LED lamp radiating with optically coupled cooling liquid

A technology of LED lamps and optical coupling, which is applied in cooling/heating devices, light sources, electric light sources, etc. of lighting devices, can solve problems such as complex manufacturing technology, difficulty in popularization, and unsatisfactory heat dissipation effect of heat dissipation channels, and achieve unique technical advantages, Effect of good light characteristics and heat transfer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

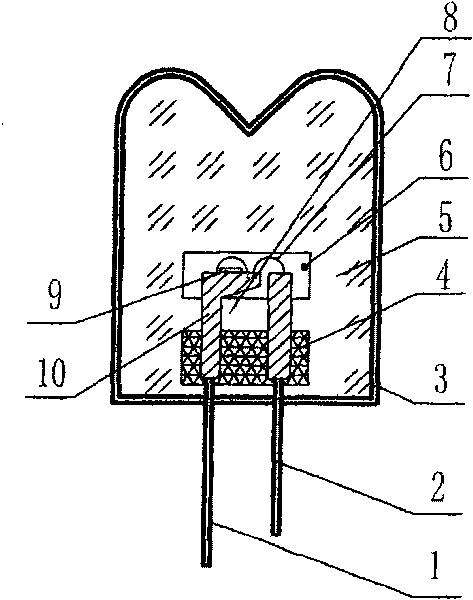

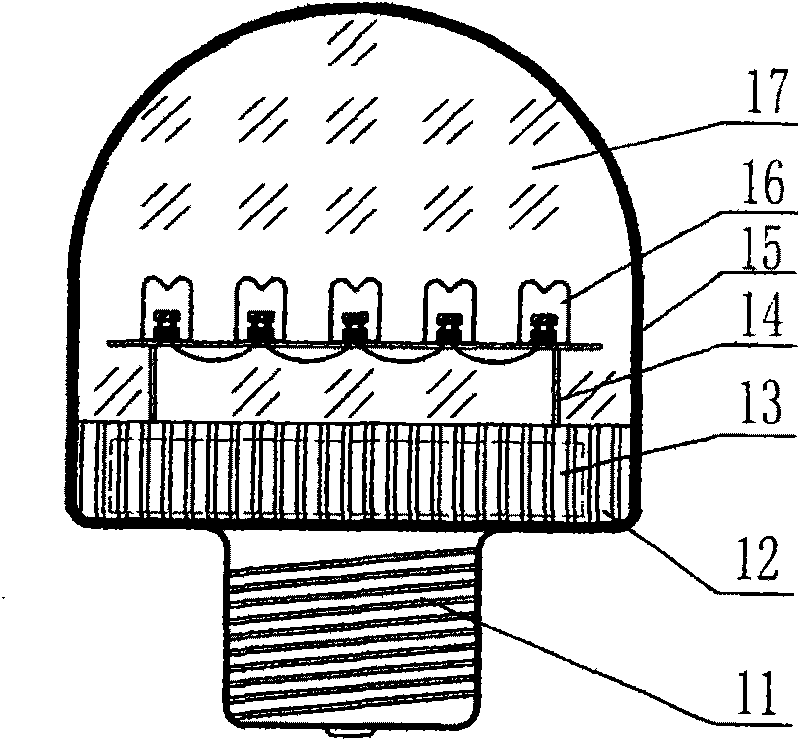

[0020] Embodiment 3. In this embodiment, the LED semi-finished product obtained in Embodiment 1 is subjected to spectroscopic and color separation detection, and the finished product is integrated into the light source board in a series (parallel) manner, and the lamp holder with the electrode column After conductively connecting one end of the lamp with one end of the light source board, it is connected to the lamp tube in a leak-free sealed connection, and then the optical coupling coolant is injected into the lamp tube, and then the other end of the lamp holder with the electrode column is conductively connected to the light source board , implement leak-free sealing connection with the lamp tube, so as to manufacture a power type LED fluorescent lamp tube lamp with integrated light source, optical coupling, cooling liquid and heat conduction.

Embodiment 4

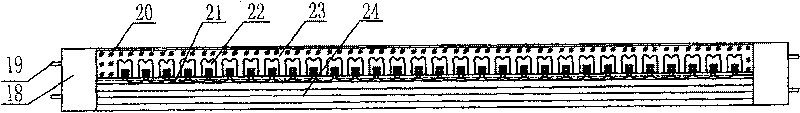

[0021] Embodiment 4. In this embodiment, the LED semi-finished products obtained in Embodiment 1 are subjected to spectroscopic and color separation detection, or other high-power LED single lamp products are integrated into the light source board in a series (parallel) manner. Complete integrated LED semi-finished products. The shell of the light source output end is integrated with LED semi-finished products, silicone sealing strips, heat dissipation shells and the inlet of the optically coupled coolant pump, and assembled into a whole without leakage, and the pipe is connected to the output end of the pump through the inner wall of the lamp support tube, and the input end of the pump The tubing is connected to the light-coupled coolant in the cooling bath. Start the pump to pump the light-coupled coolant into the combined sealed chamber until the light-coupled coolant overflows from the overflow port at the other end of the overflow port, and the connected return pipe overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com