Miniature capillary pump loop flat plate heat pipe with alcohol group nano fluid as working medium

A nano-fluid, plate heat pipe technology, applied in the field of thermal engineering, can solve the problem that the tubular evaporator is not suitable for cooling the heat load of the plate, and achieve the effects of improving the heat dissipation power, reducing the total thermal resistance and improving the heat exchange characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

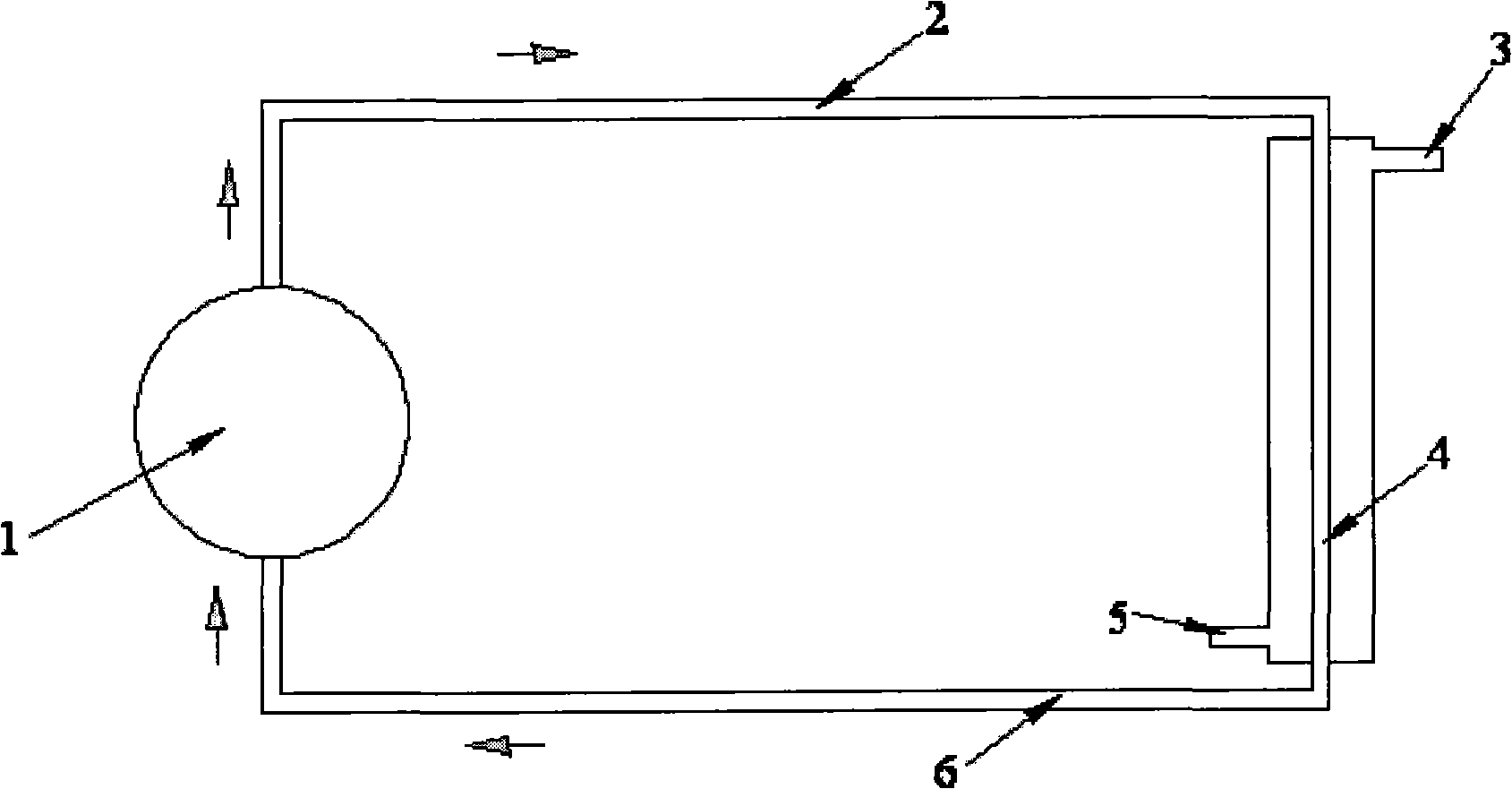

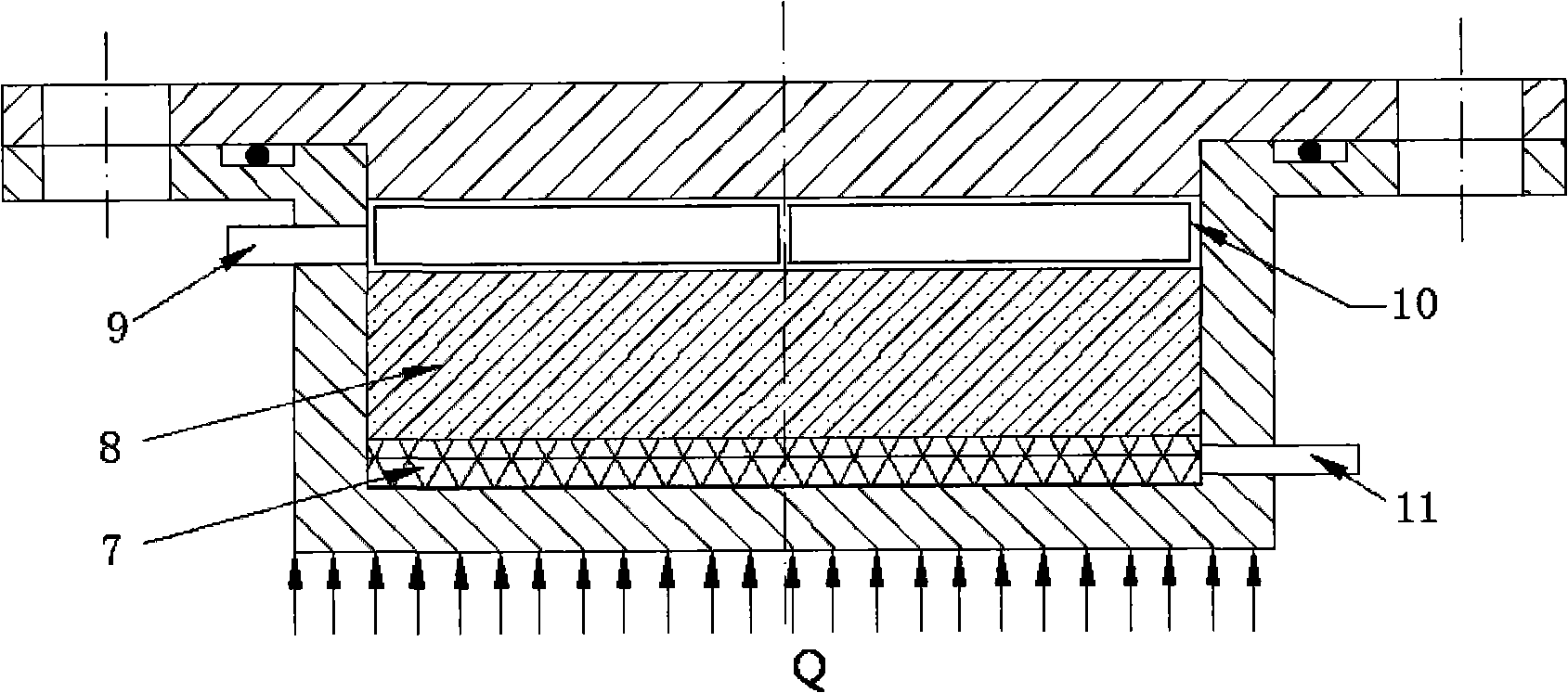

[0018] Such as figure 1 As shown, this embodiment is composed of an evaporator 1, a steam channel 2, a condenser 4, and a liquid channel 6. One end of the evaporator 1, the steam channel 2 is connected to one end of the condenser 4, and the other end of the condenser 1 is connected through the liquid channel 6. The other end of the evaporator 4. The working fluid absorbs heat in the evaporator 1 and turns into steam, the steam enters the condenser 4 through the steam channel 2 to condense, and the condensed working medium flows into the evaporator 1 through the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com