Composite liquid absorption core and manufacturing method and application thereof

A manufacturing method and liquid-absorbing core technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of uniform and continuous arrangement of difficult fibers, increase of local flow resistance, and increase of processing costs, so as to reduce sintering temperature and heat preservation Time, reduce flow resistance, increase the effect of capillary pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

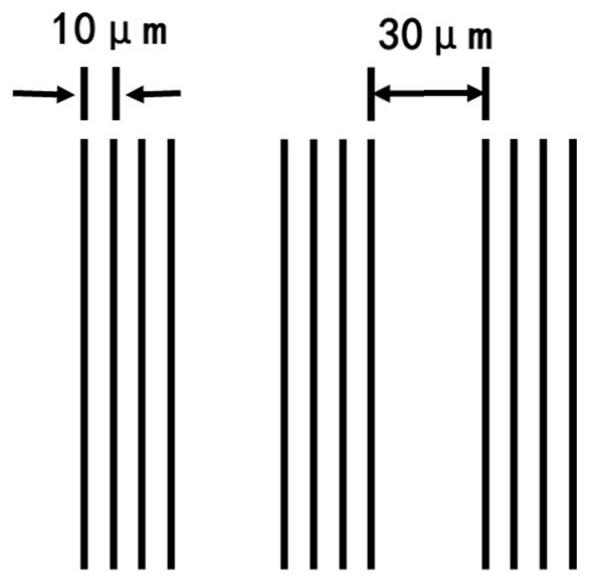

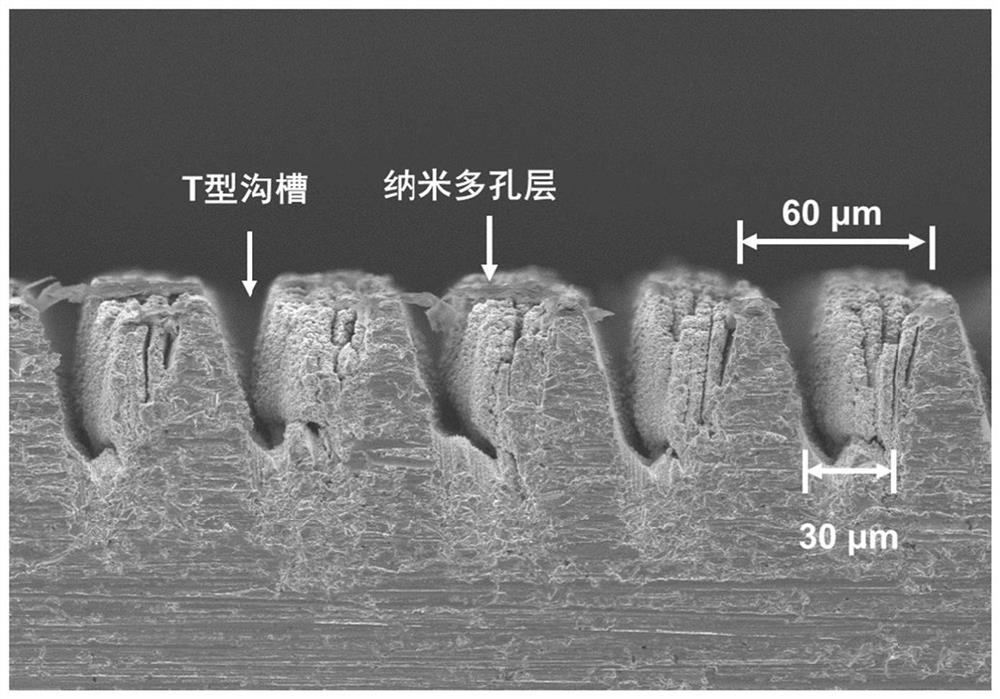

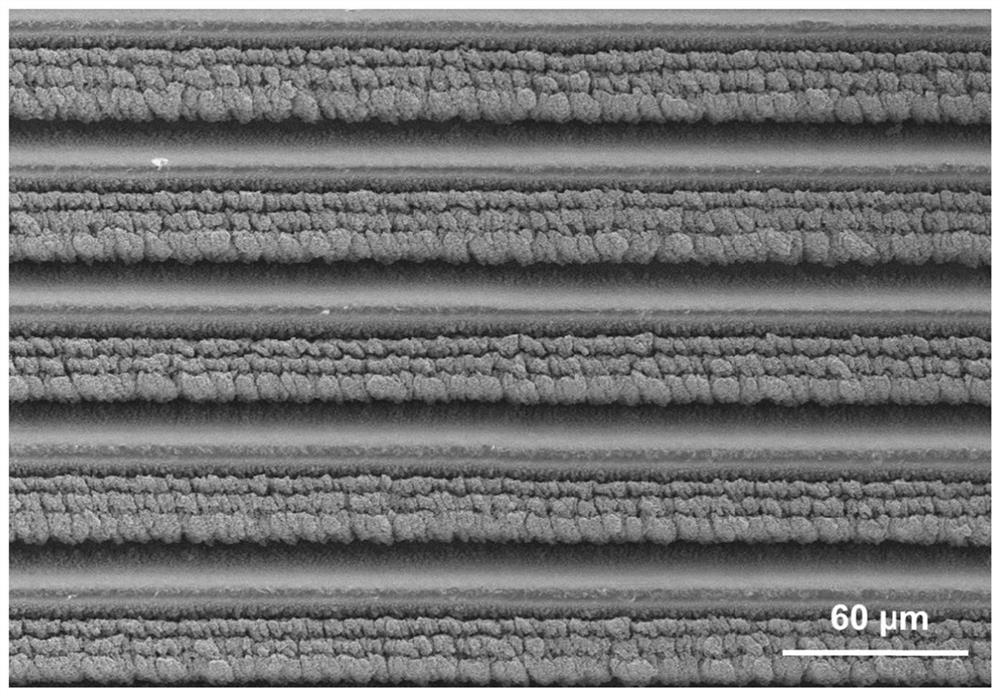

[0045] The size is 70×70×1mm 3 The surface of the copper plate is scanned by a short-pulse laser in the air, and the scanning area size is 68×68mm 2 , the laser and scanning parameters are: laser pulse width at half maximum 290fs, wavelength 515nm, repetition frequency 200kHz, laser energy flux density reaching the surface of the workpiece 2J / cm 2 , continuous parallel scanning. The scanning line pattern is a periodic array of parallel lines, figure 1 Shown is a schematic of an array of three parallel lines with a spacing of 10 μm between parallel lines and a spacing of 30 μm between arrays. The scanning speed is 10mm / s, and the number of scanning is 1 time. A unidirectional airflow field is applied during scanning. The unidirectional airflow field is formed by a high-speed micro-fan placed near the sample. The angle between the airflow direction and the sample surface and the laser scanning direction is controlled by controlling the relative position of the fan and the sa...

Embodiment 2

[0049] The size is 40×50×1mm 3 The C5191 phosphor copper plate, the surface is scanned by short pulse laser in the air, the scanning area size is 38×48mm 2 , the laser and scanning parameters are: laser pulse width at half maximum 10ps, wavelength 1030nm, repetition frequency 400kHz, laser energy flux density reaching the surface of the workpiece 1.5J / cm 2 , continuous parallel scanning, the scanning line spacing is 30 μm, the scanning speed is 40 mm / s, and the scanning is repeated 10 times. A unidirectional airflow field is applied during scanning. The one-way airflow field is realized by placing a vacuum tube near the sample. The vacuum tube is connected to a vacuum cleaner with a filter. By controlling the relative position of the vacuum tube and the sample, the clamping direction of the airflow direction, the sample surface and the laser scanning direction is controlled. Angle, the flow rate of the air flow is controlled by the power of the vacuum cleaner. In this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com