Porous special-shaped composite wick micro heat pipe and preparation method thereof

A liquid wick and micro heat pipe technology, applied in the field of micro heat pipes, can solve the problems of low capillary pressure, slow evaporation and condensation, and small airflow passages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

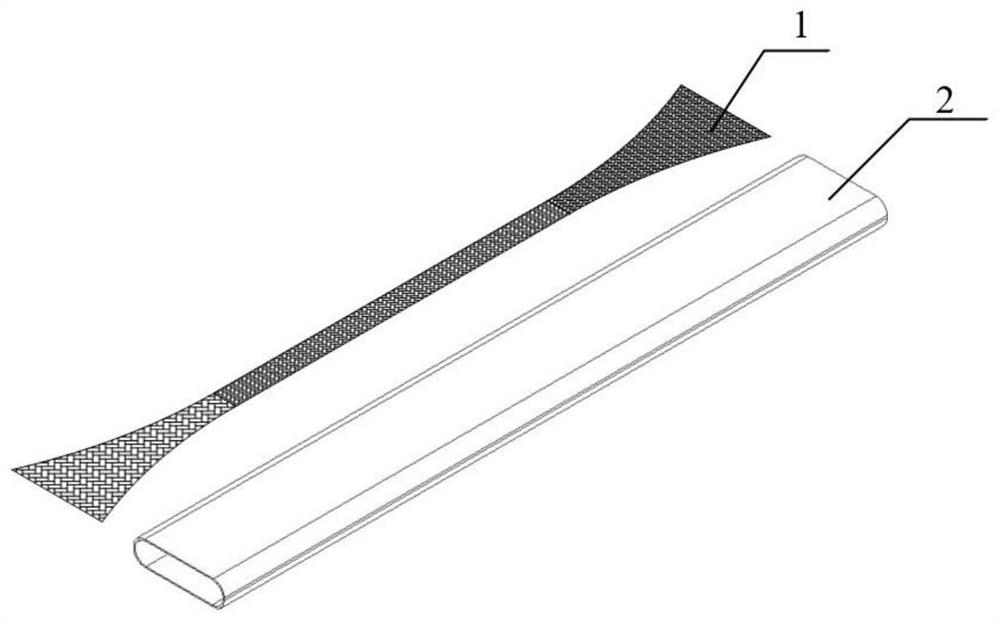

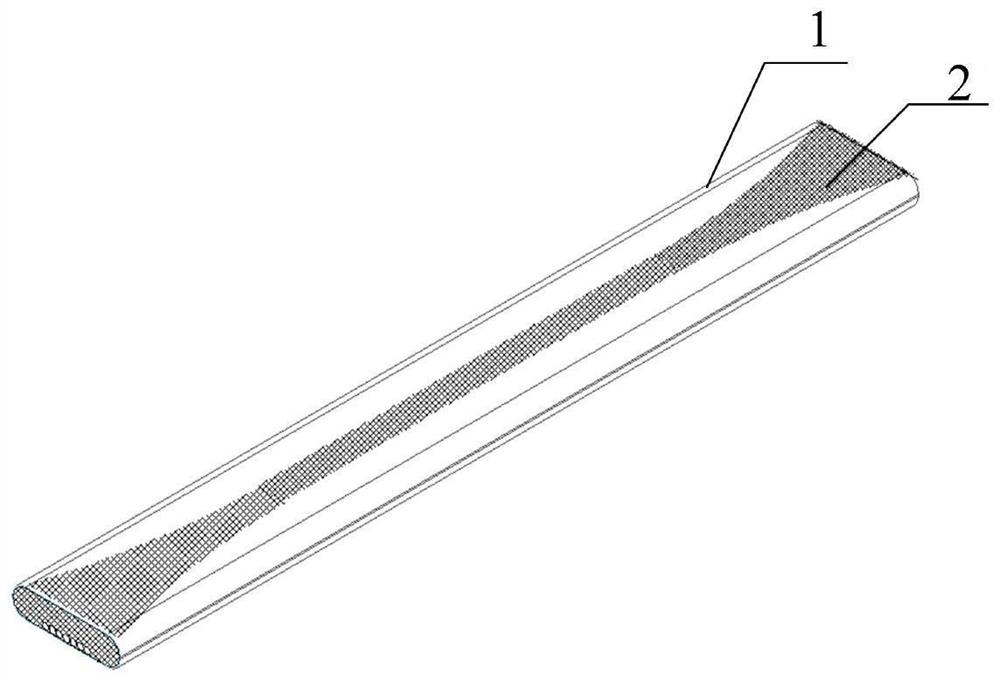

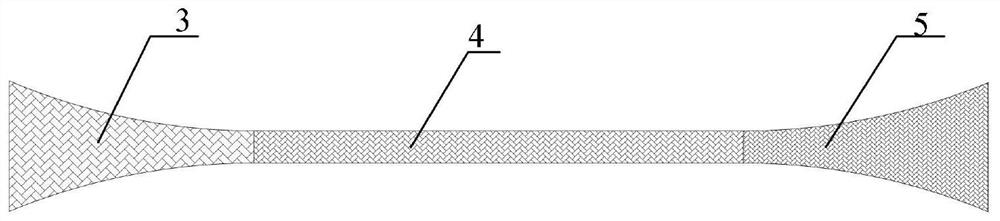

[0039] like Figure 1-Figure 5 As shown, a kind of multi-porous special-shaped composite liquid-absorbing core micro heat pipe provided in this example includes a copper-based tube 2, a liquid-absorbing core 1 and a liquid working fluid filled in the liquid-absorbing core, and copper capillary 7 and copper powder 6 are compositely sintered A composite liquid-absorbing core 1 is formed, and the composite liquid-absorbing core 1 is composed of copper powder 6-copper capillary 7-copper powder 6, and the arrangement of copper capillary 7 can be single-layer or multi-layer. The composite liquid-absorbing core 1 is parallel to the copper-based pipe 2 and placed in the center, the two ends of the liquid-absorbing core are sintered and connected to the two ends of the copper-based pipe, and the two ends of the copper-based pipe 2 are closed structures, and the inside is vacuumed. Hydrophilic treatment, and tightly bonded with copper base pipe through sintering.

[0040]The diameter o...

Embodiment 2

[0046] An example of a method for preparing a micro-heat pipe with a porous and special-shaped composite liquid-absorbing core provided by the embodiment of the present invention will be described in detail below.

[0047] (1) Production of the copper-based tube: Use a cutting machine to cut the hollow copper tube into the required length. In this embodiment, the cutting length is 75 mm, and then one end is shrunk. The shrinking length of this embodiment is 14 mm. Put the cut copper tube into the ethanol solution for ultrasonic cleaning to remove the residual oil on the surface, then rinse it with deionized water, put the washed copper tube into the mold of the desired shape, and press it Pressing, in this embodiment, the copper tube is pressed to a thickness of 2.1mm.

[0048] (2) Production of the liquid-absorbing core: according to the design of the liquid-absorbing core, a graphite mold is customized, a layer of copper powder is laid in the graphite mold, and then a capill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com