Grate etching method

An over-etching and gas technology, applied in the field of gate etching, can solve the problems of large gas flow, difficulty in forming a uniform gas flow distribution, poor gas fluidity, etc., and achieve the effect of improving gas flow uniformity, reducing consumption costs and avoiding variables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

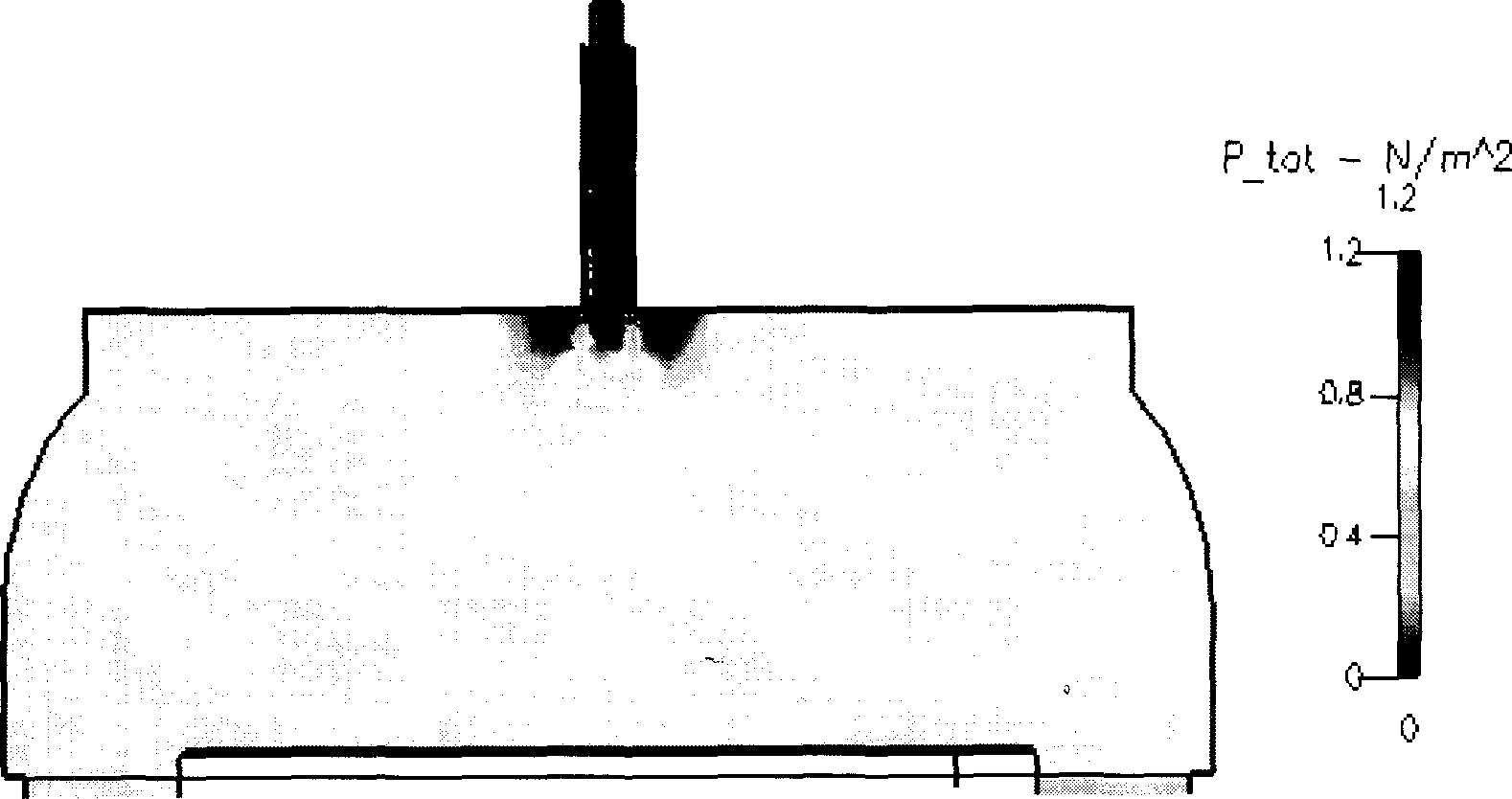

[0026] In the 300mm etching chamber, 20sccm Cl is injected in the main etching step 2 , 250sccmHBr, 10sccmO 2 , 80sccm He, 100sccm N 2 The composition of mixed gas a, gas simulation distribution state see figure 1 .

[0027] The silicon etching equipment used is the North Microelectronics 300mm principle machine, which adopts a single-zone nozzle design, and the nozzle angle is 100-150 degrees.

[0028] The silicon wafer structure used is: silicon wafer = "silicon dioxide (10-100 angstroms) = "polysilicon (1700-2500 angstroms) = "silicon dioxide (100-150 angstroms) = "silicon oxynitride (200-300A ). (The etching pattern has been transferred from the photoresist to the hard mask, that is, the silicon dioxide / silicon oxynitride double layer structure)

[0029] In the etching process, the silicon wafer is first introduced into the etching reaction chamber, and is fixed by the electrostatic chuck. The temperature of the chamber is controlled at 60 degrees Celsius, and the sil...

Embodiment 2

[0035] According to the method described in Example 1, the difference is that, in the main step, pass through 50sccm Cl 2 , 230sccm HBr, 15sccm O 2 , and 150sccm He on the mixed gas, the power of the RF power supply is 400-500W, and the process time is 80-105s.

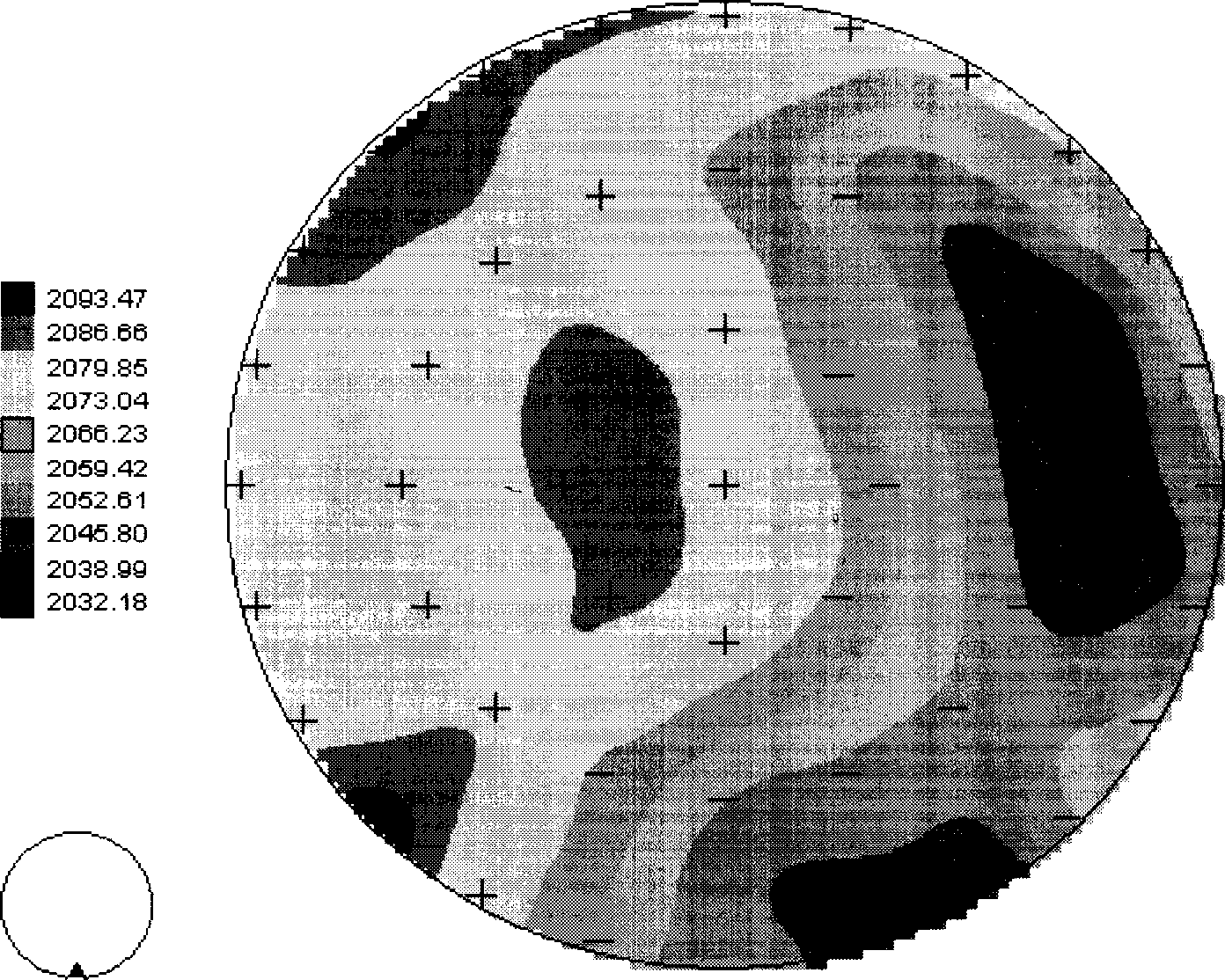

[0036] In the main step gas simulation, the gas flow uniformity on the surface of the silicon wafer is very high, which is 0.5-0.6 Pa. However, because the He gas plasma ignition ability is relatively weak and the plasma concentration is medium, in the actual process, the power of the upper RF power supply is 400 ~500W, the process time is longer, 80~105s. In the final etching result, the etching uniformity of the silicon wafer is as high as 1.80-2.10 (3 Sigma), which can fully meet the needs of the 300mm advanced etching process even without the use of hardware configurations such as dual-zone nozzles to improve the uniformity of the gas flow.

Embodiment 3

[0038] According to the method described in Example 1, the difference is that, in the main step, pass through 50sccm Cl 2 , 230sccm HBr, 15sccm O 2 、150sccmN 2 Composed of gas mixtures. The power of the upper RF power supply is 300-350W, and the process time is 45-65s.

[0039] The gas simulation of the main step, the uniformity of the gas flow on the surface of the silicon wafer is 0.6-0.8Pa, which is better. N2 gas plasma has strong ignition ability and high plasma concentration. Therefore, in the actual process, the power of the upper RF power supply is only 300-350W to maintain the normal etching process, and the process time is very short, 50-65s. The final etching result shows that the etching uniformity of silicon wafers is 2.65-2.90 (3 Sigma), which can basically meet the needs of 300mm advanced etching process when hardware configurations such as dual-zone nozzles are not used to improve airflow uniformity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com