and the retaining ribs separate the two ends of the channel 53 into A plurality of hollow holes 57 are provided, and each hollow hole 57 communicates the inside and outside of the channel 53 respectively.

[0055] Through the above arrangement, the two sides of the ventilation module 5 can be connected through the hollow holes 57 of the communication channels at both ends, so that the airflow on both sides of the ventilation module 5 can flow through the channel, and the gas on both sides can be freely exchanged under the action of the pressure difference. The purpose of flow; at the same time, a plurality of hollow holes 57 arranged at intervals are arranged at the end of the ventilation module 5, so that the airflo...

Embodiment 2

[0076] like Figure 1 to Figure 5 As shown, this embodiment introduces a door body structure of a clothes treatment device, which includes a door body 6, one side of the door body 6 is provided with an outwardly protruding air guide groove 60, and the air guide groove 60 protrudes The end is open, and the opening constitutes an air outlet 62 , and the outer peripheral side of the air guide groove 60 is provided with an air inlet 61 constituted by a radial opening.

[0077] By arranging the above-mentioned air guide grooves 60 on the door body 6 of the clothes treatment device, the external air flow can be led into the drum 3 through the air guide grooves 60, so as to achieve the obvious air flowability of the clothes treatment device during the drying process. At the same time, by arranging the above-mentioned air guide grooves 60 on the door body 6, a significant technical progress can be achieved by using the door body 6 to guide the airflow and improve the air inlet efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com