High-molecular polymer wick and high-molecular polymer wick loop heat pipe

A technology of high molecular polymer and loop heat pipe, which is applied in the field of high molecular polymer liquid-absorbing core and high-molecular polymer liquid-absorbing core loop heat pipe. Low cost, poor safety and other issues, to achieve the effect of simple operation, improve work efficiency and operation safety, and improve heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

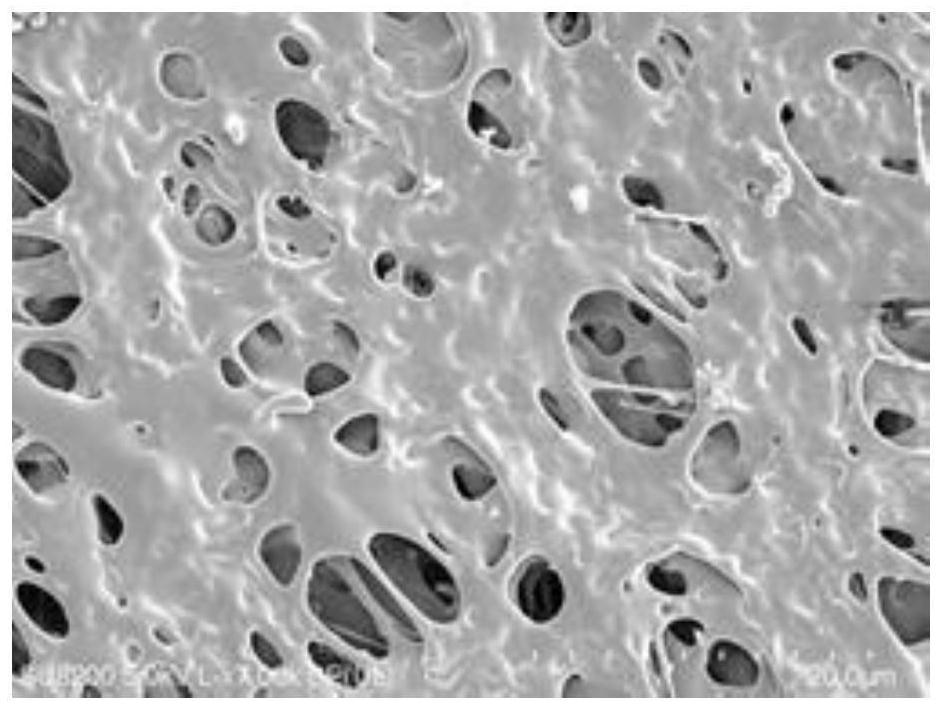

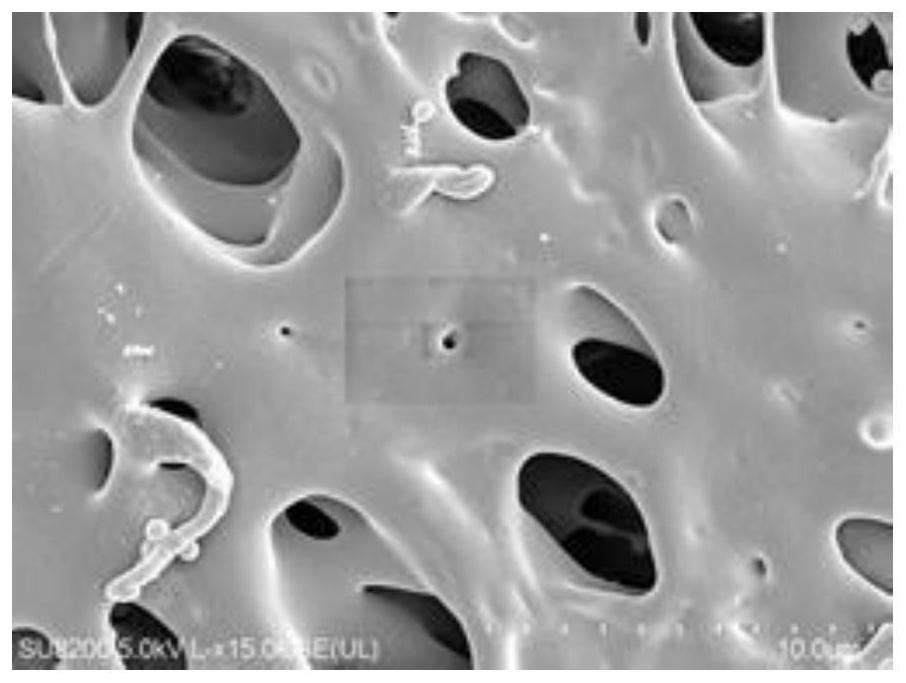

[0033] The polymer liquid-absorbing core is formed by stacking three organic polymer films and one inorganic fiber film, and has a double-aperture structure, that is, the pore size of the organic polymer film is smaller than that of the inorganic fiber film The pore size of the organic polymer film is polypropylene film, polytetrafluoroethylene film and polyethersulfone film, and the single sheet thickness of polypropylene film, polytetrafluoroethylene film and polyethersulfone film is 0.1mm; inorganic fiber The film is an aluminum silicate fiber film, and the single sheet thickness of the aluminum silicate fiber film is 0.2mm;

[0034] The pore size of the polypropylene film is 10-100 μm, the porosity is 70.3%, the pore size of the polytetrafluoroethylene film is 5-80 μm, the porosity is 67.9%, the pore size of the polyethersulfone film is 50-100 μm, the porosity is 91.4% , the pore diameter of the aluminum silicate fiber film is greater than 100 μm and less than or equal to ...

Embodiment 2

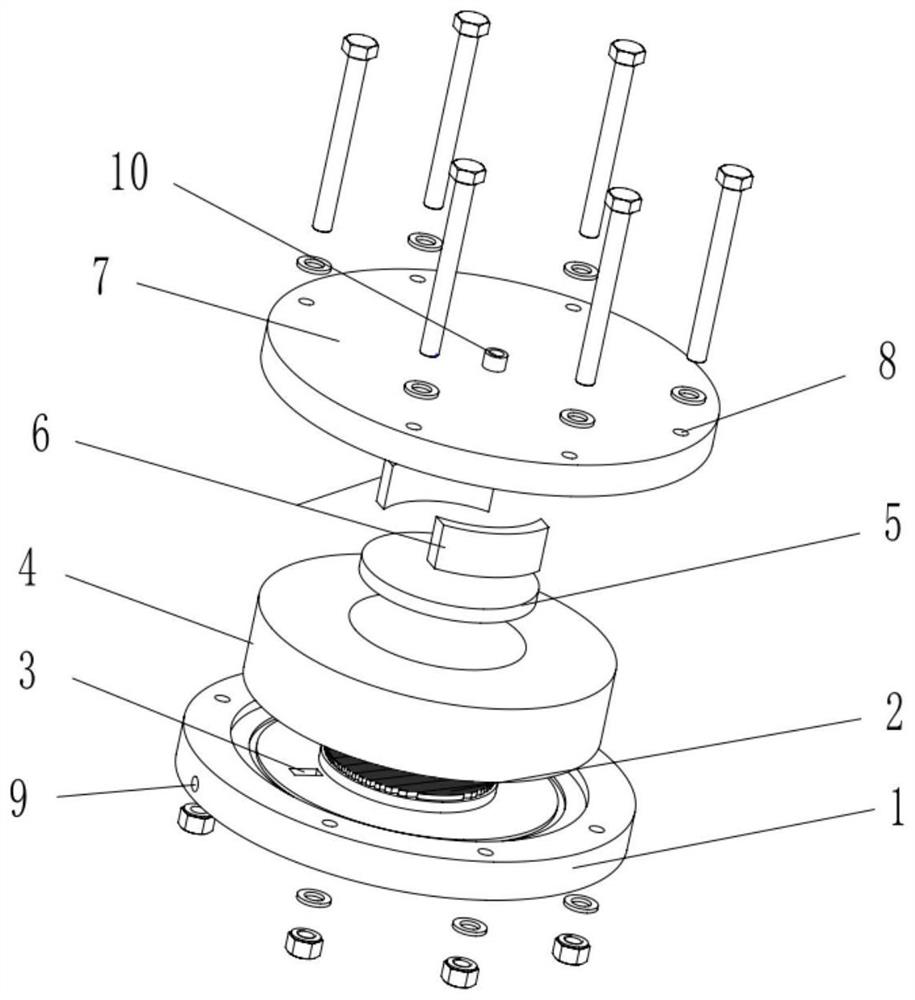

[0038] In this embodiment, the structure of the polymer liquid-absorbing core loop heat pipe is as follows: figure 1 Shown: the high molecular polymer liquid-absorbing core loop heat pipe comprises a heating base plate 1, a heating rib, a steam chamber 3, a side wall 4 and an air outlet 9, a high molecular polymer liquid-absorbing core 5 (polymer polymer in this embodiment The material liquid-absorbing core is the polymer liquid-absorbing core in embodiment 1), pressing plate 6, upper cover plate 7, heat transfer working medium, steam pipe and condenser; Heating rib is arranged on the upper end surface of heating bottom plate 1, and heating rib There are multiple (heating ribs are fins that can conduct heat, and multiple fins are elongated shapes of different lengths, and multiple elongated fins of different lengths form a circular heating area. For details, see figure 1 ), a steam channel 2 is formed between two adjacent heating ribs; the steam chamber 3 is set inside the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com