Patents

Literature

79results about How to "Small total thermal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

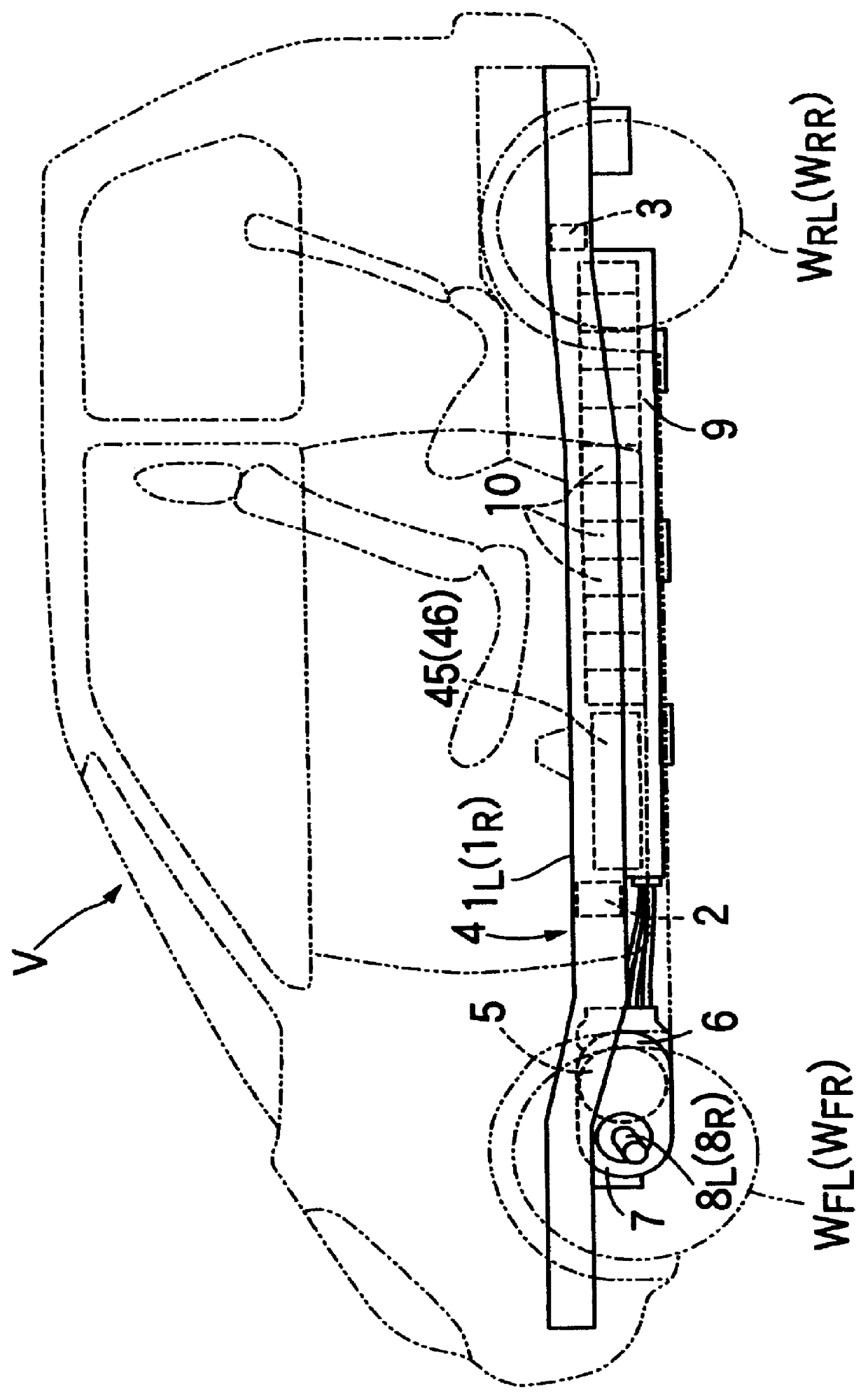

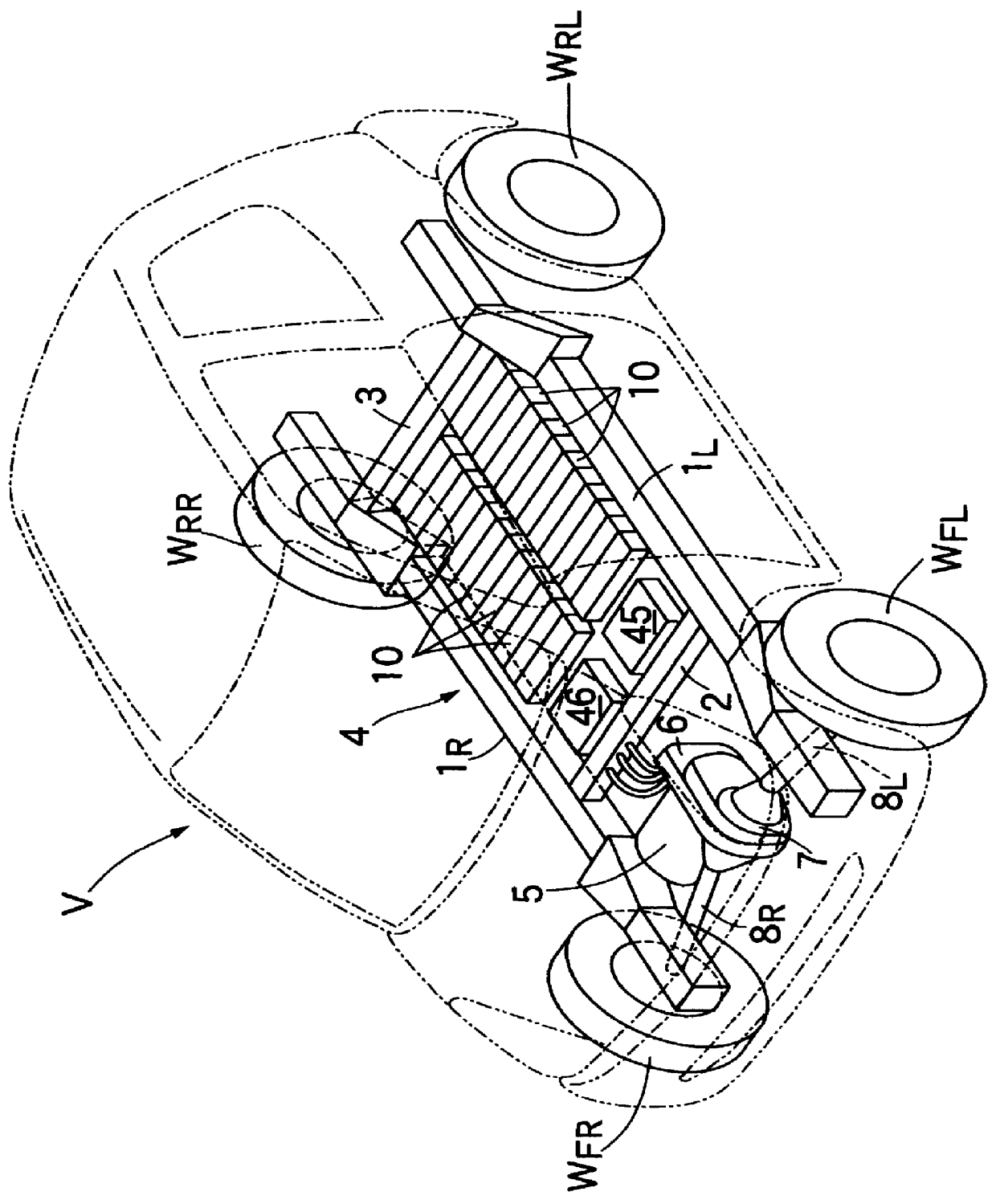

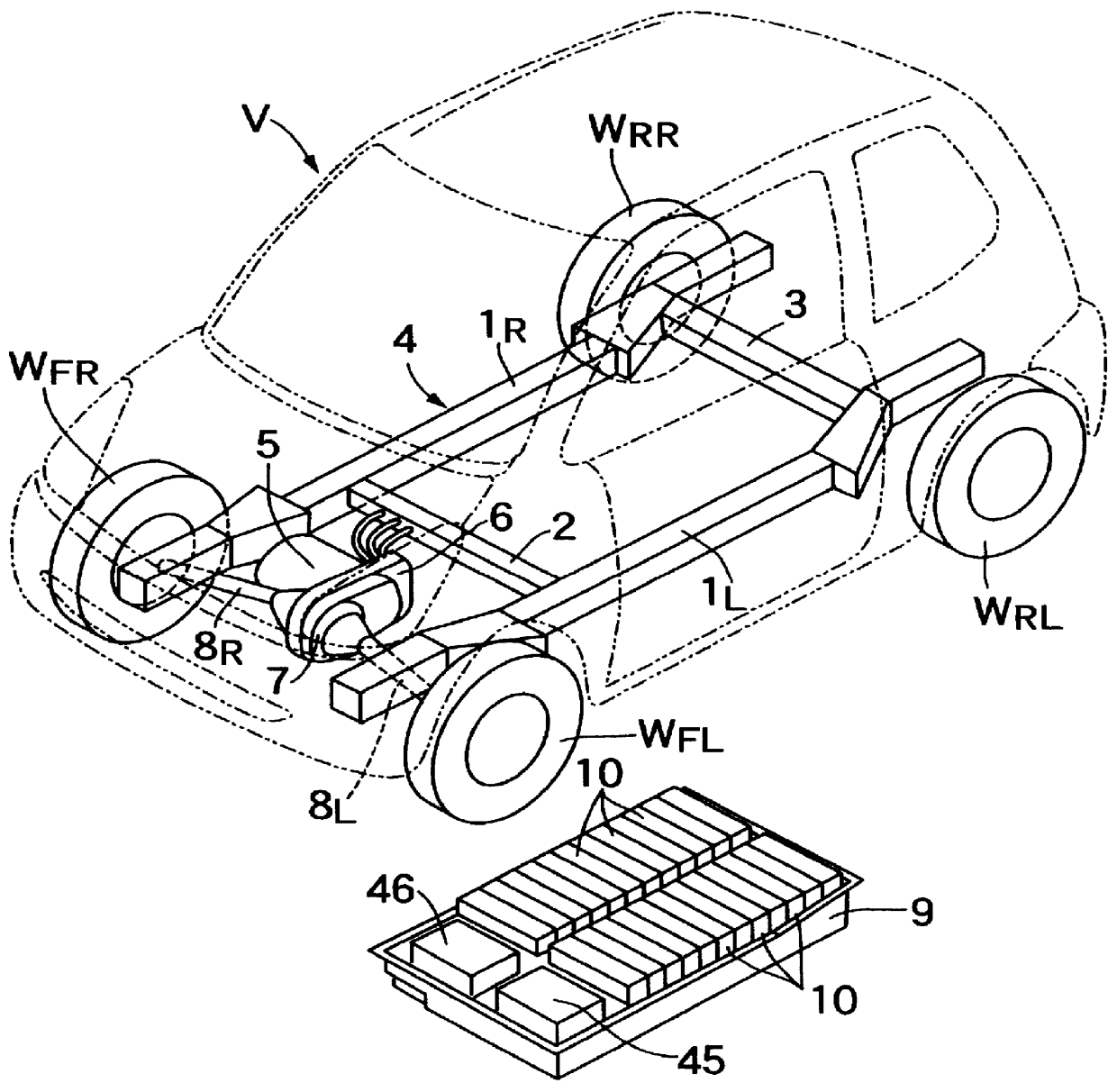

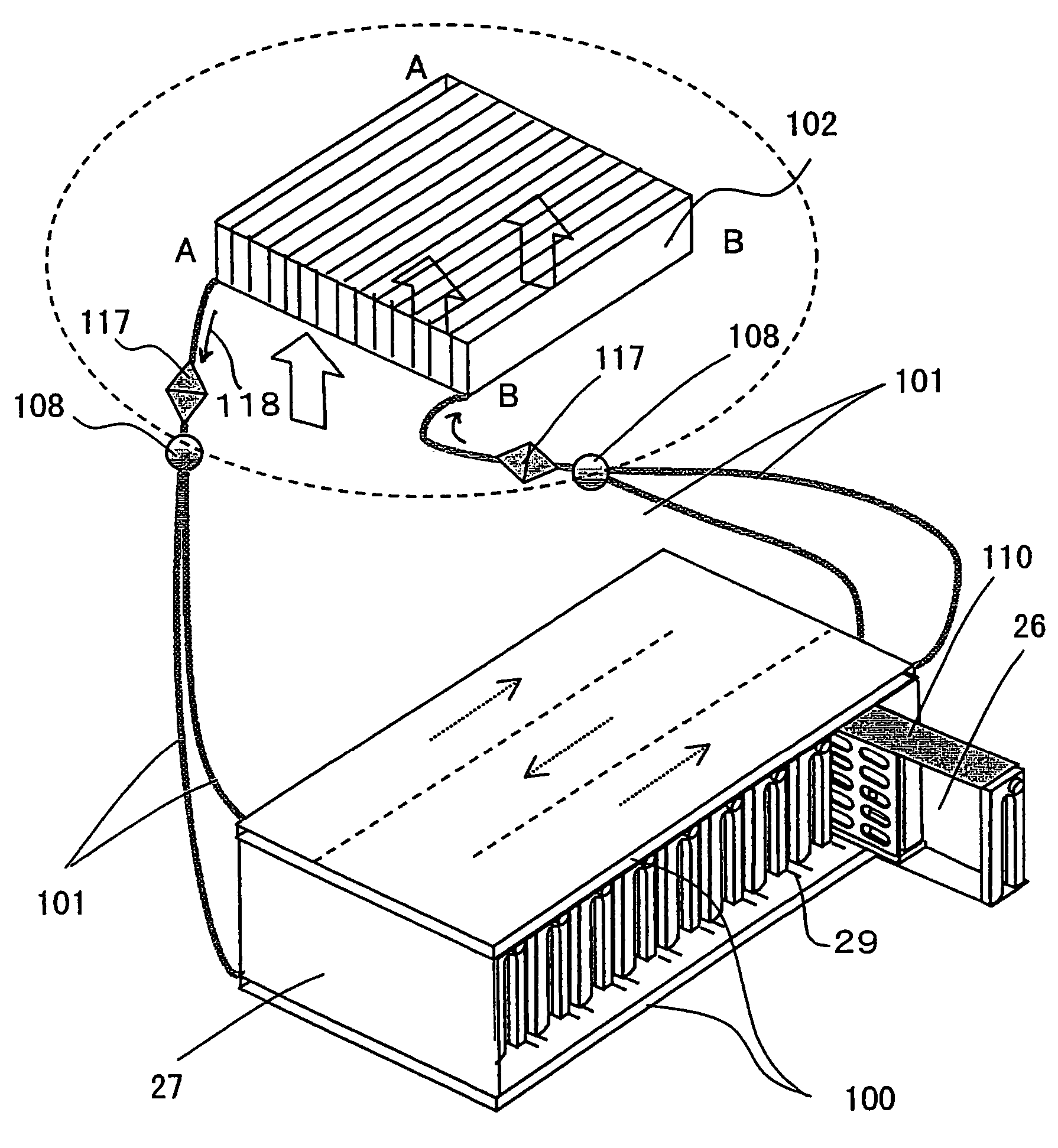

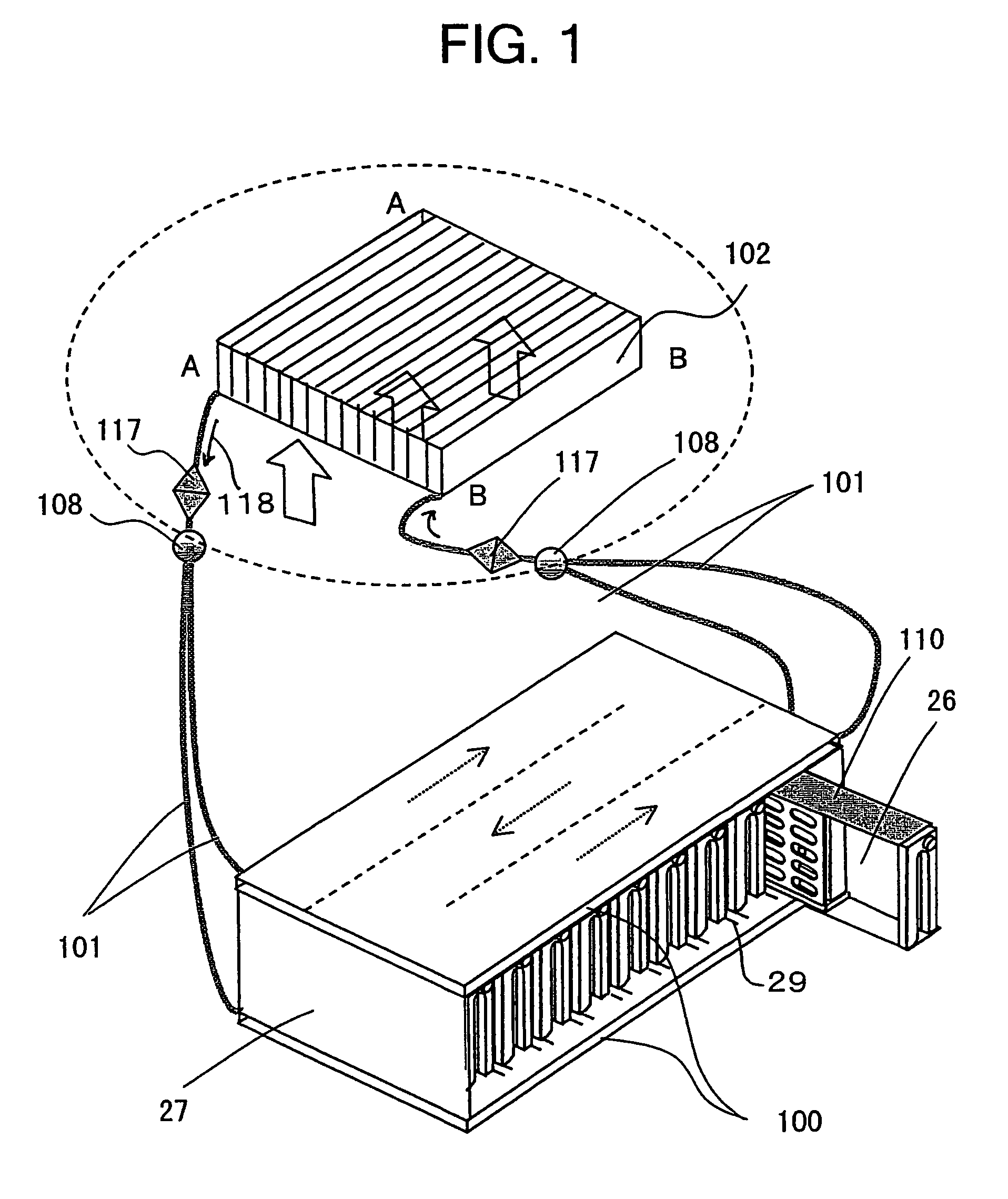

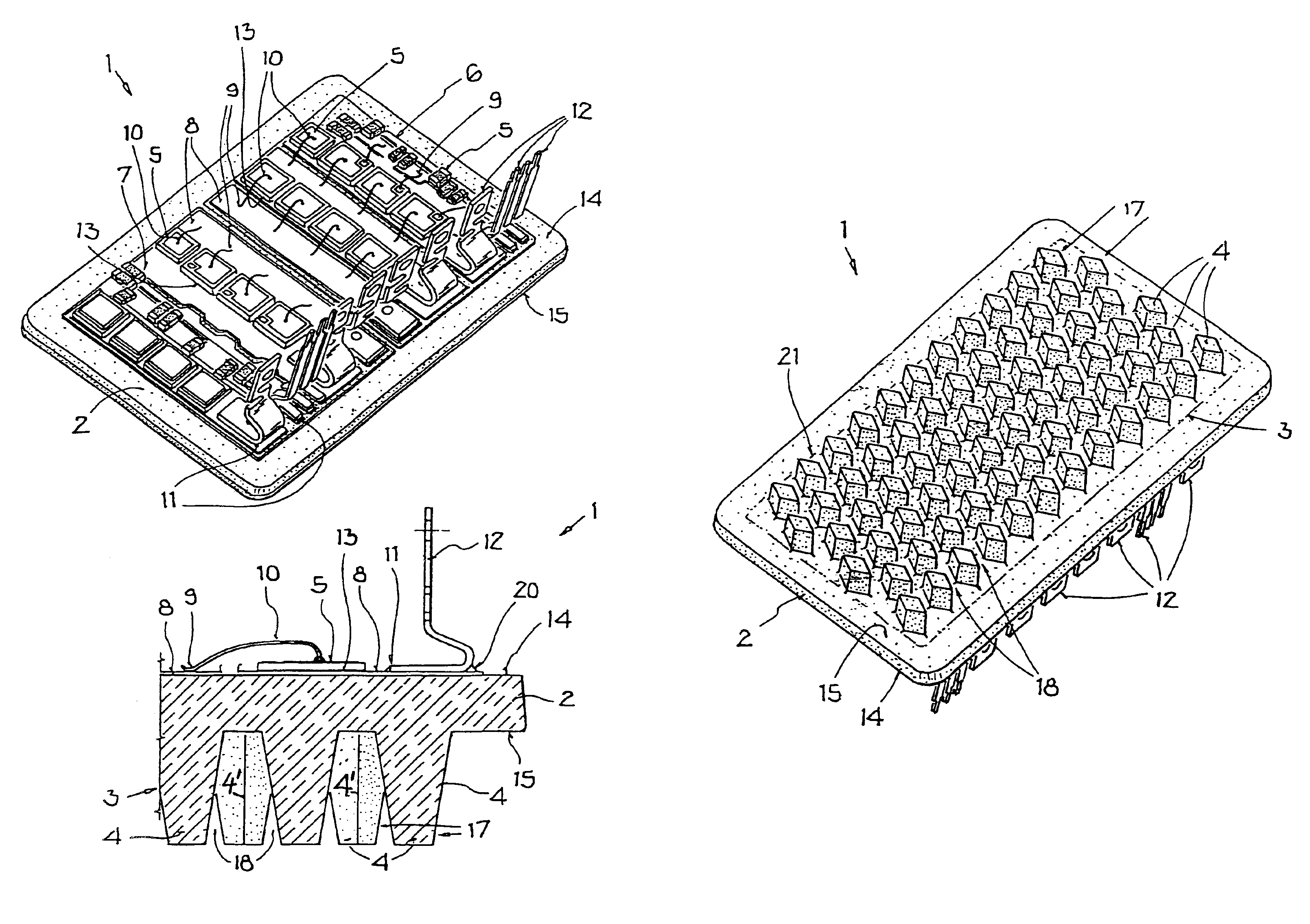

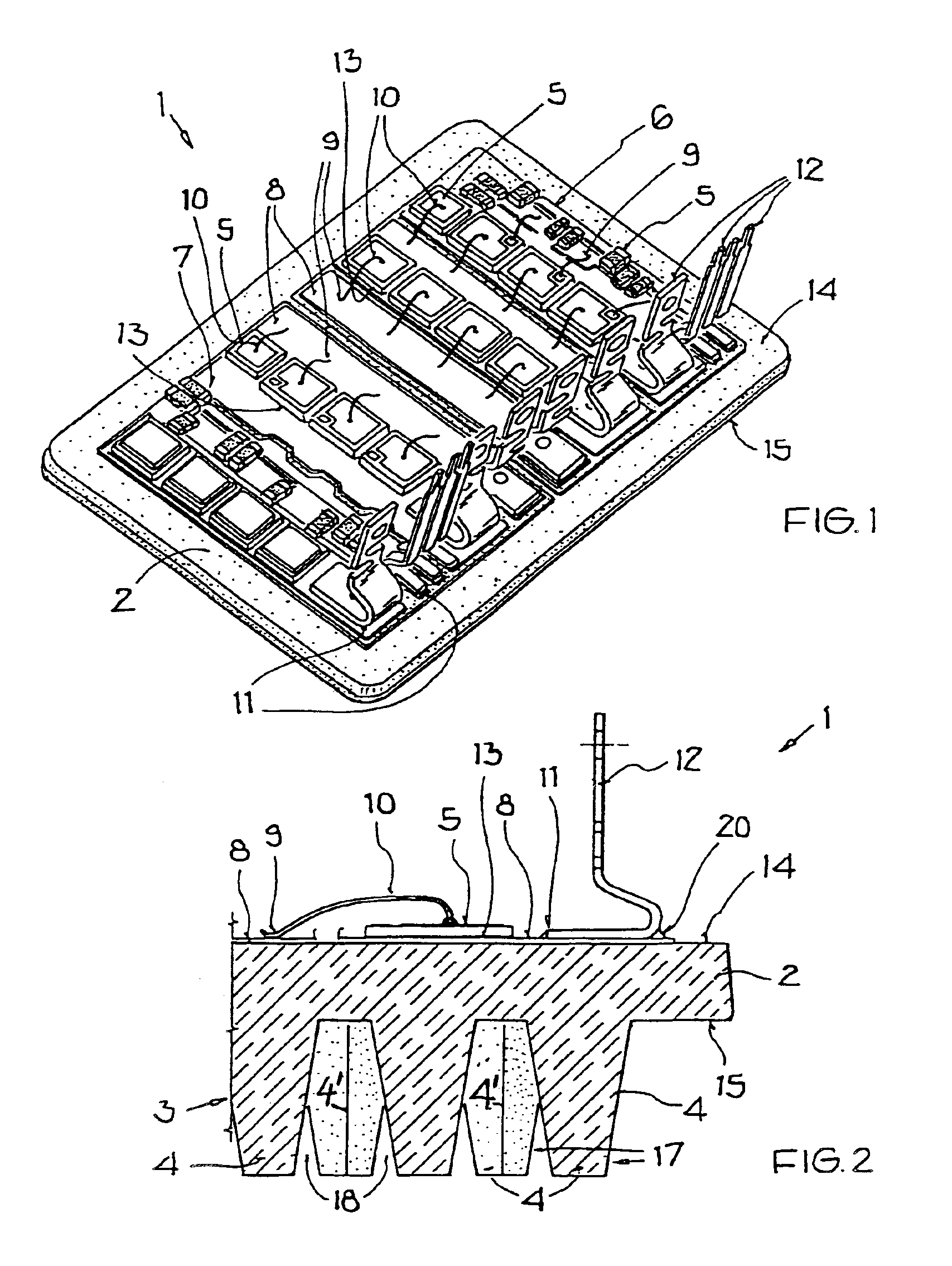

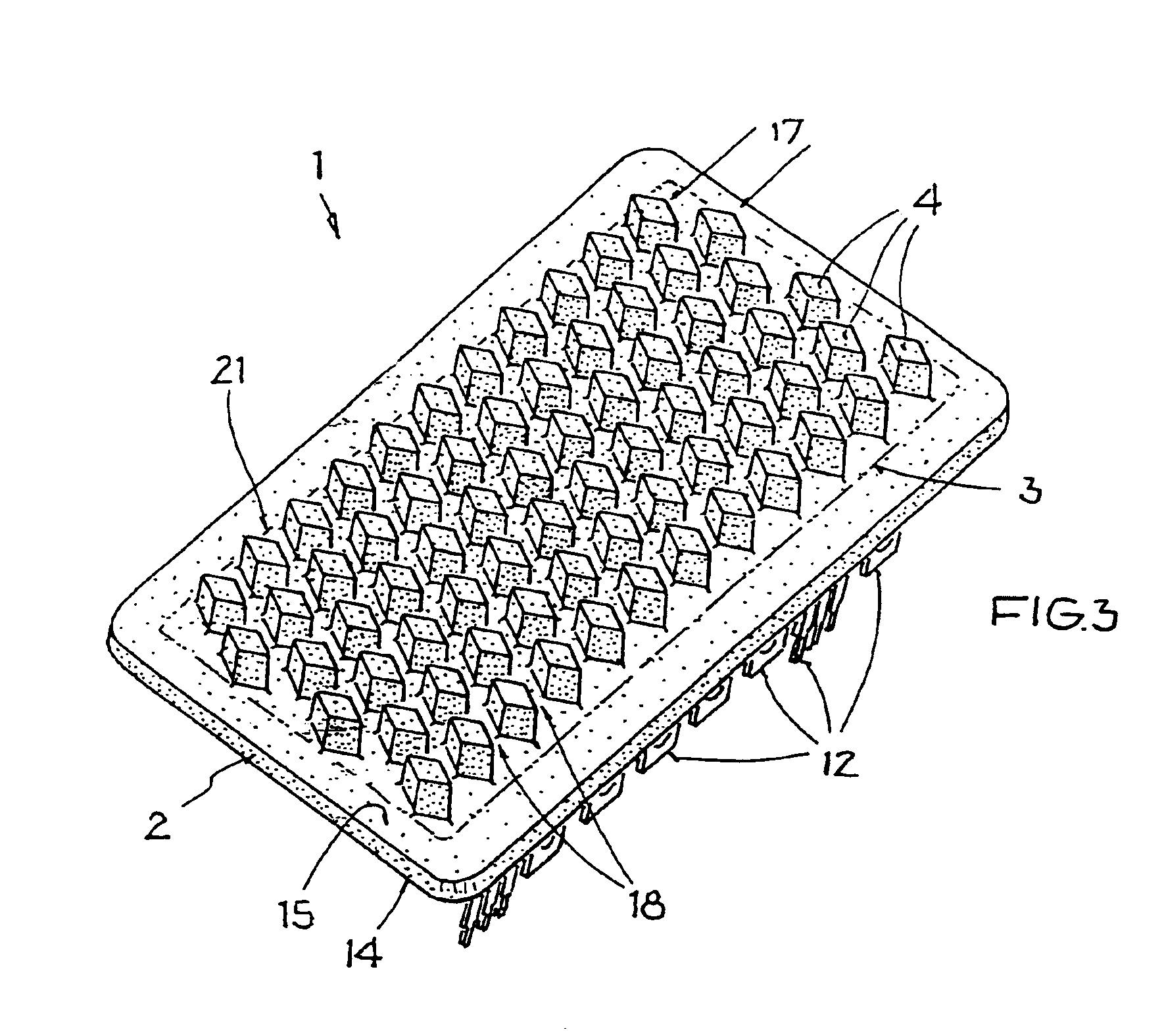

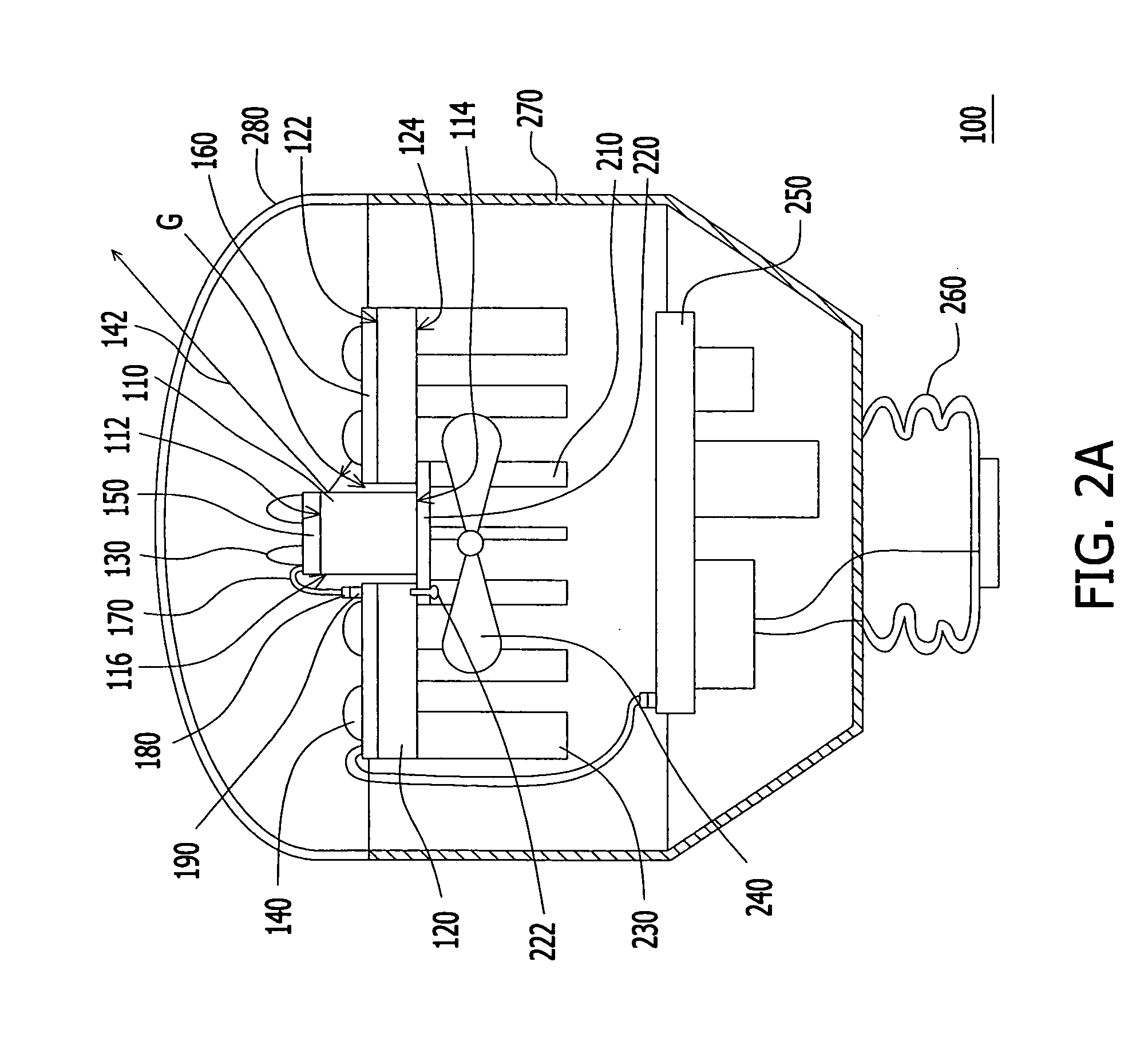

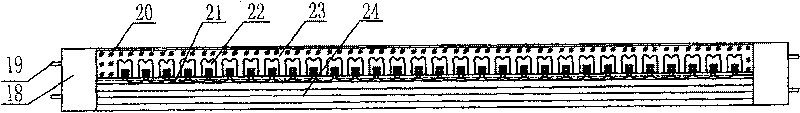

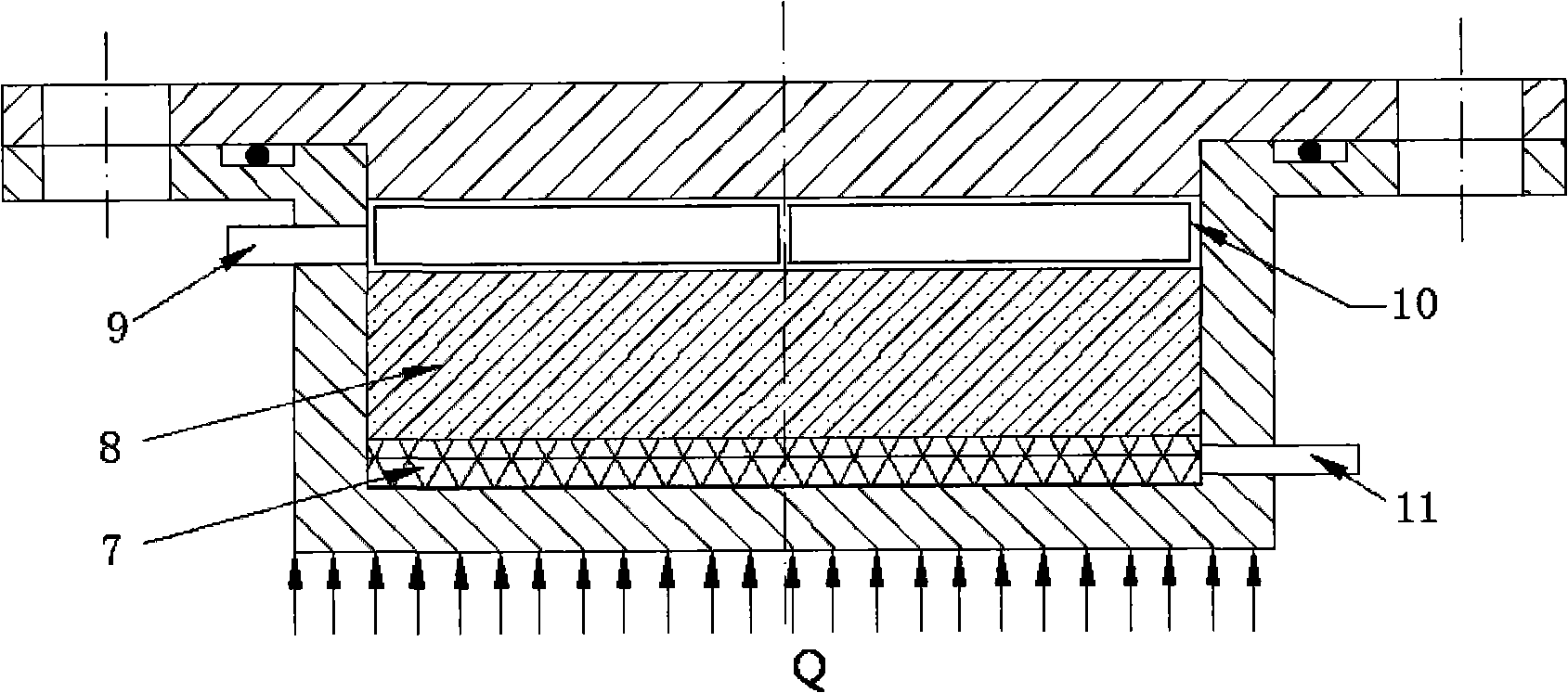

Cooling structure an electric vehicle

InactiveUS6094927AReliable coolingImprove cooling effectDomestic cooling apparatusLighting and heating apparatusAirflowThermal resistance

An electric vehicle includes plurality of batteries accommodated in a rear portion of a battery box, and an electric part is accommodated in an electric part accommodating chamber provided in a front portion of the battery box. Cooling air supplied from a cooling fan to the rear portion of the battery box cools the batteries having a large thermal resistance, while being passed through a first cooling air passage around outer peripheries of the batteries at a low flow rate. A second cooling air passage having a smaller sectional area than that of the first cooling air passage is provided below the electric part accommodating chamber, and cooling fins protruding downwards from the electric part are exposed within the second cooling air passage. The second cooling air passage extends continuously the first cooling air passage in a downstream direction of airflow, so that cooling air which has first cooled the batteries then cools the electric part having a smaller thermal resistance, while being passed through the second cooling air passage at a higher flow rate than that in the first cooling air passage.

Owner:HONDA MOTOR CO LTD

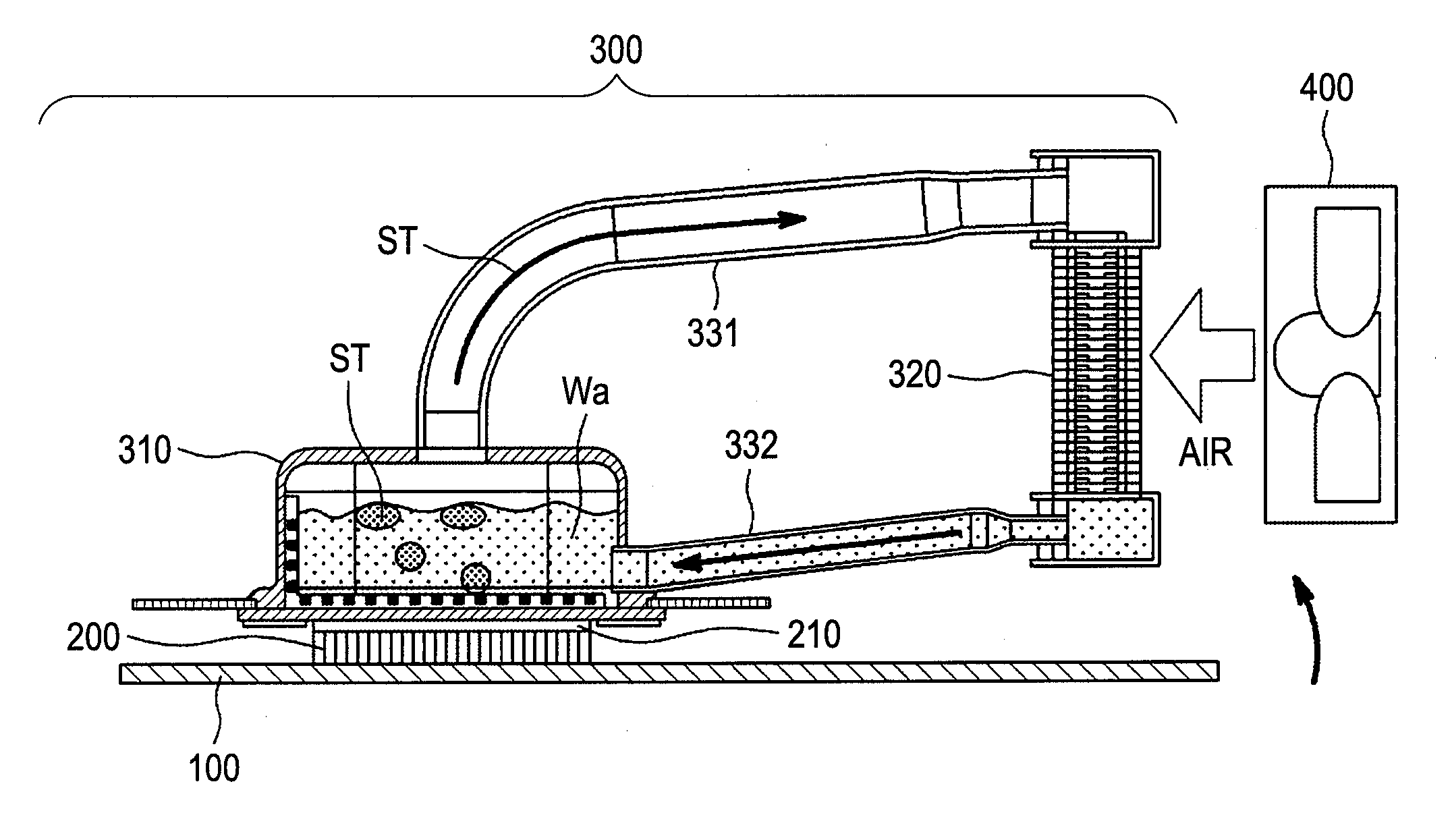

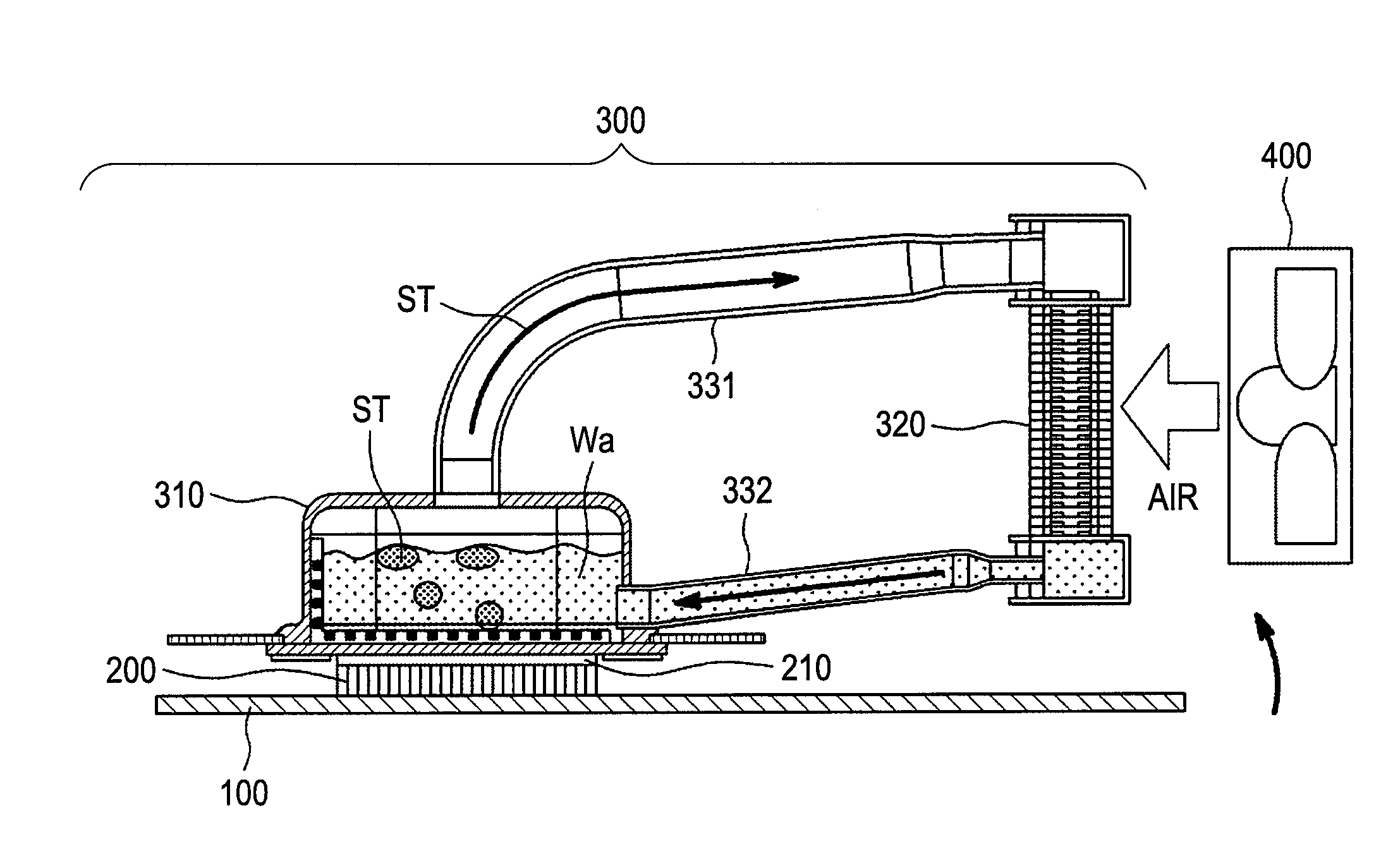

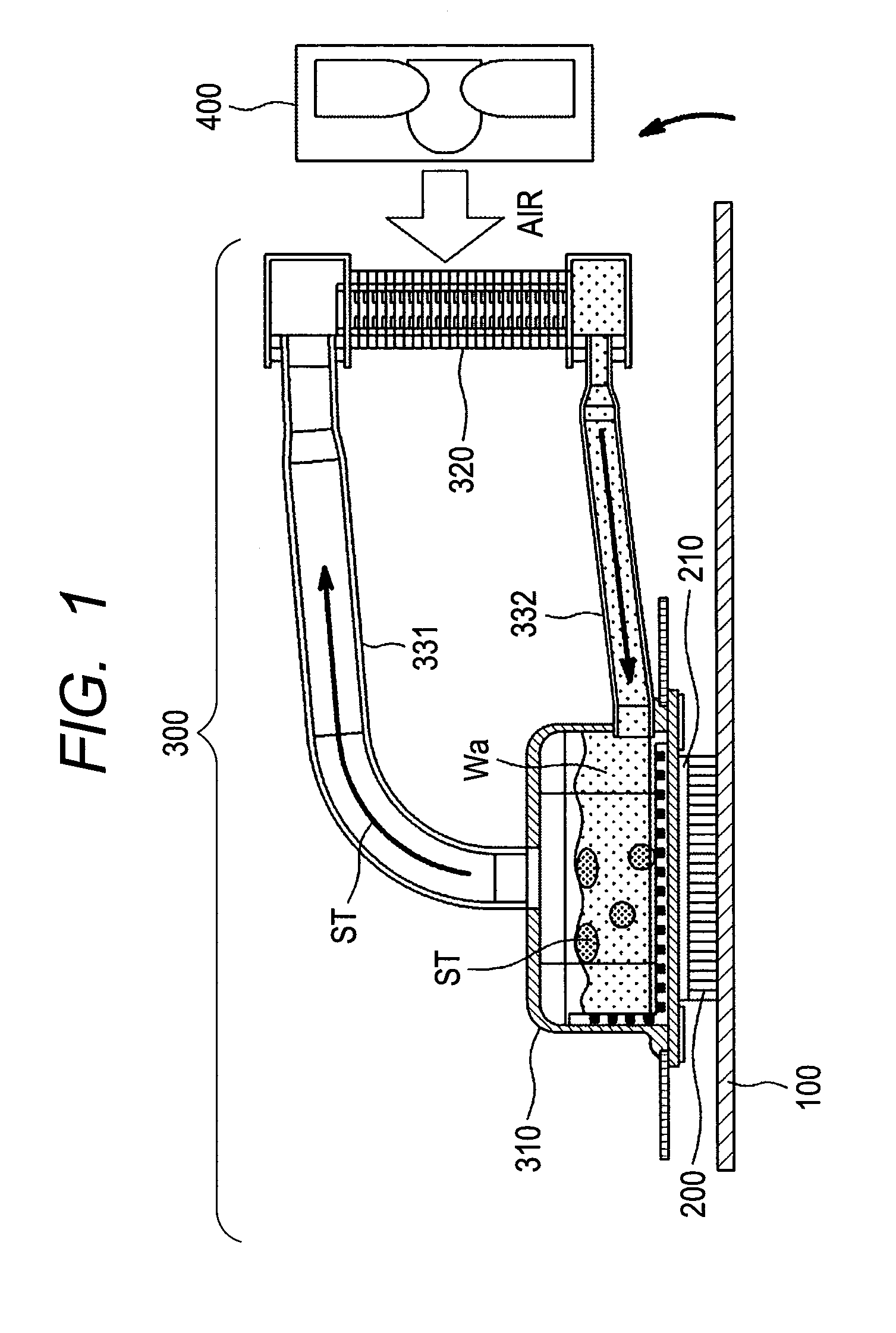

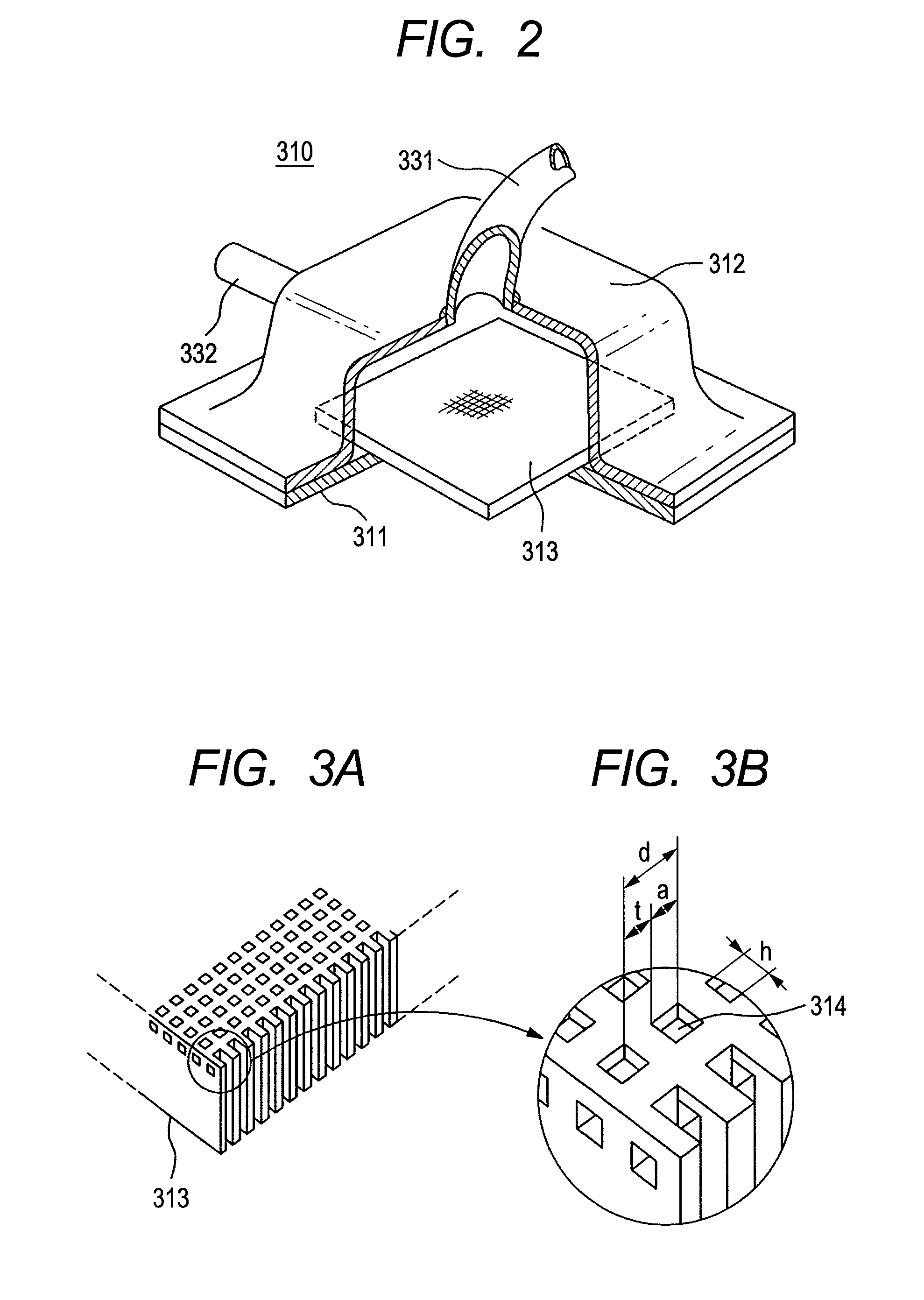

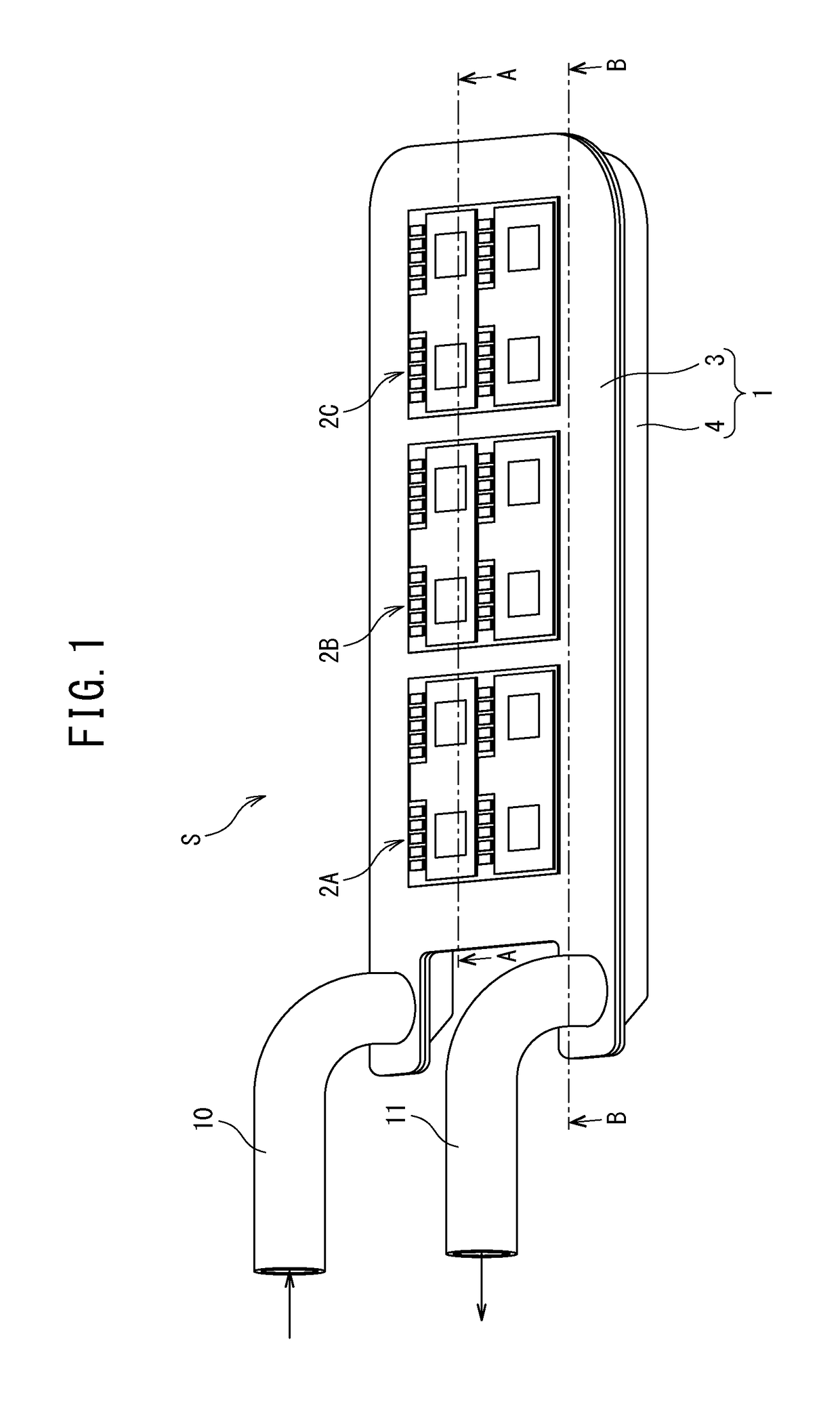

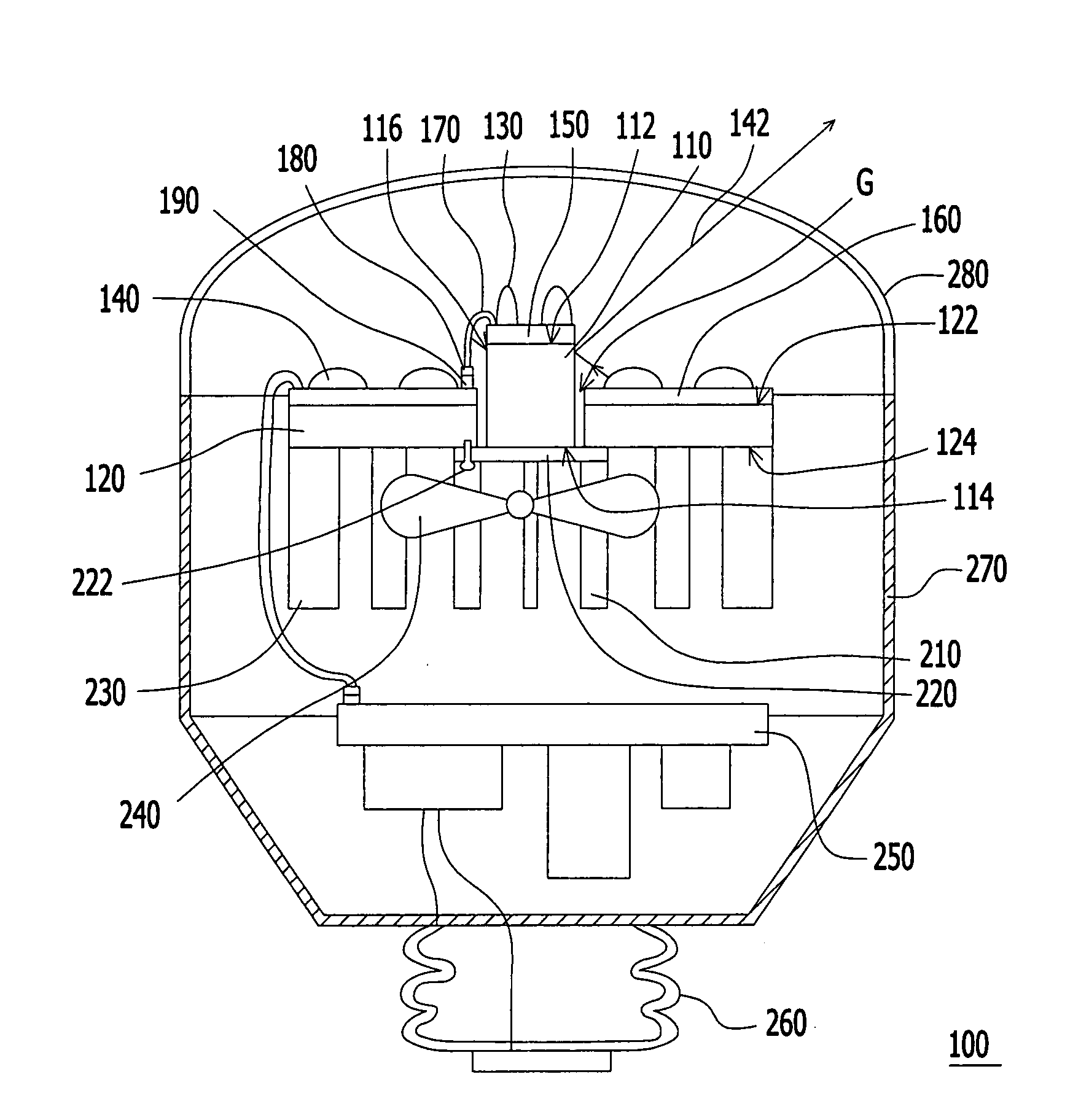

Cooling system and electronic apparatus applying the same therein

ActiveUS20110048676A1Small total thermal resistanceThermal resistanceSemiconductor/solid-state device detailsSolid-state devicesSiphonEngineering

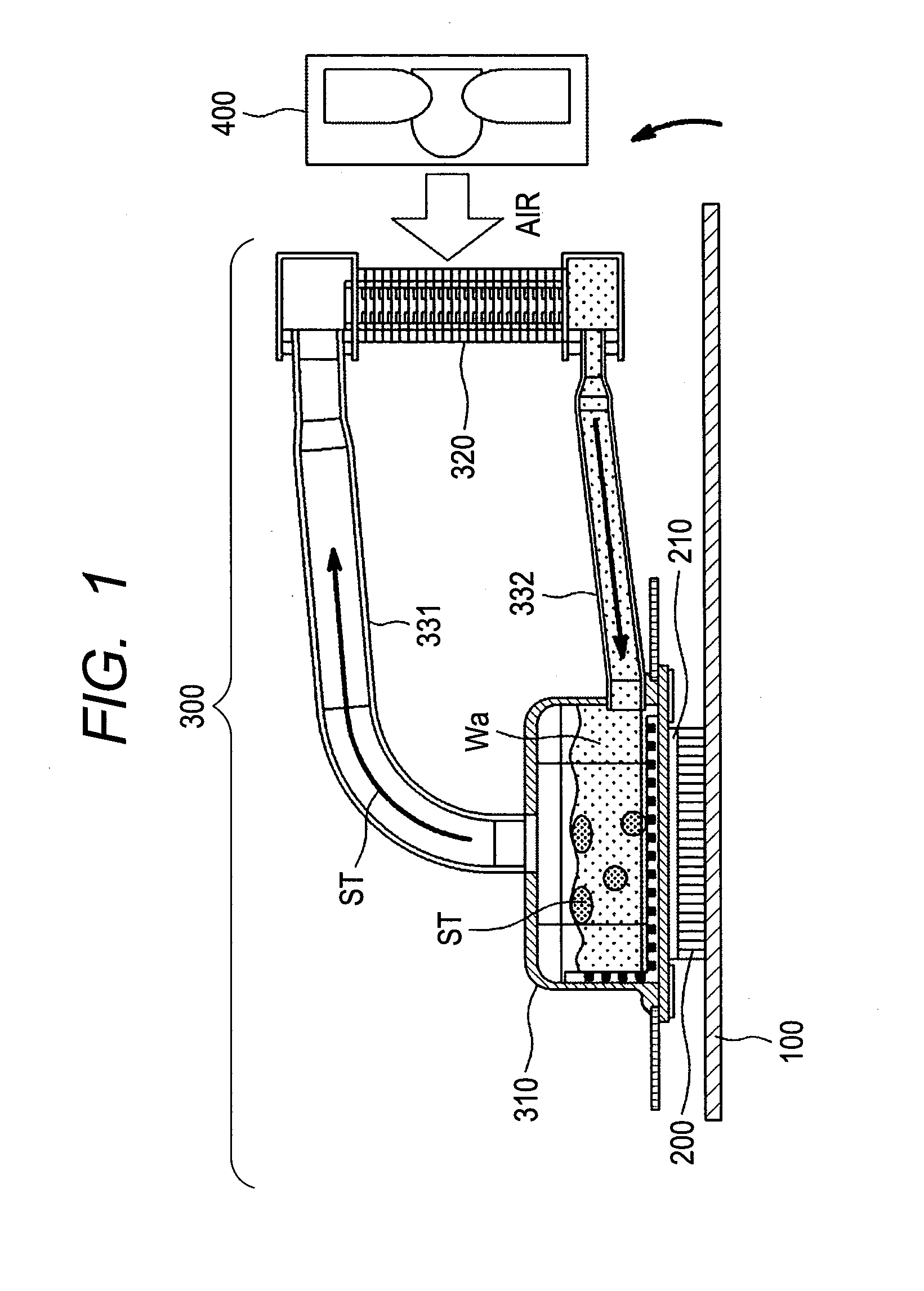

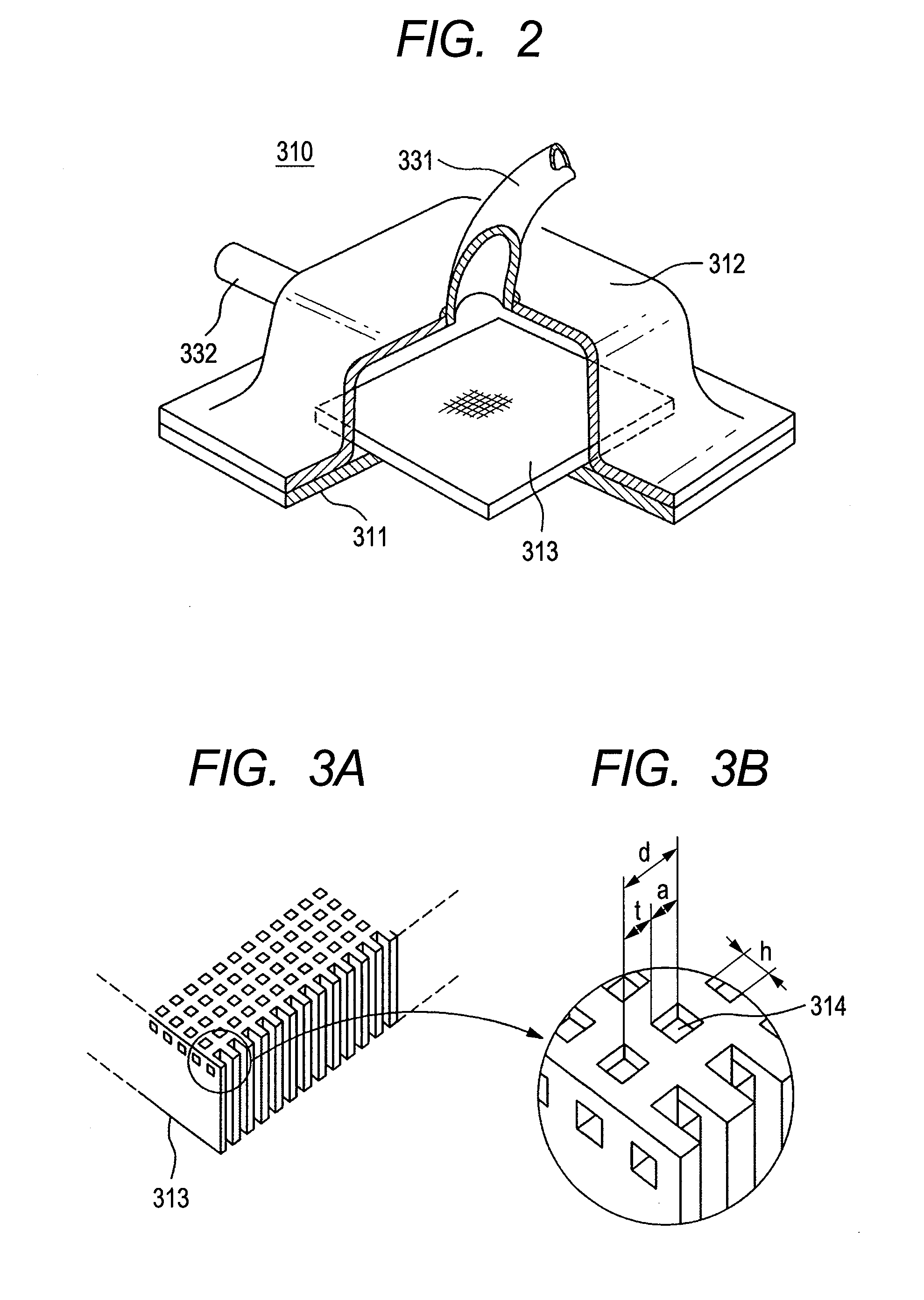

A cooling system applying a thermo siphon therein, being superior in energy saving and / or ecology, with an effective cooling, and also an electronic apparatus applying that therein, in particular, for cooling a CPU 200 mounted on a printed circuit board 100 within a housing thereof, comprises a heat-receiving jacket 310, being thermally connected with a surface of the CPU generating heats therein, and for evaporating liquid refrigerant stored in a pressure-reduced inner space with heat generation thereof, a condenser 320 for receiving refrigerant vapor from the heat-receiving jacket within a pressure-reduced inner space thereof and for condensing the refrigerant vapor into a liquid by transferring the heats into an outside of the apparatus, a vapor tube 331, and a liquid return tube 332, with applying the thermo siphon for circulating the refrigerant due to phase change thereof, wherein the condenser forms fine grooves on an inner wall surface thereof along a direction of flow of the refrigerant, and is also formed flat in a cross-section thereof, for cooling the refrigerant vapor from the heat-receiving jacket on the inner wall surface thereof, efficiently.

Owner:HITACHI LTD

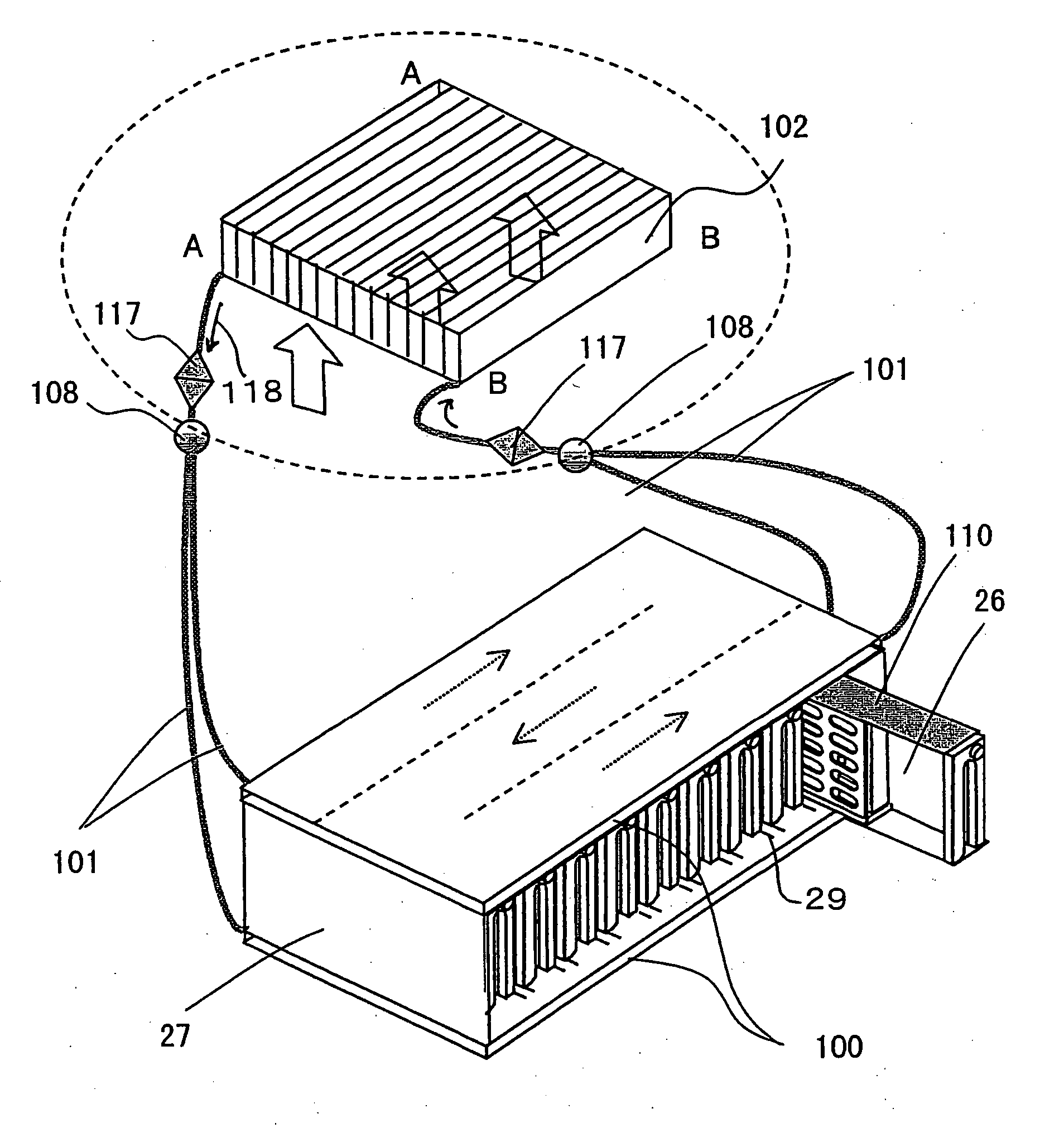

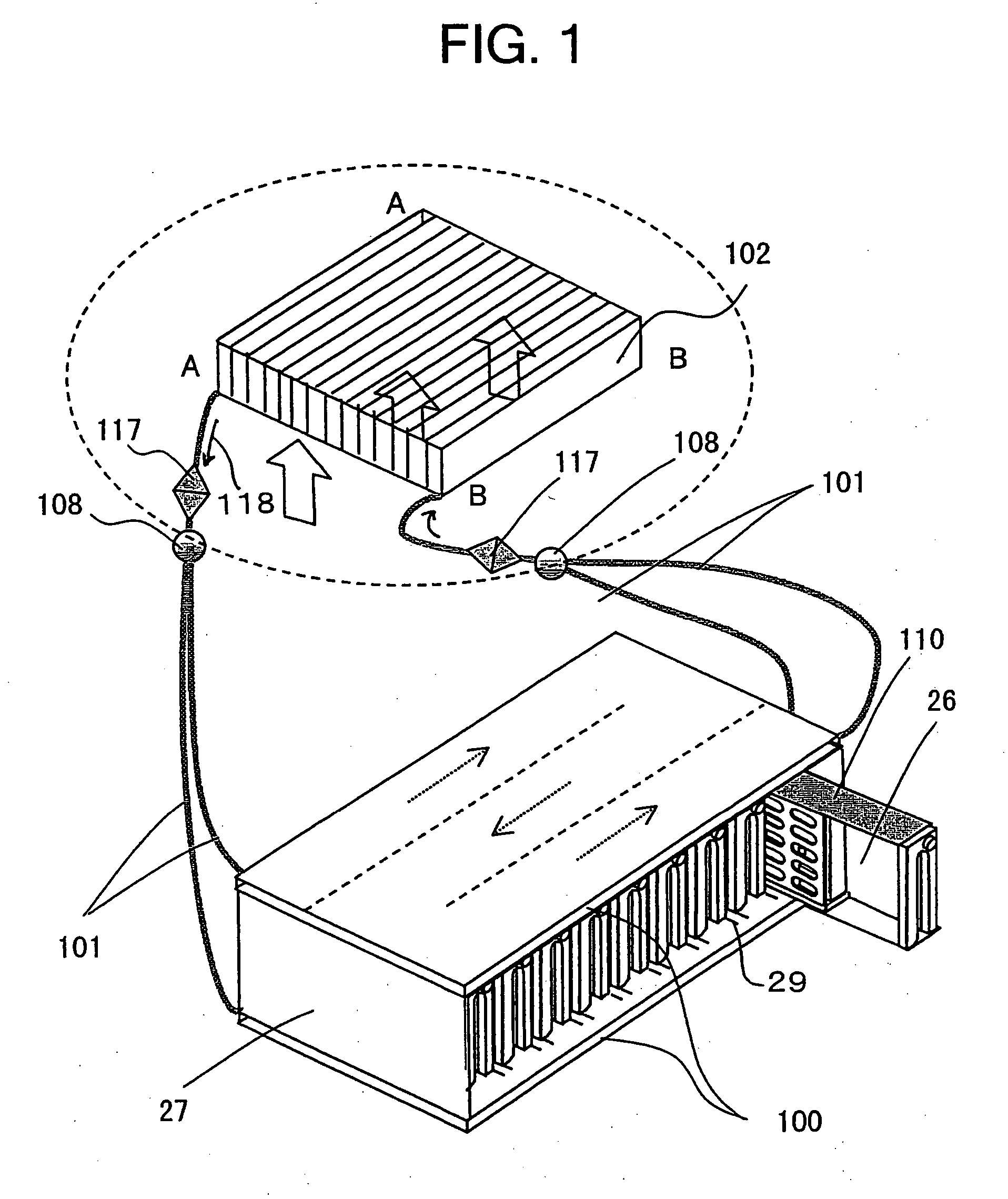

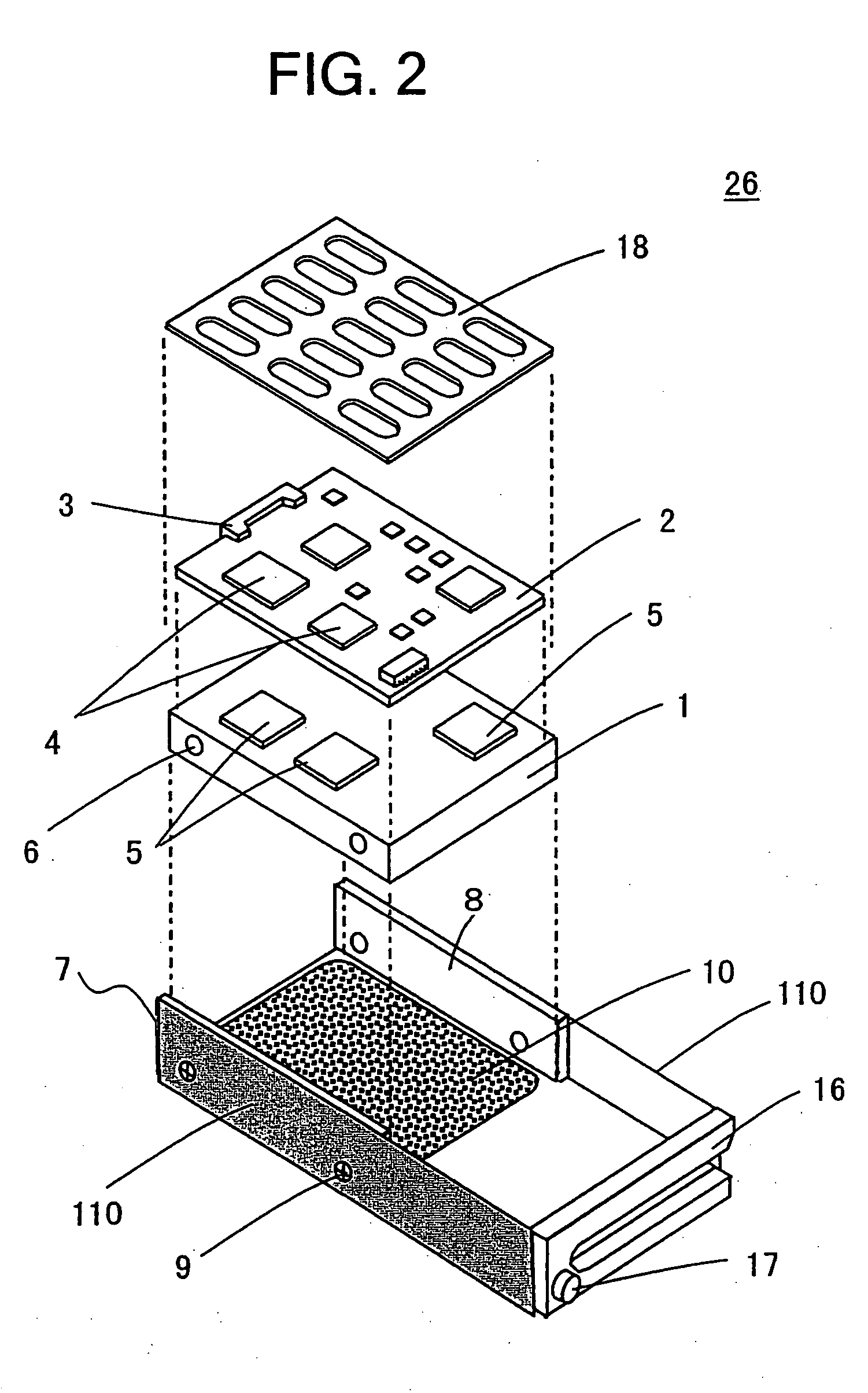

Disk array system

InactiveUS20060077776A1Improve cooling effectImprove reliabilityReducing temperature influence on carrierDigital data processing detailsEngineeringConductive materials

A disk array system includes a plurality of disk drives and at least one unit box including the plurality of disk drives aligned in the thickness direction of the disk drive, each disk drive including a thin case accommodating a recording disk, a read / write head, and a driving mechanism for driving the recording disk and the read / write head, and a control board for controlling the driving mechanism, the control board being mounted on the thin case. In the disk array system, the thin case and the unit box are composed of a thermally-conductive material, the unit box includes surfaces parallel to the thickness direction of the plurality of disk drives, and at least one of the surfaces has a cold plate filled with a refrigerant. Heat generated at the disk drives is transferred to the cold plate, thereby improving cooling performance.

Owner:HITACHI LTD

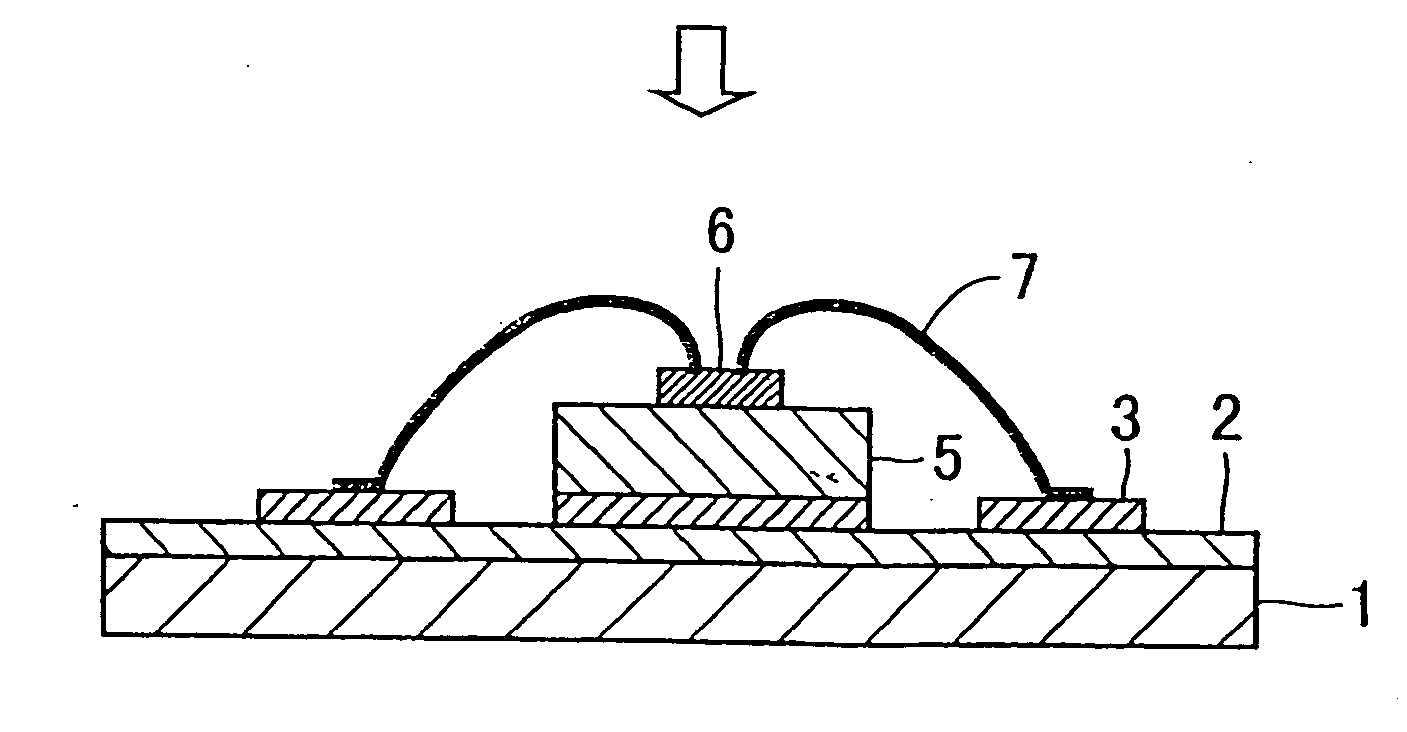

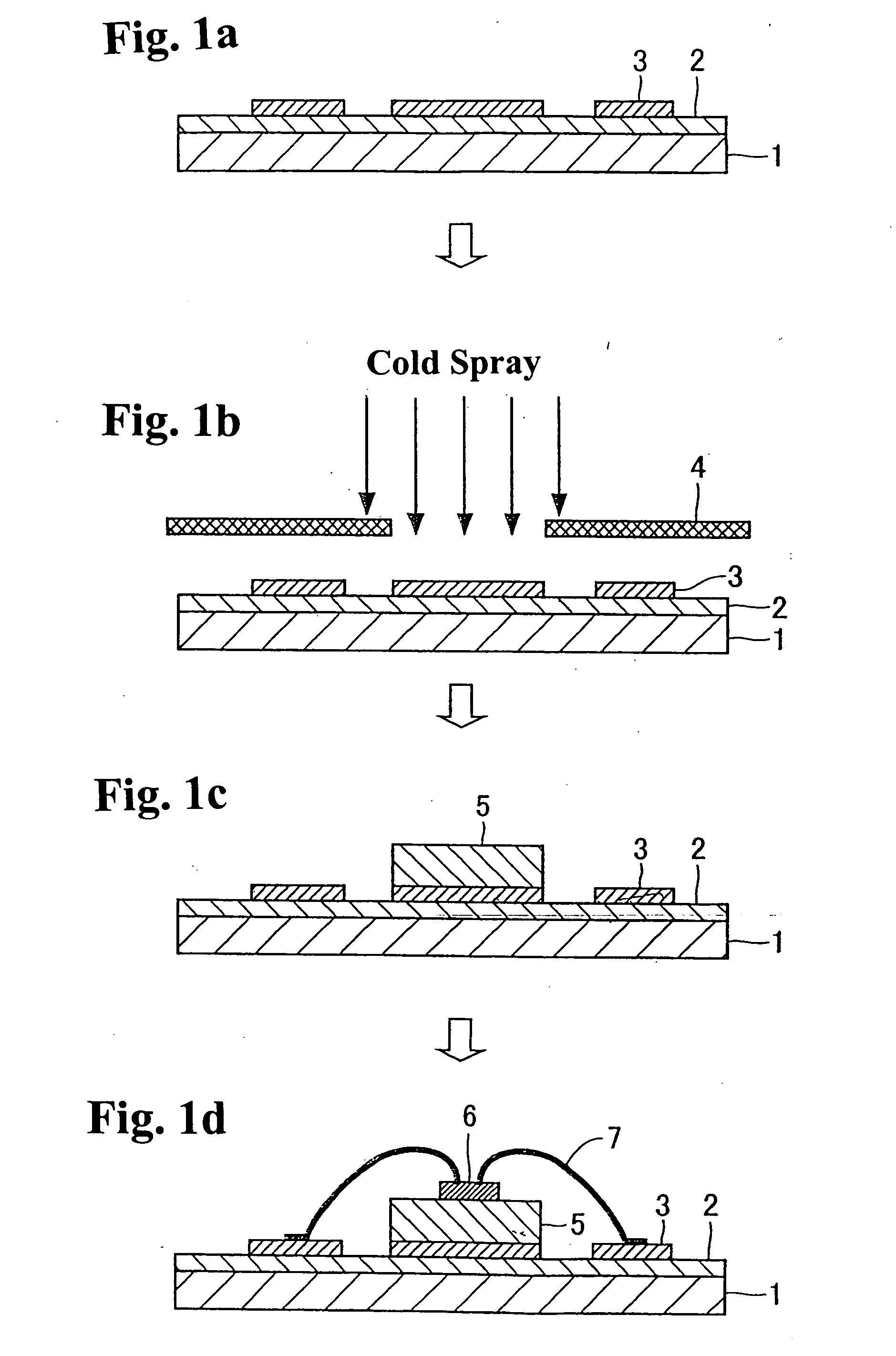

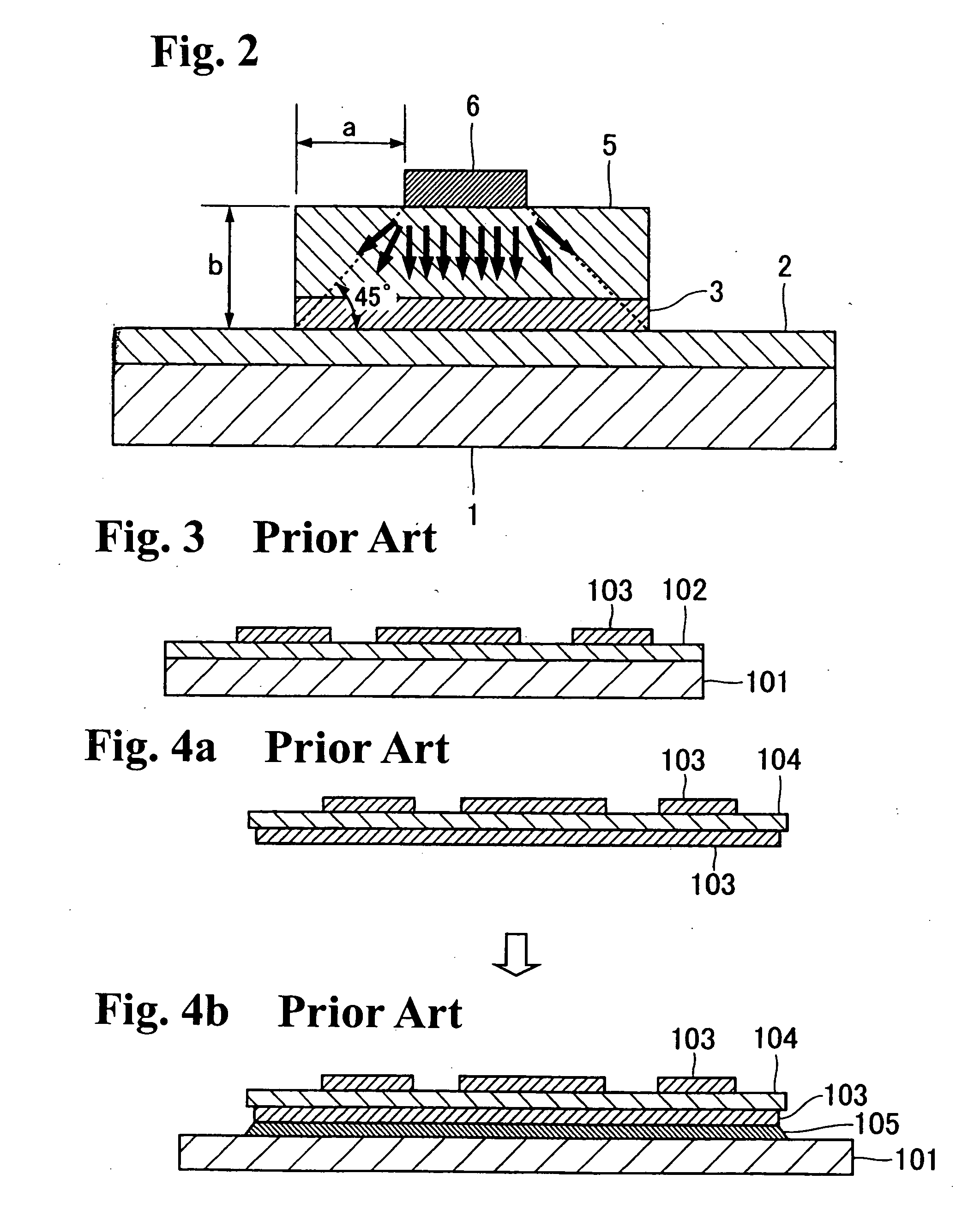

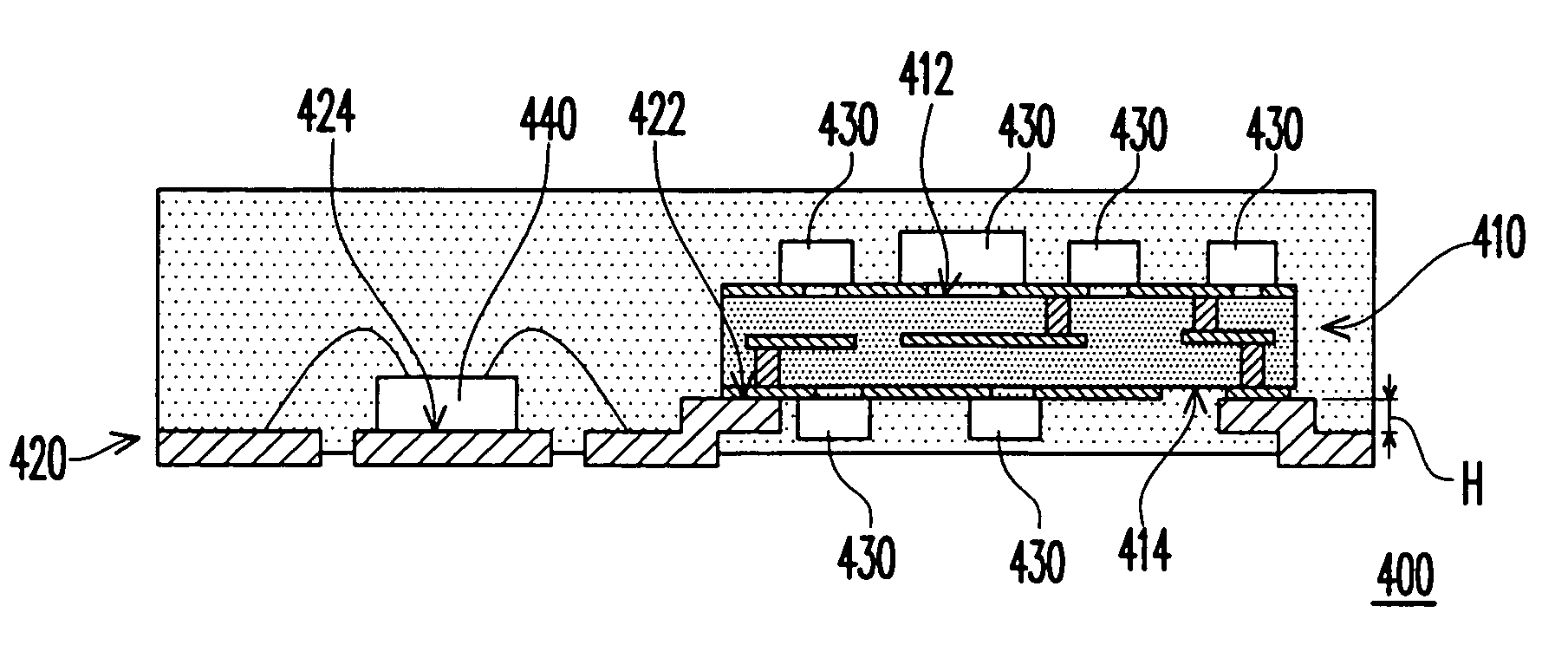

Wiring board and method of manufacturing the same

ActiveUS20060258055A1Improve cooling effectLess thermal resistanceSemiconductor/solid-state device detailsPrinted electric component incorporationMetal foilSemiconductor

A wiring board has a circuit pattern that includes metal foil attached to an insulating layer, and a built-up circuit pattern disposed on top of the metal foil circuit pattern. The built-up circuit pattern is an increased thickness laminate of cold spray processed metal material. Even when a power semiconductor is mounted on the built-up circuit pattern, the heat that is generated by losses therein can be diffused by the built-up circuit pattern. The wiring board has excellent heat dissipation, can be manufactured by a small number of process steps, and is of low cost.

Owner:FUJI ELECTRIC HLDG CO LTD

Disk array system

InactiveUS7675748B2Improve cooling effectImprove reliabilityReducing temperature influence on carrierDigital data processing detailsEngineeringConductive materials

A disk array system includes a plurality of disk drives and at least one unit box including the plurality of disk drives aligned in the thickness direction of the disk drive, each disk drive including a thin case accommodating a recording disk, a read / write head, and a driving mechanism for driving the recording disk and the read / write head, and a control board for controlling the driving mechanism, the control board being mounted on the thin case. In the disk array system, the thin case and the unit box are composed of a thermally-conductive material, the unit box includes surfaces parallel to the thickness direction of the plurality of disk drives, and at least one of the surfaces has a cold plate filled with a refrigerant. Heat generated at the disk drives is transferred to the cold plate, thereby improving cooling performance.

Owner:HITACHI LTD

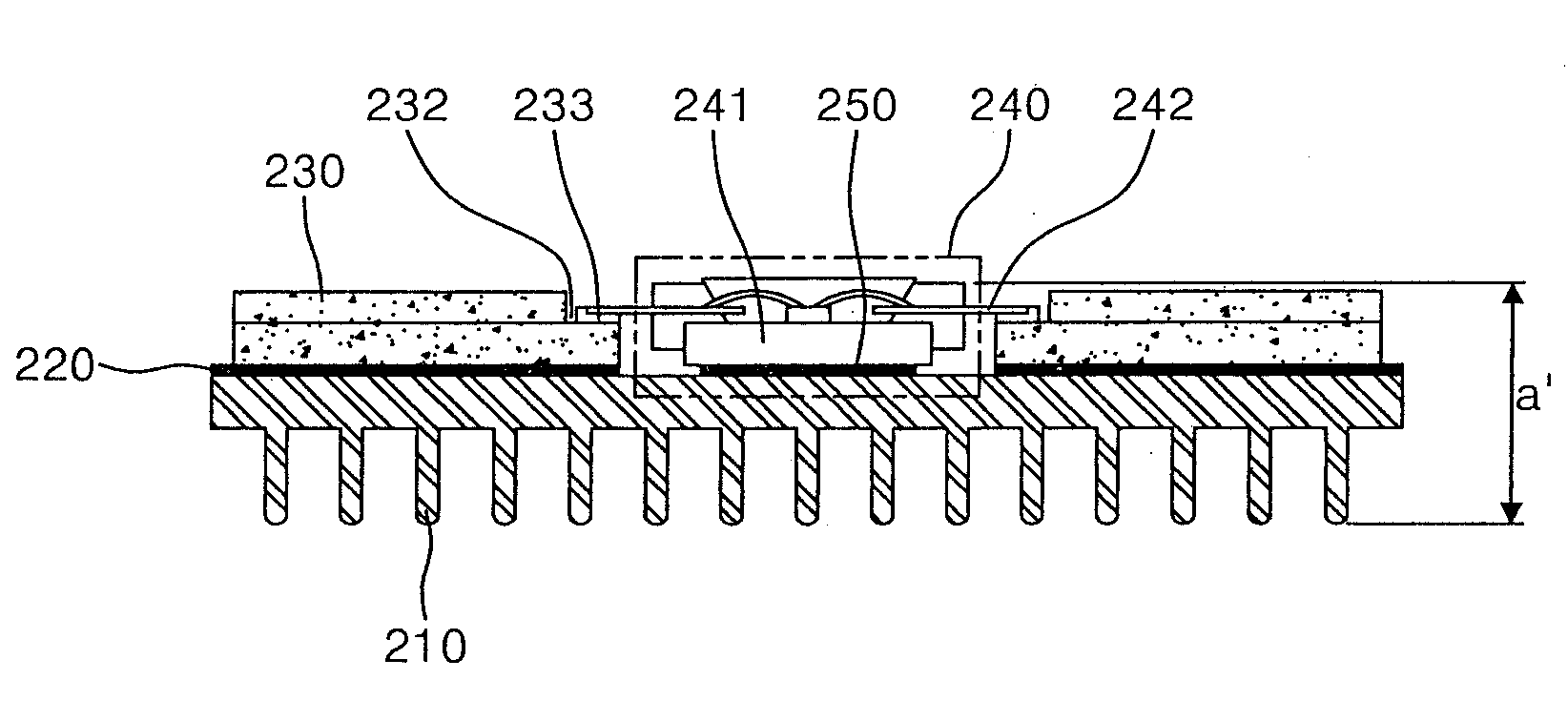

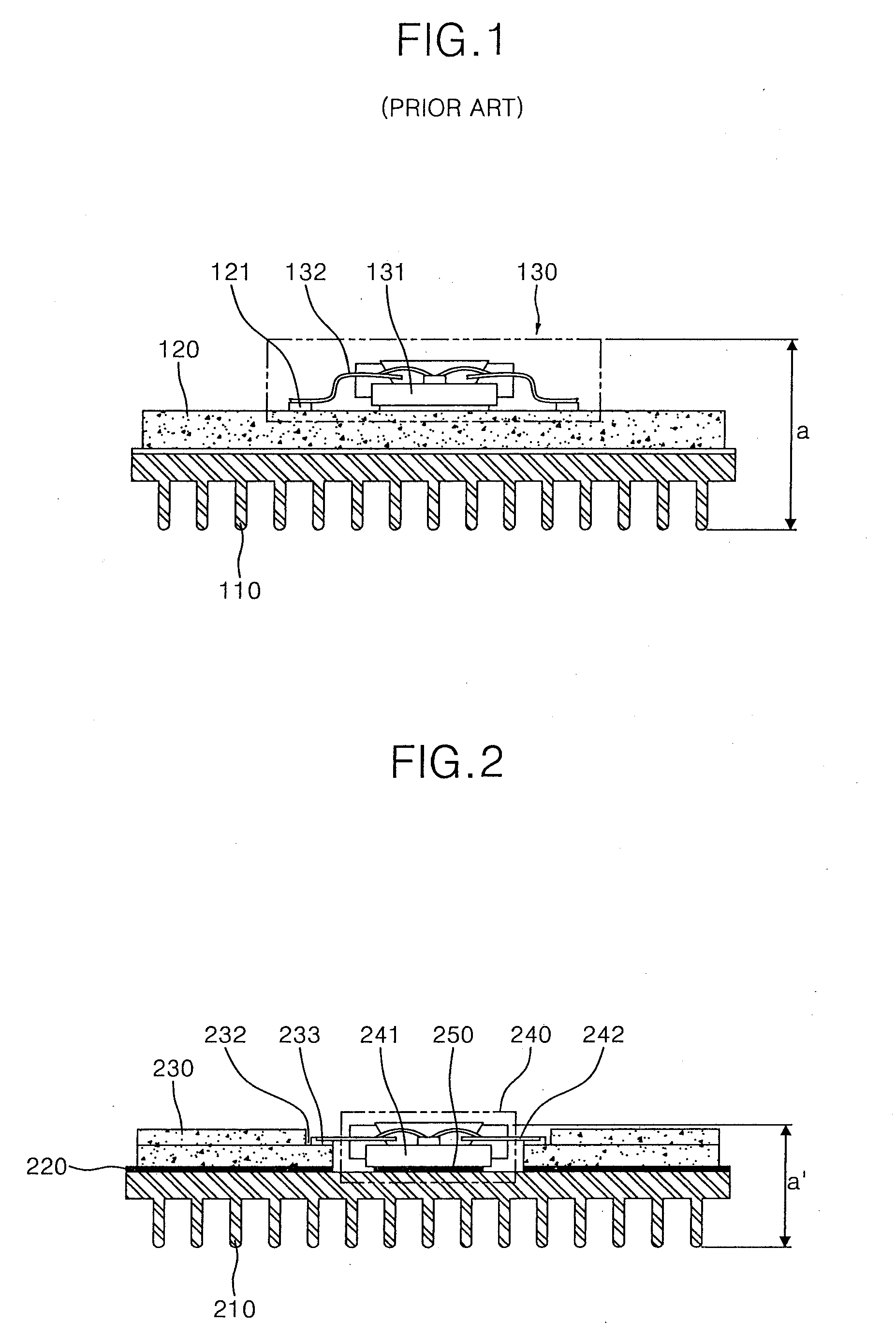

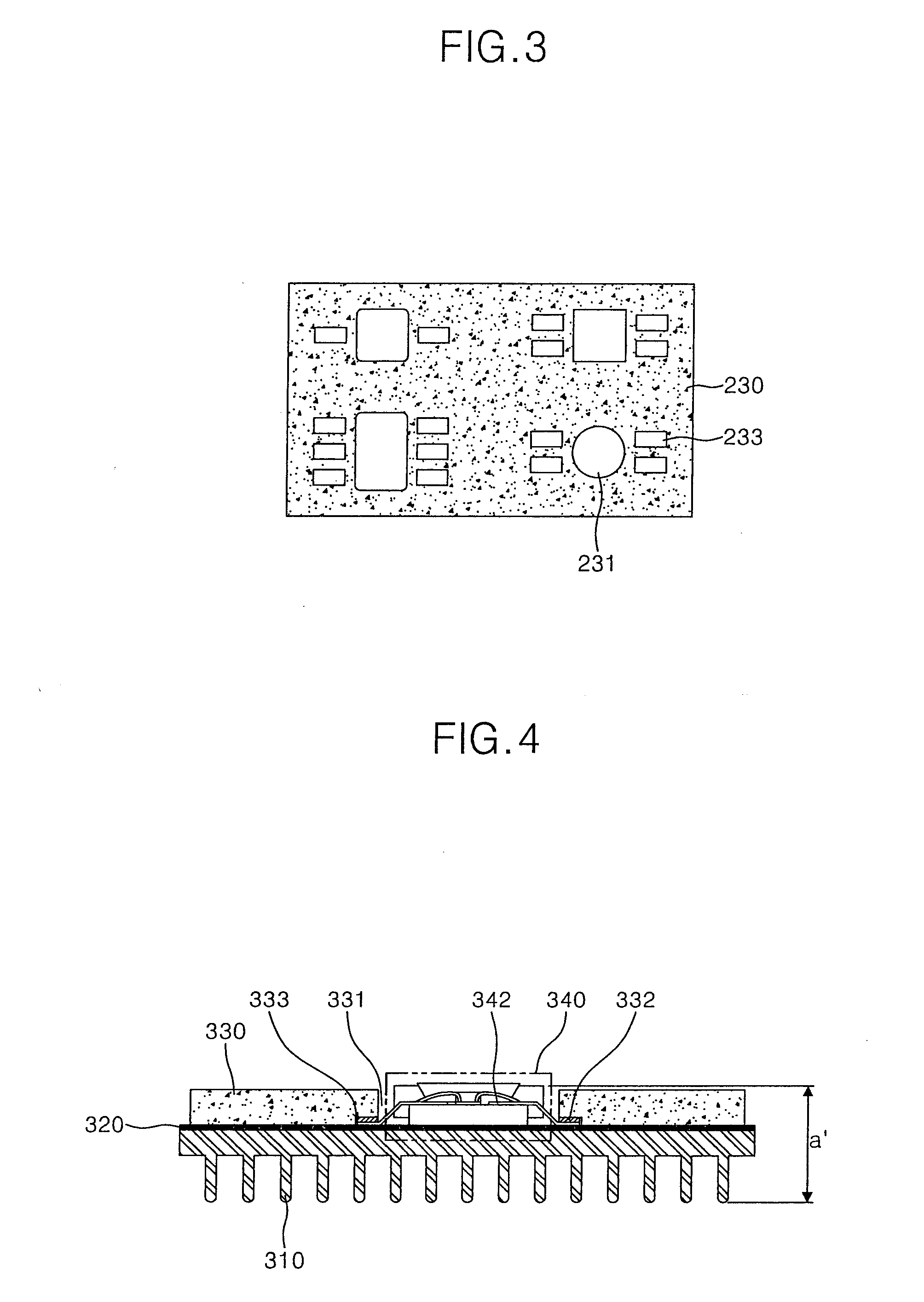

Cooling Device for Light Emitting Diode (LED) Module and Method for Fabricating the Same

InactiveUS20080019103A1Facilitated releaseReduce module thicknessPoint-like light sourceLighting heating/cooling arrangementsEngineeringLead frame

A cooling device of a light emitting diode module and a method for fabricating the same are disclosed. According to the cooling device for a light emitting diode module of the present invention, the thickness of the whole module is reduced, a thermal resistance is small since a final heat-releasing path from a heat source is shortened, it is easy to release heat, and processing efficiency is high and manufacturing cost is low because a bending process of a lead frame is removed.

Owner:ALTI ELECTRONICS

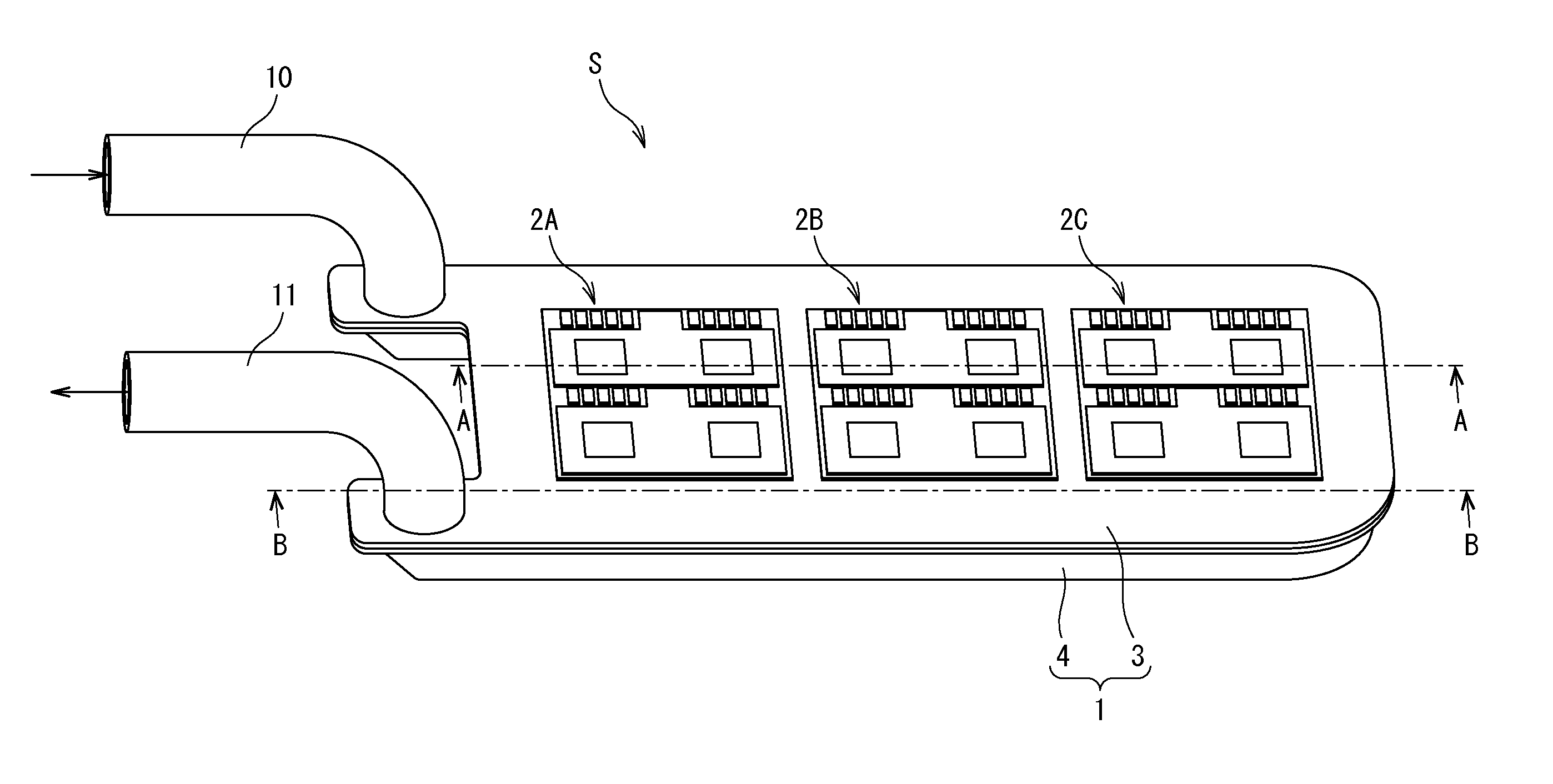

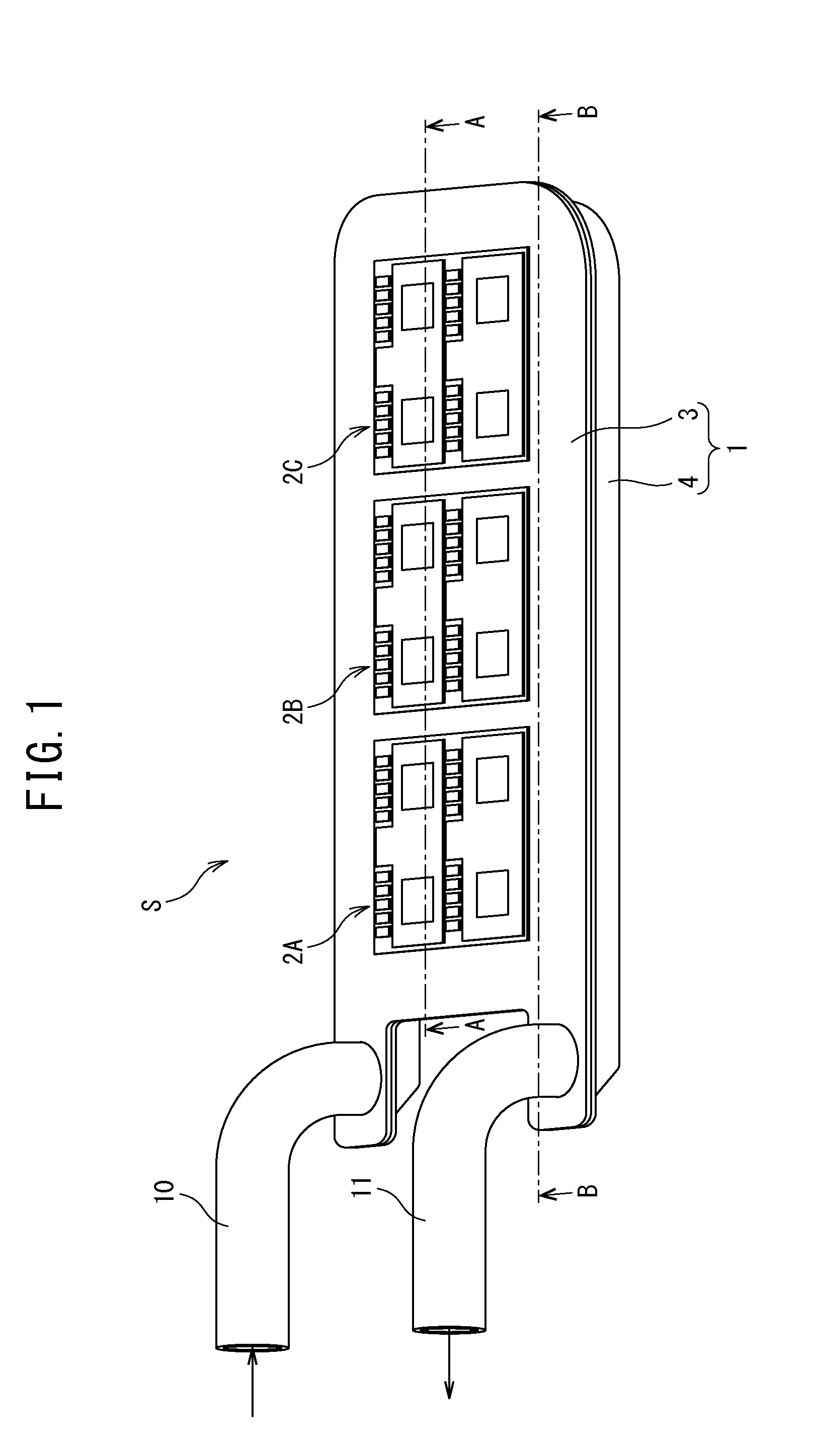

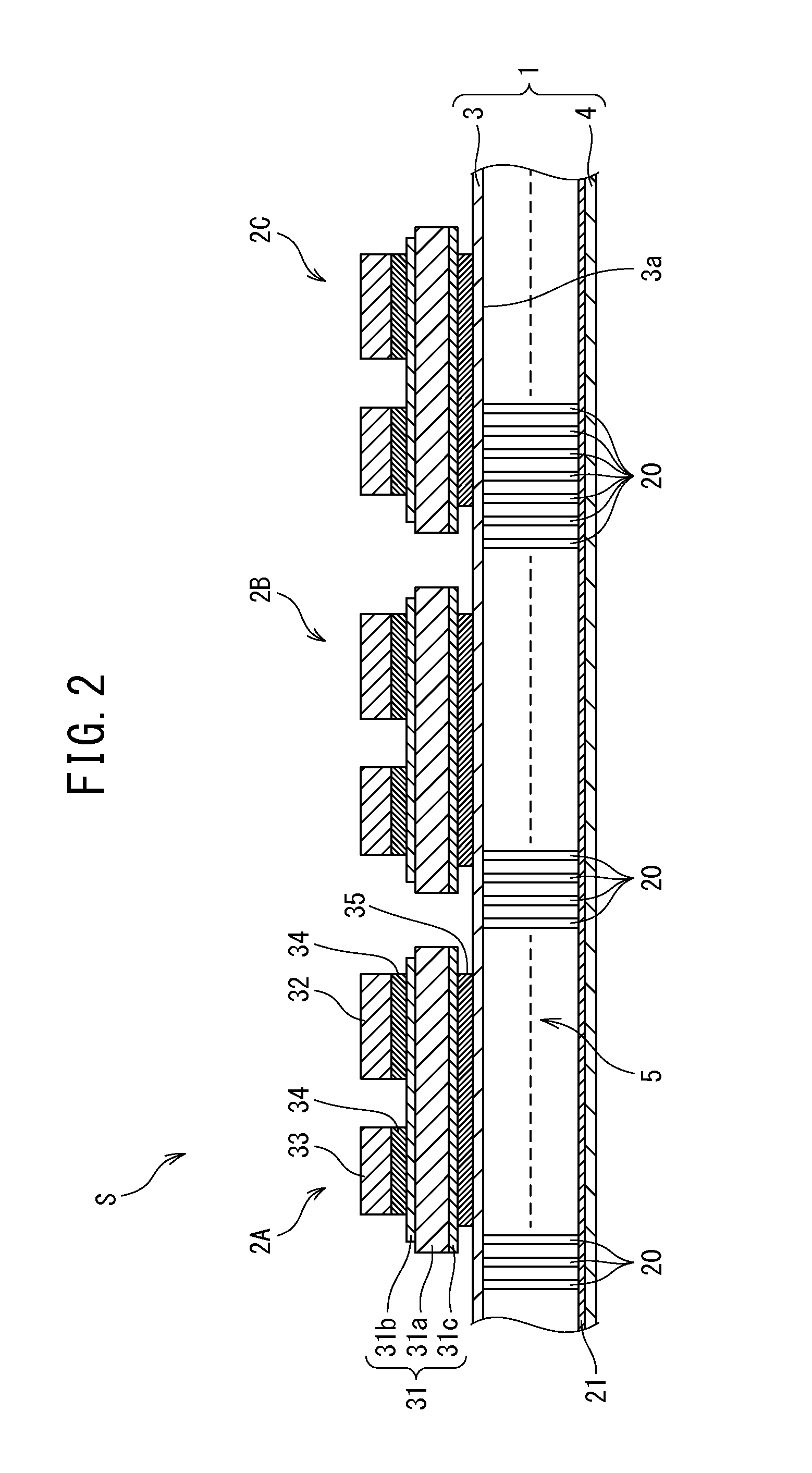

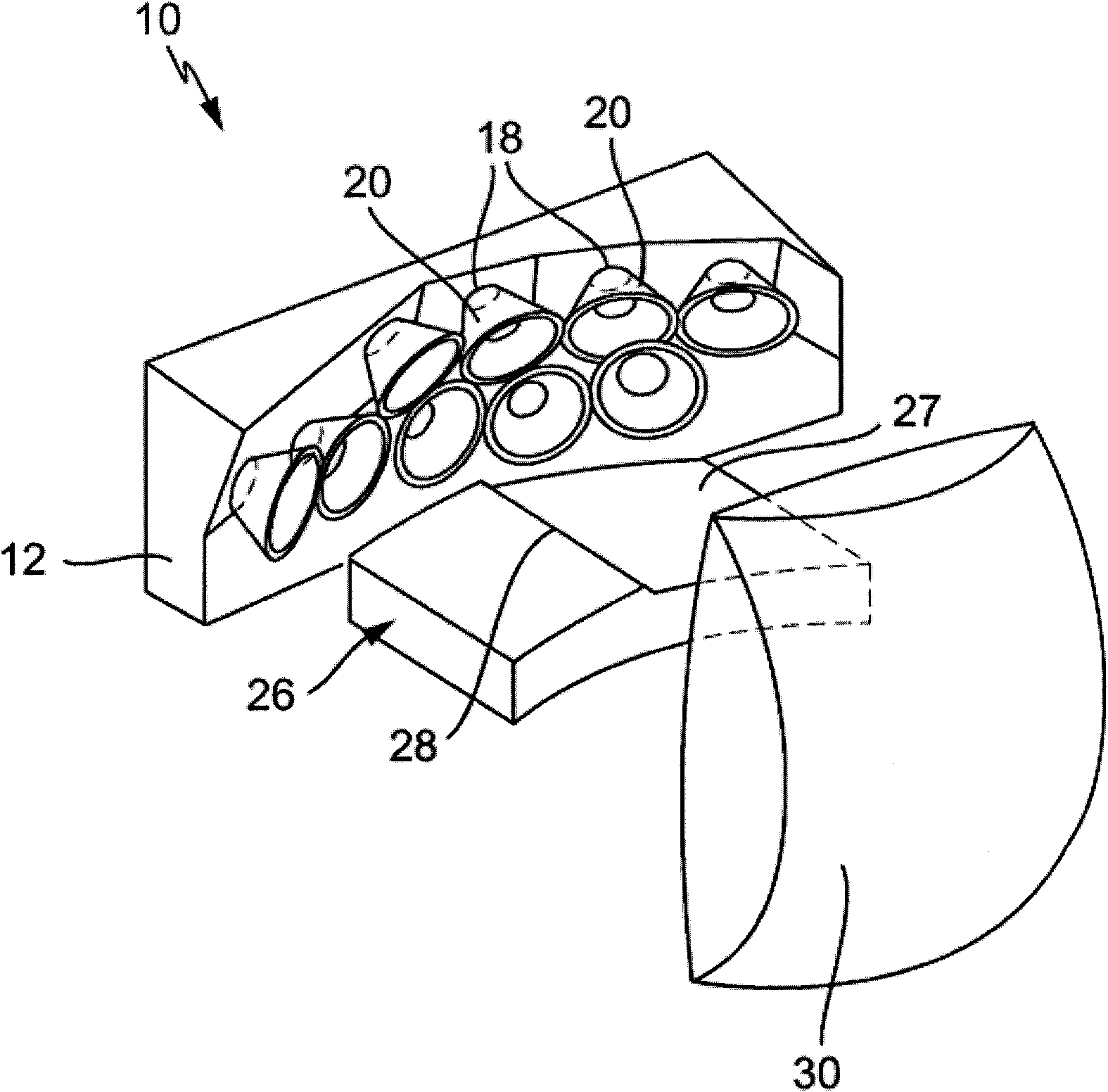

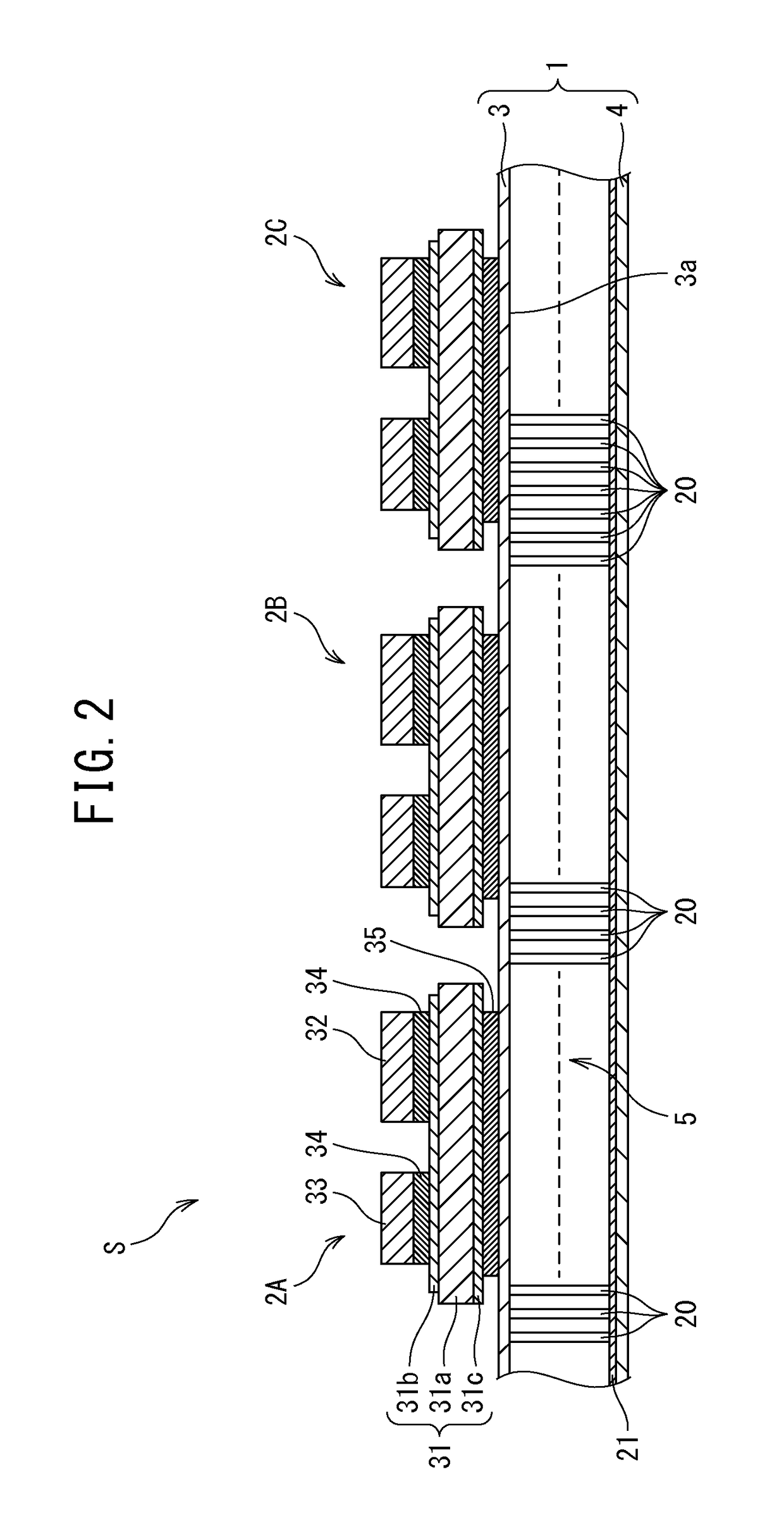

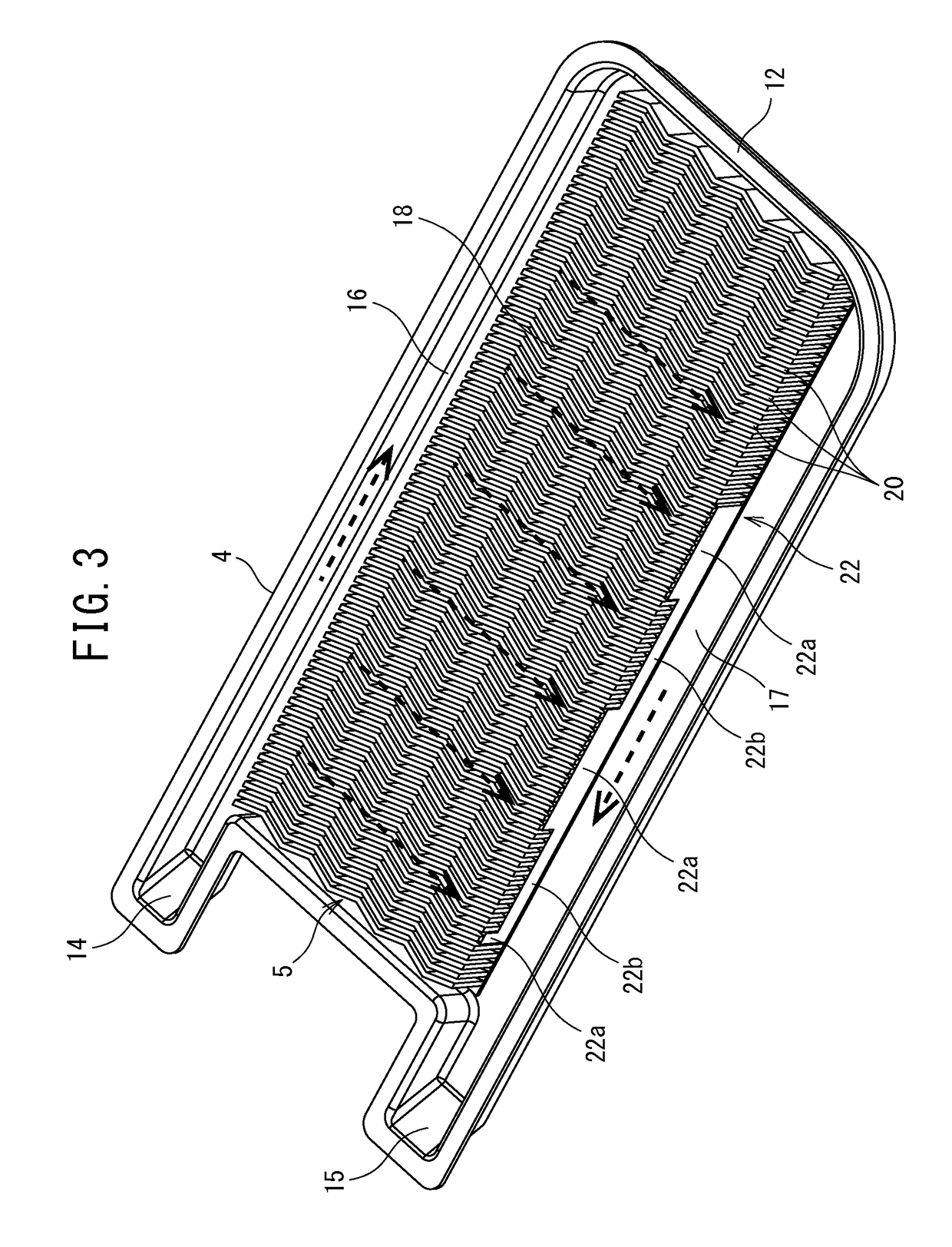

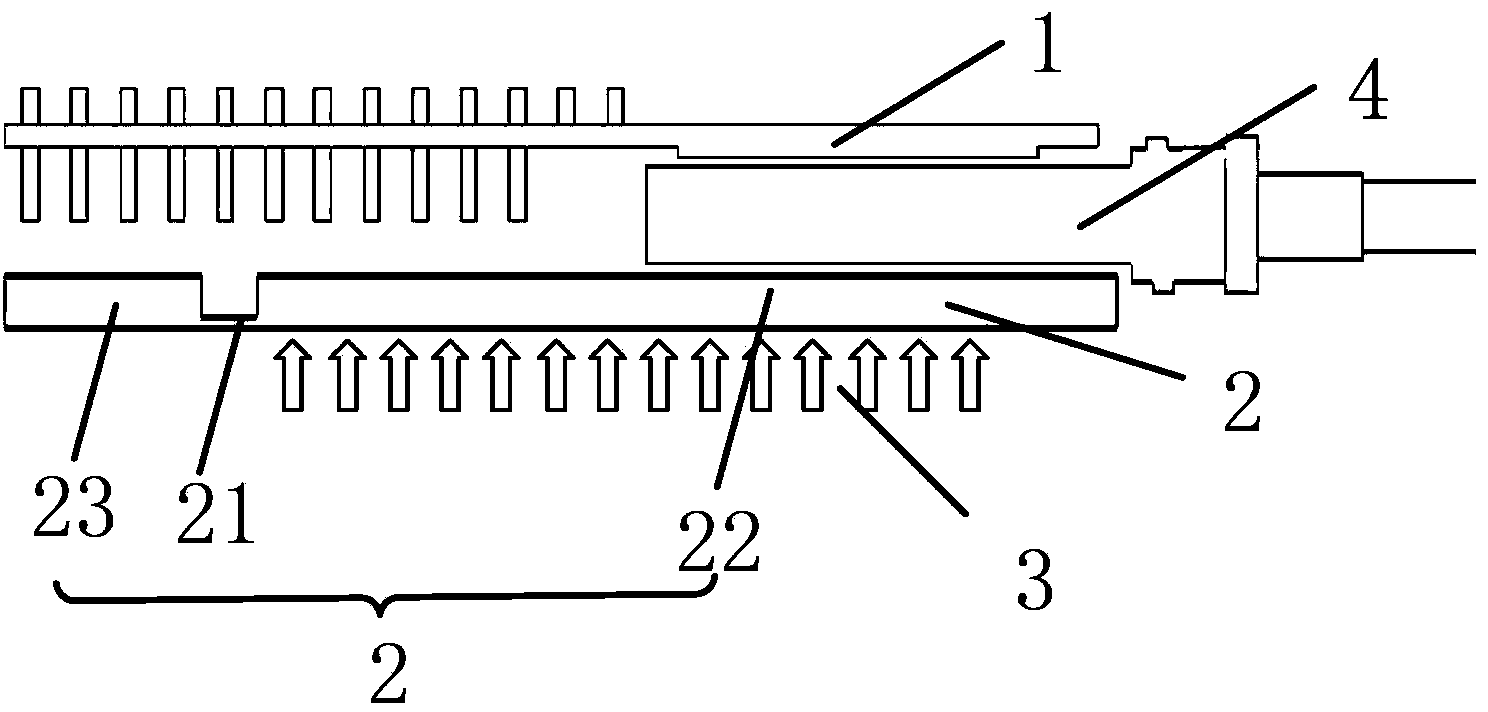

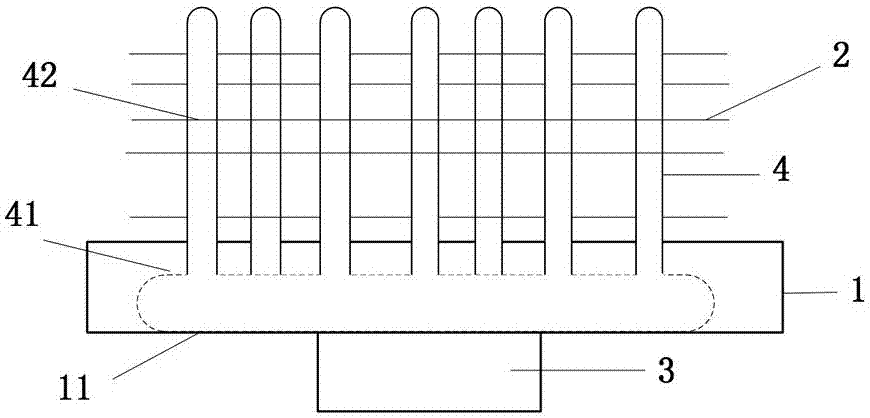

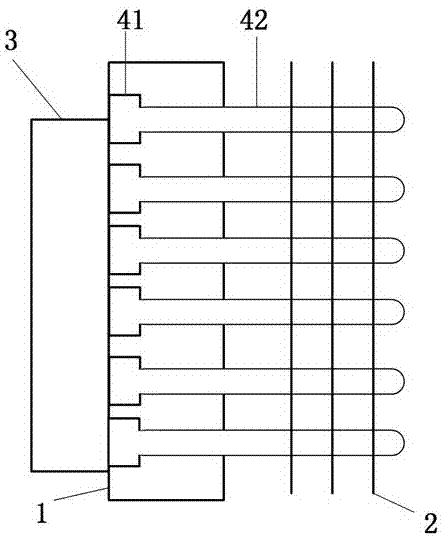

Method for manufacturing cooler for semiconductor-module, cooler for semiconductor-module, semiconductor-module and electrically-driven vehicle

ActiveUS20160129792A1Simple manufacturing processReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

A cooler for a semiconductor-module includes: a heat sink which has an appearance of a cuboid structure to one side of which a flow rate control plate is fixed; a thermal radiation plate on an outer surface of which semiconductor devices are bonded; and a tray-shaped cooling jacket having: a coolant introduction channel; a coolant extraction channel extending in parallel to the coolant introduction channel; and a cooling channel provided between the coolant introduction and extraction channels. The heat sink is provided in the cooling channel of the cooling jacket so that the flow rate control plate extends in a boundary between the coolant extraction channel and the cooling channel, and channels provided for the heat sink extend orthogonally to the coolant introduction and extraction channels. The thermal radiation plate is fixed so as to close an opening the cooling jacket.

Owner:FUJI ELECTRIC CO LTD

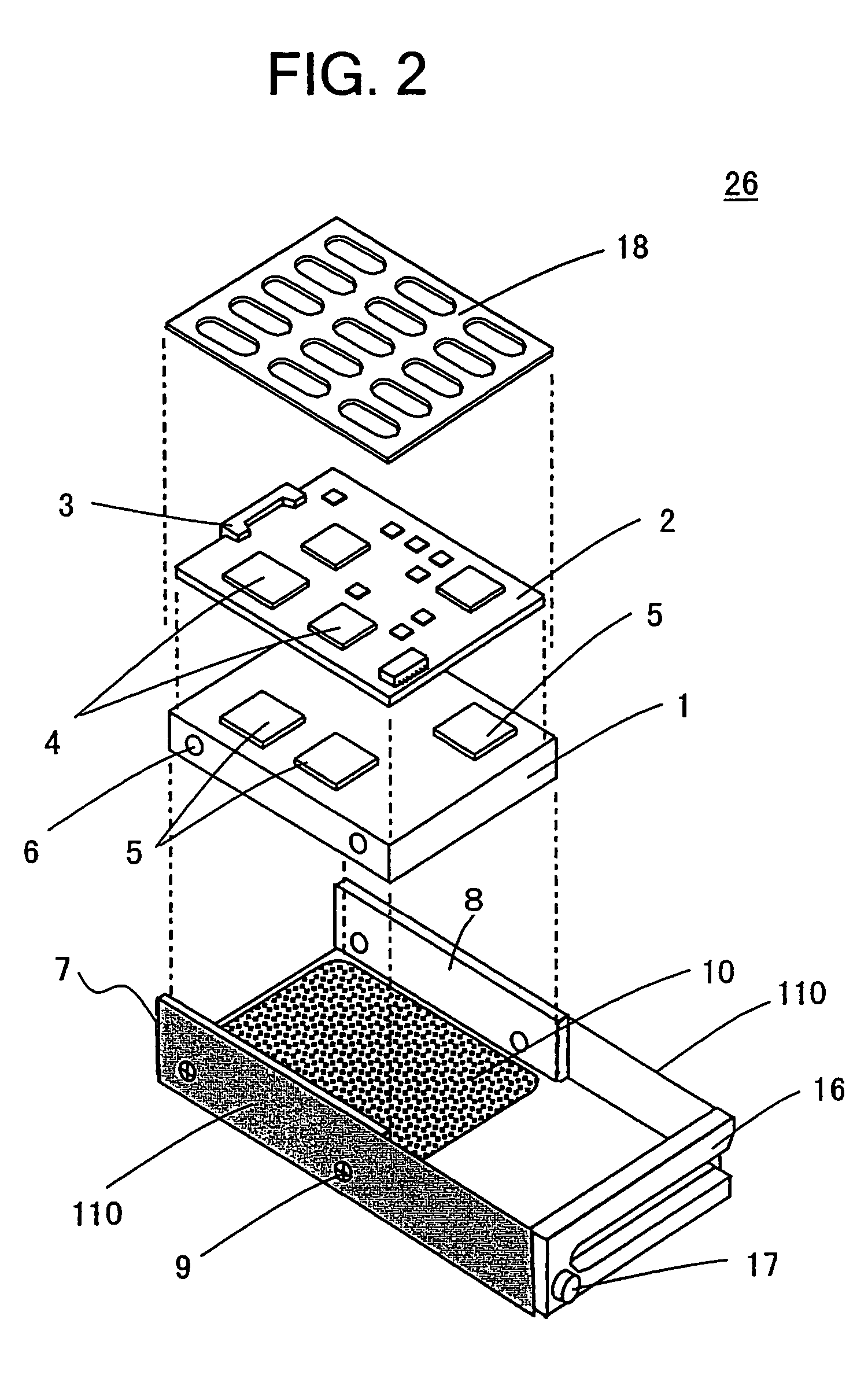

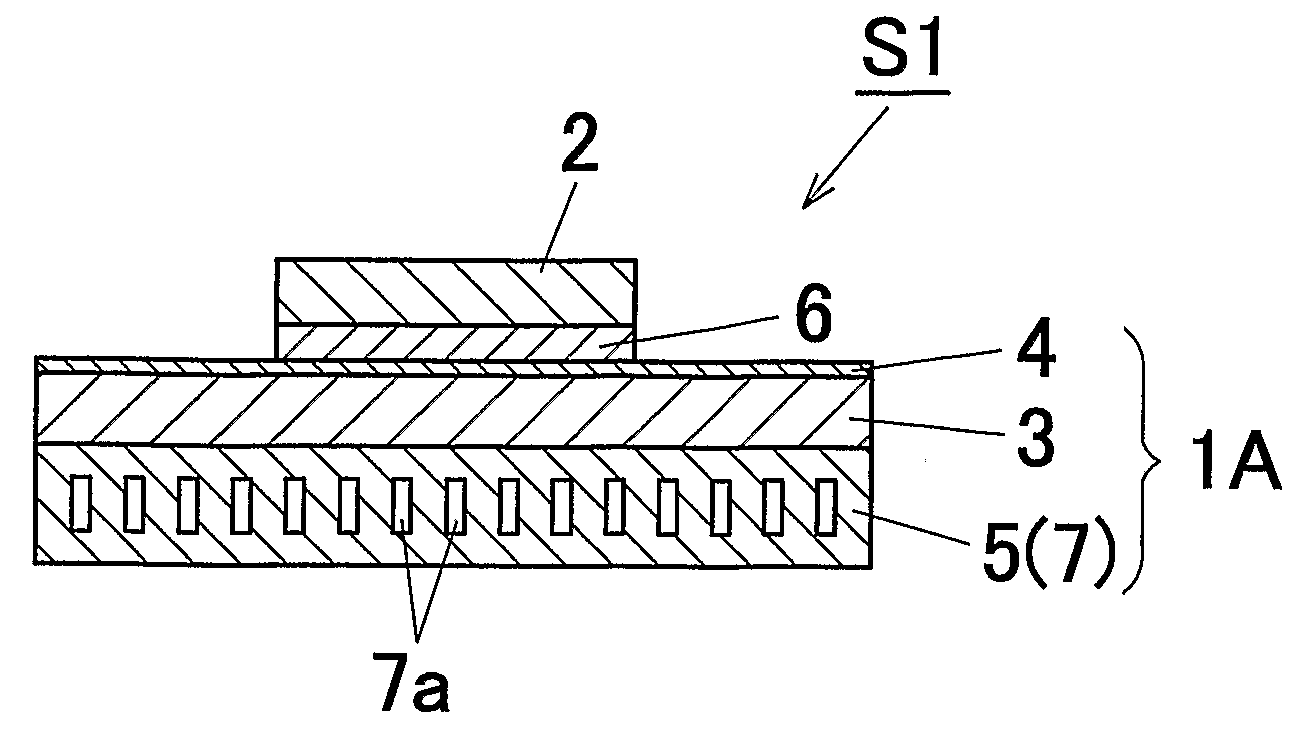

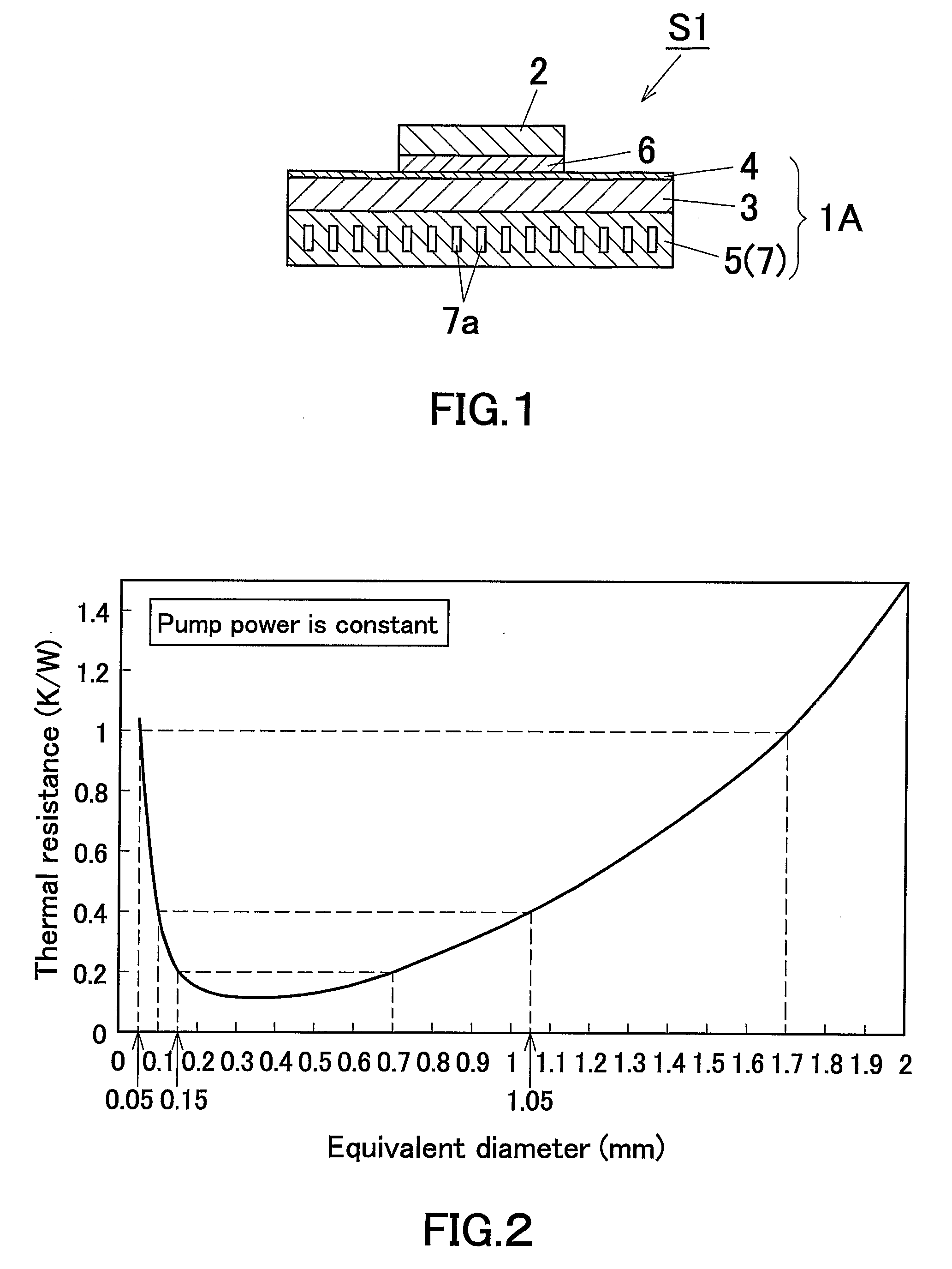

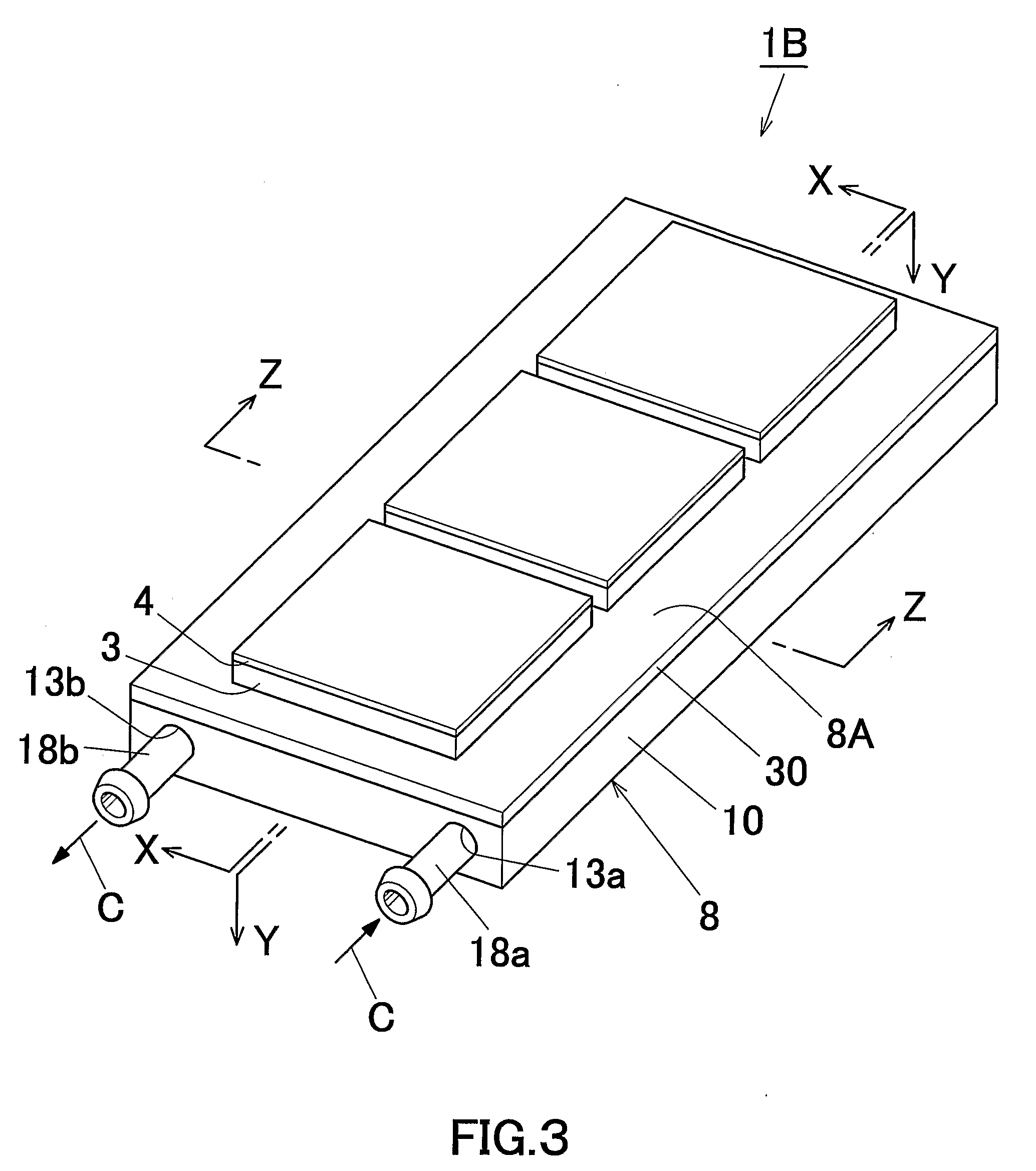

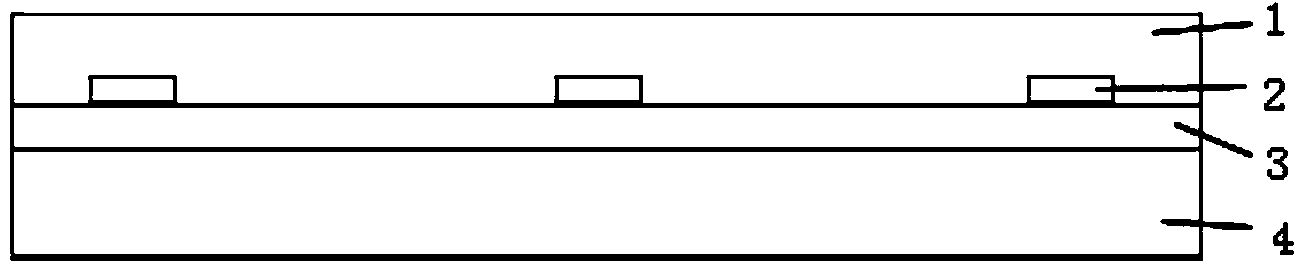

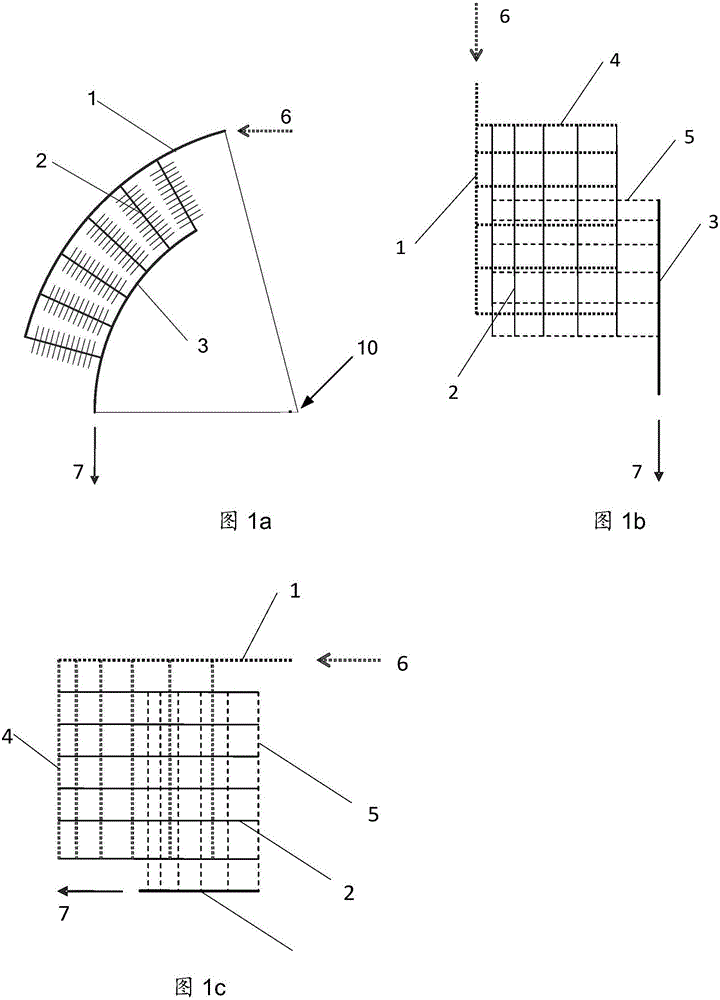

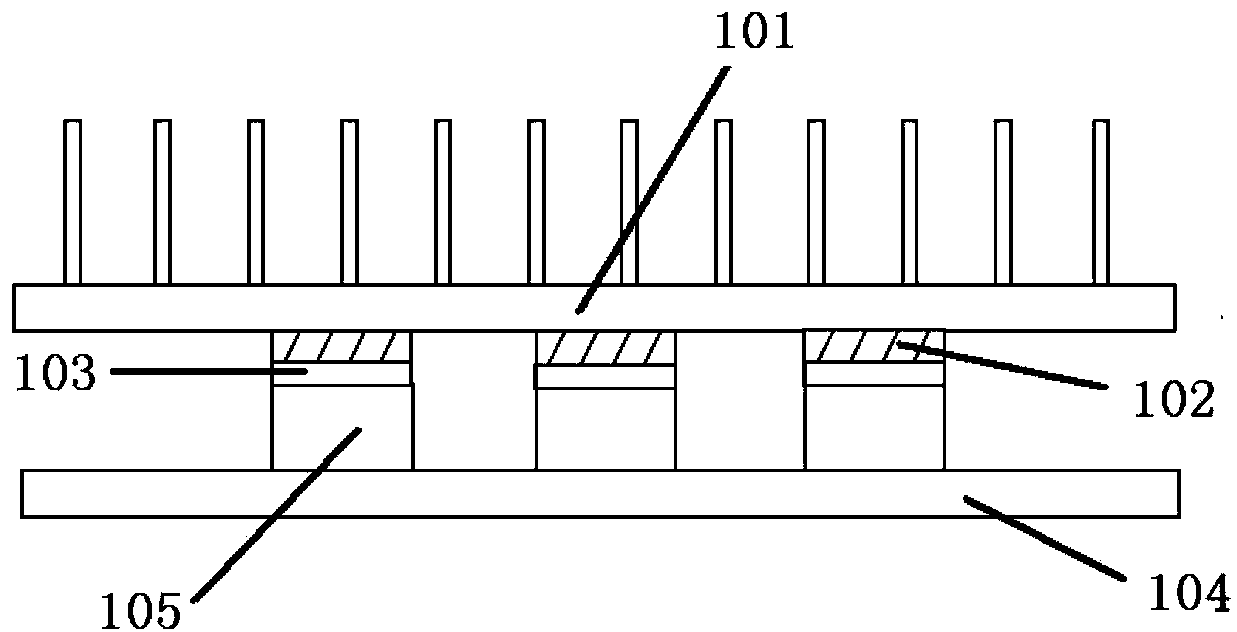

Semiconductor Element Mounting Substrate, Semiconductor Module, And Electric Vehicle

InactiveUS20080239671A1Improve cooling effectSmall total thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectric vehicle

A semiconductor element mounting substrate excellent in cooling performance and simple in structure is provided. The semiconductor element mounting substrate is a substrate 1B for mounting a semiconductor element 2, and has an insulating layer 3 and a conducting layer 4 for attaching a semiconductor element 2 on one surface of the insulating layer 3. To the other surface of the insulating layer 3, a heat releasing device 5 is directly attached. The heat releasing device 5 is preferably a liquid-cooling type cooling plate 7 having a plurality of fine passage 7a for cooling fluid. The insulating layer is preferably a composite member that an insulating cloth is impregnated with insulating resin or insulating resin composite in which thermally conductive filler is added to insulating resin.

Owner:HONDA MOTOR CO LTD +1

Cooling system and electronic apparatus applying the same therein

ActiveUS8345425B2Small total thermal resistanceThermal resistanceSemiconductor/solid-state device detailsSolid-state devicesSiphonEngineering

A cooling system for cooling a CPU 200 mounted on a printed circuit board 100 within a housing thereof, has a heat-receiving jacket 310, being thermally connected with a surface of the CPU generating heat therein, and for evaporating liquid refrigerant stored in a pressure-reduced inner space with heat generation thereof. A condenser 320 receives refrigerant vapor from the heat-receiving jacket for condensing the refrigerant vapor into a liquid by transferring the heat into an outside of the apparatus. A thermo siphon is used for circulating the refrigerant due to phase change thereof, and the condenser has fine grooves on an inner wall surface thereof along a direction of flow of the refrigerant, and is also formed flat in a cross-section thereof, for cooling the refrigerant vapor from the heat-receiving jacket on the inner wall surface thereof, efficiently.

Owner:HITACHI LTD

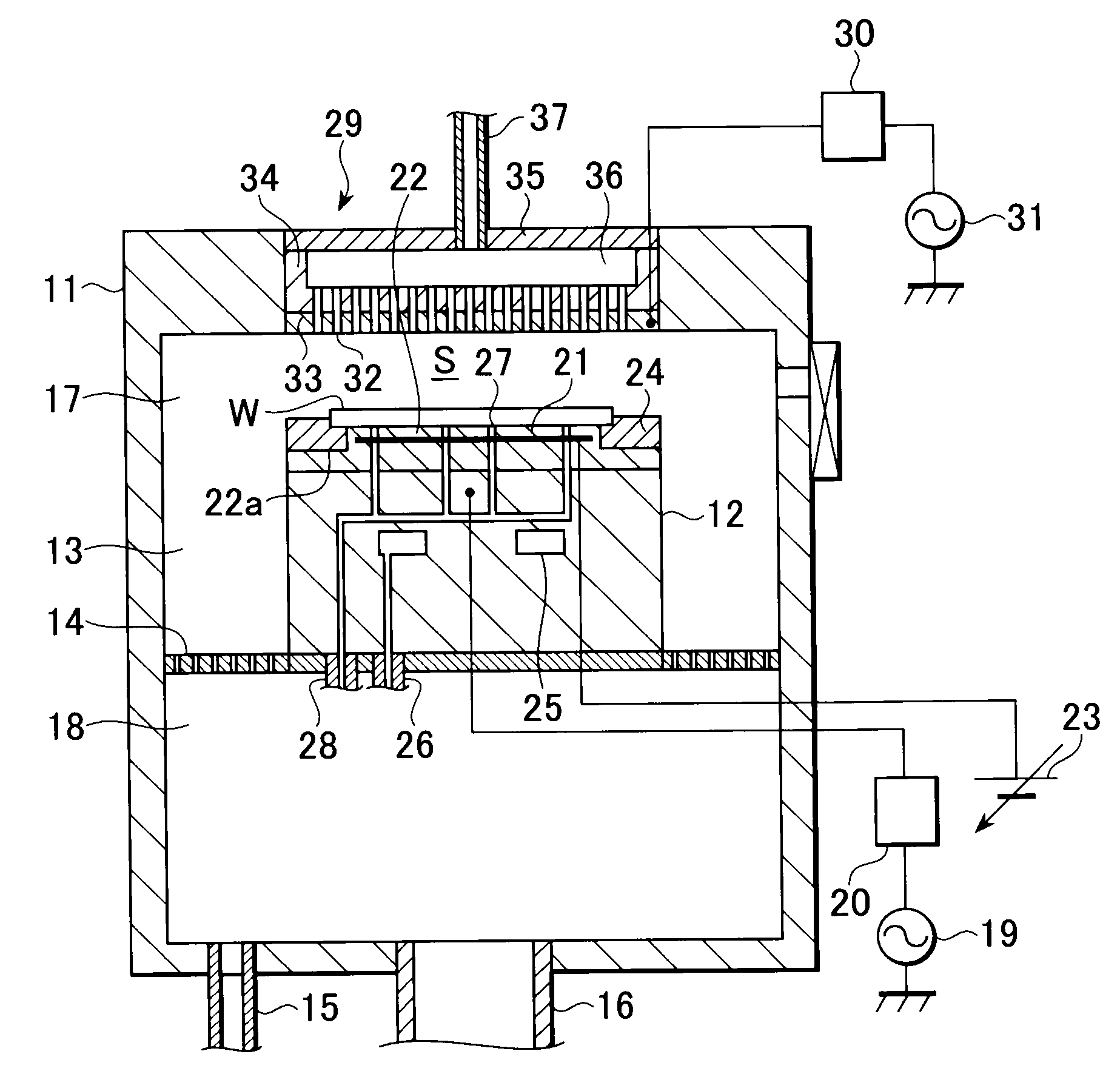

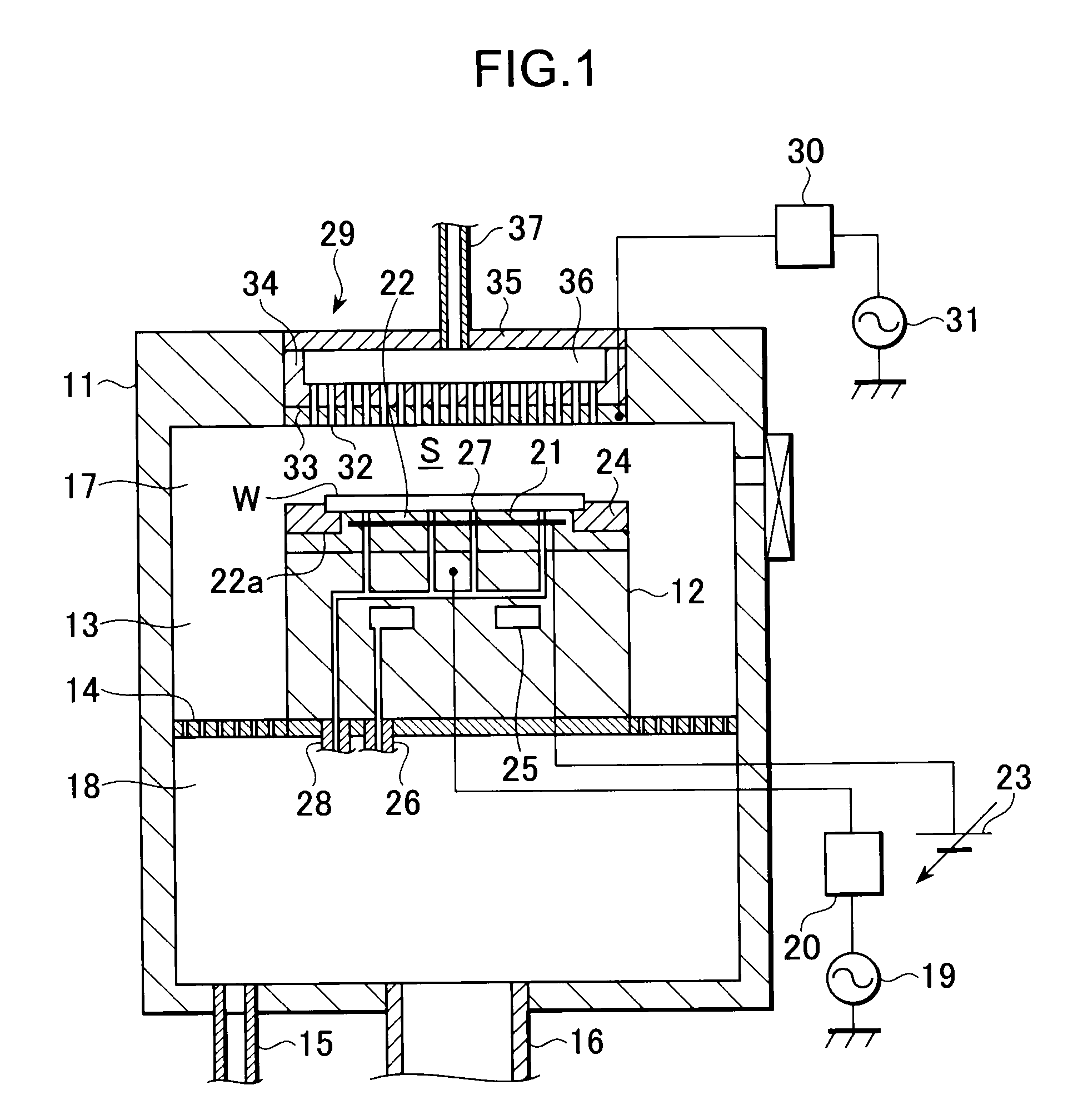

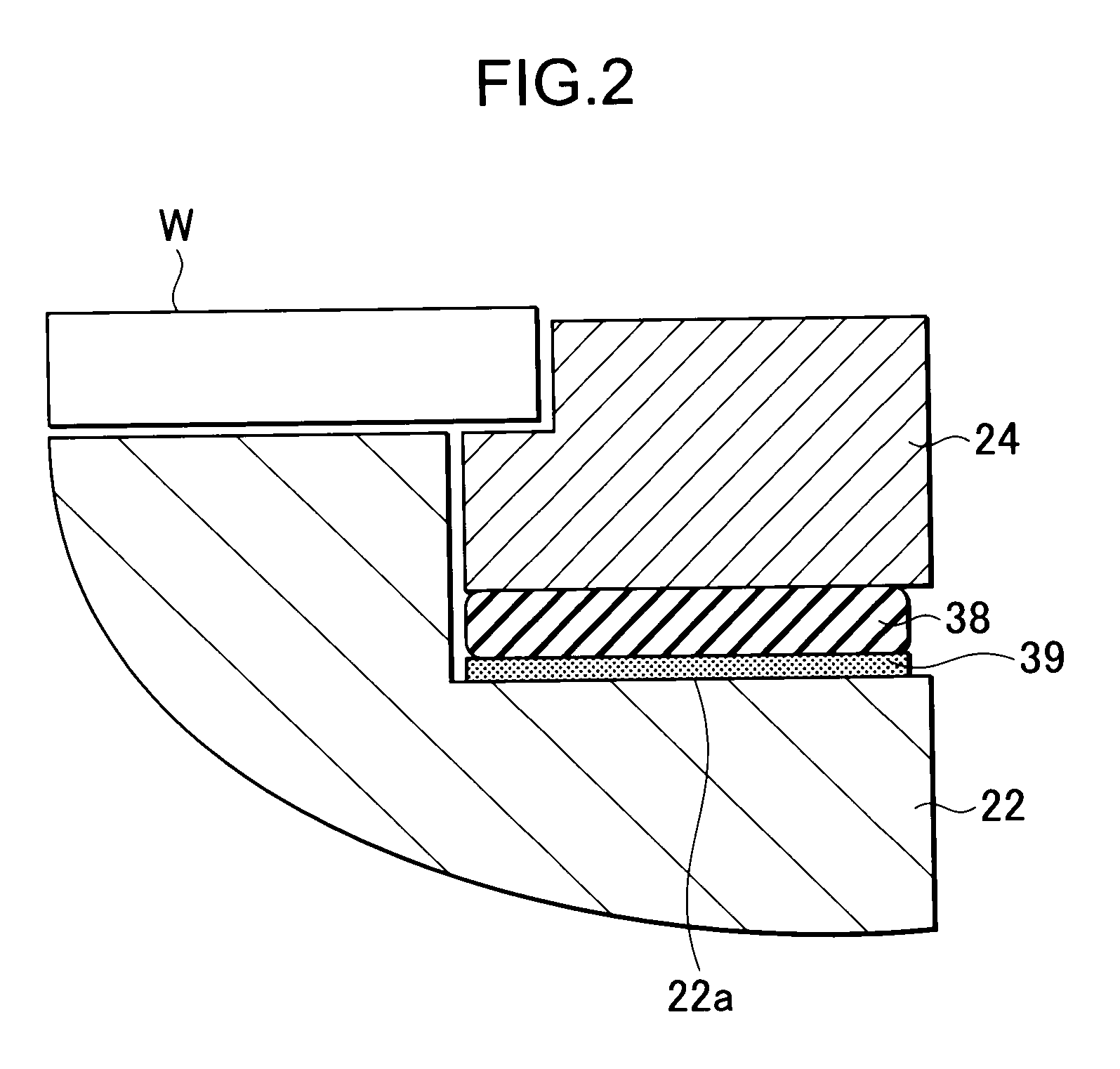

Substrate processing apparatus and substrate mounting stage on which focus ring is mounted

InactiveUS20080236746A1Inhibition of attachmentPrevent heat transferElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate processing apparatus that can prevent a heat transfer sheet from becoming attached to a focus ring mounting surface of a substrate mounting stage. The substrate mounting stage is disposed in a housing chamber of the substrate processing apparatus, and a substrate is mounted on the substrate mounting stage. A focus ring that surrounds a peripheral portion of the mounted substrate is mounted on the focus ring mounting surface. The heat transfer sheet is interposed between the focus ring and the focus ring mounting surface, and a fluorine coating is formed on the focus ring mounting surface.

Owner:TOKYO ELECTRON LTD

Power module

InactiveUS6952347B2Small total thermal resistanceExtend power lifeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

Owner:VITESCO TECH GERMANY GMBH

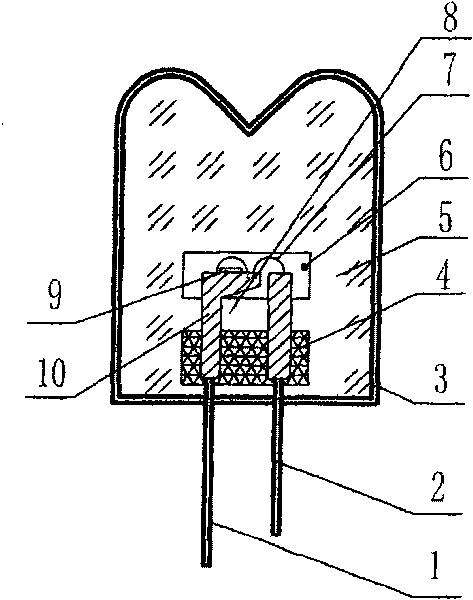

LED lamp with flexible transparent substrate

InactiveCN103629575ALighting structure is simpleLower overall system thermal resistancePoint-like light sourceElectric circuit arrangementsLight sourceEngineering

The invention discloses an LED lamp with a flexible transparent substrate. The LED lamp with the flexible transparent substrate comprises the flexible transparent substrate, a transparent conductive circuit layer is plated on the upper surface of the flexible transparent substrate, an LED light source is welded to the transparent conductive circuit layer, and a flexible transparent thin film is used for packaging the LED light source. The flexible transparent substrate is made of highly thermal conductive plastics, the structure of the lamp is simplified, production cost is saved, system heat resistance of the whole lamp is lowered, and the LED lamp with the flexible transparent substrate has good heat dissipation performance.

Owner:SOUTH CHINA UNIV OF TECH

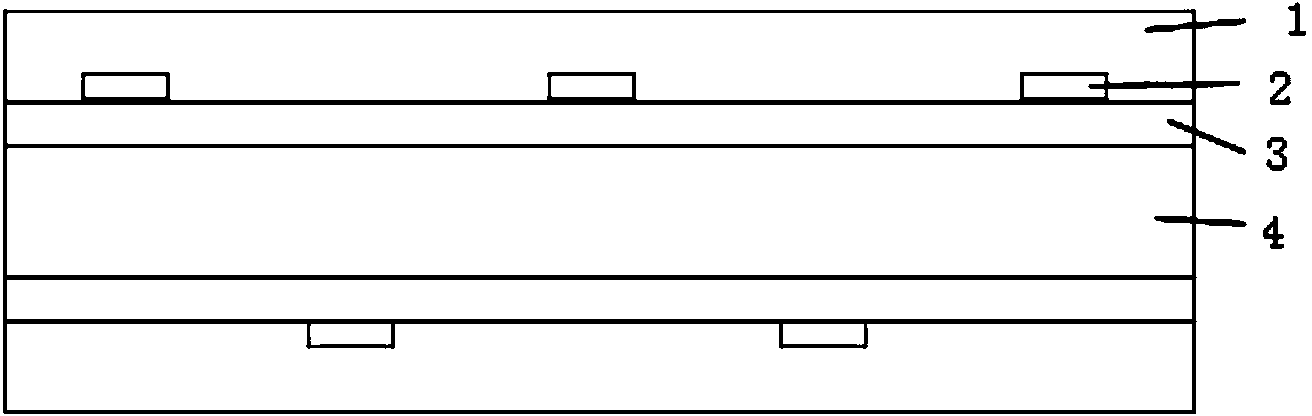

Light module for a lighting device of a motor vehicle

InactiveCN102313230AEvenly evacuatedSmall total thermal resistanceVehicle headlampsPoint-like light sourceOptical ModuleComputer module

The invention relates to a light module (10) for a lighting device of a motor vehicle, comprising at least one semiconductor light source (18) for emitting the light, at least one main optical unit (20;20') for concentrating light from the light source, a light shielding plate (26) and a secondary optical unit (30), wherein the light shielding plate (26) is used for shielding one part of the light beam, the secondary optical unit is used for imaging a part of the light across the light shielding plate (26) and a part of the light reflected from the light shielding plate (26), therefore the desired light distribution is obtained on the runway before the motor vehicle. The light shielding plate (26) extends basically on a horizontal plane, the plane comprises an optical axle (32) of the secondary optical unit (30). The light module (10) comprises a plurality of semiconductor light sources (18) for distributing at least one main optical unit (20;20'), wherein the main optical unit is positioned and designed that: at least one optical axle (22) with the main optical unit (20;20') extends in at least one plane and the plane is crossed with the horizontal surface of the light shielding plate (26).

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

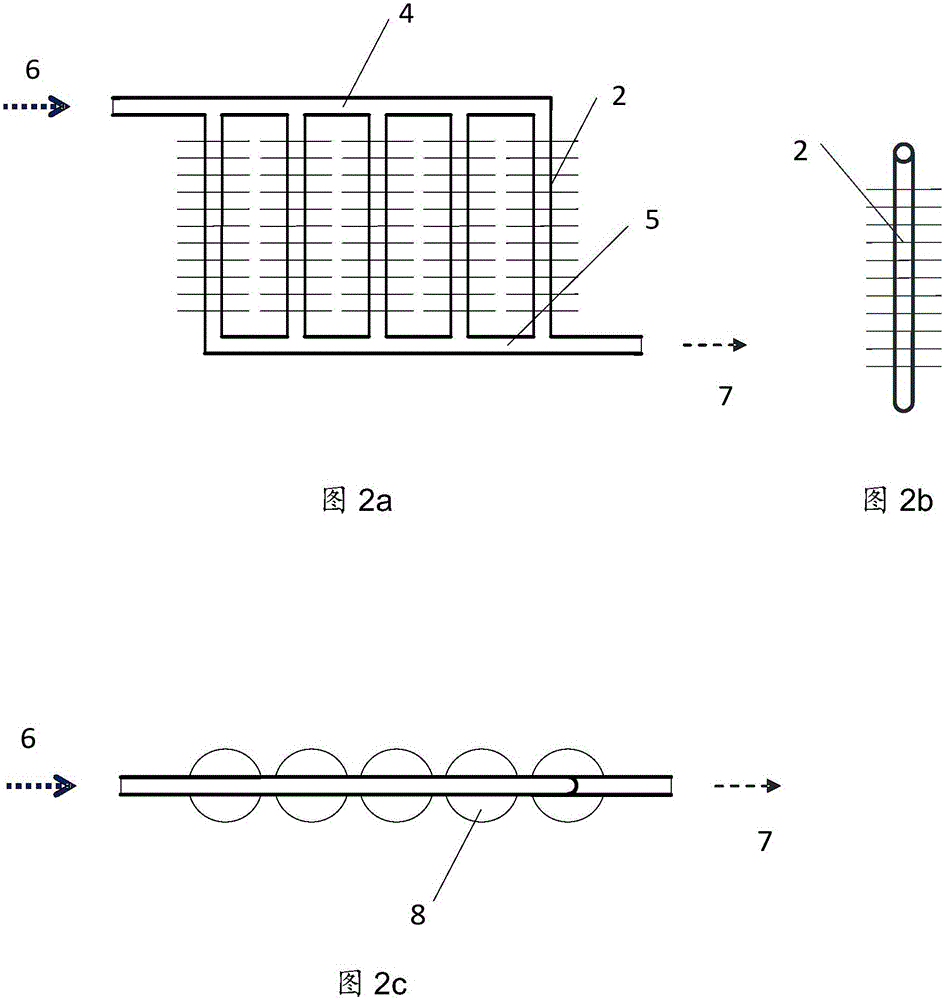

Loop heat tube condenser applicable to arrangement in circular ring-shaped chamber body

ActiveCN106017167AReduce thicknessReduce thermal resistanceIndirect heat exchangersHeat resistanceHorizontal axis

The invention relates to a loop heat tube condenser applicable to arrangement in a circular ring-shaped chamber body. The condenser comprises a plurality of condensing tube components, circular arc-shaped steam headers and circular arc-shaped liquid headers; each condensing tube component comprises n condensing tubes, one straight steam header and one straight liquid header; the n condensing tubes are equal in length and are arranged in parallel; the straight steam headers communicate with one end of each of the n condensing tubes; the straight liquid headers communicate with the other end of each of the n condensing tubes; the condensing tube components are arranged around the horizontal axis of the circular ring-shaped chamber body so that all axes of the n condensing tubes in each condensing tube component point to the axis of the circular ring-shaped chamber body; the straight steam headers in the condensing tube components can communicate with one another through the circular arc-shaped steam headers; the straight liquid headers in the condensing tube components can communicate with one another through the circular arc-shaped liquid headers; the condenser has the advantages of reducing heat resistance, remarkably improving the heat exchange capability, being adaptive to arrangement in an upper space of a horizontal annular chamber, fully utilizing the space of a circular ring-shaped columnar chamber body and realizing high performance and compactness.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

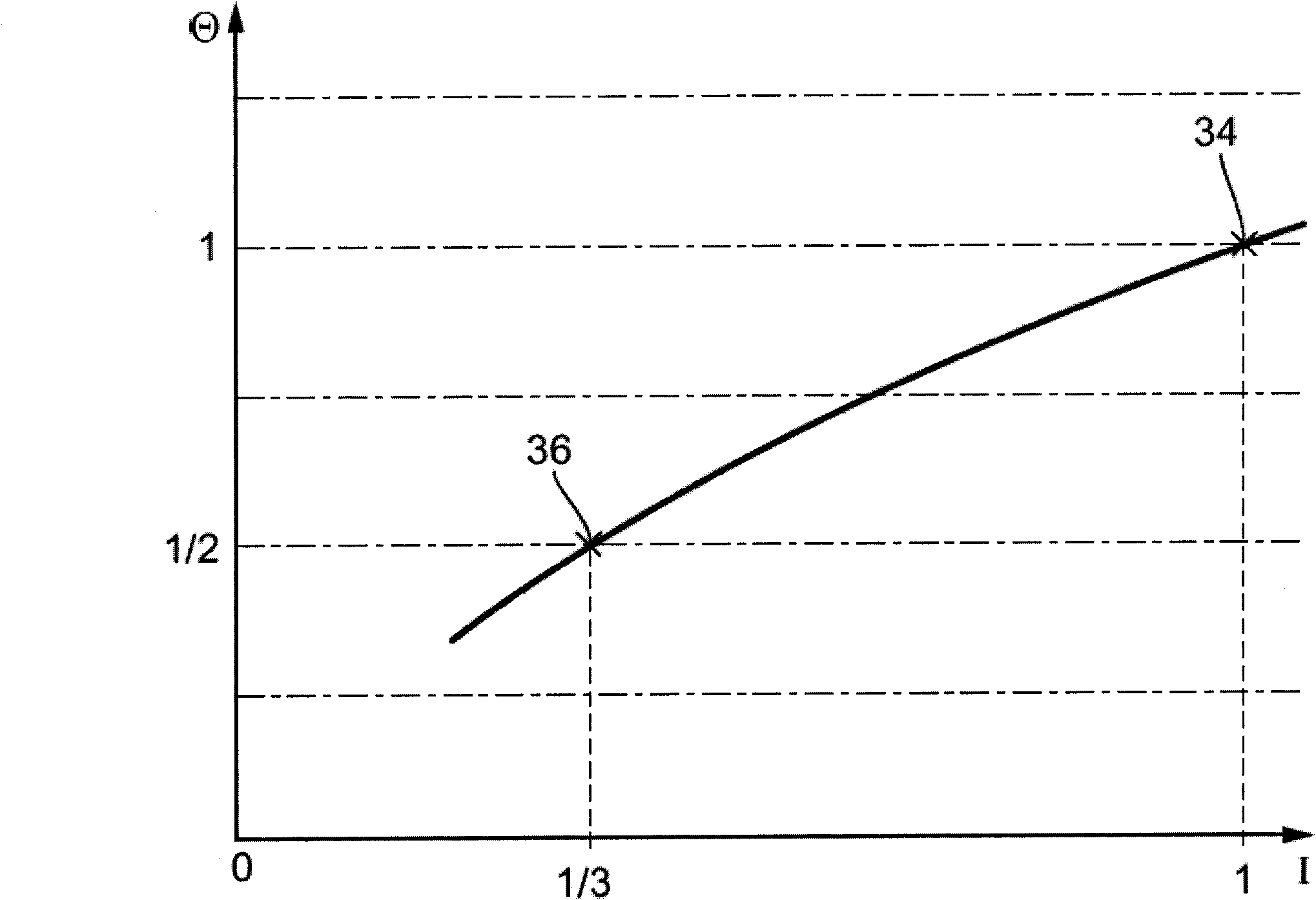

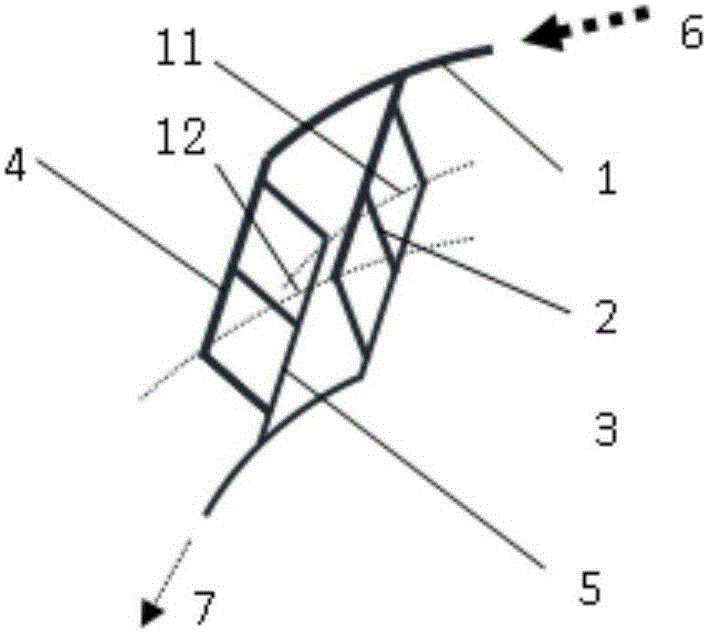

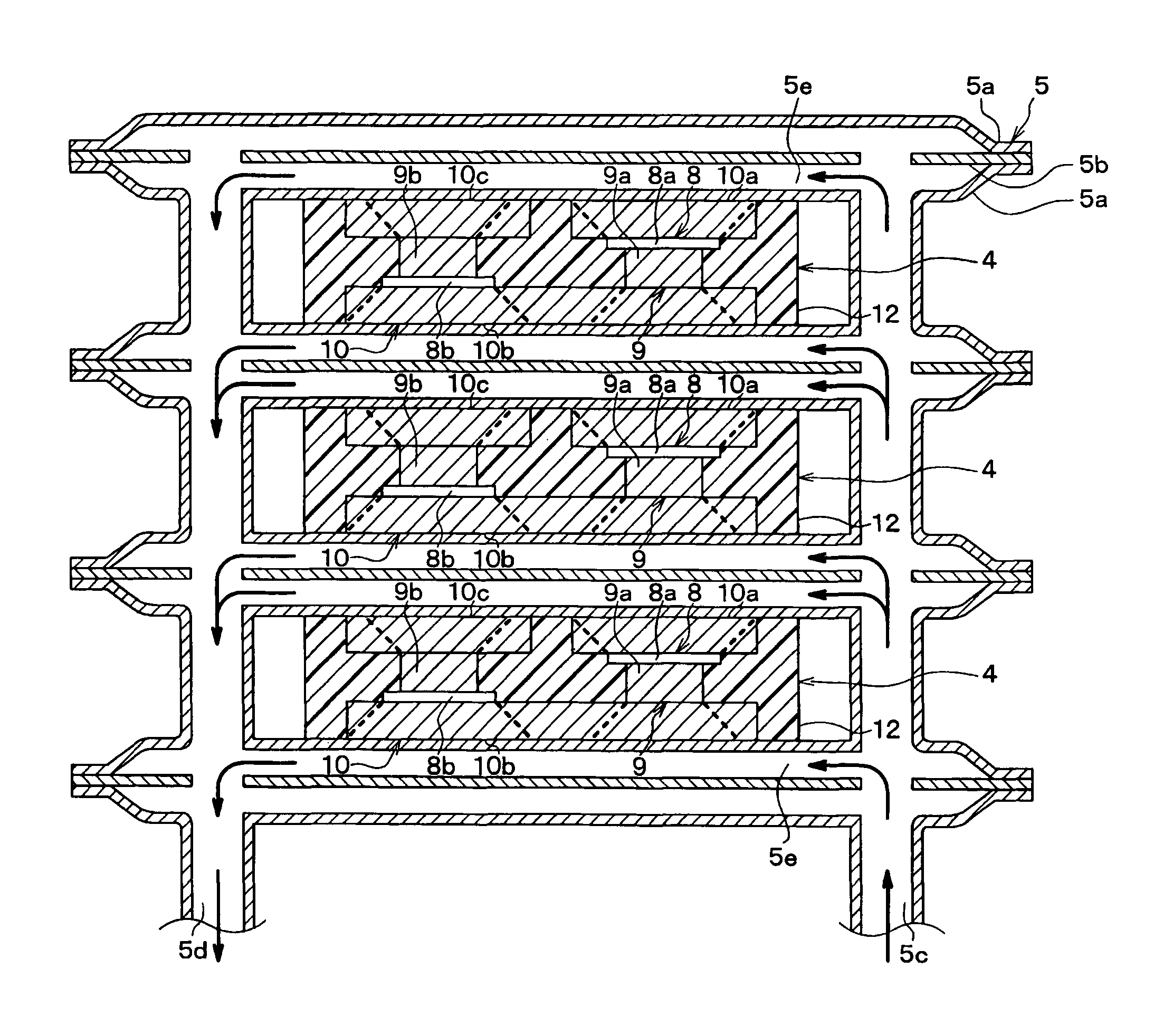

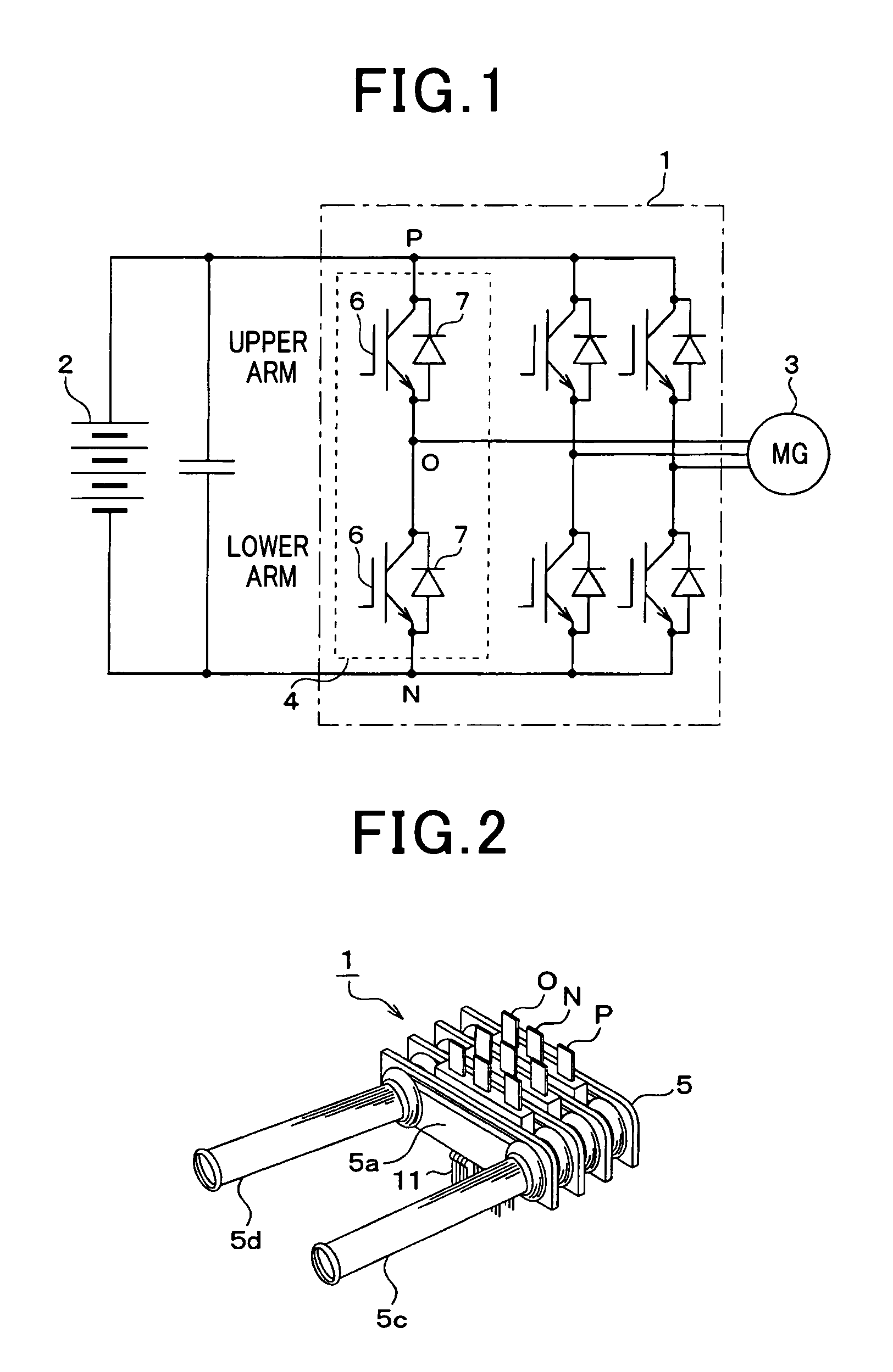

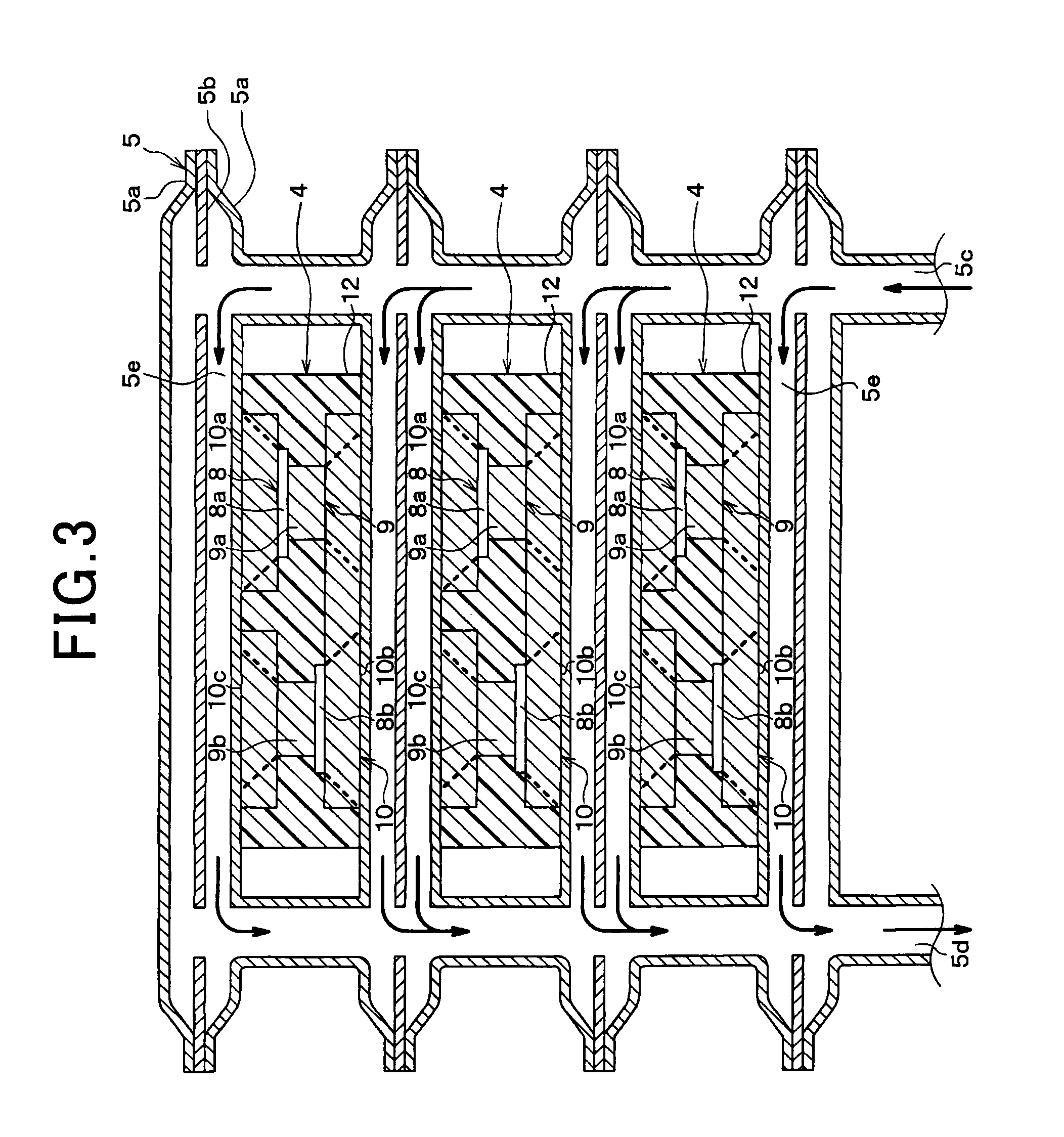

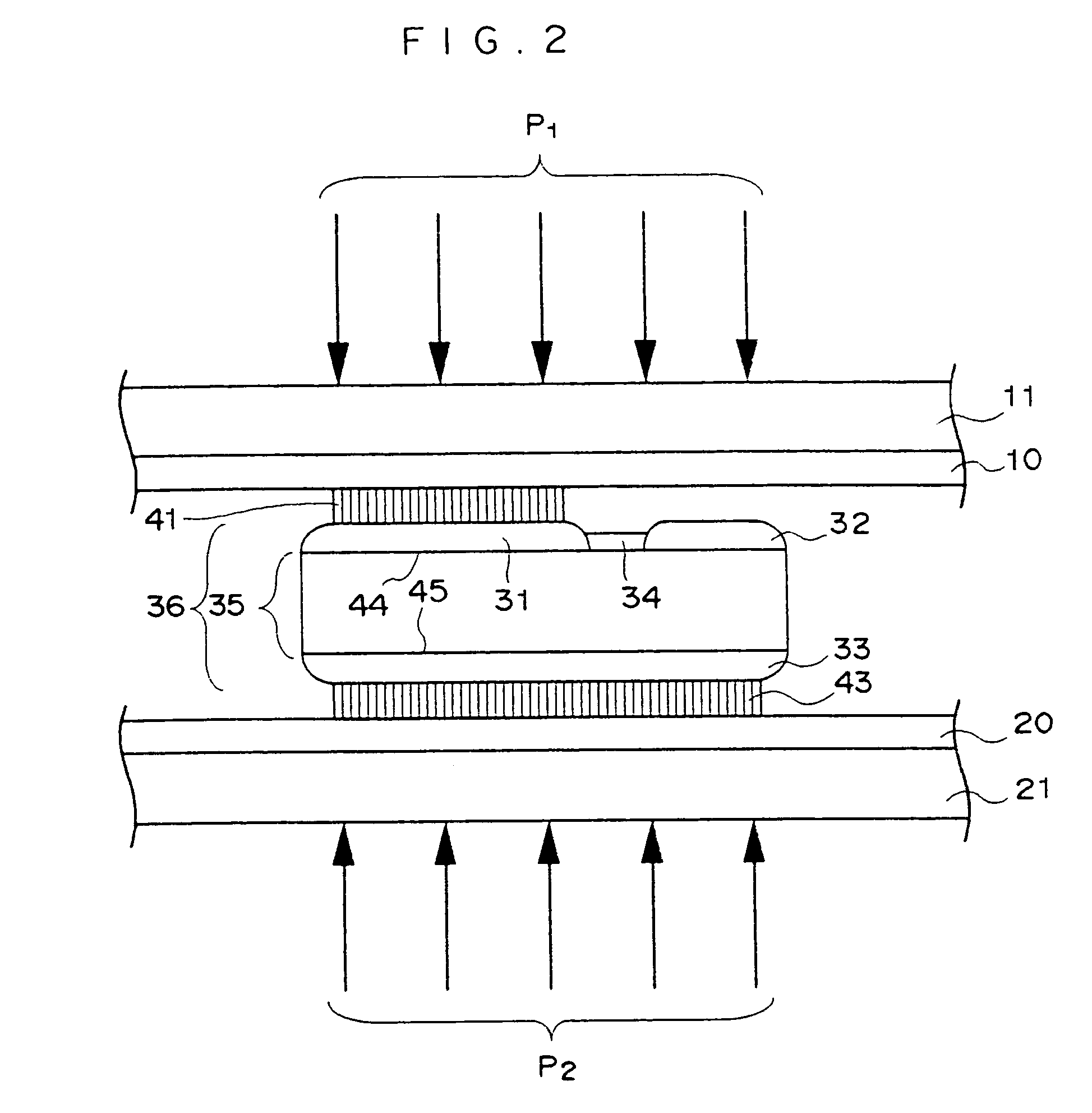

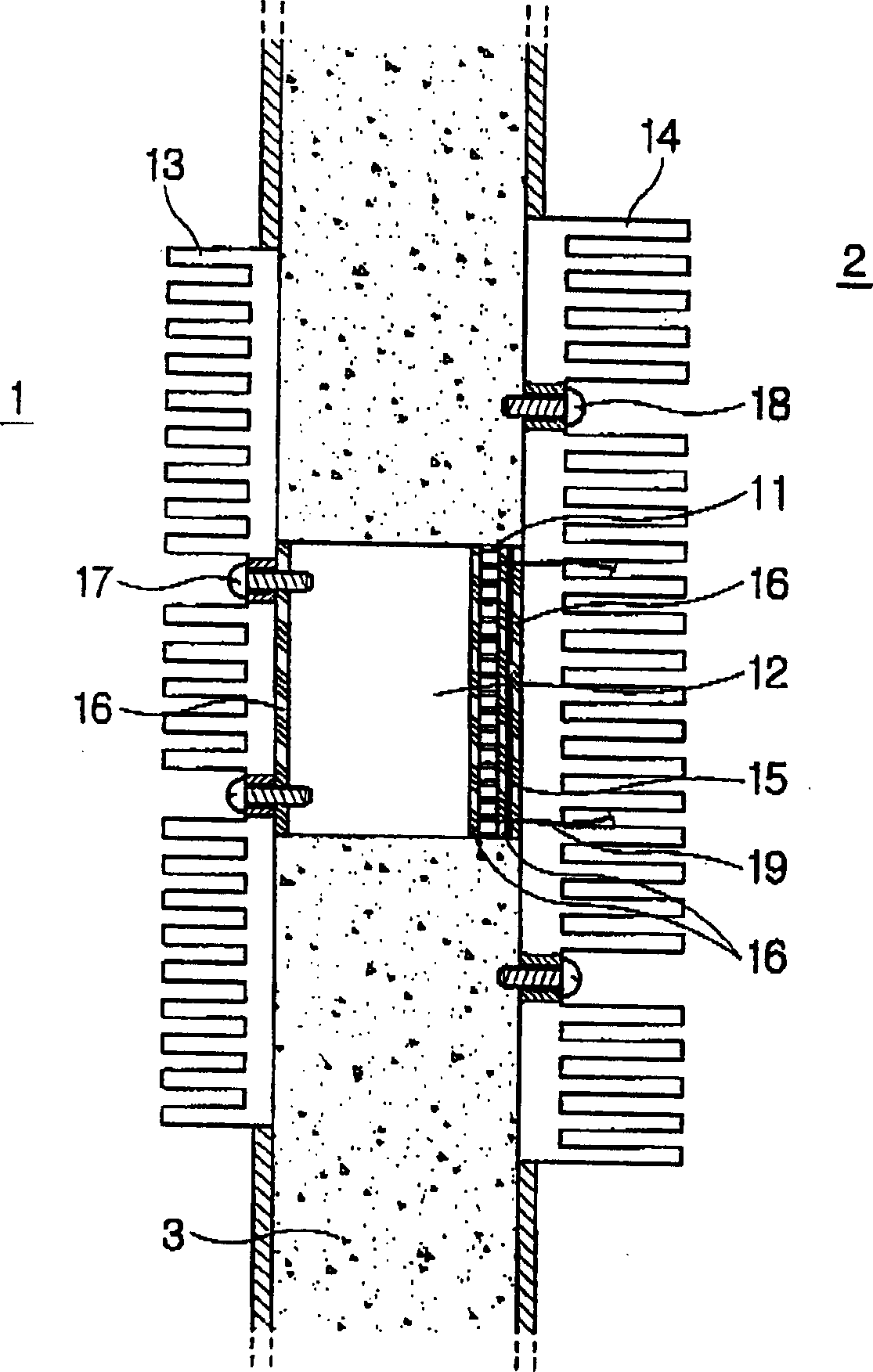

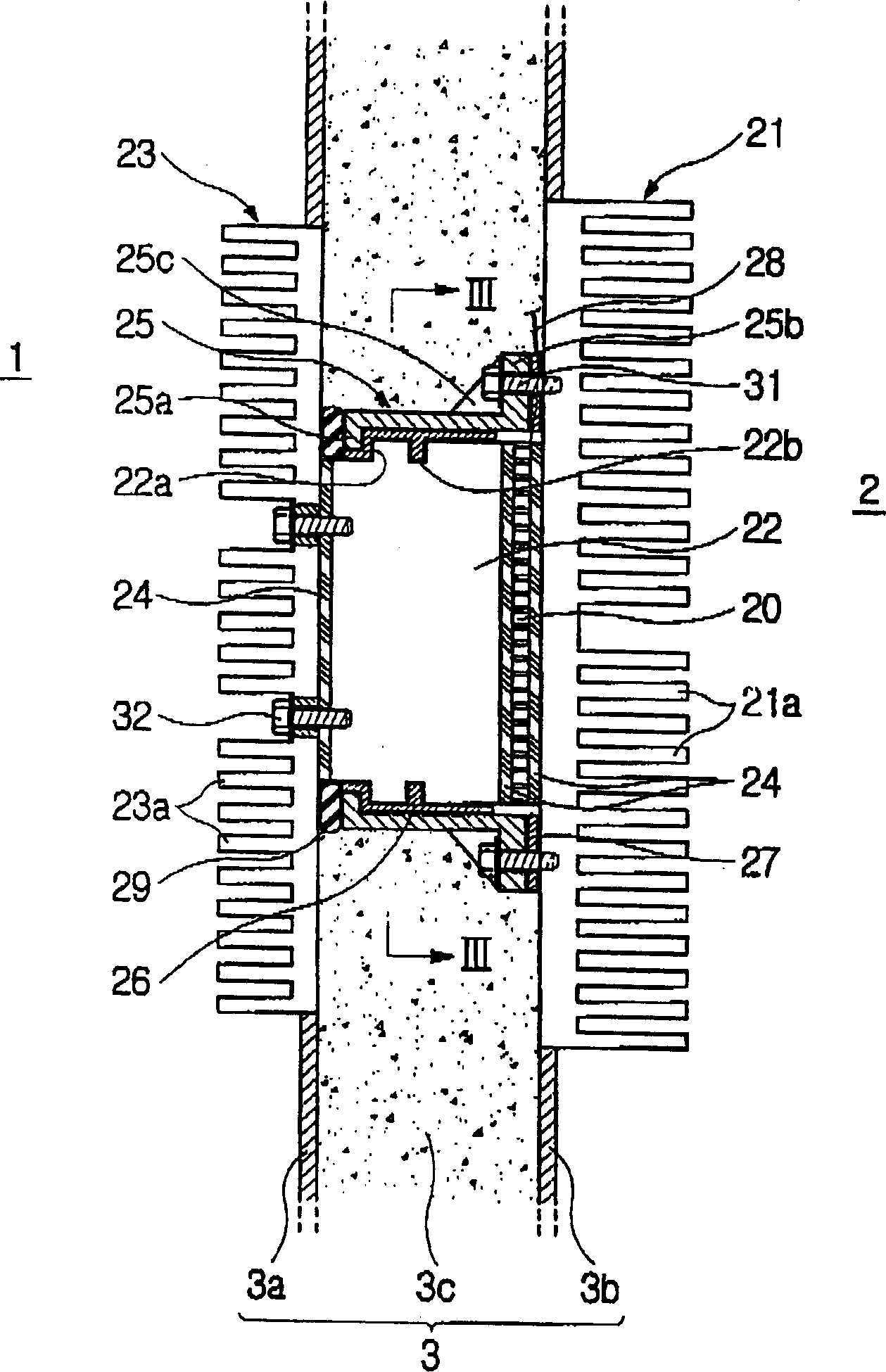

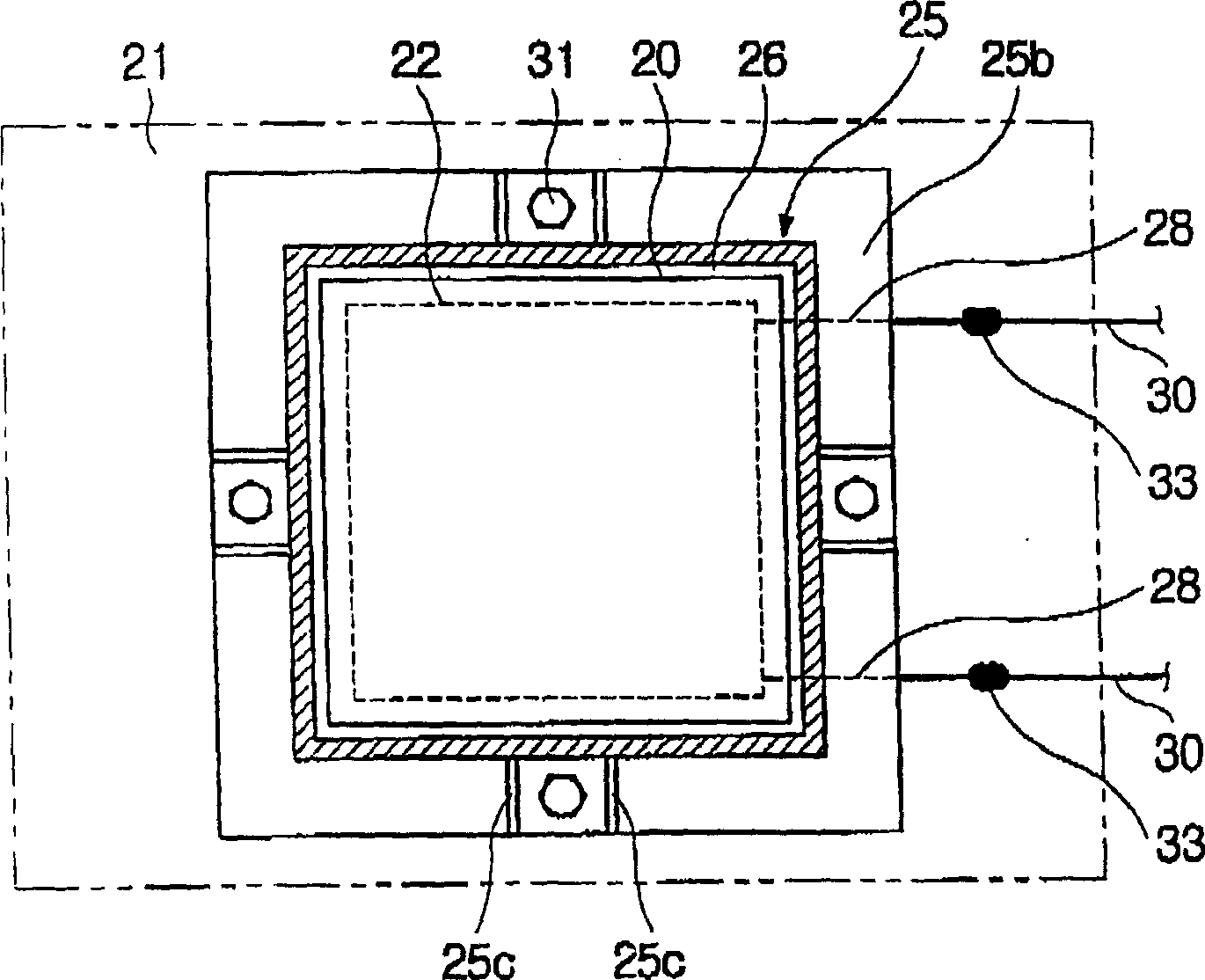

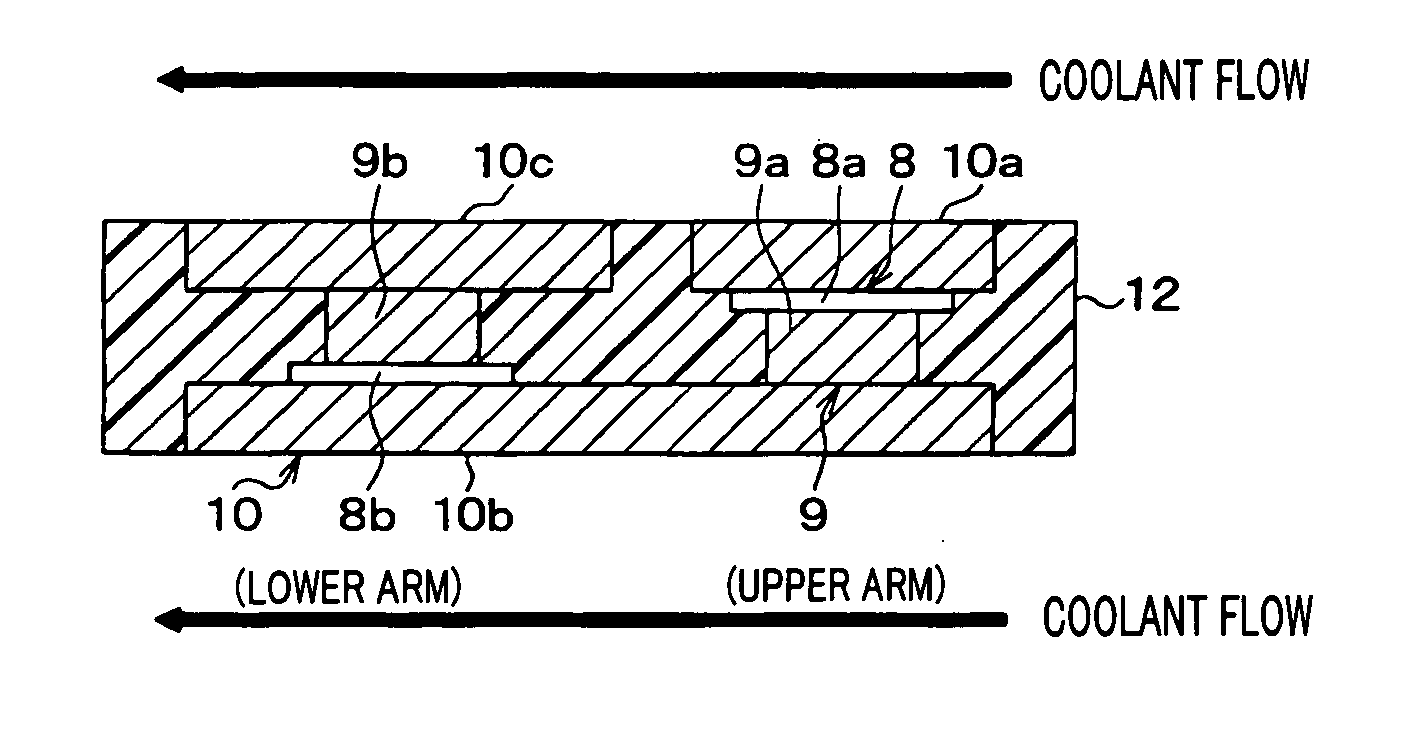

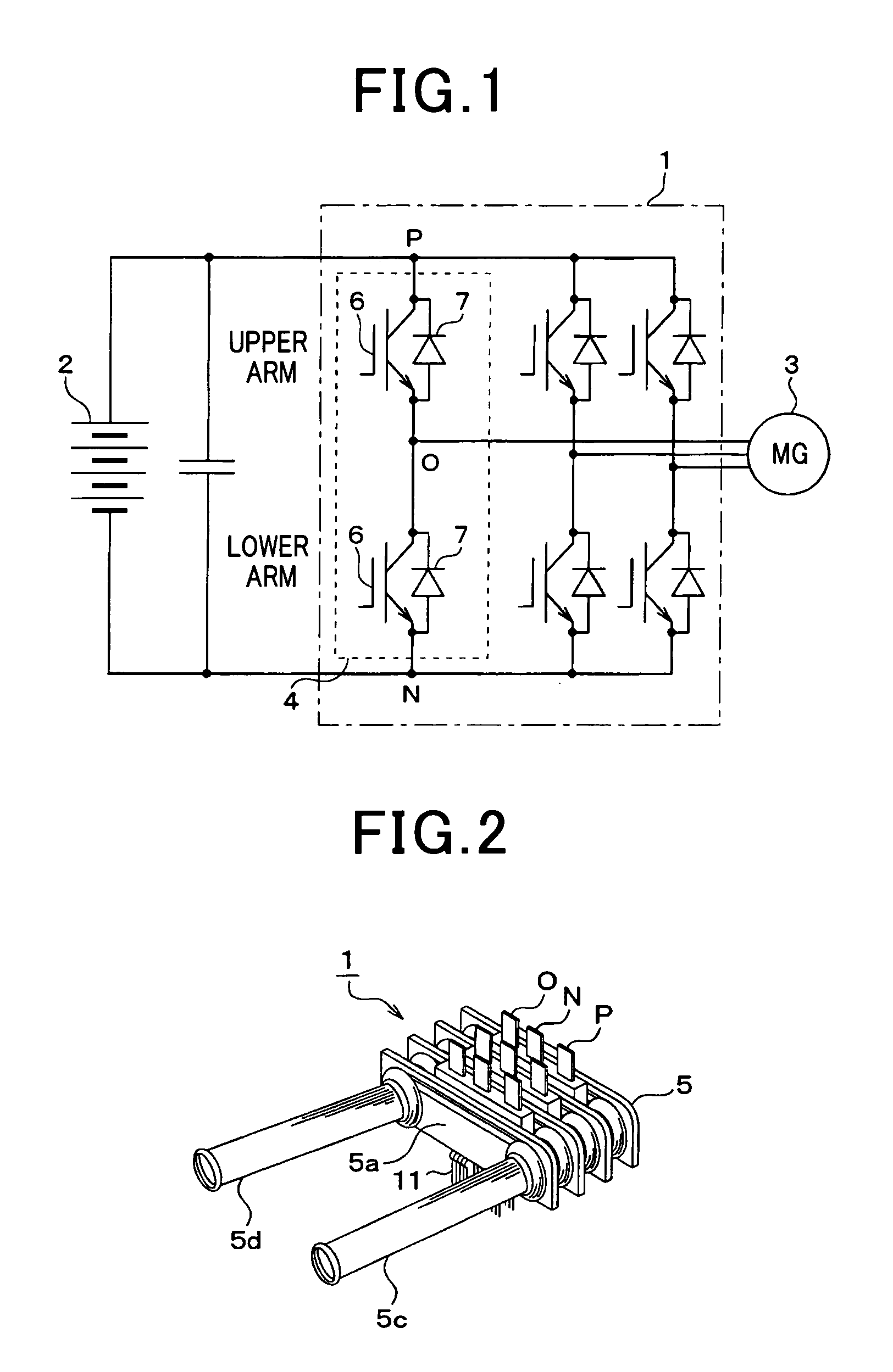

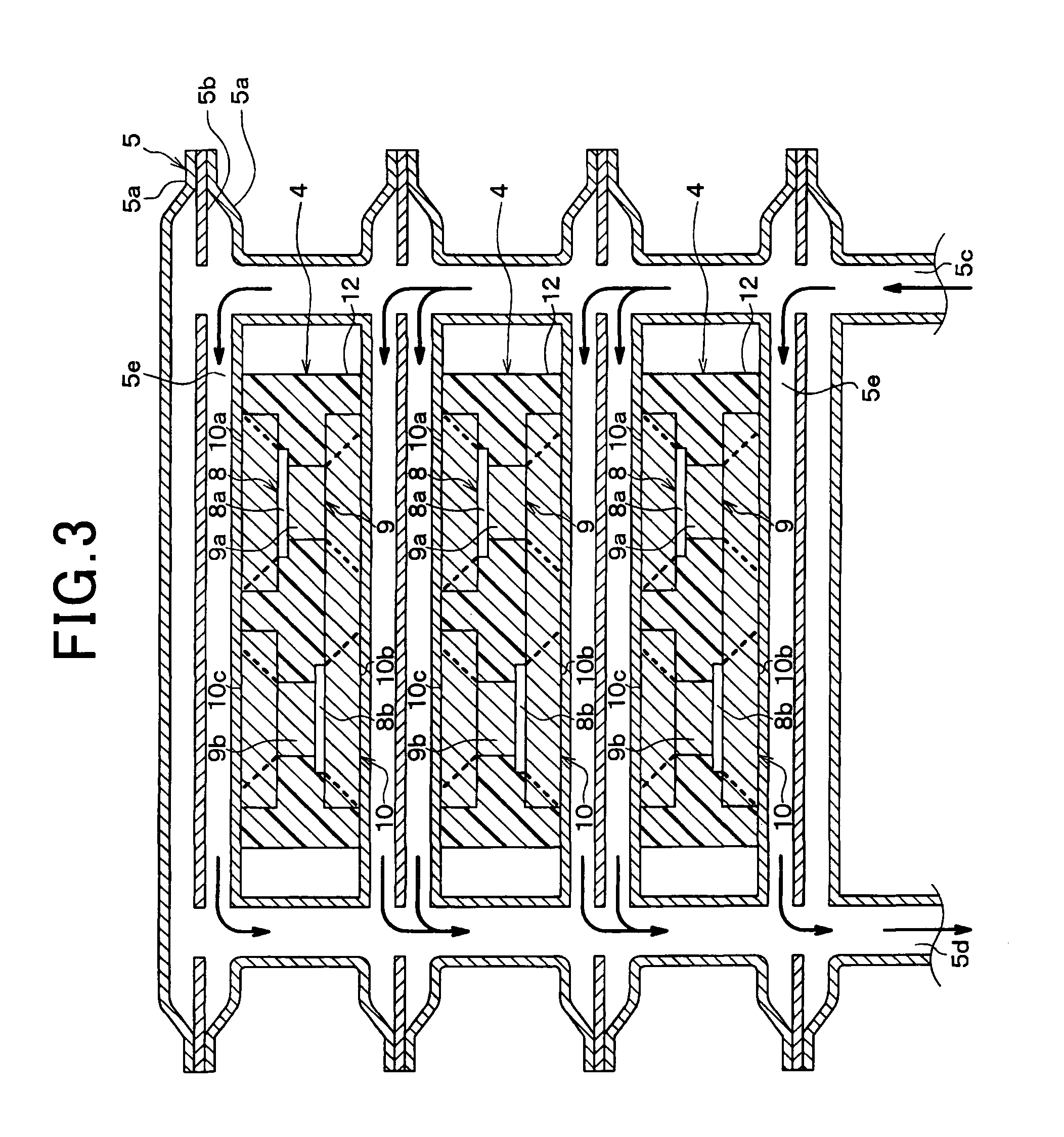

Semiconductor device accommodating semiconductor module with heat radiation structure

ActiveUS8363403B2Improve cooling effectImprove heat resistanceSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceCoolant flow

As a result of a lower arm side having a small thermal resistance being positioned downstream of the coolant flow, cooling efficiency of the lower arm positioned on the downstream side of the coolant flow becomes higher than that of an upper arm positioned on an upstream side. Hence, rise in coolant temperature on the upstream side can be suppressed, and the first and second semiconductor chips disposed upstream and downstream can be effectively cooled. Alternatively, even when the coolant temperature rises on the upstream side, the first and second semiconductor chips disposed upstream and downstream can be effectively cooled by sufficient cooling being performed on the downstream side based on the high cooling efficiency. Therefore, the rise in semiconductor chip temperature on the downstream side to a temperature higher than that on the upstream side can be suppressed.

Owner:DENSO CORP

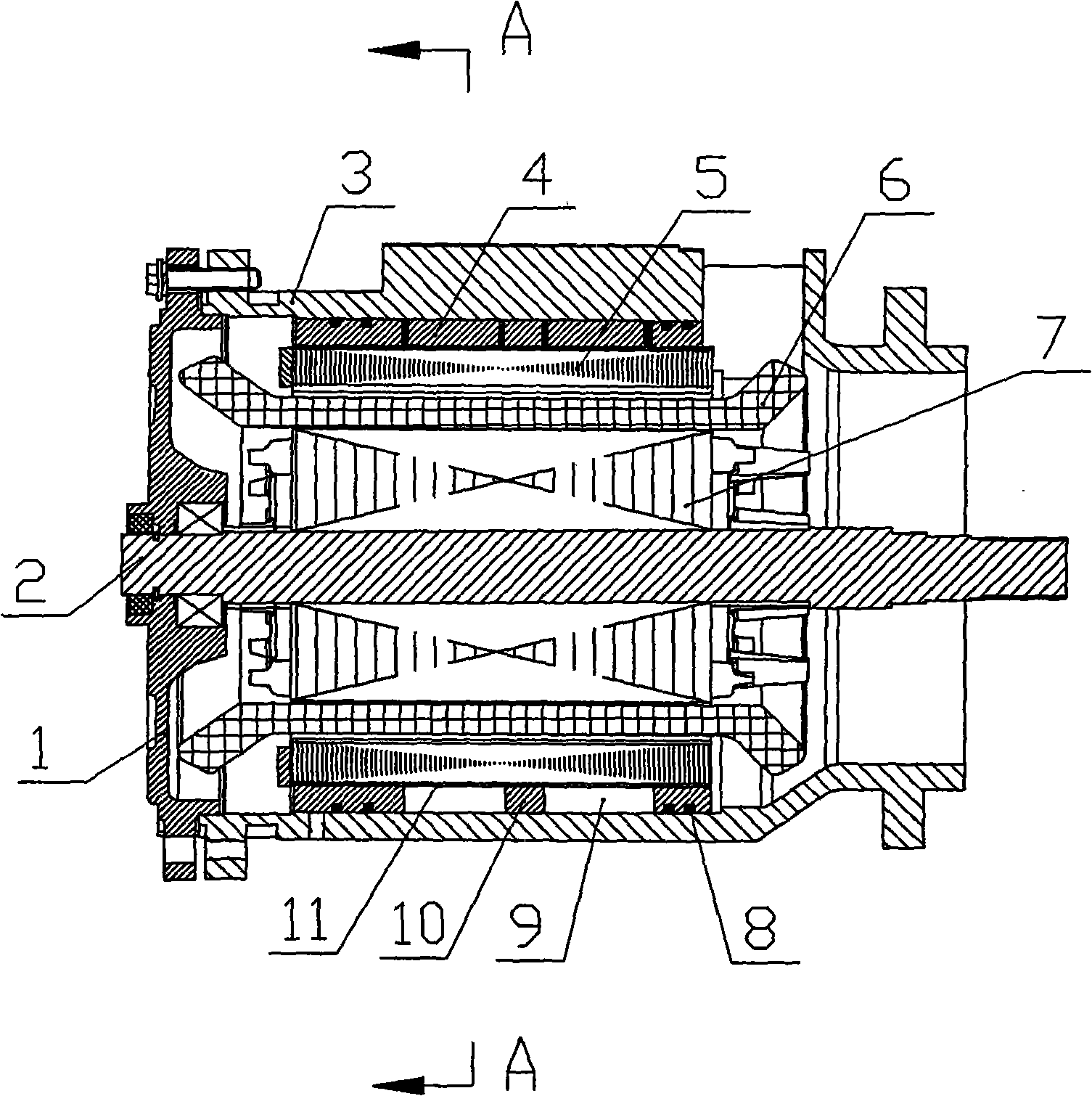

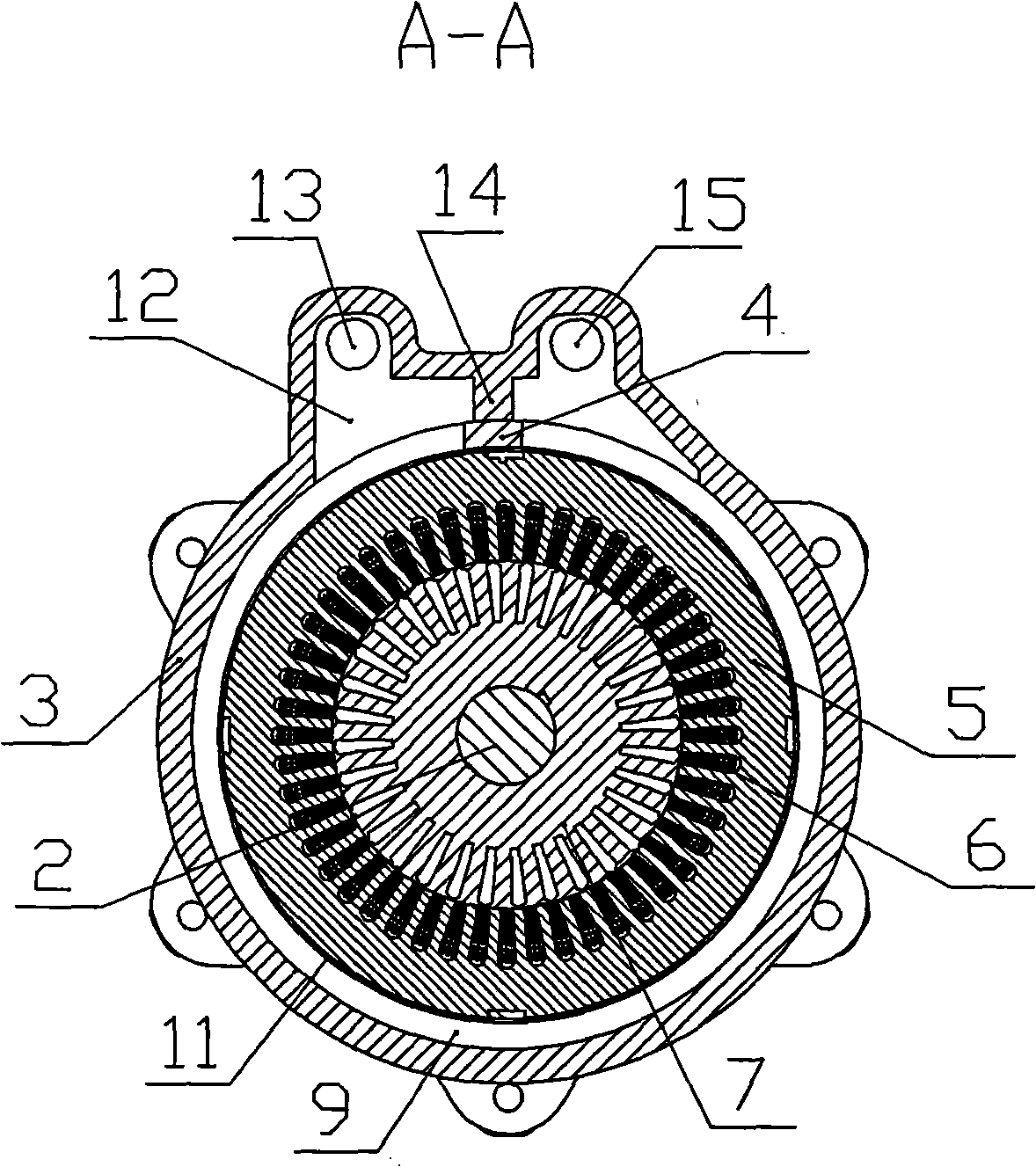

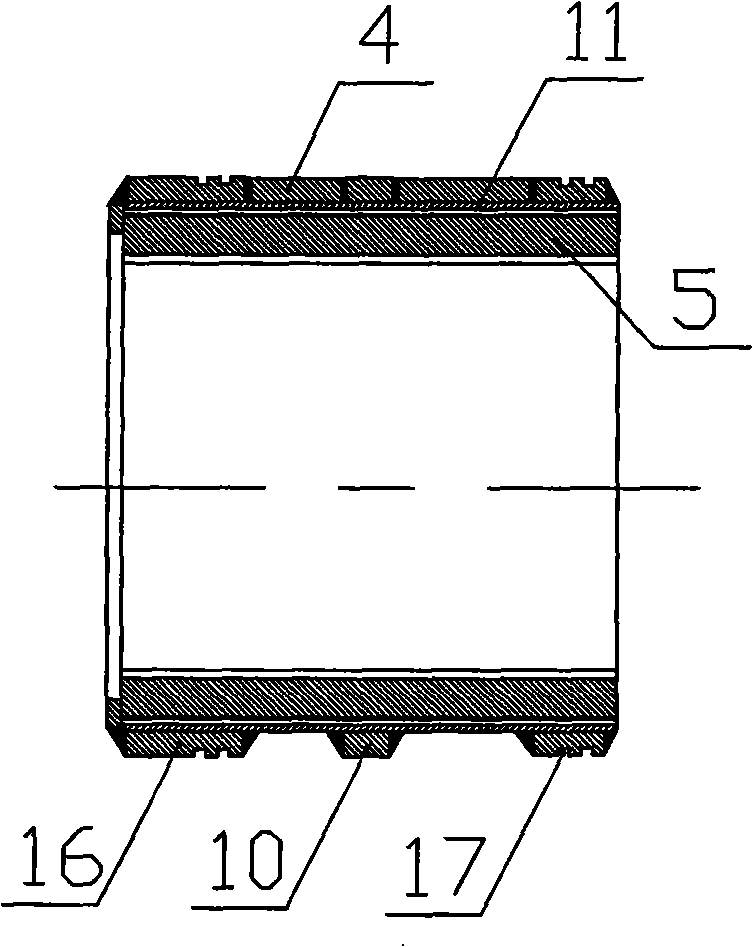

Water cooling electric machine for vehicle

InactiveCN101350544AReduce temperature riseSmall total thermal resistanceCooling/ventillation arrangementSupports/enclosures/casingsElectricityElectric machine

The present invention relates to a water cooling motor of engineering vehicle. In the technical proposal, a motor shaft is arranged in a motor shell, and is provided with a rotor; the outside of the rotor is provided with a stator which consists of a stator winding and a stator core; and an end cover is arranged at the end of the motor shell. The water cooling motor is characterized in that a cooling water cavity is arranged between the motor shell and the stator core and; the cooling water cavity is connected with a water inlet and a water outlet, which are arranged on the motor shell. The stator core is connected with a peripheral sink; two ends of the peripheral sink are connected with a side plate; and the external surface of the side plate is provided with a sealing groove. The water cooling motor has the advantages of small size, excellent performance of heat dissipation, high cooling speed, low temperature rise, and high security. Moreover, the water cooling motor can effectively prevent the leakage of cooling water, temporarily store the cold water flowing inwards and the hot water flowing outwards, guarantee the circulating use of the cooling water, and satisfy the requirements of electrically driven engineering vehicles.

Owner:WUXI KIPOR POWER CO LTD

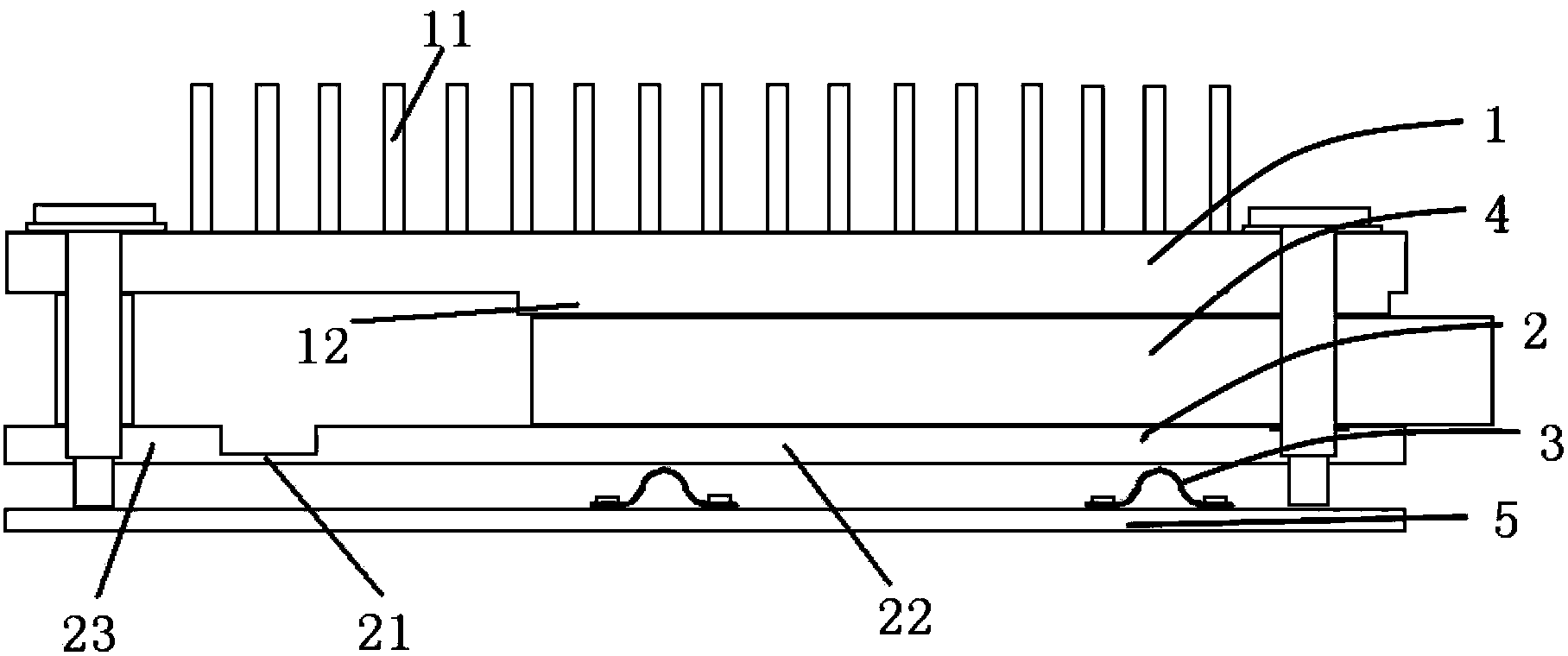

Method for manufacturing cooler for semiconductor-module, cooler for semiconductor-module, semiconductor-module and electrically-driven vehicle

ActiveUS10214109B2Simple manufacturing processReduce the number of partsSpeed controllerElectric devicesComputer moduleEngineering

A cooler for a semiconductor-module includes: a heat sink which has an appearance of a cuboid structure to one side of which a flow rate control plate is fixed; a thermal radiation plate on an outer surface of which semiconductor devices are bonded; and a tray-shaped cooling jacket having: a coolant introduction channel; a coolant extraction channel extending in parallel to the coolant introduction channel; and a cooling channel provided between the coolant introduction and extraction channels. The heat sink is provided in the cooling channel of the cooling jacket so that the flow rate control plate extends in a boundary between the coolant extraction channel and the cooling channel, and channels provided for the heat sink extend orthogonally to the coolant introduction and extraction channels. The thermal radiation plate is fixed so as to close an opening the cooling jacket.

Owner:FUJI ELECTRIC CO LTD

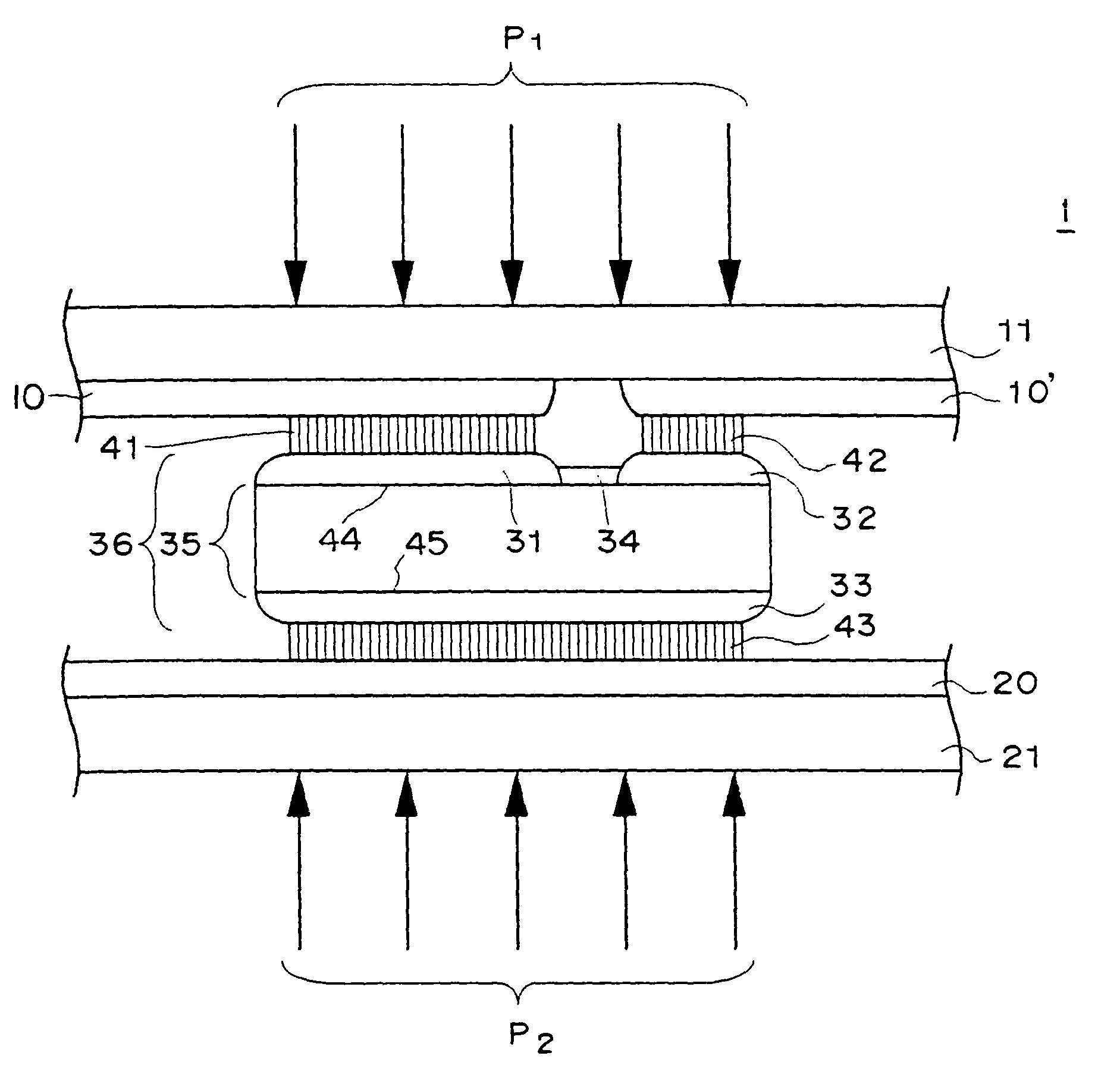

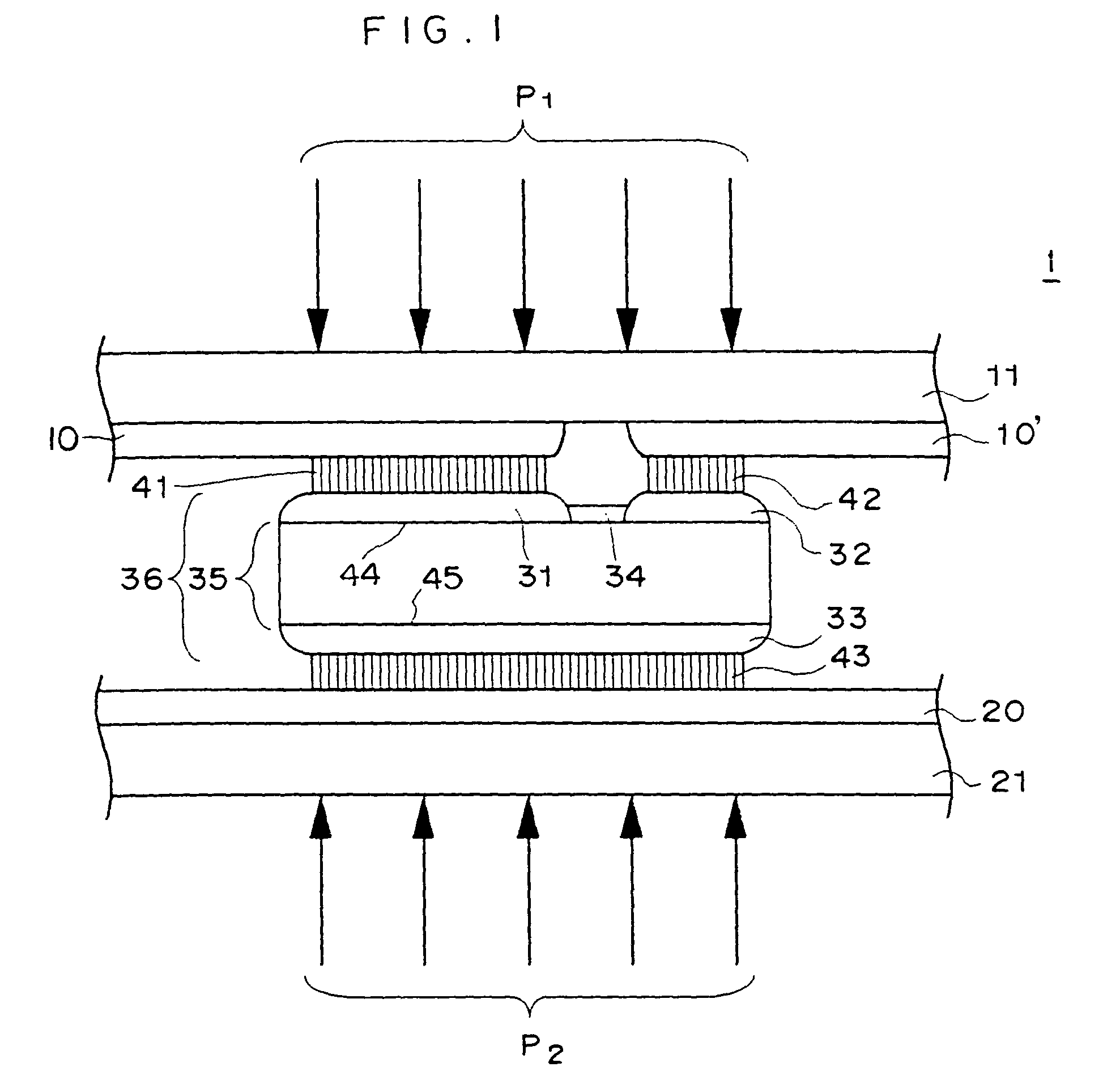

Pressure-welded semiconductor device

InactiveUS6987320B2Small total thermal resistanceHigh mechanical reliabilitySemiconductor/solid-state device detailsIndividual molecule manipulationEngineeringSemiconductor device

In a pressure-welded semiconductor device where at least one semiconductor element is disposed inside a casing, a buffer conductive layer including conductive carbons is disposed at pressure-welded portions between first casing-side electrodes and element-side electrodes disposed on a first main surface and at pressure-welded portions between second casing-side electrodes and element-side electrodes disposed on a second main surface.

Owner:TOYOTA CENT RES & DEV LAB INC

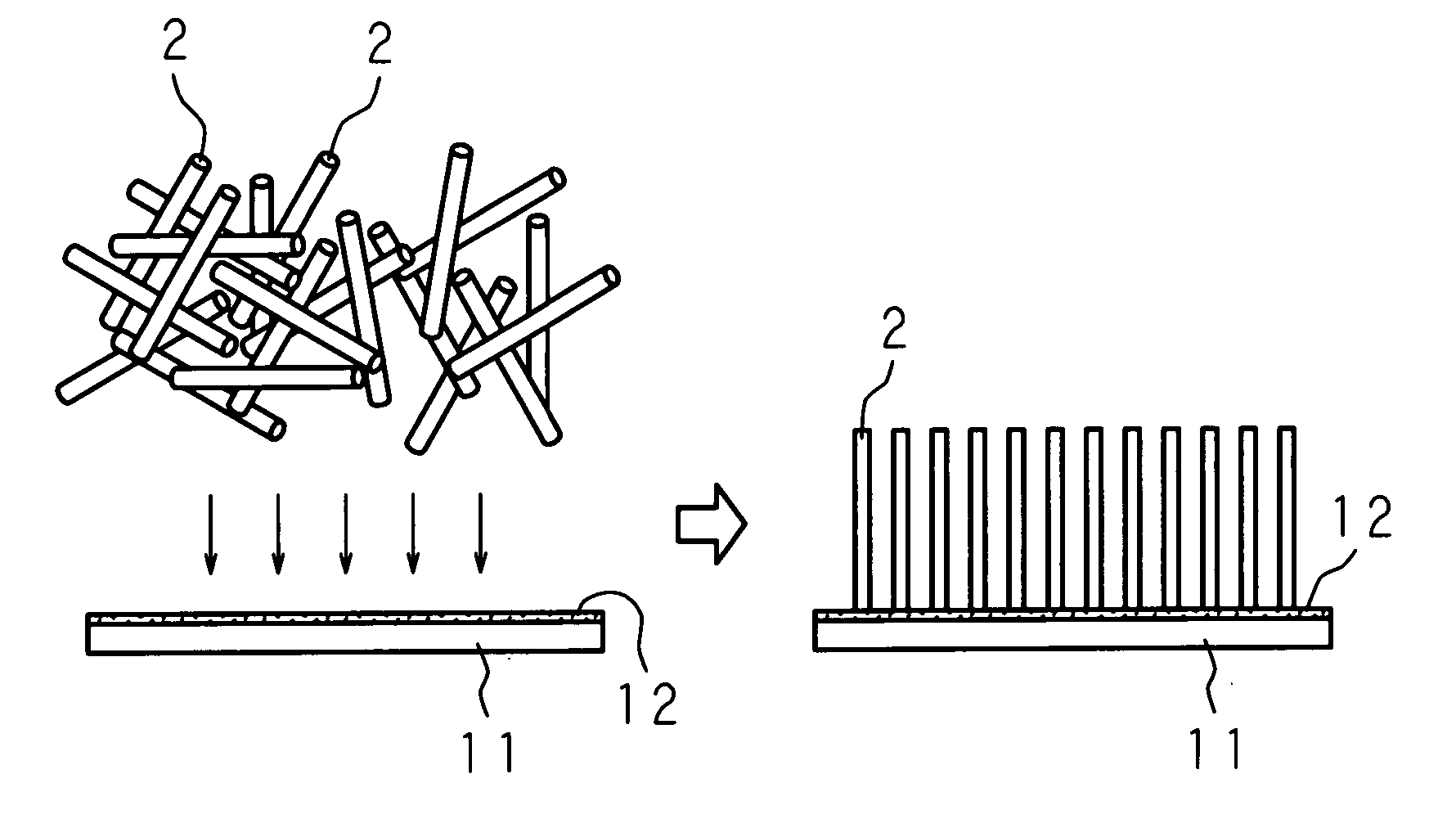

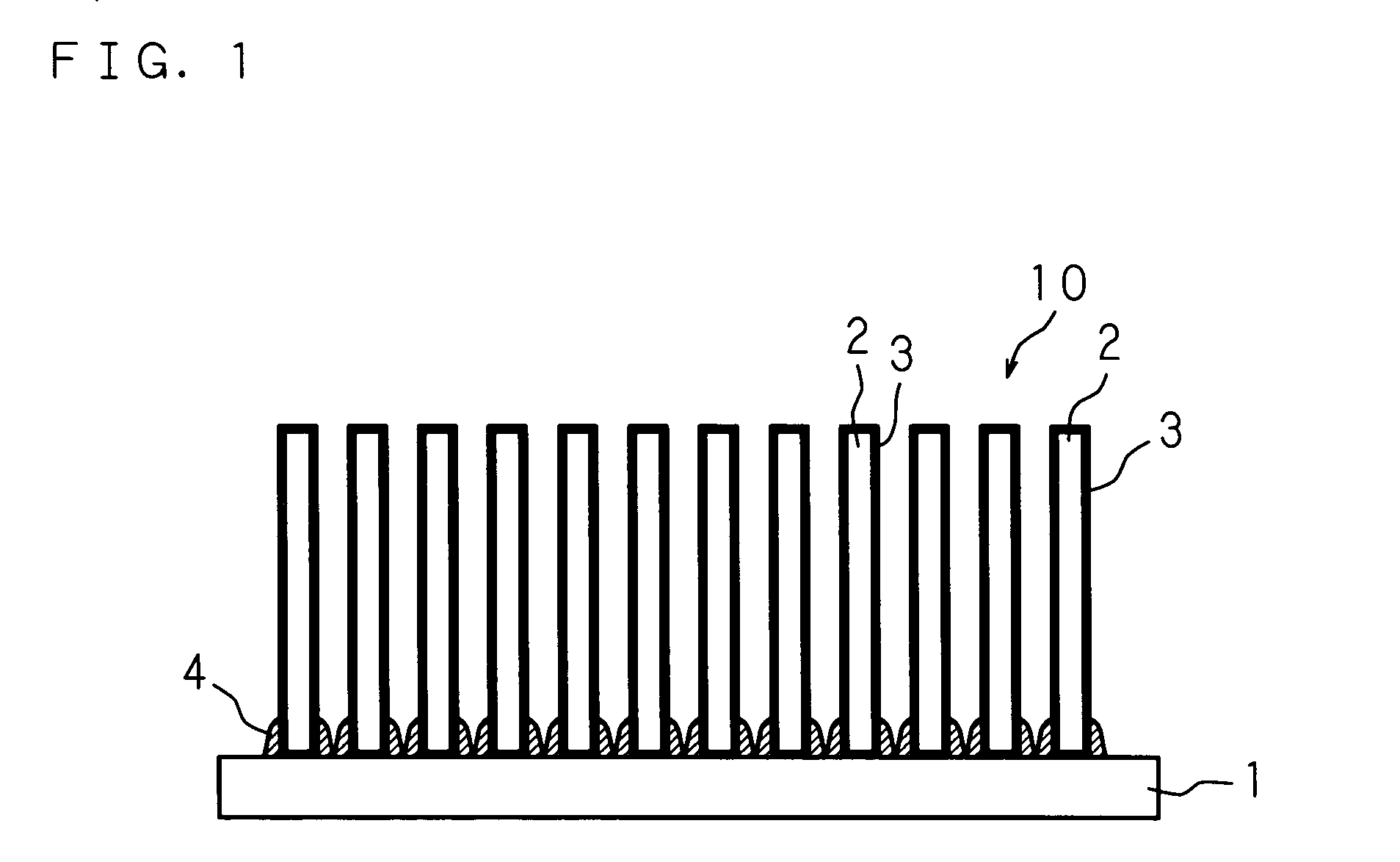

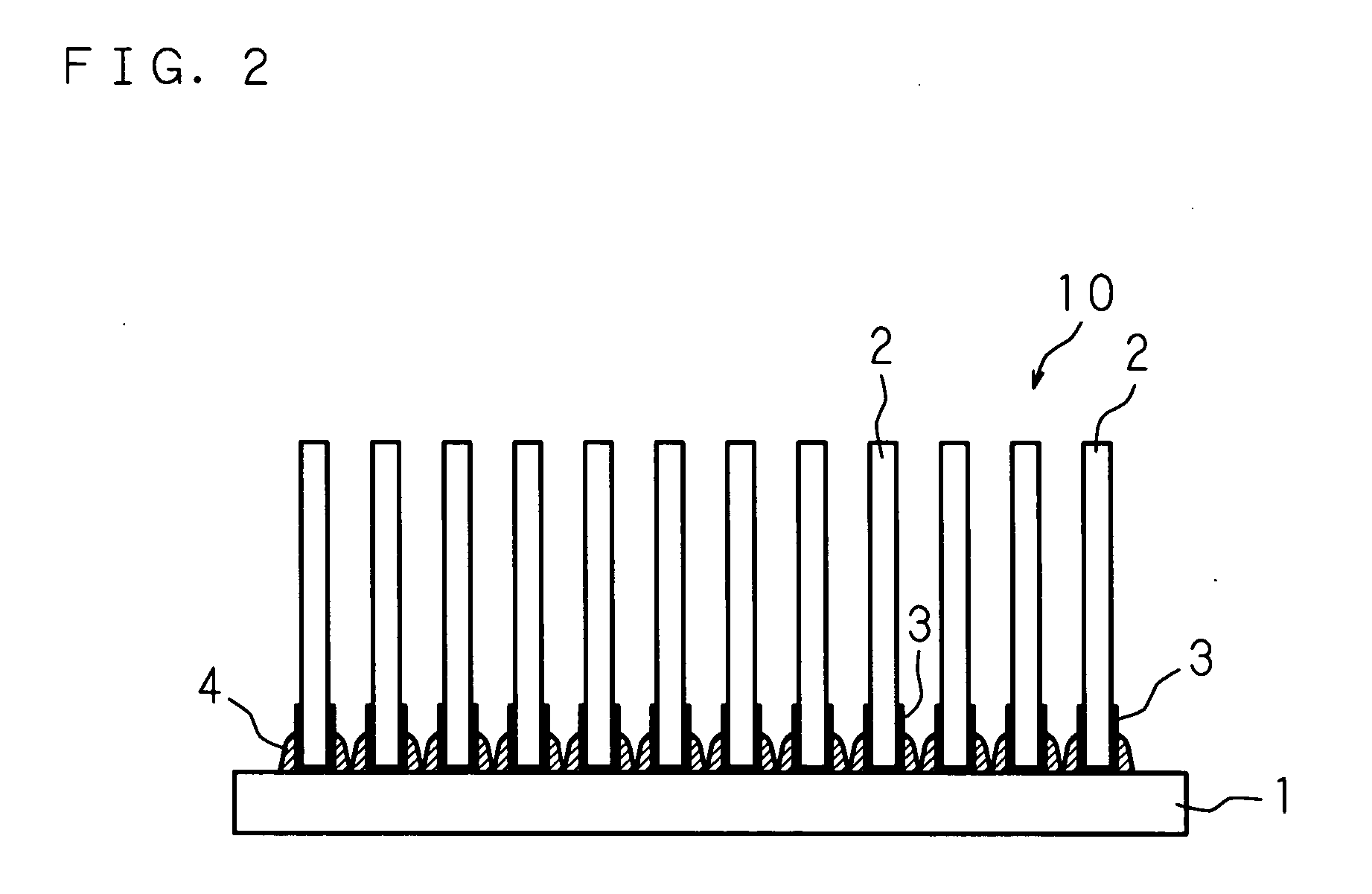

Radiating fin and method for manufacturing the same

InactiveUS20060065970A1Improve cooling effectEasy can be wettedSemiconductor/solid-state device detailsSolid-state devicesFiberOrganic solvent

A plurality of carbon fibers having a surface having a metal-plated layer (Cu-plated layer) are stood vertically on a flat plate-like provisional substrate by electrostatic flocking, and one end of the carbon fibers is provisionally adhered to the provisional substrate with an adhesive. The other end of the carbon fibers which is not provisionally adhered is contacted with a substrate (Cu plate) having a surface coated with a solder paste and, in this state, a brazing material (solder) is melted and cooled, and carbon fibers and a substrate are brazed (soldered). After completion of mechanical and thermal connection between the substrate and the carbon fibers, this is immersed in an organic solvent, and the provisionally adhered provisional substrate is peeled from the carbon fibers to manufacture a radiating fin.

Owner:FUJITSU LTD

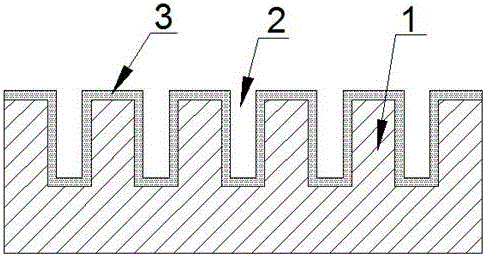

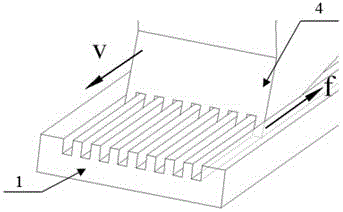

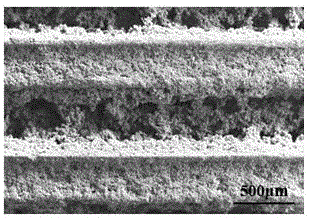

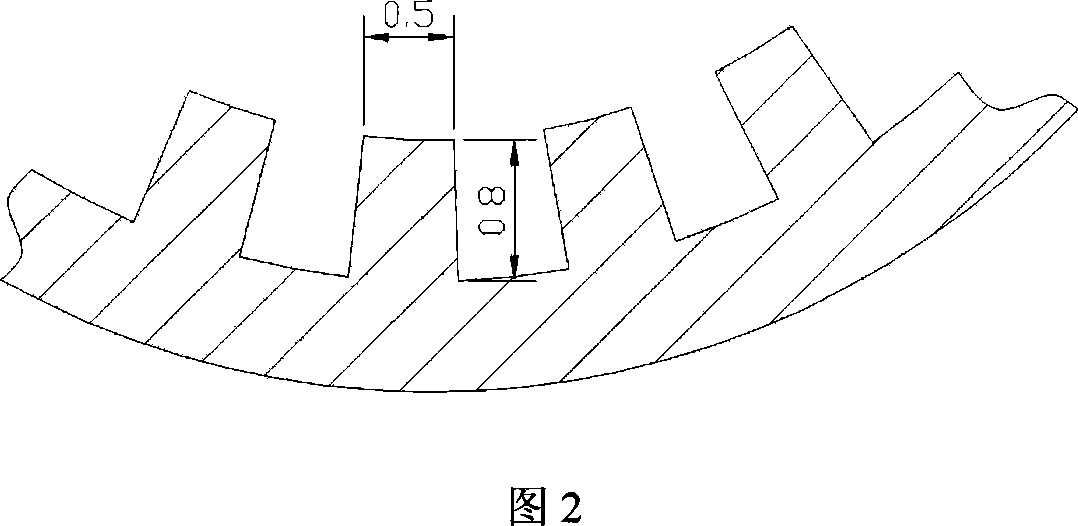

Groove and microstructure composite liquid absorption core and manufacturing method thereof

InactiveCN105091648ASmall capillary radiusIncrease capillary pressureIndirect heat exchangersEvaporation (deposition)Electroless deposition

The invention discloses a groove and microstructure composite liquid absorption core. The groove and microstructure composite liquid absorption core comprises a red copper basal body provided with a groove in the surface, wherein microstructure layers with thicknesses of 0.1-1000 microns are respectively arranged on the inner surface of the groove and the outer surface, provided with the groove, of the red copper basal body; and the microstructure layers mainly consist of fine copper particles with particle sizes within 0.1-20 microns. The invention further discloses a manufacturing method of the composite liquid core; and the method comprises the following steps: (1) the groove structure is machined on the red copper basal body by a broaching or planing process; (2) after the groove structure is cleaned, the microstructure is built on the surface of the groove as a cathode by an electrochemical deposition method; and (3) the interface bonding strength between the microstructure and the surface of the groove is improved through a sintering curing process. The composite liquid absorption core, provided by the invention, can provide excellent capillary force, is excellent in permeability, and facilitates to flow liquid on a condensation section back to an evaporation section; and the manufacturing method is simple, easy to be controlled, high in production efficiency and low in cost, and can be widely applied to such two-phase heat transfer devices as heat pipes, heat columns and soaking plates.

Owner:SOUTH CHINA UNIV OF TECH

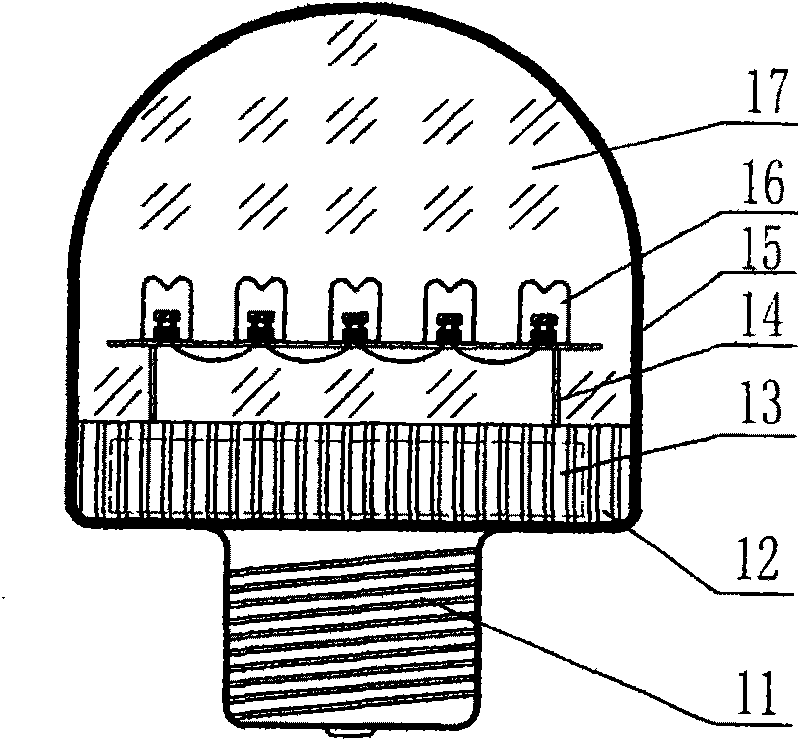

Light source apparatus

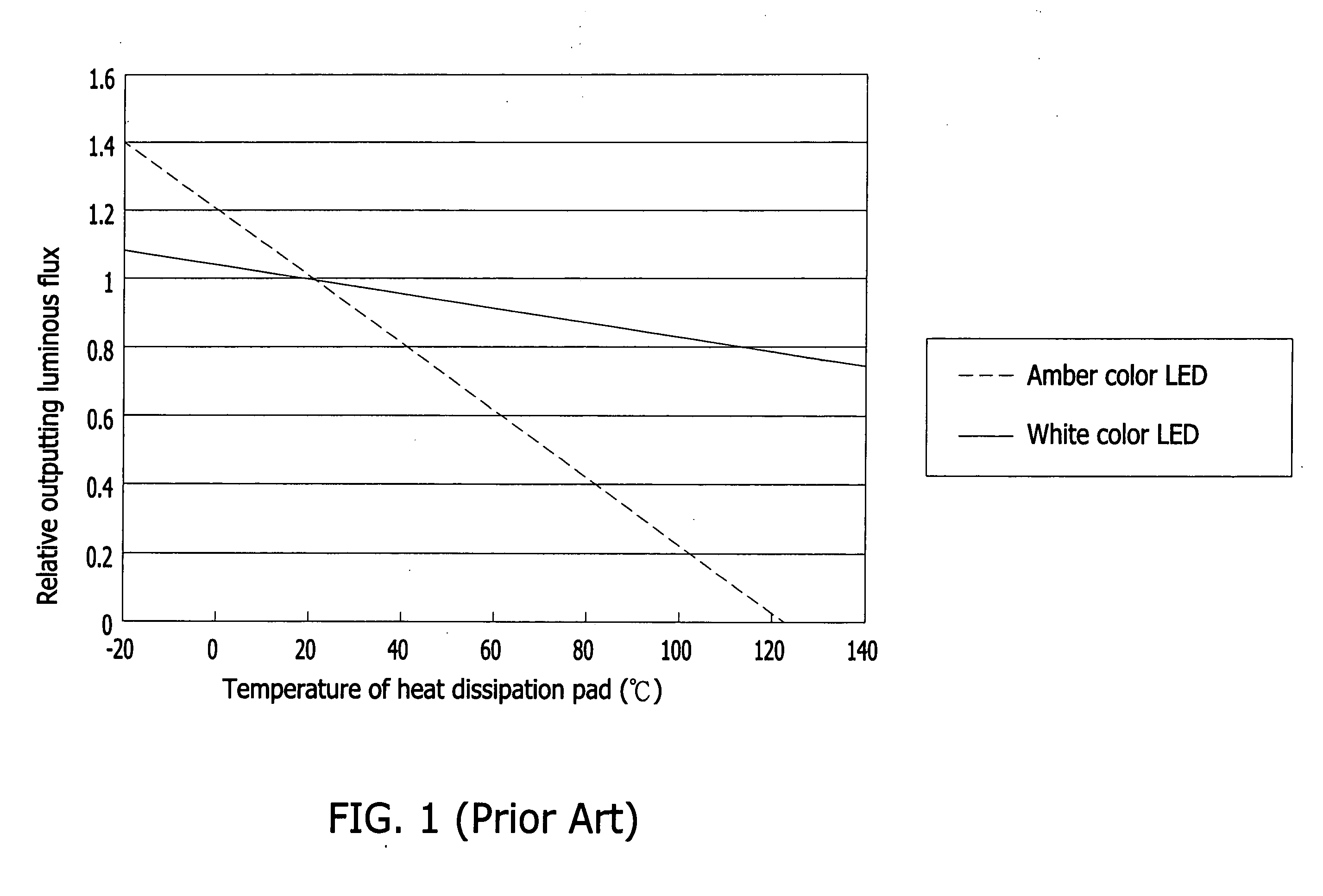

InactiveUS20100149807A1Easy to changeSmall total thermal resistanceLighting support devicesPoint-like light sourceEngineeringLight source

A light source apparatus including a first heat transfer element, a second heat transfer element, at least one first light emitting element, and at least one second light emitting element is provided. The first heat transfer element has a first carrying surface and a first heat dissipation surface opposite to the first carrying surface. The second heat transfer element surrounds the first heat transfer element and has a second carrying surface and a second heat dissipation surface opposite to the second carrying surface. The thermal resistance of the first heat transfer element is smaller than the thermal resistance of the second heat transfer element. The first and the second light emitting elements are disposed over the first and the second carrying surfaces respectively. The luminance of the first light emitting element is easier to vary with a change of temperature than the luminance of the second light emitting element.

Owner:YOUNG GREEN ENERGY

LED lamp radiating with optically coupled cooling liquid

InactiveCN101725858AFacilitate conductionImprove featuresPoint-like light sourceLighting heating/cooling arrangementsOptical propertyHeat conducting

The invention provides an LED lamp radiating with optically coupled cooling liquid. An excellent heat-conducting optically coupled cooling liquid is filled between the luminous body of the outgoing end of the LED lamp and an enclosed shell so as to complete leakage-free encapsulation. Excellent heat-conducting properties and excellent optical characters of the optically coupled cooling liquid are used for realizing the improvement of the excellent heat conduction and optical characters between the luminous body of the LED lamp and the shell. When the radiating effect is needed to further improve, the optically coupled cooling liquid is forced to complete adequate heat exchange in a cold pool in the manner of pumping in the cold optically coupled cooling liquid and overflowing the hot optically coupled cooling liquid so that the junction temperature of the luminous body is maintained below 125 DEG C, so as to completely improve the radiating conditions of the luminous body in the LED lamp, prolong the service life of the LED lamp radiating with optically coupled cooling liquid with power LED integrated light source and the outgoing effect of the outgoing end.

Owner:陈炜旻

Heat-dissipating structure of optical module

ActiveCN104125751AReduce thermal contact resistanceSmall total thermal resistanceCooling/ventilation/heating modificationsEngineeringElectrical and Electronics engineering

The invention relates to a heat-dissipating structure of an optical module. The heat-dissipating structure comprises a radiator, a circuit board and an elastic component. The radiator is fixedly arranged on the circuit board. The optical module is pluggably arranged between the radiator and the circuit board. The circuit board area occupied by the optical module and the circuit board area adjacent to the circuit board area occupied by the optical module are connected through a flexible connection structure, so that the circuit board corresponding to the optical module can move along the vertical direction of the plane where the circuit board locates independently. The elastic component is arranged at the side, opposite to the optical module, of the circuit board. When the optical module is inserted, the circuit board is pressed by the optical module and moves to the direction of the elastic component; and the elastic component is then pressed to generate elastic force to enable the optical module to be in close contact with the radiator. The heat-dissipating structure of the optical module provided in the invention is small in thermal resistance, easy to insert and unplug, and can enable the optical module to dissipate heat well.

Owner:HUAWEI TECH CO LTD

Cooling and heating device using thermoelectric module

InactiveCN1435608ASmall total thermal resistanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHeat conducting

A cooling and heating apparatus using a thermoelectric module, in which the thermoelectric module, a heat emitting member and a heat conducting block are integrated into a single unit, to improve the performance and durability of the thermoelectric module. The cooling and heating apparatus includes a thermoelectric module. The heat emitting member is attached to a first surface of the thermoelectric module. The heat conducting block is attached to a second surface of the thermoelectric module. The heat absorbing member is attached to the heat conducting block. A cover integrates the thermoelectric module and the heat conducting block into the single unit by fixedly covering side surfaces of the thermoelectric module and the heat conducting block and a part of an inner surface of the heat emitting member.

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor device accomodating semiconductor module with heat radiation structure

ActiveUS20110242761A1Improve cooling effectImprove heat resistanceSemiconductor/solid-state device detailsSolid-state devicesCoolant flowSemiconductor chip

As a result of a lower arm side having a small thermal resistance being positioned downstream of the coolant flow, cooling efficiency of the lower arm positioned on the downstream side of the coolant flow becomes higher than that of an upper arm positioned on an upstream side. Hence, rise in coolant temperature on the upstream side can be suppressed, and the first and second semiconductor chips disposed upstream and downstream can be effectively cooled. Alternatively, even when the coolant temperature rises on the upstream side, the first and second semiconductor chips disposed upstream and downstream can be effectively cooled by sufficient cooling being performed on the downstream side based on the high cooling efficiency. Therefore, the rise in semiconductor chip temperature on the downstream side to a temperature higher than that on the upstream side can be suppressed.

Owner:DENSO CORP

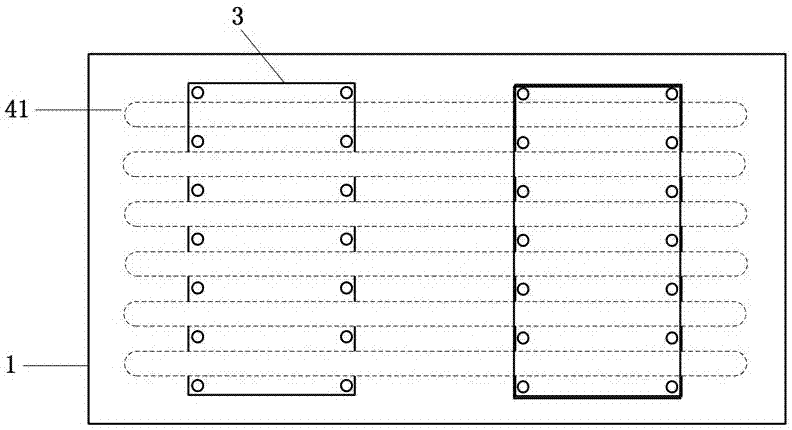

Air-cooled heat pipe radiator for high-capacity SVG

PendingCN107466194AThermal resistance does not affectDoes not affect thermal resistanceModifications for power electronicsHeat pipeHeat spreader

The invention discloses an air-cooled heat pipe radiator for high-capacity SVG. The air-cooled heat pipe radiator for the high-capacity SVG comprises a substrate and a fin group which is arranged on the front surface of the substrate; the back surface of the substrate is connected with a radiator piece; a plurality of embedding grooves which are formed in parallel are formed in the front surface of the substrate; a comb-shaped heat pipe is embedded into each embedding groove; the bottom of each comb-shaped heat pipe is in contact with the radiated piece; the top end of each comb-shaped heat pipe is inserted into the fin group. The radiator has the advantages of being simple in structure, high in reliability, and capable of reducing total thermal resistance remarkably.

Owner:STATE GRID HUNAN ELECTRIC POWER +3

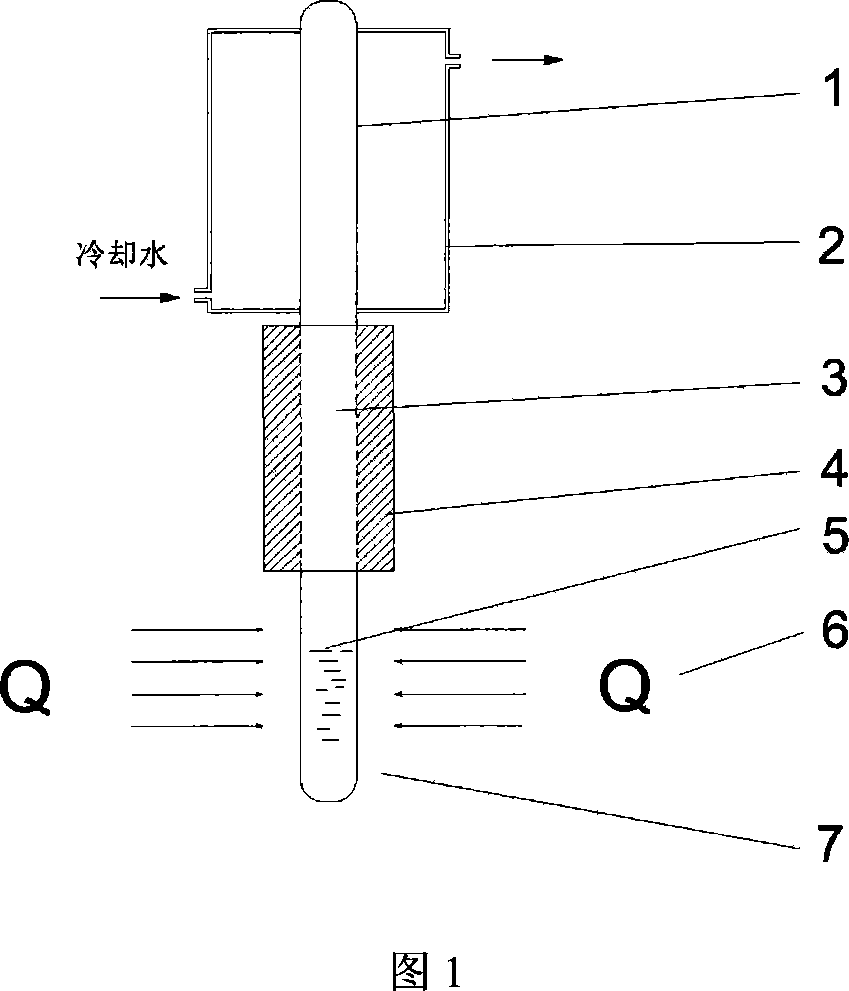

Two-phase closed type hot siphon tube using water-based carbon nanotube suspension liquid as working fluid

InactiveCN101078600ASmall total thermal resistanceDecrease the tilt angleIndirect heat exchangersHeat-exchange elementsSiphonWater based

The invention relates to a two-phase closed thermosyphon with water-based carbon nano-tube suspension, comprising vaporizing segment, thermal insulation segment and condensing segment. Axial micro grooves arranged evenly are set on the inner wall of condensing segment to increase the area of heat transferring face. Carbon nano-tube suspension, as working fluid is filled in the vaporizing segment. Fluid-loaded rate is 40-60% of vaporizing segment cubage. The carbon nano-tube suspension is mixed solution of de-ionized water and carbon nano-tube. Mass concentration of carbon nano-tube in suspension is 1-2.5%. In using, required heat dispersing elements are attached on the lower end of heat pipe. Depending on evaporation of working fluid in the vaporizing segment of thermosyphon heat is transferred so that heat quantity of required heat dispersing elements is transferred to cooling water in the condensing segment. The invention uses water-based carbon nano-tube suspension as working fluid. Not only heat exchanging performance is improved but also total heat resistance of heat pipe is decreased. Oblique angle of heat pipe is decreased greatly and when the oblique angle of heat achieves horizontal 15 degrees heat exchanging performance is still good.

Owner:SHANGHAI JIAO TONG UNIV

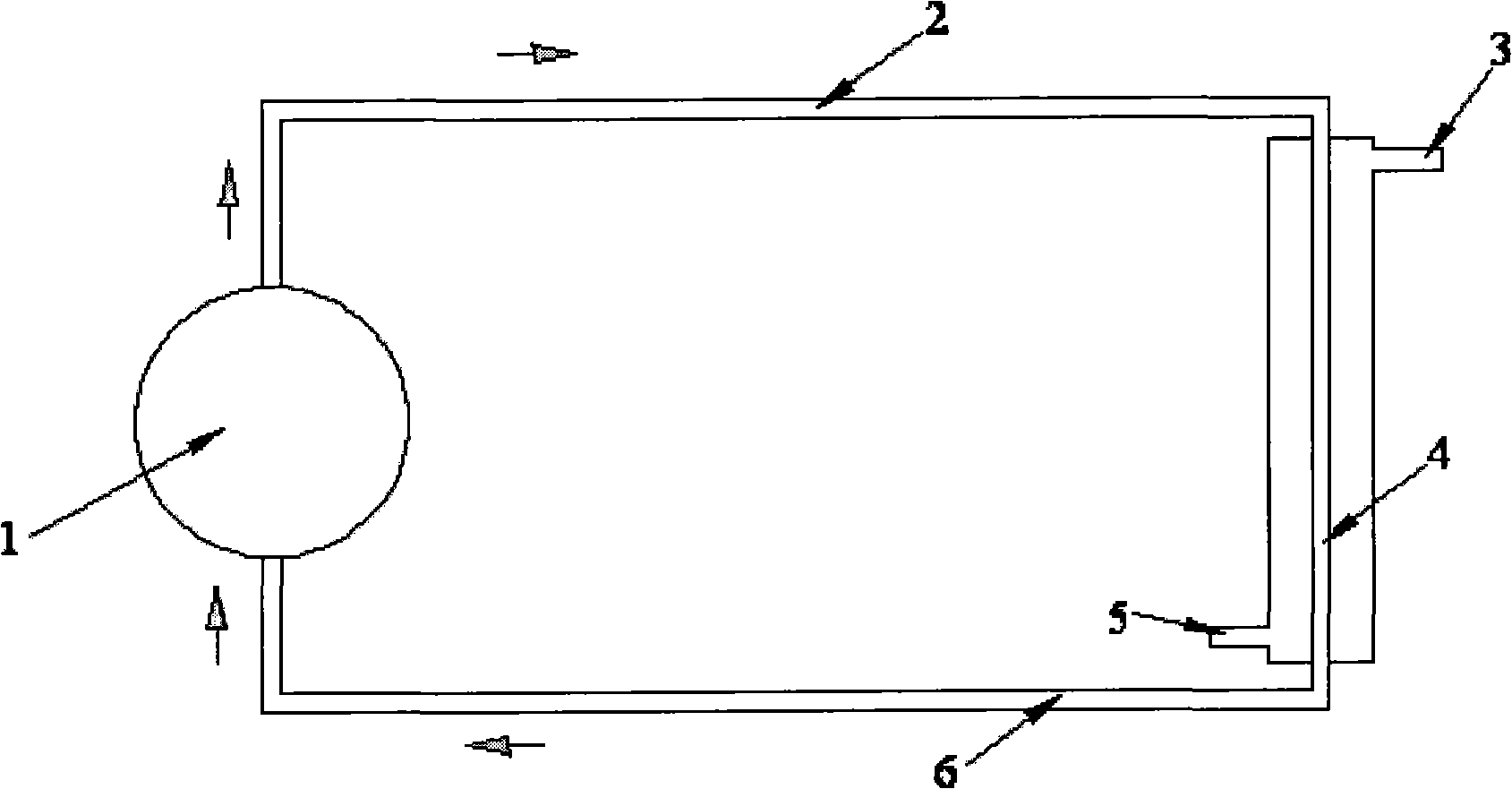

Miniature capillary pump loop flat plate heat pipe with alcohol group nano fluid as working medium

InactiveCN101315257ASmall total thermal resistanceImprove heat transfer characteristicsIndirect heat exchangersWorking fluidEngineering

The invention provides a capillary pump return passage flat heat pipe which adopts an alcohol nano-particle suspension as the working fluid, and relates to the cooling technology field of electronic components. The flat heat pipe comprises an evaporator, a gas passage, a condenser and a fluid passage. A double-layer capillary structure composed of stainless steel screens of two specifications is used in the evaporator; the double-layer capillary screen structure composed of the stainless steel screens of two specifications is used in the evaporator; an alcohol-group nano-particle suspension is adopted as the working fluid, wherein the alcohol-group nano-particle suspension is a mixture of the alcohol liquid and the nano-particles, the mass concentration of copper nano-particle in the suspension is 1%-2%, and the filling factor is 50%-60% of the total volume of the system. By adopting the alcohol nano-particle suspension as the working fluid, the heat transfer characteristic of the capillary pump return passage flat heat pipe is strengthened, thereby effectively reducing the entire thermal resistance and increasing the maximum heat dissipation power.

Owner:SHANGHAI JIAO TONG UNIV

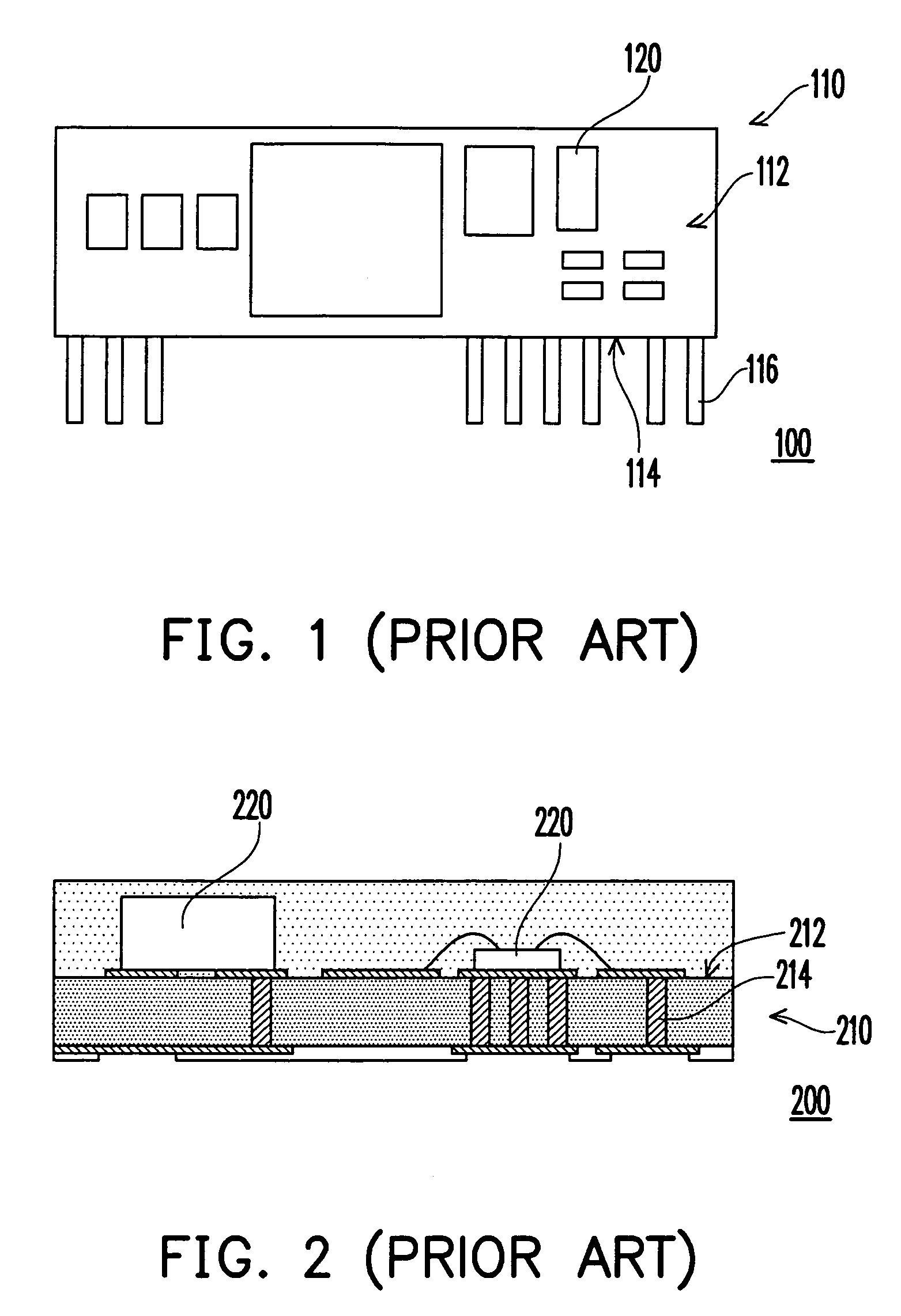

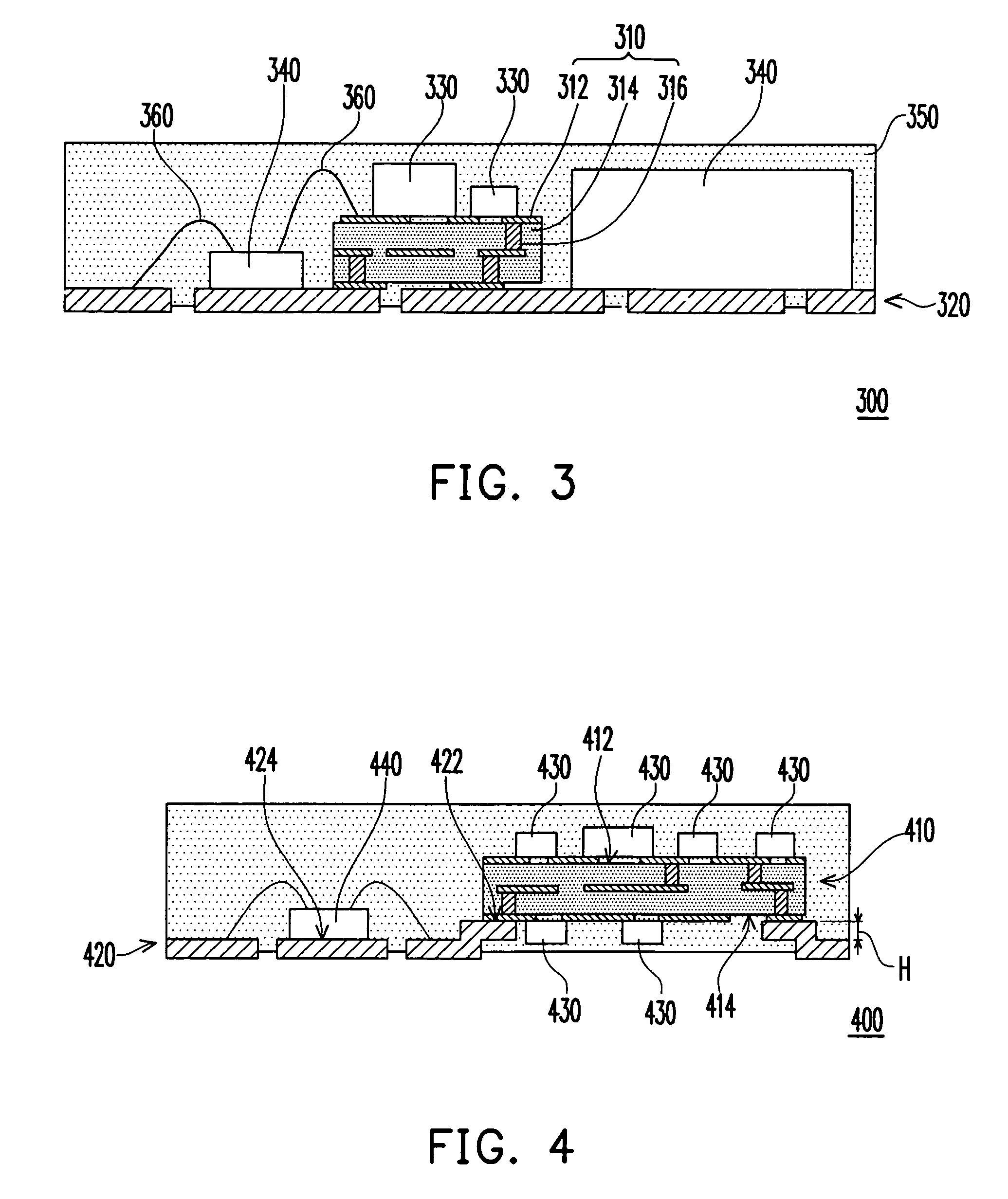

Package structure

ActiveUS7551455B2High wiring densityIncrease ratingsSemiconductor/solid-state device detailsSolid-state devicesElectronic component

A package structure including a first carrier, a second carrier, at least a first electronic component and at least a second electronic component is provided. The second carrier is electrically connected to the first carrier. The first electronic component is disposed on the first carrier and electrically connected to the first carrier. The second electronic component is disposed on the second carrier and electrically connected to the second carrier.

Owner:CYNTEC

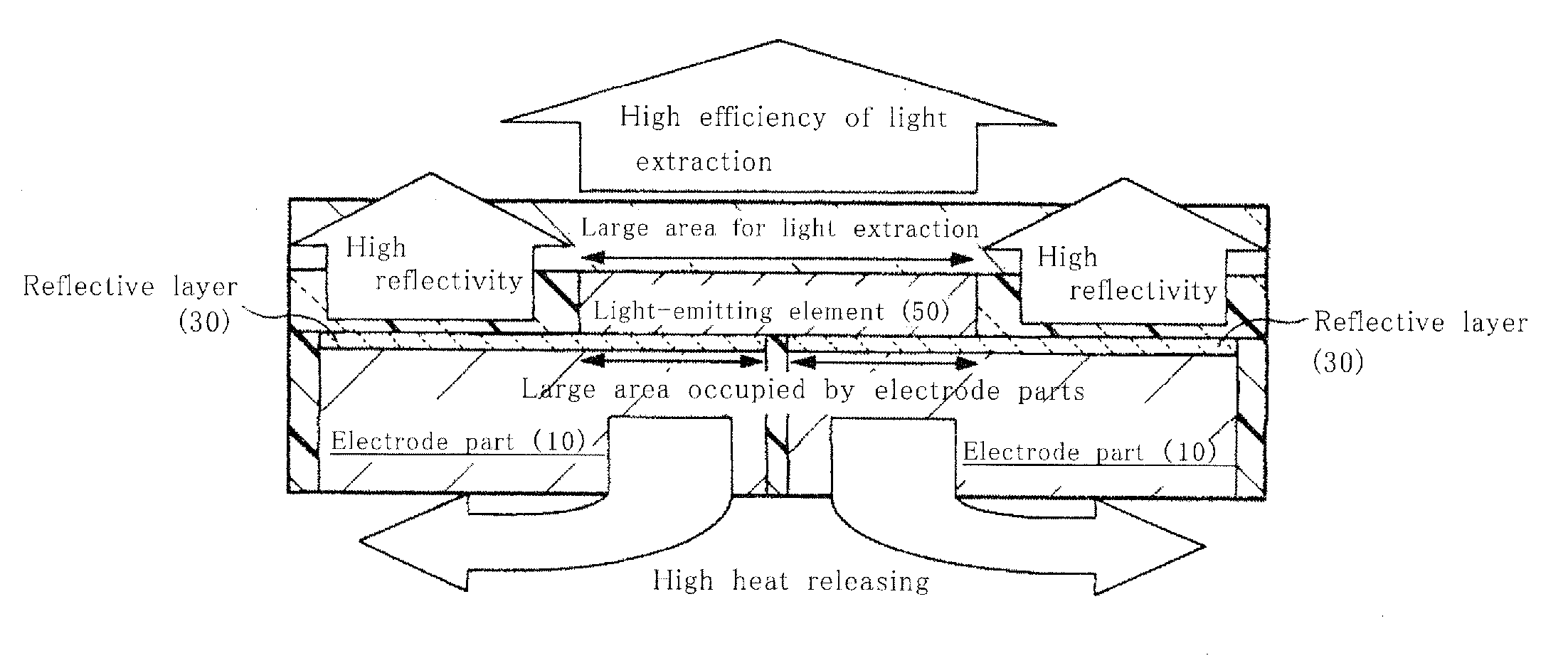

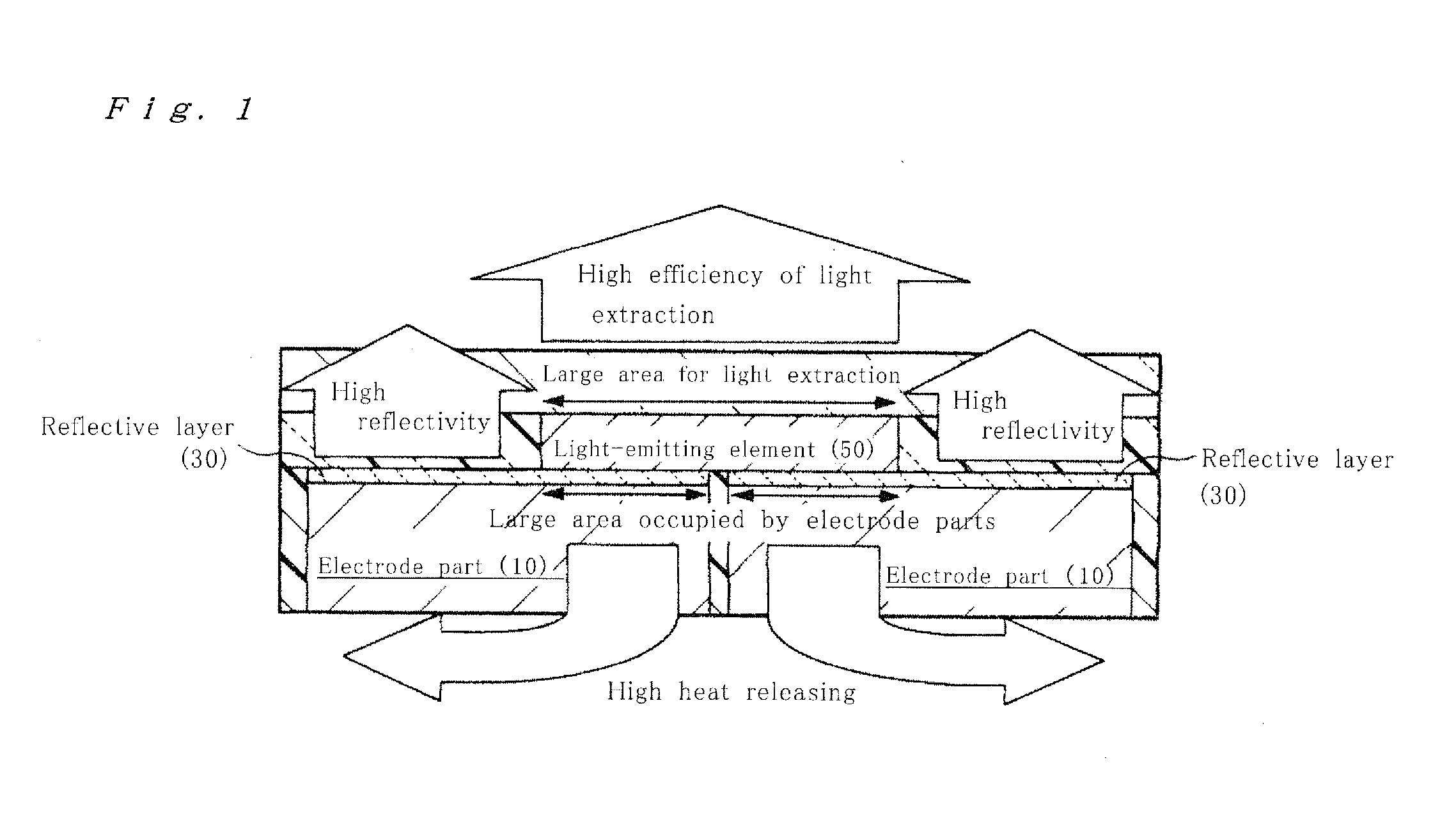

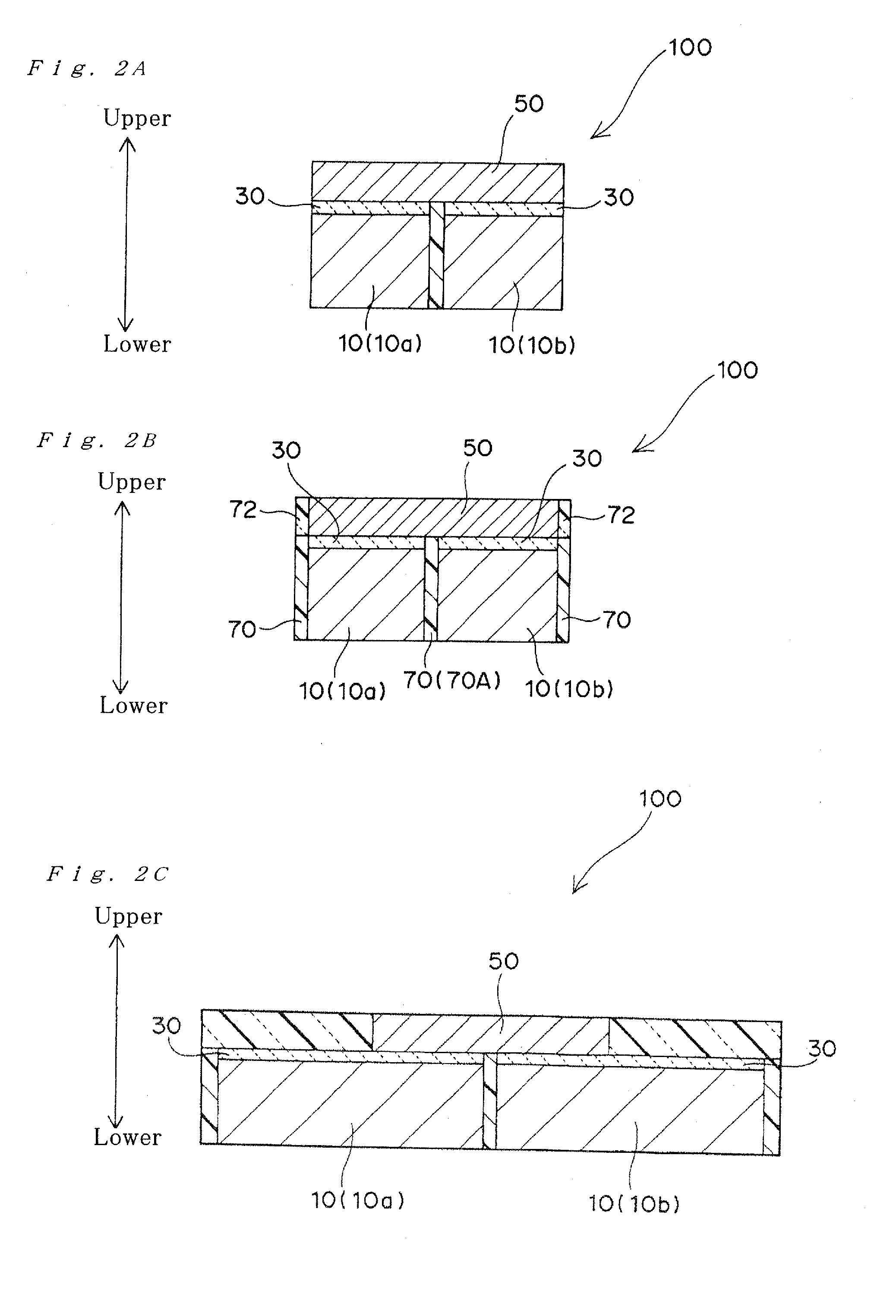

Light-emitting device and method for manufacturing the same

InactiveUS20150008467A1Wide range of fieldsImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingElectrical connectionEngineering

There is provided a light-emitting device comprising a light-emitting element. The light-emitting device of the present invention comprises an electrode part for the light-emitting element; a reflective layer provided on the electrode part; and the light-emitting element provided on the reflective layer such that the light-emitting element is in contact with at least a part of the reflective layer, wherein the light-emitting element and the electrode part are in an electrical connection with each other by mutual surface contact via the at least a part of the reflective layer, wherein the electrode part serves as a supporting layer for supporting the light-emitting element, and wherein the electrode part extends toward the outside of the light-emitting element and beyond the light-emitting element.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com