Two-phase closed type hot siphon tube using water-based carbon nanotube suspension liquid as working fluid

A carbon nanotube and thermosiphon technology, which is applied in indirect heat exchangers, heat exchange materials, lighting and heating equipment, etc., can solve the problem of carbon nanotube suspensions that no one has proposed, and achieve the reduction of inclination angle and heat exchange. The effect of improved performance and reduced overall thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The parameters in the following examples do not limit the present invention.

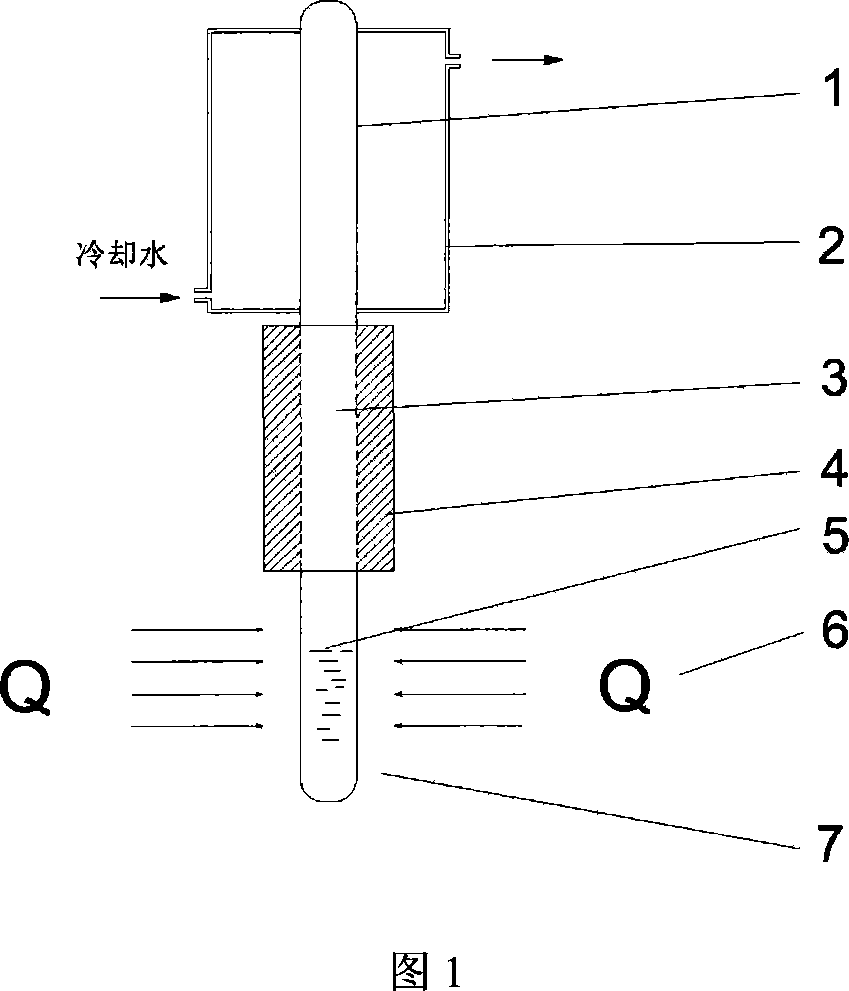

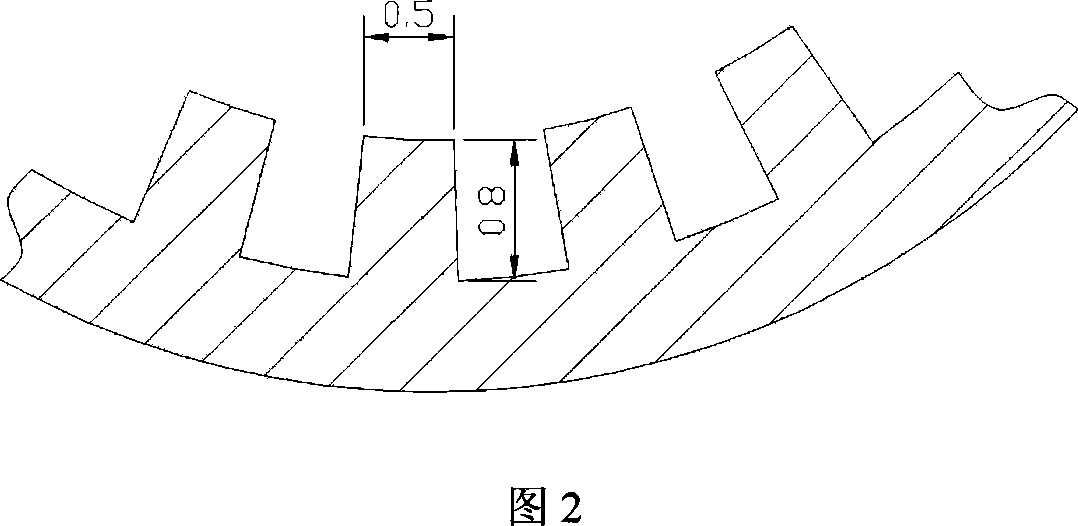

[0025] In one embodiment of the present invention, the structure of the two-phase closed thermosiphon is shown in Figure 1. The entire heat pipe is made of copper tubes. The outer diameter of the copper tube is 8mm, the wall thickness is 1mm, and the total length is 350mm. The length of section 7 is 100mm, the length of adiabatic section 3 is 100mm, and the length of condensation section 1 is 150mm. The size of the heat pipe can be designed arbitrarily. The evaporating section 7 is heated by an electric heater, the adiabatic section 3 is covered with a Teflon rod 4 for heat preservation, and the inner wall of the tube of the condensing section 1 is processed with evenly arranged axial micro-channels, and the size is not limited. It is recommended to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com