A kind of hydrogen fuel cell gas diffusion layer with double microporous layer structure and preparation method thereof

A technology of gas diffusion layer and microporous layer, which is applied in the direction of fuel cells, structural parts, electrical components, etc., can solve the problem of the limited scope of the comprehensive performance of gas diffusion layer fuel cells, the limited space for selecting the particle size of carbon powder materials, and the problem of gas diffusion. The gradient of layer pore size distribution is not obvious, etc., to achieve the effect of facilitating processing and assembly, optimizing internal and surface structure, and facilitating transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

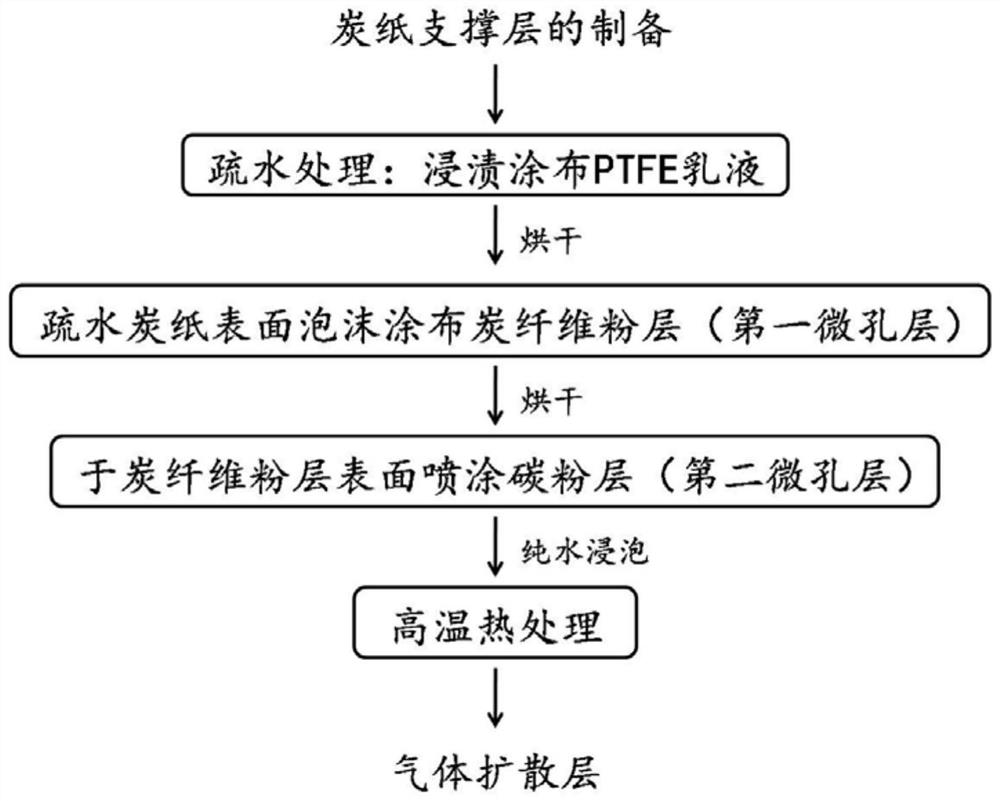

Method used

Image

Examples

Embodiment 1

[0063] (1) Preparation of carbon paper support layer

[0064] First, the carbon paper base paper was prepared by wet papermaking process, and the basis weight was 43±5g / m 2 Second, the base paper is dipped and coated with thermosetting phenolic resin, and the coating weight is 1 times that of the base paper; again, the hot-pressing curing process is carried out, the hot-pressing pressure is 5MPa, the hot-pressing temperature is 180 ℃, and the hot-pressing time is 20min; The substrate is carbonized and graphitized, the carbonization temperature is 1200 °C, the carbonization time is 1 h, the graphitization temperature is 2200 °C, and the graphitization time is 1 h, and finally a carbon paper product as a support layer is obtained.

[0065] (2) Preparation of slurry

[0066] A. Preparation of carbon paper hydrophobic treatment slurry: take 60wt% aqueous polytetrafluoroethylene (PTFE) emulsion, add deionized water to dilute to 10wt% PTFE, stir evenly at medium or low speed for us...

Embodiment 2

[0080] (2) Preparation of slurry

[0081]B. Preparation of the first microporous layer coating slurry: Mix carbon fiber powder, sodium carboxymethyl cellulose, benzenesulfonyl hydrazide foaming agent, and deionized water in a ratio of 15:2:3:80 to prepare for use. Transfer to a foam slurry storage device for use, and keep stirring at a low speed to ensure good distribution of carbon fiber powder in the foam, and the concentration of the slurry is 15wt%.

[0082] Other steps are the same as in Example 1.

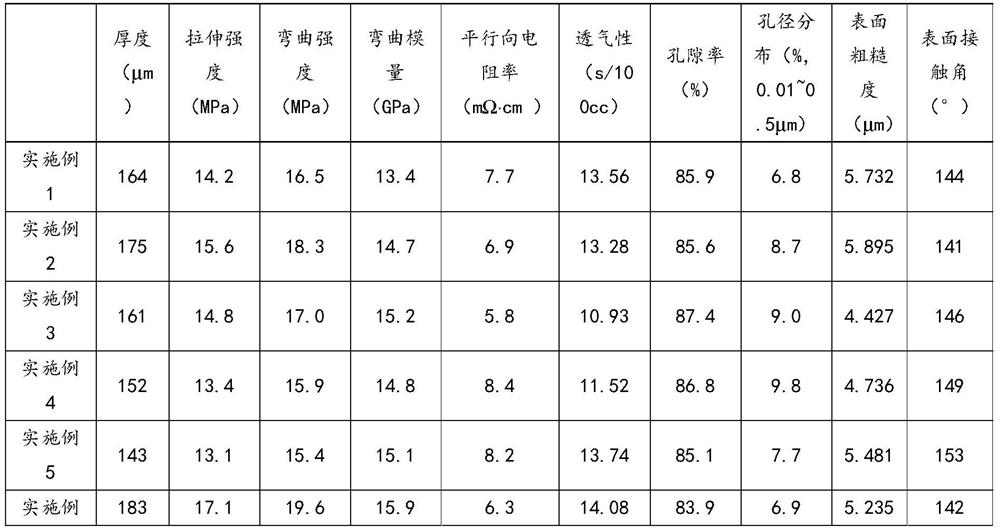

[0083] The performance parameters of the final gas diffusion layer product are shown in Table 1.

Embodiment 3

[0085] (2) Preparation of slurry

[0086] C. Preparation of the second microporous layer coating slurry: First, ethanol, isopropanol and water were mixed uniformly in a ratio of 4:4:2; In the mixed solvent of isopropyl alcohol / water, the ratio of carbon powder to mixed solvent is 1:9, and the concentration of carbon powder is 10wt%; use a double planetary mixer to stir at a low speed of 300rpm at room temperature, and wait until the carbon powder is completely covered by alcohol. After the solution is wrapped, the high-speed shearing and dispersing is carried out at a rotating speed of 1500 rpm, and finally the carbon powder and the solvent are fully mixed to obtain a continuous and uninterrupted uniform black oily liquid; 10wt% sodium chloride aqueous solution is then added. 3wt%, stir evenly at medium speed (800rpm); finally, weigh 10wt% of the PTFE suspension with 43wt% of the carbon powder consumption (according to the solute), add it to the mixed solution, keep stirring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com