Groove and microstructure composite liquid absorption core and manufacturing method thereof

A manufacturing method and microstructure technology, which are applied in the field of liquid absorbent cores to achieve the effects of weight reduction, good comprehensive capillary performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

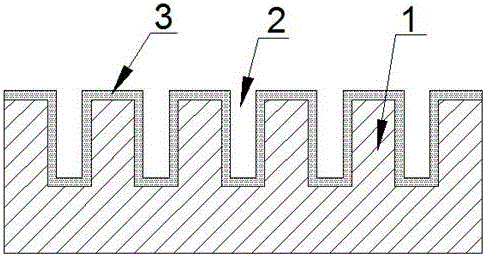

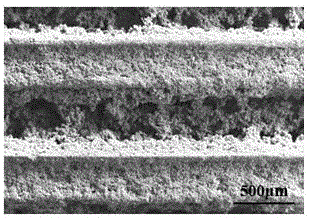

[0032] Such as figure 1 As shown, a groove and microstructure composite liquid-absorbing core includes a copper substrate 1 with grooves processed on the surface, and the inner surface of the groove and the outer surface of the copper substrate 1 processed with grooves are all provided with a thickness of 0.1-1000 μm microstructure layer 3, the microstructure 3 covers all the surface of the trench, but does not fill the trench, there are still gaps 2 between the walls of the trench, the microstructure layer 3 is mainly composed of particles It is composed of fine copper particles with a diameter between 0.1 and 20 μm, and tiny pores of 1 to 100 μm are formed between the fine copper particles.

[0033] Specifically, the cross-sectional shape of the groove in this embodiment is V-shaped, rectangular, trapezoidal or arc-shaped, or other irregular shapes, and the cross-sectional shape of the groove in this embodiment is rectangular.

[0034] Specifically, the maximum width of th...

Embodiment 2

[0037] A method for manufacturing a groove and microstructure composite liquid-absorbent core as described, comprising the following steps and process conditions:

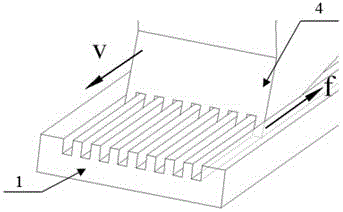

[0038] (1) Using the planing process and the multi-tooth cutter 4 to process a plurality of groove structures on the copper plate substrate 1;

[0039] (2) After cleaning the groove structure, use the electrochemical deposition method to build a microstructure on the surface of the groove as the cathode. Before the electrochemical deposition, the groove base needs to be cleaned ultrasonically. The cleaning time is about 5 minutes. The cleaning solution is cleaned with ethanol and a mixture of deionized water;

[0040] (3) Improve the interfacial bonding strength between the microstructure and the groove surface by sintering and curing process.

[0041] Specifically, the electrolytic solution used in the electrochemical deposition described in this implementation is a solution CuSO containing copper ions. 4 , the ...

Embodiment 3

[0045] A method for manufacturing a groove and microstructure composite liquid-absorbent core as described, comprising the following steps and process conditions:

[0046] (1) Using the planing process and the multi-tooth cutter 4 to process a plurality of groove structures on the copper plate substrate 1;

[0047] (2) After cleaning the groove structure, use the electrochemical deposition method to build a microstructure on the surface of the groove as the cathode. Before the electrochemical deposition, the groove base needs to be cleaned ultrasonically. The cleaning time is about 5 minutes. The cleaning solution is cleaned with ethanol and a mixture of deionized water;

[0048] (3) Improve the interfacial bonding strength between the microstructure and the groove surface by sintering and curing process.

[0049] Specifically, the electrolytic solution used in the electrochemical deposition described in this implementation is a solution CuCl containing copper ions. 2 , the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com