Heat-dissipating structure of optical module

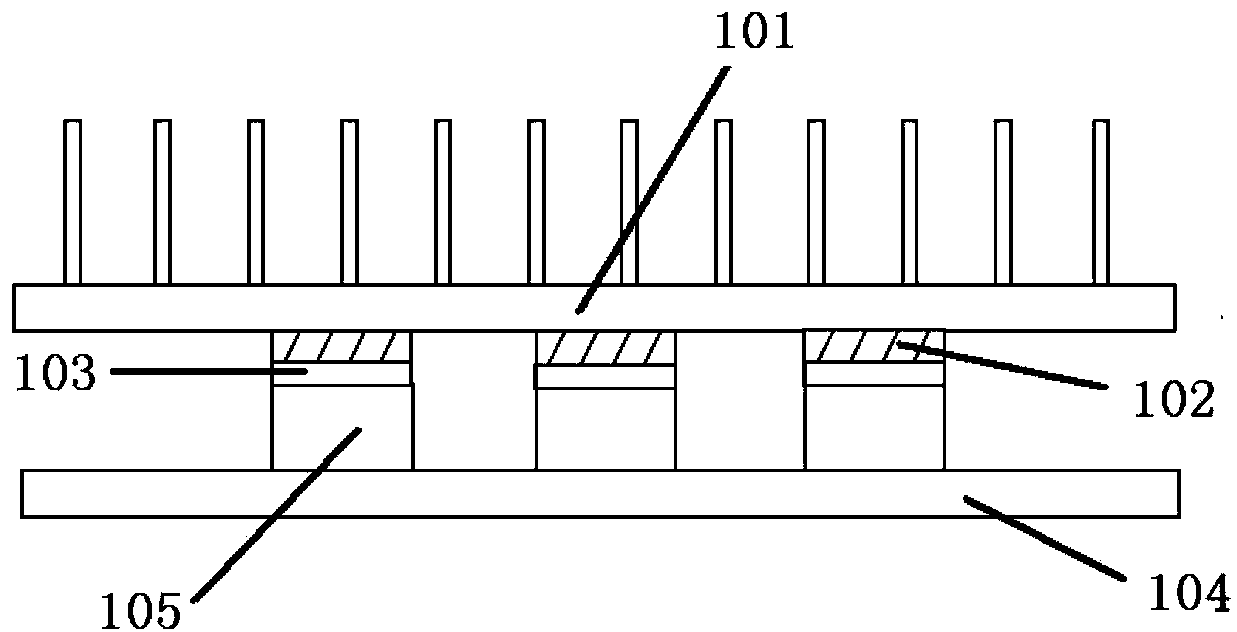

A technology of heat dissipation structure and optical module, which is applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of large compression force of heat conduction pad 102, great influence of heat dissipation, and difficulty in plugging and unplugging, so as to reduce contact thermal resistance and total thermal resistance , easy plug-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

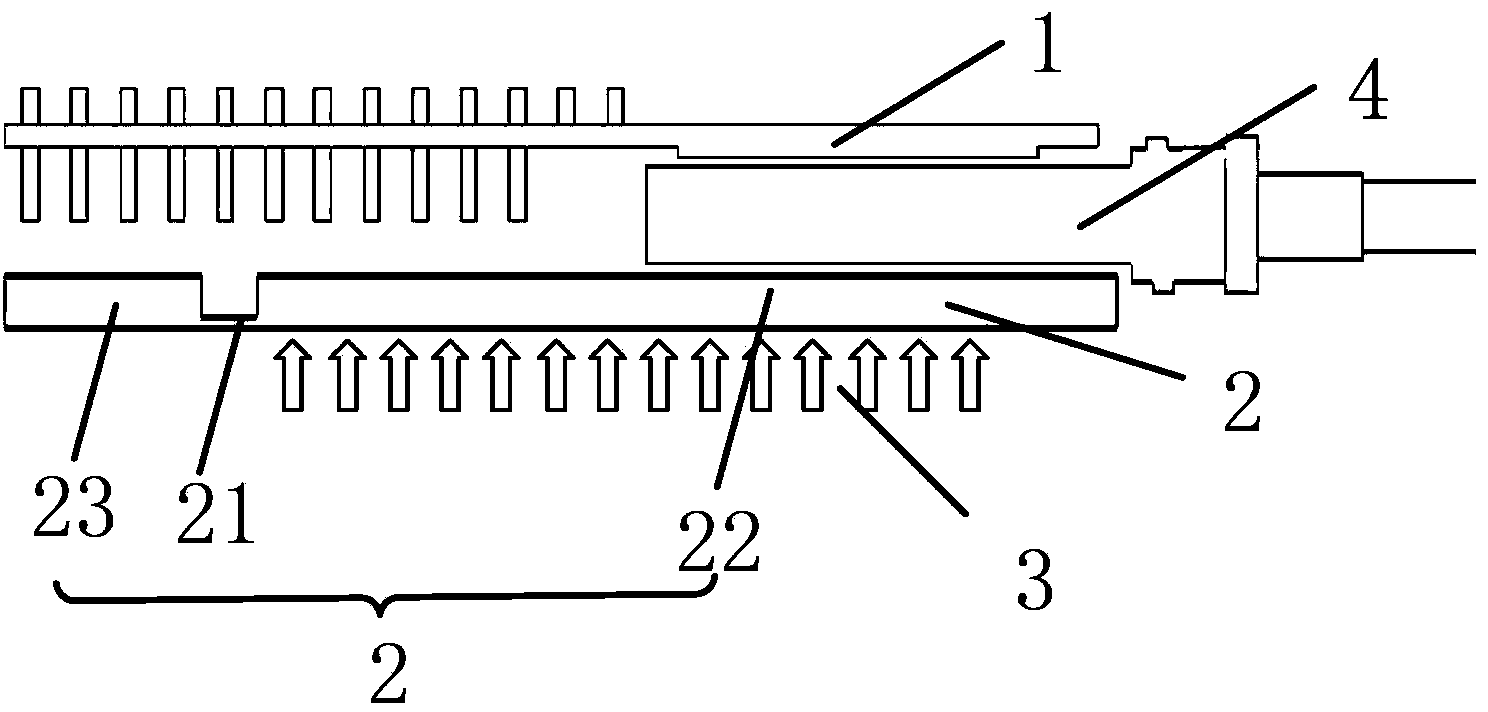

[0026] image 3 is a schematic diagram of the heat dissipation structure of the optical module provided in this embodiment, such as image 3 As shown, the heat dissipation structure of the optical module of the present invention includes: a heat sink 1 , a circuit board 2 and an elastic component 3 . The radiator 1 is fixed on the circuit board 2 by studs and screws. The optical module 4 is pluggably placed between the radiator 1 and the circuit board 2 . The circuit board 2 includes a flexible connection structure 21, a circuit board 22 occupied by the optical module 4, and a circuit board 23 adjacent to the circuit board 22 in the corresponding area of the optical module 4, and a circuit board 23 adjacent to the circuit board 22 in the corresponding area of the optical module 4 The flexible connection structure 21 is used to connect them, so that the circuit board 22 in the corresponding area of the optical module 4 can move up and down.

[0027] Normally, the dista...

Embodiment 2

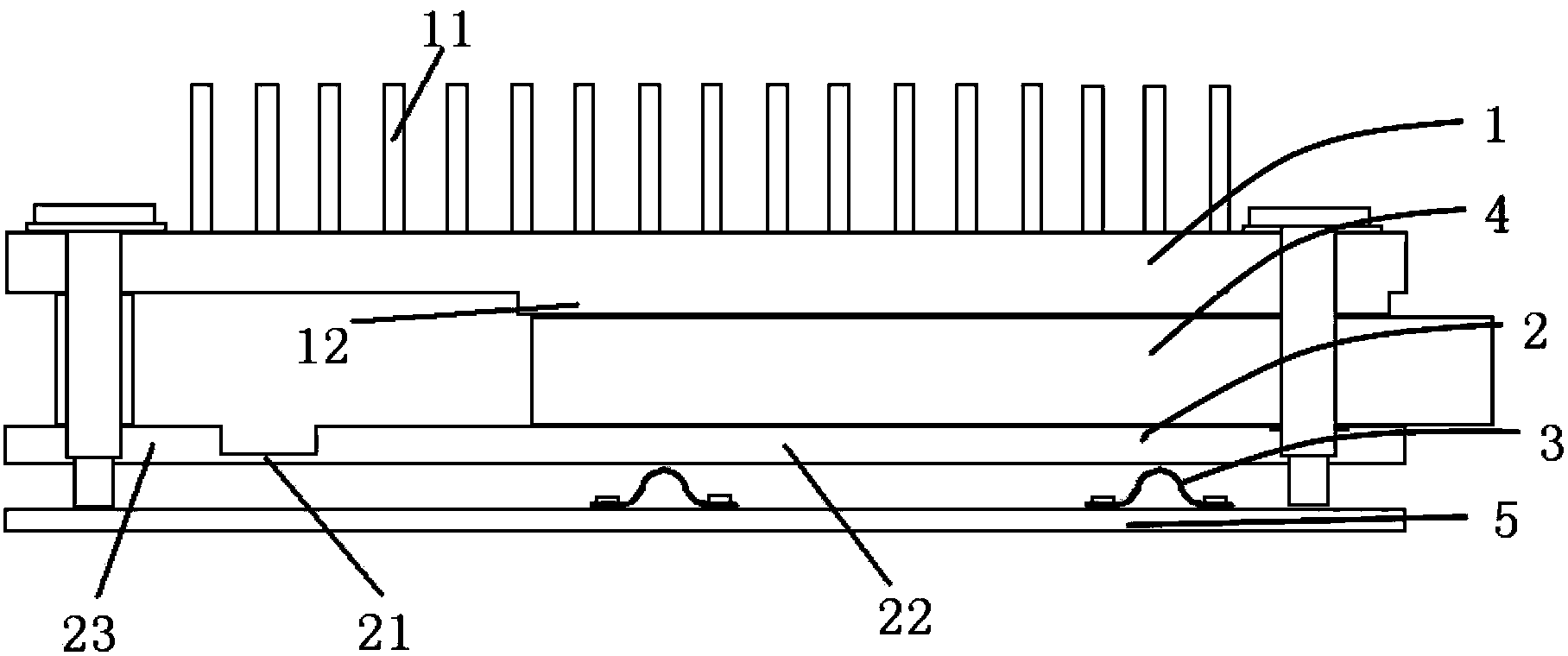

[0036] Figure 4 is a schematic diagram of the heat dissipation structure of the optical module provided in this embodiment, such as Figure 4As shown, the heat dissipation structure of the optical module of the present invention includes: a heat sink 1 , a circuit board 2 and an elastic component 3 .

[0037] The heat dissipation structure of the optical module of this embodiment is basically the same as that of Embodiment 1. The difference is that in this embodiment, the elastic component 3 and the fireproof board 5 are integrally structured, and the fireproof board 5 is a thin metal plate. , the shrapnel can be punched out on the fireproof board 5 through a stamping process, which has a certain degree of elasticity.

[0038] When the optical module 4 is inserted, the shrapnel punched on the fireproof board 5 is deformed under pressure, and the elastic force generated by the shrapnel ensures good contact between the optical module 4 and the boss 12 of the heat sink 1 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com